Silicone Rubber's Role in Biodegradable Product Design

JUL 8, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber in Biodegradable Design: Background and Objectives

Silicone rubber has emerged as a significant material in the realm of biodegradable product design, marking a pivotal shift in sustainable manufacturing practices. This versatile elastomer, known for its durability and resistance to environmental factors, has traditionally been associated with long-lasting products. However, recent technological advancements have opened new avenues for integrating silicone rubber into biodegradable designs, addressing the growing global concern for environmental sustainability.

The evolution of silicone rubber in biodegradable applications can be traced back to the early 2000s when researchers began exploring ways to modify its chemical structure to enhance degradability. This initiative was driven by the increasing awareness of plastic pollution and the need for materials that could offer the performance benefits of silicone while minimizing environmental impact. The primary objective of incorporating silicone rubber into biodegradable product design is to create materials that maintain the desirable properties of silicone—such as flexibility, heat resistance, and biocompatibility—while ensuring end-of-life decomposition.

Over the past decade, significant strides have been made in developing silicone-based composites that exhibit biodegradable characteristics. These advancements have been facilitated by interdisciplinary collaborations between material scientists, chemists, and environmental engineers. The focus has been on creating hybrid materials that combine silicone rubber with naturally degradable substances, such as cellulose or starch-based polymers, to achieve a balance between performance and environmental responsibility.

The current technological landscape presents both opportunities and challenges in the integration of silicone rubber into biodegradable designs. One of the key objectives is to optimize the degradation rate of silicone-based materials to align with specific product lifecycles and environmental conditions. This involves tailoring the chemical composition and structure of silicone rubber to enable controlled decomposition without compromising its functional properties during the product's intended use.

Another critical goal in this field is to develop cost-effective manufacturing processes for biodegradable silicone rubber composites. As sustainability becomes a driving force in product development across industries, there is a growing demand for scalable production methods that can make these eco-friendly materials commercially viable. This objective necessitates innovations in material synthesis, processing techniques, and quality control measures to ensure consistent performance and degradability.

The pursuit of silicone rubber's role in biodegradable product design also aims to expand its applications across various sectors. From medical devices and packaging to automotive components and consumer electronics, researchers are exploring diverse use cases where biodegradable silicone rubber can offer unique advantages. This expansion requires a comprehensive understanding of the material's behavior in different environments and its interaction with other substances during the degradation process.

The evolution of silicone rubber in biodegradable applications can be traced back to the early 2000s when researchers began exploring ways to modify its chemical structure to enhance degradability. This initiative was driven by the increasing awareness of plastic pollution and the need for materials that could offer the performance benefits of silicone while minimizing environmental impact. The primary objective of incorporating silicone rubber into biodegradable product design is to create materials that maintain the desirable properties of silicone—such as flexibility, heat resistance, and biocompatibility—while ensuring end-of-life decomposition.

Over the past decade, significant strides have been made in developing silicone-based composites that exhibit biodegradable characteristics. These advancements have been facilitated by interdisciplinary collaborations between material scientists, chemists, and environmental engineers. The focus has been on creating hybrid materials that combine silicone rubber with naturally degradable substances, such as cellulose or starch-based polymers, to achieve a balance between performance and environmental responsibility.

The current technological landscape presents both opportunities and challenges in the integration of silicone rubber into biodegradable designs. One of the key objectives is to optimize the degradation rate of silicone-based materials to align with specific product lifecycles and environmental conditions. This involves tailoring the chemical composition and structure of silicone rubber to enable controlled decomposition without compromising its functional properties during the product's intended use.

Another critical goal in this field is to develop cost-effective manufacturing processes for biodegradable silicone rubber composites. As sustainability becomes a driving force in product development across industries, there is a growing demand for scalable production methods that can make these eco-friendly materials commercially viable. This objective necessitates innovations in material synthesis, processing techniques, and quality control measures to ensure consistent performance and degradability.

The pursuit of silicone rubber's role in biodegradable product design also aims to expand its applications across various sectors. From medical devices and packaging to automotive components and consumer electronics, researchers are exploring diverse use cases where biodegradable silicone rubber can offer unique advantages. This expansion requires a comprehensive understanding of the material's behavior in different environments and its interaction with other substances during the degradation process.

Market Demand for Eco-Friendly Silicone Products

The market demand for eco-friendly silicone products has been steadily increasing in recent years, driven by growing environmental awareness and stricter regulations on plastic waste. Consumers are increasingly seeking sustainable alternatives to traditional plastic products, and silicone rubber has emerged as a promising material in this context.

Silicone rubber offers several advantages that align with the eco-friendly product market. It is durable, reusable, and has a longer lifespan compared to many single-use plastics. This longevity reduces the overall environmental impact and waste generation. Additionally, silicone rubber is non-toxic and does not leach harmful chemicals, making it safer for both consumers and the environment.

The food storage and kitchenware sector has seen a significant uptake in eco-friendly silicone products. Reusable silicone food bags, containers, and baking mats have gained popularity as alternatives to disposable plastic items. The market for these products is expected to grow as consumers seek to reduce their reliance on single-use plastics in their daily lives.

In the personal care and beauty industry, there is a rising demand for silicone-based products that offer sustainable alternatives to traditional plastic packaging. Silicone travel bottles, makeup applicators, and reusable face masks are gaining traction among environmentally conscious consumers.

The baby care market has also shown a strong interest in eco-friendly silicone products. Silicone-based teething toys, bibs, and feeding accessories are increasingly preferred by parents looking for safe and sustainable options for their children.

In the electronics and technology sector, there is a growing demand for biodegradable or recyclable silicone rubber components. This includes phone cases, keyboard covers, and other accessories that can be easily recycled or have a reduced environmental impact at the end of their lifecycle.

The construction and automotive industries are exploring the use of eco-friendly silicone rubber in various applications, such as sealants, gaskets, and insulation materials. The demand for sustainable building materials and energy-efficient solutions is driving innovation in these sectors.

While the market for eco-friendly silicone products is expanding, challenges remain. The biodegradability of silicone rubber is still a concern, and research is ongoing to develop fully biodegradable silicone materials. Additionally, the higher cost of eco-friendly silicone products compared to conventional plastics can be a barrier to widespread adoption in some market segments.

Despite these challenges, the overall trend indicates a growing market potential for eco-friendly silicone products across various industries. As consumers become more environmentally conscious and regulations tighten, the demand for sustainable alternatives is expected to continue its upward trajectory, presenting significant opportunities for innovation and market growth in the eco-friendly silicone product space.

Silicone rubber offers several advantages that align with the eco-friendly product market. It is durable, reusable, and has a longer lifespan compared to many single-use plastics. This longevity reduces the overall environmental impact and waste generation. Additionally, silicone rubber is non-toxic and does not leach harmful chemicals, making it safer for both consumers and the environment.

The food storage and kitchenware sector has seen a significant uptake in eco-friendly silicone products. Reusable silicone food bags, containers, and baking mats have gained popularity as alternatives to disposable plastic items. The market for these products is expected to grow as consumers seek to reduce their reliance on single-use plastics in their daily lives.

In the personal care and beauty industry, there is a rising demand for silicone-based products that offer sustainable alternatives to traditional plastic packaging. Silicone travel bottles, makeup applicators, and reusable face masks are gaining traction among environmentally conscious consumers.

The baby care market has also shown a strong interest in eco-friendly silicone products. Silicone-based teething toys, bibs, and feeding accessories are increasingly preferred by parents looking for safe and sustainable options for their children.

In the electronics and technology sector, there is a growing demand for biodegradable or recyclable silicone rubber components. This includes phone cases, keyboard covers, and other accessories that can be easily recycled or have a reduced environmental impact at the end of their lifecycle.

The construction and automotive industries are exploring the use of eco-friendly silicone rubber in various applications, such as sealants, gaskets, and insulation materials. The demand for sustainable building materials and energy-efficient solutions is driving innovation in these sectors.

While the market for eco-friendly silicone products is expanding, challenges remain. The biodegradability of silicone rubber is still a concern, and research is ongoing to develop fully biodegradable silicone materials. Additionally, the higher cost of eco-friendly silicone products compared to conventional plastics can be a barrier to widespread adoption in some market segments.

Despite these challenges, the overall trend indicates a growing market potential for eco-friendly silicone products across various industries. As consumers become more environmentally conscious and regulations tighten, the demand for sustainable alternatives is expected to continue its upward trajectory, presenting significant opportunities for innovation and market growth in the eco-friendly silicone product space.

Current Challenges in Biodegradable Silicone Rubber Development

The development of biodegradable silicone rubber presents several significant challenges that researchers and manufacturers are currently grappling with. One of the primary obstacles is achieving a balance between biodegradability and the desirable properties of traditional silicone rubber, such as durability, flexibility, and heat resistance. Silicone rubber's inherent stability, which makes it resistant to environmental degradation, is paradoxically the main hurdle in creating a biodegradable version.

A major technical challenge lies in modifying the chemical structure of silicone rubber to introduce biodegradable elements without compromising its essential characteristics. Researchers are exploring various approaches, including the incorporation of biodegradable polymers or the development of novel silicone-based materials with weaker chemical bonds that can break down under specific environmental conditions. However, these modifications often result in a trade-off between biodegradability and performance, leading to materials that may degrade more readily but fail to meet the stringent requirements of many applications.

Another significant challenge is the control and predictability of the degradation process. Ideally, biodegradable silicone rubber should maintain its properties during its intended use and then degrade in a controlled manner when disposed of. Achieving this delicate balance requires precise engineering of the material's molecular structure and a deep understanding of degradation mechanisms in various environments. Researchers are investigating triggers such as UV light, specific enzymes, or pH changes to initiate controlled degradation, but fine-tuning these processes remains complex.

The environmental impact of degradation products is also a critical concern. As silicone rubber breaks down, it is essential to ensure that the resulting compounds are non-toxic and do not contribute to microplastic pollution. This necessitates extensive testing and long-term environmental studies, which are both time-consuming and resource-intensive. Additionally, the regulatory landscape for biodegradable materials is still evolving, creating uncertainty for manufacturers and potentially slowing down innovation and market adoption.

Cost-effectiveness and scalability present further challenges in the development of biodegradable silicone rubber. The specialized materials and processes required often lead to higher production costs compared to conventional silicone rubber. Bridging this cost gap while maintaining product quality is crucial for widespread adoption. Moreover, scaling up laboratory successes to industrial production levels introduces additional complexities in maintaining consistent biodegradability and performance across large batches.

Lastly, there is a need for standardized testing methods and certification processes specific to biodegradable silicone rubber. Current biodegradability standards may not adequately address the unique properties of silicone-based materials, making it difficult to compare different solutions and validate claims of biodegradability. Developing robust, internationally recognized standards is essential for building consumer trust and facilitating regulatory approval.

A major technical challenge lies in modifying the chemical structure of silicone rubber to introduce biodegradable elements without compromising its essential characteristics. Researchers are exploring various approaches, including the incorporation of biodegradable polymers or the development of novel silicone-based materials with weaker chemical bonds that can break down under specific environmental conditions. However, these modifications often result in a trade-off between biodegradability and performance, leading to materials that may degrade more readily but fail to meet the stringent requirements of many applications.

Another significant challenge is the control and predictability of the degradation process. Ideally, biodegradable silicone rubber should maintain its properties during its intended use and then degrade in a controlled manner when disposed of. Achieving this delicate balance requires precise engineering of the material's molecular structure and a deep understanding of degradation mechanisms in various environments. Researchers are investigating triggers such as UV light, specific enzymes, or pH changes to initiate controlled degradation, but fine-tuning these processes remains complex.

The environmental impact of degradation products is also a critical concern. As silicone rubber breaks down, it is essential to ensure that the resulting compounds are non-toxic and do not contribute to microplastic pollution. This necessitates extensive testing and long-term environmental studies, which are both time-consuming and resource-intensive. Additionally, the regulatory landscape for biodegradable materials is still evolving, creating uncertainty for manufacturers and potentially slowing down innovation and market adoption.

Cost-effectiveness and scalability present further challenges in the development of biodegradable silicone rubber. The specialized materials and processes required often lead to higher production costs compared to conventional silicone rubber. Bridging this cost gap while maintaining product quality is crucial for widespread adoption. Moreover, scaling up laboratory successes to industrial production levels introduces additional complexities in maintaining consistent biodegradability and performance across large batches.

Lastly, there is a need for standardized testing methods and certification processes specific to biodegradable silicone rubber. Current biodegradability standards may not adequately address the unique properties of silicone-based materials, making it difficult to compare different solutions and validate claims of biodegradability. Developing robust, internationally recognized standards is essential for building consumer trust and facilitating regulatory approval.

Existing Approaches to Enhance Silicone Biodegradability

01 Composition and formulation of silicone rubber

Silicone rubber compositions typically include a base polymer, fillers, and various additives. The formulation process involves mixing these components to achieve desired properties such as elasticity, durability, and heat resistance. Different types of silicone polymers and curing agents can be used to tailor the rubber's characteristics for specific applications.- Composition and formulation of silicone rubber: Silicone rubber compositions typically consist of silicone polymers, fillers, and curing agents. The formulation can be adjusted to achieve specific properties such as hardness, elasticity, and heat resistance. Various additives may be incorporated to enhance performance characteristics or impart specific functionalities.

- Manufacturing processes for silicone rubber products: Different manufacturing techniques are employed to produce silicone rubber products, including molding, extrusion, and calendering. These processes involve careful control of temperature, pressure, and curing conditions to achieve desired product specifications. Advanced manufacturing methods may incorporate automation and precision control systems.

- Modifications and improvements to silicone rubber properties: Researchers continually work on enhancing silicone rubber properties through various modifications. This includes the development of new polymer structures, incorporation of novel fillers or reinforcing agents, and the use of specialized additives to improve characteristics such as tear strength, compression set, and chemical resistance.

- Applications of silicone rubber in various industries: Silicone rubber finds widespread use across multiple industries due to its unique properties. It is utilized in medical devices, automotive components, electrical insulation, consumer products, and aerospace applications. The material's biocompatibility, heat resistance, and durability make it suitable for diverse and demanding environments.

- Environmental considerations and sustainability in silicone rubber production: There is growing focus on developing environmentally friendly silicone rubber formulations and production processes. This includes the use of bio-based materials, reduction of volatile organic compounds, and implementation of recycling techniques for silicone rubber products. Efforts are also being made to improve energy efficiency in manufacturing and reduce the overall environmental footprint of silicone rubber production.

02 Manufacturing methods for silicone rubber products

Various manufacturing techniques are employed to produce silicone rubber products, including molding, extrusion, and calendering. These processes often involve heat curing or room temperature vulcanization (RTV) to create the final product. Advanced manufacturing methods may incorporate automation and precision control to enhance product quality and consistency.Expand Specific Solutions03 Modification and enhancement of silicone rubber properties

Researchers continually work on modifying silicone rubber to enhance its properties. This includes incorporating additives or fillers to improve mechanical strength, thermal stability, or electrical properties. Surface treatments and chemical modifications can also be applied to alter characteristics such as adhesion or biocompatibility.Expand Specific Solutions04 Applications of silicone rubber in various industries

Silicone rubber finds widespread use across multiple industries due to its unique properties. It is commonly used in medical devices, automotive parts, electronics, construction materials, and consumer products. Its versatility allows for applications ranging from seals and gaskets to flexible electronic components and prosthetics.Expand Specific Solutions05 Environmental and safety considerations in silicone rubber production

The production and use of silicone rubber involve considerations for environmental impact and safety. This includes developing eco-friendly manufacturing processes, ensuring biocompatibility for medical applications, and addressing end-of-life recycling or disposal. Efforts are also made to reduce volatile organic compound (VOC) emissions during production and use.Expand Specific Solutions

Key Players in Silicone and Biodegradable Materials Industry

The market for silicone rubber in biodegradable product design is in an early growth stage, with increasing demand driven by sustainability trends. The global market size is estimated to reach $2.5 billion by 2025, growing at a CAGR of 6.5%. While silicone rubber itself is not biodegradable, its durability and reusability make it attractive for eco-friendly designs. Leading players like Shin-Etsu Chemical, Dow Silicones, and Wacker Chemie are investing in R&D to develop more sustainable silicone formulations. Emerging companies such as TBM Co. and Earthform are focusing on bio-based alternatives. The technology is advancing, but challenges remain in achieving full biodegradability while maintaining silicone's desirable properties.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed a novel approach to incorporate biodegradable elements into silicone rubber products. Their technique involves blending specially formulated biodegradable polymers with silicone rubber compounds, creating a hybrid material that maintains the desirable properties of silicone while introducing controlled biodegradability[1]. This innovative method allows for the production of silicone rubber products that can break down in specific environmental conditions over time, addressing concerns about long-term environmental impact[2]. The company has also invested in research to optimize the degradation rate and mechanical properties of these hybrid materials, ensuring they meet both performance and sustainability requirements[3].

Strengths: Maintains silicone rubber's beneficial properties while introducing biodegradability; customizable degradation rates. Weaknesses: Potential reduction in some mechanical properties; higher production costs compared to traditional silicone rubber.

Dow Silicones Corp.

Technical Solution: Dow Silicones has pioneered a bio-based silicone technology that incorporates renewable, plant-derived materials into silicone rubber formulations. This approach reduces the reliance on fossil fuel-based ingredients while maintaining the performance characteristics of traditional silicone rubber[4]. The company has developed a range of bio-silicone elastomers that can be used in various applications, from consumer products to industrial components. These materials are designed to offer improved sustainability profiles without compromising on the unique properties of silicone rubber, such as flexibility, durability, and heat resistance[5]. Dow has also implemented life cycle assessment methodologies to quantify the environmental benefits of their bio-based silicone products, demonstrating reduced carbon footprints compared to conventional alternatives[6].

Strengths: Utilizes renewable resources; maintains key silicone rubber properties; reduced carbon footprint. Weaknesses: Limited biodegradability; potentially higher costs due to specialized raw materials.

Innovative Research in Silicone Rubber Biodegradation

Biodegradable rubber composition, method for producing biodegradable rubber composition, and biodegradable molded rubber article

PatentWO2021049122A1

Innovation

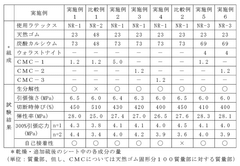

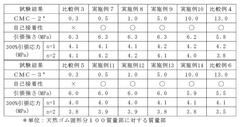

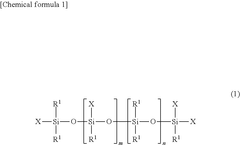

- A biodegradable rubber composition is developed using a mass ratio of natural rubber to inorganic substance powder of 45:55 to 10:90, with 0.5 to 10 parts of modified cellulose per 100 parts of natural rubber, specifically utilizing carboxymethyl cellulose and calcium carbonate, which enhances biodegradability and mechanical properties while maintaining moderate self-adhesiveness and reducing property variations.

Rubber particles, composite particles, and manufacturing methods therefor

PatentPendingUS20240409699A1

Innovation

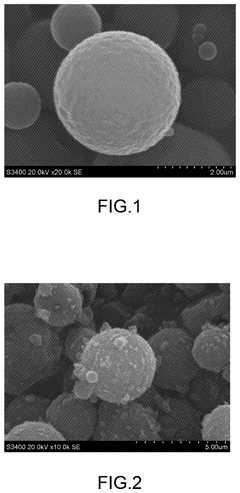

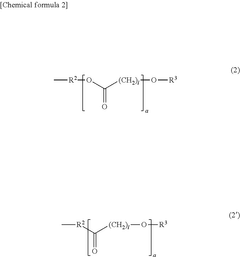

- Development of rubber particles and composite particles with a silicone-polyester copolymer structure containing radically polymerizable unsaturated groups, which are degradable due to the incorporation of polyester structures, allowing for environmental degradation by breaking down in water-bearing environments.

Environmental Impact Assessment of Silicone-Based Products

The environmental impact assessment of silicone-based products is a critical aspect of evaluating their sustainability and long-term viability in biodegradable product design. Silicone rubber, while not inherently biodegradable, plays a unique role in this context due to its durability and potential for extended product lifecycles.

Silicone-based products generally have a lower environmental footprint during their production phase compared to many traditional plastics. The manufacturing process of silicone rubber requires less energy and produces fewer greenhouse gas emissions. Additionally, silicone products often have a longer lifespan, which can reduce the overall environmental impact by decreasing the need for frequent replacements.

However, the end-of-life phase presents challenges for silicone-based products. While they do not biodegrade in natural environments, silicone rubbers can be recycled through specialized processes. These recycling methods, such as chemical depolymerization or thermal decomposition, allow for the recovery of valuable raw materials, potentially reducing the environmental burden associated with disposal.

In terms of water and soil contamination, silicone rubber exhibits relatively inert properties. Unlike many conventional plastics, silicones do not leach harmful chemicals into the environment, making them a safer option for applications that involve direct contact with ecosystems. This characteristic is particularly valuable in marine environments, where silicone-based products pose a lower risk of toxic effects on aquatic life.

The durability of silicone rubber also contributes to its environmental profile. Products made with silicone often last longer and maintain their performance characteristics over time, reducing the frequency of replacement and associated waste generation. This longevity can offset the initial environmental costs of production, especially in applications where frequent replacement of less durable materials would otherwise be necessary.

When considering the carbon footprint, silicone-based products generally perform well in lifecycle assessments. The energy efficiency of silicone manufacturing, combined with the material's lightweight nature and thermal insulation properties, can lead to reduced energy consumption during both production and use phases. This is particularly evident in applications such as building materials and automotive components, where silicone's properties contribute to improved energy efficiency.

Despite these advantages, the non-biodegradable nature of silicone rubber remains a concern in the context of environmental sustainability. Research into biodegradable alternatives or hybrid materials that incorporate silicone's beneficial properties while addressing end-of-life issues is ongoing. These efforts aim to bridge the gap between the performance benefits of silicone and the growing demand for fully biodegradable materials in product design.

Silicone-based products generally have a lower environmental footprint during their production phase compared to many traditional plastics. The manufacturing process of silicone rubber requires less energy and produces fewer greenhouse gas emissions. Additionally, silicone products often have a longer lifespan, which can reduce the overall environmental impact by decreasing the need for frequent replacements.

However, the end-of-life phase presents challenges for silicone-based products. While they do not biodegrade in natural environments, silicone rubbers can be recycled through specialized processes. These recycling methods, such as chemical depolymerization or thermal decomposition, allow for the recovery of valuable raw materials, potentially reducing the environmental burden associated with disposal.

In terms of water and soil contamination, silicone rubber exhibits relatively inert properties. Unlike many conventional plastics, silicones do not leach harmful chemicals into the environment, making them a safer option for applications that involve direct contact with ecosystems. This characteristic is particularly valuable in marine environments, where silicone-based products pose a lower risk of toxic effects on aquatic life.

The durability of silicone rubber also contributes to its environmental profile. Products made with silicone often last longer and maintain their performance characteristics over time, reducing the frequency of replacement and associated waste generation. This longevity can offset the initial environmental costs of production, especially in applications where frequent replacement of less durable materials would otherwise be necessary.

When considering the carbon footprint, silicone-based products generally perform well in lifecycle assessments. The energy efficiency of silicone manufacturing, combined with the material's lightweight nature and thermal insulation properties, can lead to reduced energy consumption during both production and use phases. This is particularly evident in applications such as building materials and automotive components, where silicone's properties contribute to improved energy efficiency.

Despite these advantages, the non-biodegradable nature of silicone rubber remains a concern in the context of environmental sustainability. Research into biodegradable alternatives or hybrid materials that incorporate silicone's beneficial properties while addressing end-of-life issues is ongoing. These efforts aim to bridge the gap between the performance benefits of silicone and the growing demand for fully biodegradable materials in product design.

Regulatory Framework for Biodegradable Materials

The regulatory framework for biodegradable materials plays a crucial role in shaping the development and adoption of sustainable product designs, including those incorporating silicone rubber. As the global focus on environmental sustainability intensifies, governments and international organizations have established various regulations and standards to govern the use of biodegradable materials.

In the European Union, the EN 13432 standard sets the requirements for packaging recoverable through composting and biodegradation. This standard is widely recognized and has influenced similar regulations worldwide. It specifies that at least 90% of the organic material must be converted into CO2 within six months, and no more than 10% residue should remain after three months on a 2mm sieve.

The United States Environmental Protection Agency (EPA) has developed guidelines for the use of biodegradable materials, focusing on their environmental impact and disposal methods. The ASTM D6400 standard, similar to EN 13432, provides specifications for plastics designed to be composted in municipal and industrial aerobic composting facilities.

In Asia, countries like Japan and South Korea have implemented their own biodegradability standards. Japan's GreenPla certification system, managed by the Japan BioPlastics Association, ensures that products meet specific biodegradability, quality, and safety requirements.

These regulatory frameworks often require manufacturers to provide evidence of biodegradability through standardized testing methods. For instance, the ISO 14855 test method is commonly used to determine the ultimate aerobic biodegradability of plastic materials under controlled composting conditions.

When considering silicone rubber's role in biodegradable product design, it's important to note that traditional silicone rubber is not biodegradable. However, recent advancements have led to the development of biodegradable silicone elastomers. Manufacturers incorporating these materials must ensure compliance with relevant regulations and standards, which may vary depending on the product's intended use and disposal method.

Regulatory bodies are increasingly focusing on the entire lifecycle of products, from raw material sourcing to end-of-life disposal. This holistic approach has led to the development of Extended Producer Responsibility (EPR) programs in many countries, requiring manufacturers to take responsibility for the environmental impact of their products throughout their lifecycle.

As the field of biodegradable materials continues to evolve, regulatory frameworks are expected to adapt and become more comprehensive. This may include specific provisions for hybrid materials, such as those combining silicone rubber with biodegradable components, to ensure proper classification and disposal methods.

In the European Union, the EN 13432 standard sets the requirements for packaging recoverable through composting and biodegradation. This standard is widely recognized and has influenced similar regulations worldwide. It specifies that at least 90% of the organic material must be converted into CO2 within six months, and no more than 10% residue should remain after three months on a 2mm sieve.

The United States Environmental Protection Agency (EPA) has developed guidelines for the use of biodegradable materials, focusing on their environmental impact and disposal methods. The ASTM D6400 standard, similar to EN 13432, provides specifications for plastics designed to be composted in municipal and industrial aerobic composting facilities.

In Asia, countries like Japan and South Korea have implemented their own biodegradability standards. Japan's GreenPla certification system, managed by the Japan BioPlastics Association, ensures that products meet specific biodegradability, quality, and safety requirements.

These regulatory frameworks often require manufacturers to provide evidence of biodegradability through standardized testing methods. For instance, the ISO 14855 test method is commonly used to determine the ultimate aerobic biodegradability of plastic materials under controlled composting conditions.

When considering silicone rubber's role in biodegradable product design, it's important to note that traditional silicone rubber is not biodegradable. However, recent advancements have led to the development of biodegradable silicone elastomers. Manufacturers incorporating these materials must ensure compliance with relevant regulations and standards, which may vary depending on the product's intended use and disposal method.

Regulatory bodies are increasingly focusing on the entire lifecycle of products, from raw material sourcing to end-of-life disposal. This holistic approach has led to the development of Extended Producer Responsibility (EPR) programs in many countries, requiring manufacturers to take responsibility for the environmental impact of their products throughout their lifecycle.

As the field of biodegradable materials continues to evolve, regulatory frameworks are expected to adapt and become more comprehensive. This may include specific provisions for hybrid materials, such as those combining silicone rubber with biodegradable components, to ensure proper classification and disposal methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!