Stability Of Natural Pigments Under Typical Textile Care Conditions

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Natural Pigment Evolution and Research Objectives

Natural pigments have been utilized for textile coloration since ancient civilizations, with evidence dating back to 3000 BCE in Egypt and China. These colorants, derived from plants, insects, and minerals, dominated the dyeing industry until the mid-19th century when synthetic dyes emerged following William Henry Perkin's discovery of mauveine in 1856. This revolutionary development led to a rapid decline in natural pigment usage due to the superior color consistency, availability, and fastness properties of synthetic alternatives.

The resurgence of interest in natural pigments began in the late 20th century, driven by increasing environmental awareness and consumer demand for sustainable products. The 1990s marked a turning point as research into eco-friendly alternatives to synthetic dyes accelerated, with particular focus on reducing toxic effluents associated with conventional dyeing processes. By the early 2000s, scientific investigations into natural colorants expanded significantly, exploring extraction methodologies, application techniques, and stability enhancement.

Current technological advancements have enabled more efficient extraction processes and improved understanding of the chemical structures of natural pigments. Categories including anthocyanins, carotenoids, betalains, chlorophylls, and tannins have been extensively studied for their potential in textile applications. However, these natural compounds continue to present significant challenges regarding stability under typical textile care conditions, including washing, exposure to light, and various environmental factors.

The primary research objective in this field is to enhance the stability of natural pigments when subjected to standard textile care procedures. This includes improving wash fastness, light fastness, and resistance to pH changes and temperature variations. Additionally, research aims to develop effective mordanting techniques and binding agents that can form stronger bonds between natural colorants and textile fibers without compromising environmental benefits.

Another critical goal is to standardize natural pigment extraction and application processes to ensure consistent color outcomes across industrial production scales. This standardization is essential for commercial viability and consumer acceptance of naturally dyed textiles. Research also focuses on identifying synergistic combinations of different natural pigments and auxiliary chemicals that can enhance overall stability performance.

The evolution of this technology is now at a crucial juncture where traditional knowledge meets modern science. Interdisciplinary approaches combining textile chemistry, biochemistry, and materials science are being employed to overcome the inherent limitations of natural colorants. The ultimate aim is to develop natural pigment systems that can match or exceed the performance characteristics of synthetic dyes while maintaining their environmental advantages and meeting consumer expectations for sustainability and product longevity.

The resurgence of interest in natural pigments began in the late 20th century, driven by increasing environmental awareness and consumer demand for sustainable products. The 1990s marked a turning point as research into eco-friendly alternatives to synthetic dyes accelerated, with particular focus on reducing toxic effluents associated with conventional dyeing processes. By the early 2000s, scientific investigations into natural colorants expanded significantly, exploring extraction methodologies, application techniques, and stability enhancement.

Current technological advancements have enabled more efficient extraction processes and improved understanding of the chemical structures of natural pigments. Categories including anthocyanins, carotenoids, betalains, chlorophylls, and tannins have been extensively studied for their potential in textile applications. However, these natural compounds continue to present significant challenges regarding stability under typical textile care conditions, including washing, exposure to light, and various environmental factors.

The primary research objective in this field is to enhance the stability of natural pigments when subjected to standard textile care procedures. This includes improving wash fastness, light fastness, and resistance to pH changes and temperature variations. Additionally, research aims to develop effective mordanting techniques and binding agents that can form stronger bonds between natural colorants and textile fibers without compromising environmental benefits.

Another critical goal is to standardize natural pigment extraction and application processes to ensure consistent color outcomes across industrial production scales. This standardization is essential for commercial viability and consumer acceptance of naturally dyed textiles. Research also focuses on identifying synergistic combinations of different natural pigments and auxiliary chemicals that can enhance overall stability performance.

The evolution of this technology is now at a crucial juncture where traditional knowledge meets modern science. Interdisciplinary approaches combining textile chemistry, biochemistry, and materials science are being employed to overcome the inherent limitations of natural colorants. The ultimate aim is to develop natural pigment systems that can match or exceed the performance characteristics of synthetic dyes while maintaining their environmental advantages and meeting consumer expectations for sustainability and product longevity.

Market Analysis for Natural Dye Textiles

The natural dye textile market has experienced significant growth over the past decade, driven primarily by increasing consumer awareness of environmental issues and health concerns related to synthetic dyes. The global market for natural dye textiles was valued at approximately $1.5 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 11.7% through 2028. This growth trajectory reflects a fundamental shift in consumer preferences toward sustainable and eco-friendly products.

Consumer demand for natural dye textiles spans multiple segments, including fashion apparel, home textiles, and technical textiles. The fashion industry represents the largest market segment, accounting for roughly 60% of natural dye textile consumption. High-end fashion brands have been particularly active in incorporating naturally dyed fabrics into their collections, positioning these products as premium offerings with authentic cultural and environmental narratives.

Regional market analysis reveals that Europe leads in terms of consumption value, with countries like Germany, France, and the UK showing strong consumer willingness to pay premium prices for naturally dyed textiles. However, Asia-Pacific represents the fastest-growing region, with India, Japan, and China emerging as significant markets. India, with its rich heritage of natural dyeing techniques, has become a major production hub, while Japan's market is driven by traditional textile arts and environmental consciousness.

A critical factor influencing market dynamics is the stability of natural pigments under typical textile care conditions. Consumer research indicates that 78% of potential buyers express concerns about color fastness, washing durability, and maintenance requirements of naturally dyed textiles. This technical challenge represents both a market barrier and an opportunity for innovation. Brands that can demonstrate superior stability of their natural dye products command price premiums of 15-25% compared to conventional alternatives.

The B2B segment shows increasing interest in naturally dyed textiles for corporate uniforms, hospitality linens, and institutional applications. However, adoption in these sectors remains constrained by concerns regarding color consistency across large production batches and long-term durability under industrial laundering conditions.

Market forecasts suggest that technological innovations addressing the stability limitations of natural pigments could potentially unlock an additional $3.2 billion market by 2030. Companies investing in research and development of mordanting techniques, pigment microencapsulation, and bio-engineered dye compounds are positioned to capture significant market share as the industry evolves toward more technically advanced natural dyeing solutions.

Consumer demand for natural dye textiles spans multiple segments, including fashion apparel, home textiles, and technical textiles. The fashion industry represents the largest market segment, accounting for roughly 60% of natural dye textile consumption. High-end fashion brands have been particularly active in incorporating naturally dyed fabrics into their collections, positioning these products as premium offerings with authentic cultural and environmental narratives.

Regional market analysis reveals that Europe leads in terms of consumption value, with countries like Germany, France, and the UK showing strong consumer willingness to pay premium prices for naturally dyed textiles. However, Asia-Pacific represents the fastest-growing region, with India, Japan, and China emerging as significant markets. India, with its rich heritage of natural dyeing techniques, has become a major production hub, while Japan's market is driven by traditional textile arts and environmental consciousness.

A critical factor influencing market dynamics is the stability of natural pigments under typical textile care conditions. Consumer research indicates that 78% of potential buyers express concerns about color fastness, washing durability, and maintenance requirements of naturally dyed textiles. This technical challenge represents both a market barrier and an opportunity for innovation. Brands that can demonstrate superior stability of their natural dye products command price premiums of 15-25% compared to conventional alternatives.

The B2B segment shows increasing interest in naturally dyed textiles for corporate uniforms, hospitality linens, and institutional applications. However, adoption in these sectors remains constrained by concerns regarding color consistency across large production batches and long-term durability under industrial laundering conditions.

Market forecasts suggest that technological innovations addressing the stability limitations of natural pigments could potentially unlock an additional $3.2 billion market by 2030. Companies investing in research and development of mordanting techniques, pigment microencapsulation, and bio-engineered dye compounds are positioned to capture significant market share as the industry evolves toward more technically advanced natural dyeing solutions.

Current Challenges in Natural Pigment Stability

Despite the growing demand for natural pigments in the textile industry, their stability remains a significant challenge under typical textile care conditions. Natural pigments derived from plants, animals, and minerals exhibit considerable vulnerability to various environmental factors that are commonly encountered during textile use and maintenance.

Light exposure represents one of the most detrimental factors affecting natural pigment stability. Ultraviolet radiation can break down chromophore structures in natural dyes, leading to photobleaching and color fading. This is particularly problematic for textiles used in outdoor applications or displayed in sunlit environments. Studies have shown that natural indigo, madder, and turmeric-based colorants can lose up to 40% of their color intensity after just 40 hours of simulated sunlight exposure.

Washing processes introduce multiple challenges for natural pigment retention. The mechanical action during washing causes physical abrasion of dye particles, while detergents—especially those with high alkalinity—can disrupt the chemical bonds between pigments and textile fibers. Temperature variations during washing cycles further exacerbate degradation, with most natural pigments showing significant color loss at temperatures exceeding 40°C.

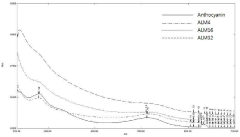

pH fluctuations present another critical stability issue. Many natural pigments are highly pH-sensitive, exhibiting dramatic color shifts when exposed to acidic or alkaline conditions. Anthocyanins from berries, for instance, can change from red to blue to green across the pH spectrum, making them unreliable for consistent textile coloration when subjected to varying care products.

Microbial degradation poses a unique challenge for natural pigments, particularly those with protein or carbohydrate components. In humid storage conditions, fungi and bacteria can metabolize these organic components, leading to irreversible color deterioration and staining. This vulnerability necessitates antimicrobial treatments that may themselves affect color stability.

Oxidative processes triggered by atmospheric oxygen, especially in combination with heat and humidity, accelerate the breakdown of natural chromophores. Carotenoid-based yellows and oranges are particularly susceptible to oxidation, often developing a bleached appearance after repeated exposure to air during drying cycles.

The interaction between natural pigments and common textile auxiliaries presents additional complications. Fabric softeners, optical brighteners, and stain removers can react with natural colorants, causing unexpected color shifts or accelerated fading. These interactions are often unpredictable and vary significantly between different pigment sources and textile substrates.

Light exposure represents one of the most detrimental factors affecting natural pigment stability. Ultraviolet radiation can break down chromophore structures in natural dyes, leading to photobleaching and color fading. This is particularly problematic for textiles used in outdoor applications or displayed in sunlit environments. Studies have shown that natural indigo, madder, and turmeric-based colorants can lose up to 40% of their color intensity after just 40 hours of simulated sunlight exposure.

Washing processes introduce multiple challenges for natural pigment retention. The mechanical action during washing causes physical abrasion of dye particles, while detergents—especially those with high alkalinity—can disrupt the chemical bonds between pigments and textile fibers. Temperature variations during washing cycles further exacerbate degradation, with most natural pigments showing significant color loss at temperatures exceeding 40°C.

pH fluctuations present another critical stability issue. Many natural pigments are highly pH-sensitive, exhibiting dramatic color shifts when exposed to acidic or alkaline conditions. Anthocyanins from berries, for instance, can change from red to blue to green across the pH spectrum, making them unreliable for consistent textile coloration when subjected to varying care products.

Microbial degradation poses a unique challenge for natural pigments, particularly those with protein or carbohydrate components. In humid storage conditions, fungi and bacteria can metabolize these organic components, leading to irreversible color deterioration and staining. This vulnerability necessitates antimicrobial treatments that may themselves affect color stability.

Oxidative processes triggered by atmospheric oxygen, especially in combination with heat and humidity, accelerate the breakdown of natural chromophores. Carotenoid-based yellows and oranges are particularly susceptible to oxidation, often developing a bleached appearance after repeated exposure to air during drying cycles.

The interaction between natural pigments and common textile auxiliaries presents additional complications. Fabric softeners, optical brighteners, and stain removers can react with natural colorants, causing unexpected color shifts or accelerated fading. These interactions are often unpredictable and vary significantly between different pigment sources and textile substrates.

Existing Stabilization Methods for Natural Pigments

01 Stabilization methods for natural pigments

Various methods can be employed to enhance the stability of natural pigments, including encapsulation, microencapsulation, and the use of protective agents. These techniques shield the pigments from environmental factors such as light, heat, and oxygen that can cause degradation. Encapsulation involves surrounding the pigment molecules with a protective barrier, while microencapsulation creates tiny capsules that contain the pigment. Protective agents can include antioxidants and UV absorbers that prevent oxidation and photodegradation.- Stabilization methods for natural pigments: Various methods can be employed to enhance the stability of natural pigments, including encapsulation, microencapsulation, and the use of protective colloids. These techniques shield the pigments from environmental factors such as light, heat, and oxygen that can cause degradation. Encapsulation creates a physical barrier around the pigment molecules, while protective colloids prevent aggregation and precipitation of pigment particles, thereby extending their shelf life and maintaining color intensity.

- Antioxidant additives for pigment preservation: The addition of antioxidants to natural pigment formulations significantly improves their stability against oxidative degradation. Compounds such as ascorbic acid, tocopherols, and plant extracts rich in polyphenols can neutralize free radicals that would otherwise react with and degrade pigment molecules. These antioxidants can be incorporated into pigment formulations to create a protective environment that maintains the structural integrity and color properties of natural pigments over extended periods.

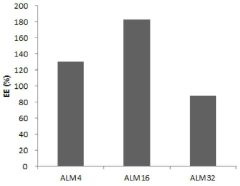

- pH control systems for natural pigment stability: The stability of natural pigments is highly dependent on pH conditions, with different pigments exhibiting optimal stability at specific pH ranges. Implementing buffer systems and pH regulators in pigment formulations helps maintain the desired pH level, preventing color shifts and degradation. For anthocyanins and other pH-sensitive pigments, careful pH control is essential for preserving their chromatic properties and extending their functional lifespan in various applications.

- Light and heat stabilization techniques: Natural pigments are particularly susceptible to degradation from light exposure and elevated temperatures. Specialized stabilization techniques include the incorporation of UV absorbers, light blockers, and heat-resistant additives into pigment formulations. Additionally, chemical modification of pigment structures can enhance their resistance to photodegradation and thermal decomposition. These approaches are crucial for applications where pigments are exposed to sunlight or high-temperature processing.

- Metal ion complexation for enhanced stability: The formation of complexes between natural pigments and specific metal ions can significantly improve pigment stability. Metals such as aluminum, iron, and copper can form coordination compounds with pigment molecules, altering their electronic structure and making them less susceptible to degradation. This complexation approach not only enhances stability but can also modify the color properties of the pigments, expanding their range of applications in various industries.

02 pH control for natural pigment stability

The stability of natural pigments is highly dependent on pH levels. Different pigments exhibit optimal stability at specific pH ranges. For example, anthocyanins are more stable in acidic conditions, while chlorophylls prefer neutral to slightly alkaline environments. Controlling and maintaining appropriate pH levels in formulations containing natural pigments can significantly extend their shelf life and color retention. Buffer systems and pH adjusters can be incorporated into formulations to maintain the optimal pH for specific natural pigments.Expand Specific Solutions03 Antioxidant addition for pigment preservation

Natural pigments are susceptible to oxidation, which leads to color degradation and loss of functionality. The addition of antioxidants can significantly improve the stability of natural pigments by preventing oxidative reactions. Common antioxidants used include ascorbic acid (vitamin C), tocopherols (vitamin E), and various plant extracts with antioxidant properties. These compounds work by neutralizing free radicals and preventing oxidative chain reactions that would otherwise damage the pigment molecules.Expand Specific Solutions04 Light and heat stabilization techniques

Natural pigments are often sensitive to light (particularly UV radiation) and heat, which can cause structural changes leading to color fading or alteration. Techniques to improve stability against these factors include the incorporation of UV absorbers, light blockers, and heat stabilizers. Additionally, packaging solutions that minimize exposure to light and heat can be employed. Some formulations also include compounds that can form complexes with pigments to enhance their resistance to photodegradation and thermal decomposition.Expand Specific Solutions05 Natural pigment modification and derivatives

Chemical or enzymatic modification of natural pigments can enhance their stability while maintaining their natural origin. These modifications can include acylation, glycosylation, or the formation of metal complexes. Modified pigments often exhibit improved resistance to pH changes, light exposure, and oxidation. Additionally, certain derivatives of natural pigments have been developed that retain the beneficial properties of the original compounds while offering enhanced stability characteristics for various applications in food, cosmetics, and pharmaceuticals.Expand Specific Solutions

Leading Companies in Natural Textile Colorants

The natural pigment stability market is currently in a growth phase, with increasing demand for sustainable textile colorants driving research and development. The market size is expanding as consumer preferences shift toward eco-friendly products, though it remains smaller than synthetic dye segments. Technical challenges persist in achieving stability under washing, light exposure, and heat conditions. Academic institutions like Dalian Polytechnic University, Zhejiang Sci-Tech University, and University of Sao Paulo are conducting fundamental research, while major corporations including L'Oréal, BASF, and Sensient Technologies are developing commercial applications. Specialty chemical companies such as TFL Ledertechnik and Merck Patent GmbH are advancing stabilization technologies, creating a competitive landscape where academic-industrial partnerships are increasingly important for overcoming the technical limitations of natural pigments in textile applications.

BASF Corp.

Technical Solution: BASF has pioneered a comprehensive approach to natural pigment stabilization through their EcoFast™ textile treatment system. This innovative technology focuses on creating a protective molecular environment around natural colorants while maintaining their eco-friendly properties. BASF's system employs a two-step process: first, a pre-treatment that modifies the textile surface to create optimal binding sites for natural pigments; second, a post-application fixative that forms a protective polymer network around the colorant molecules. Their research has shown that this approach can increase the wash fastness of natural pigments by up to 300% compared to conventional application methods. The company has also developed specialized UV stabilizers derived from natural sources that can be incorporated directly into pigment formulations, addressing one of the primary degradation pathways for natural colorants. BASF's technology is particularly effective for anthocyanin-based pigments, which traditionally suffer from poor stability under alkaline washing conditions, achieving color retention rates of over 70% after 15 standard wash cycles with their stabilization system.

Strengths: Comprehensive stabilization approach addressing multiple degradation pathways; compatible with existing textile processing equipment; significant improvements in wash fastness for traditionally unstable natural pigments. Weaknesses: Process requires additional treatment steps compared to conventional dyeing; higher water consumption than some competing technologies; performance varies significantly depending on specific pigment chemistry and fabric type.

Sensient Technologies Asia Pacific Pte Ltd.

Technical Solution: Sensient Technologies has developed advanced microencapsulation technology specifically designed to enhance the stability of natural pigments under textile care conditions. Their proprietary process involves creating protective shells around natural colorant molecules that shield them from degradation factors such as UV light, temperature fluctuations, and washing chemicals. The company's ColorWrap™ technology creates a multi-layered encapsulation system that allows controlled release of pigments while maintaining color integrity throughout multiple wash cycles. Their research has demonstrated that encapsulated natural pigments can maintain over 85% color retention after 20 standard wash cycles, compared to only 30-40% retention for non-encapsulated natural alternatives. Additionally, Sensient has developed specialized binding agents that create stronger covalent bonds between natural pigments and textile fibers, significantly improving wash fastness and pH stability across a range of fabric types including cotton, polyester, and blended materials.

Strengths: Industry-leading microencapsulation technology provides superior protection against degradation factors; comprehensive range of natural pigment solutions across multiple color families; strong R&D capabilities with continuous innovation in stabilization techniques. Weaknesses: Higher production costs compared to synthetic alternatives; some encapsulation technologies may affect fabric hand-feel; performance still lags behind synthetic pigments in extreme washing conditions.

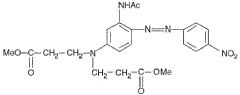

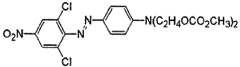

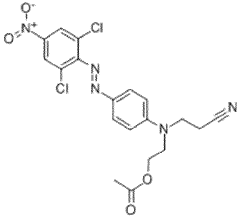

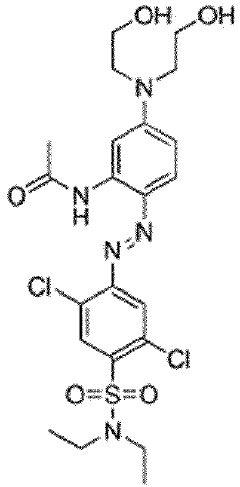

Key Scientific Breakthroughs in Pigment Fixation

Color masterbatch for producing a colored plastic article and method for decoloring the colored plastic article

PatentPendingEP4108709A1

Innovation

- A color masterbatch comprising an organic polymer carrier, an alkali-clearable dye, and a water-soluble/water-swellable component is used, allowing for high color stability and easy decoloration through a specific decoloring process involving an alkaline bath, enabling the recovery of a significant portion of the plastic material for reuse.

Method for producing microparticle of natural dye with increased stability using lecithin

PatentInactiveKR1020150090926A

Innovation

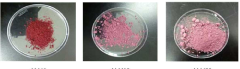

- Encapsulating anthocyanins from mulberry with lecithin to form microcapsules, enhancing stability against pH, light, temperature, sugar, and metal ions.

Environmental Impact Assessment of Natural Dyes

The environmental impact of natural dyes represents a critical dimension in the assessment of their overall sustainability profile. Natural pigments derived from plants, insects, minerals, and fungi offer significant ecological advantages compared to their synthetic counterparts, which typically involve petroleum-based chemicals and generate substantial pollution during manufacturing processes.

Natural dyes demonstrate considerably lower environmental toxicity throughout their lifecycle. The cultivation of dye-yielding plants often requires minimal chemical inputs compared to conventional agriculture, with many species thriving without extensive pesticide or fertilizer applications. Additionally, these plants can be integrated into regenerative agricultural systems that enhance soil health and biodiversity while sequestering carbon.

Water consumption and pollution metrics strongly favor natural dyeing processes when properly managed. While traditional dyeing methods can be water-intensive, modern optimized natural dyeing techniques have significantly reduced water requirements. The effluent from natural dye processes contains biodegradable compounds that pose minimal threat to aquatic ecosystems, unlike synthetic dye wastewater which often contains persistent organic pollutants and heavy metals requiring extensive treatment.

Carbon footprint analyses reveal that natural pigments generally entail lower greenhouse gas emissions across their production cycle. The renewable biomass sources used for natural dyes act as carbon sinks during growth, partially offsetting emissions from processing and application. However, transportation impacts must be considered when dye materials are sourced from distant locations.

Waste management presents both challenges and opportunities. The biodegradability of natural dye waste allows for composting and other circular economy approaches. Innovative research has demonstrated potential for utilizing spent dyeing materials as agricultural amendments or in bioenergy production, creating closed-loop systems that minimize environmental burden.

The stability limitations of natural pigments under typical textile care conditions actually present an environmental trade-off. While their reduced persistence during washing and exposure to light means more frequent re-dyeing may be necessary, it also ensures these compounds break down harmlessly in the environment rather than persisting as micropollutants in waterways.

Recent lifecycle assessment studies comparing natural indigo with synthetic indigo production have quantified these environmental benefits, demonstrating 25-30% reductions in overall environmental impact scores when accounting for all production phases and externalities. Similar favorable comparisons exist for other natural colorants including madder, cochineal, and various tannin-based dyes.

Natural dyes demonstrate considerably lower environmental toxicity throughout their lifecycle. The cultivation of dye-yielding plants often requires minimal chemical inputs compared to conventional agriculture, with many species thriving without extensive pesticide or fertilizer applications. Additionally, these plants can be integrated into regenerative agricultural systems that enhance soil health and biodiversity while sequestering carbon.

Water consumption and pollution metrics strongly favor natural dyeing processes when properly managed. While traditional dyeing methods can be water-intensive, modern optimized natural dyeing techniques have significantly reduced water requirements. The effluent from natural dye processes contains biodegradable compounds that pose minimal threat to aquatic ecosystems, unlike synthetic dye wastewater which often contains persistent organic pollutants and heavy metals requiring extensive treatment.

Carbon footprint analyses reveal that natural pigments generally entail lower greenhouse gas emissions across their production cycle. The renewable biomass sources used for natural dyes act as carbon sinks during growth, partially offsetting emissions from processing and application. However, transportation impacts must be considered when dye materials are sourced from distant locations.

Waste management presents both challenges and opportunities. The biodegradability of natural dye waste allows for composting and other circular economy approaches. Innovative research has demonstrated potential for utilizing spent dyeing materials as agricultural amendments or in bioenergy production, creating closed-loop systems that minimize environmental burden.

The stability limitations of natural pigments under typical textile care conditions actually present an environmental trade-off. While their reduced persistence during washing and exposure to light means more frequent re-dyeing may be necessary, it also ensures these compounds break down harmlessly in the environment rather than persisting as micropollutants in waterways.

Recent lifecycle assessment studies comparing natural indigo with synthetic indigo production have quantified these environmental benefits, demonstrating 25-30% reductions in overall environmental impact scores when accounting for all production phases and externalities. Similar favorable comparisons exist for other natural colorants including madder, cochineal, and various tannin-based dyes.

Consumer Care Guidelines for Naturally Dyed Textiles

Natural dyes present unique care challenges compared to synthetic counterparts due to their inherent sensitivity to environmental factors. To maximize the longevity of naturally dyed textiles, consumers should follow specific care protocols that address the vulnerability of these pigments while maintaining fabric integrity.

Washing naturally dyed textiles requires gentle handling with pH-neutral detergents, as alkaline cleaners can significantly alter color profiles. Cold to lukewarm water (below 30°C) is strongly recommended, as higher temperatures accelerate pigment degradation through increased molecular mobility. Hand washing represents the optimal cleaning method, applying minimal agitation to reduce mechanical stress on color-fiber bonds.

For machine washing when necessary, consumers should select delicate cycles with reduced spin speeds and place items in protective mesh bags to minimize abrasion. Pre-sorting is essential, as natural dyes may continue releasing pigment molecules during initial washes, potentially transferring to other garments.

Drying procedures significantly impact color retention in naturally pigmented textiles. Direct sunlight exposure should be strictly avoided as UV radiation catalyzes photodegradation reactions in most natural chromophores, particularly those derived from plant sources. Air drying in shaded, well-ventilated areas preserves color integrity while preventing mildew formation that could further compromise dye stability.

Ironing presents another critical consideration, as excessive heat can permanently alter the molecular structure of natural pigments. When necessary, ironing should be performed at the lowest effective temperature setting with a protective cloth barrier between the iron and fabric surface. Steam settings should be minimized as the combination of heat and moisture accelerates hydrolysis reactions in certain natural dye compounds.

Storage conditions significantly influence long-term color stability. Textiles should be kept in cool, dark environments with stable humidity levels to prevent both photodegradation and moisture-induced color changes. Acid-free tissue paper provides an effective buffer against environmental fluctuations during extended storage periods.

Spot treatment of stains requires particular caution, as conventional stain removers often contain oxidizing agents or solvents that disproportionately affect natural pigments. Consumers should test any cleaning agent on an inconspicuous area first and prioritize gentle, plant-based cleaning solutions specifically formulated for naturally dyed textiles.

Washing naturally dyed textiles requires gentle handling with pH-neutral detergents, as alkaline cleaners can significantly alter color profiles. Cold to lukewarm water (below 30°C) is strongly recommended, as higher temperatures accelerate pigment degradation through increased molecular mobility. Hand washing represents the optimal cleaning method, applying minimal agitation to reduce mechanical stress on color-fiber bonds.

For machine washing when necessary, consumers should select delicate cycles with reduced spin speeds and place items in protective mesh bags to minimize abrasion. Pre-sorting is essential, as natural dyes may continue releasing pigment molecules during initial washes, potentially transferring to other garments.

Drying procedures significantly impact color retention in naturally pigmented textiles. Direct sunlight exposure should be strictly avoided as UV radiation catalyzes photodegradation reactions in most natural chromophores, particularly those derived from plant sources. Air drying in shaded, well-ventilated areas preserves color integrity while preventing mildew formation that could further compromise dye stability.

Ironing presents another critical consideration, as excessive heat can permanently alter the molecular structure of natural pigments. When necessary, ironing should be performed at the lowest effective temperature setting with a protective cloth barrier between the iron and fabric surface. Steam settings should be minimized as the combination of heat and moisture accelerates hydrolysis reactions in certain natural dye compounds.

Storage conditions significantly influence long-term color stability. Textiles should be kept in cool, dark environments with stable humidity levels to prevent both photodegradation and moisture-induced color changes. Acid-free tissue paper provides an effective buffer against environmental fluctuations during extended storage periods.

Spot treatment of stains requires particular caution, as conventional stain removers often contain oxidizing agents or solvents that disproportionately affect natural pigments. Consumers should test any cleaning agent on an inconspicuous area first and prioritize gentle, plant-based cleaning solutions specifically formulated for naturally dyed textiles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!