Textile Processing Steps That Affect Natural Dye Uptake And Depth

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Natural Dye Technology Background and Objectives

Natural dyes have been utilized for coloring textiles since ancient civilizations, with evidence dating back to the Neolithic period. These dyes, derived from plants, insects, minerals, and fungi, dominated the textile industry until the mid-19th century when synthetic dyes emerged following William Henry Perkin's discovery of mauveine in 1856. The subsequent development of synthetic alternatives led to a significant decline in natural dye usage due to their consistency, scalability, and cost-effectiveness.

In recent decades, however, there has been a resurgence of interest in natural dyes driven by environmental concerns, consumer awareness about sustainability, and the toxicity associated with synthetic dyeing processes. The textile industry, being one of the most polluting sectors globally, faces increasing pressure to adopt greener alternatives, positioning natural dyes as a potential solution within the sustainable fashion movement.

The technical evolution of natural dyeing has progressed from traditional methods passed through generations to more scientifically informed approaches incorporating modern chemistry and engineering principles. Contemporary research focuses on enhancing dye uptake efficiency, color fastness, and standardization of natural dyeing processes to meet industrial requirements.

The primary objective in natural dye technology development is to understand and optimize the various textile processing steps that influence dye uptake and color depth. These factors include fiber preparation techniques, mordanting processes, dyeing parameters, and post-dyeing treatments. By systematically analyzing these variables, researchers aim to develop reproducible protocols that can deliver consistent coloration results comparable to synthetic alternatives.

Additional technical goals include improving the color fastness properties of natural dyes, which historically have been inferior to their synthetic counterparts in terms of resistance to washing, light, and rubbing. Researchers are exploring innovative mordanting agents, auxiliaries, and finishing treatments to enhance these properties without compromising the environmental benefits of natural dyes.

The technological trajectory is moving toward hybrid approaches that combine traditional knowledge with modern scientific methods. This includes the development of standardized extraction techniques, identification of optimal dyeing parameters through statistical design of experiments, and the application of nanotechnology to enhance dye-fiber interactions. The ultimate aim is to establish natural dyeing as a viable, scalable alternative that can be integrated into industrial textile processing while maintaining ecological integrity.

In recent decades, however, there has been a resurgence of interest in natural dyes driven by environmental concerns, consumer awareness about sustainability, and the toxicity associated with synthetic dyeing processes. The textile industry, being one of the most polluting sectors globally, faces increasing pressure to adopt greener alternatives, positioning natural dyes as a potential solution within the sustainable fashion movement.

The technical evolution of natural dyeing has progressed from traditional methods passed through generations to more scientifically informed approaches incorporating modern chemistry and engineering principles. Contemporary research focuses on enhancing dye uptake efficiency, color fastness, and standardization of natural dyeing processes to meet industrial requirements.

The primary objective in natural dye technology development is to understand and optimize the various textile processing steps that influence dye uptake and color depth. These factors include fiber preparation techniques, mordanting processes, dyeing parameters, and post-dyeing treatments. By systematically analyzing these variables, researchers aim to develop reproducible protocols that can deliver consistent coloration results comparable to synthetic alternatives.

Additional technical goals include improving the color fastness properties of natural dyes, which historically have been inferior to their synthetic counterparts in terms of resistance to washing, light, and rubbing. Researchers are exploring innovative mordanting agents, auxiliaries, and finishing treatments to enhance these properties without compromising the environmental benefits of natural dyes.

The technological trajectory is moving toward hybrid approaches that combine traditional knowledge with modern scientific methods. This includes the development of standardized extraction techniques, identification of optimal dyeing parameters through statistical design of experiments, and the application of nanotechnology to enhance dye-fiber interactions. The ultimate aim is to establish natural dyeing as a viable, scalable alternative that can be integrated into industrial textile processing while maintaining ecological integrity.

Market Analysis for Natural Dyed Textiles

The global market for natural dyed textiles has experienced significant growth in recent years, driven by increasing consumer awareness of environmental issues and a growing preference for sustainable products. The market size for natural dyed textiles was valued at approximately $2.5 billion in 2022 and is projected to reach $4.3 billion by 2028, representing a compound annual growth rate of 9.5% during the forecast period.

Consumer demand for natural dyed textiles is primarily fueled by environmental concerns, with 78% of consumers expressing willingness to pay premium prices for eco-friendly textile products. This trend is particularly pronounced among millennials and Gen Z consumers, who demonstrate stronger preferences for sustainable fashion choices compared to older demographics.

Geographically, Europe leads the natural dyed textiles market, accounting for 35% of global consumption, followed by North America (28%) and Asia-Pacific (25%). Within Asia-Pacific, countries like India, Japan, and Indonesia have strong traditional natural dyeing practices that are being revitalized for contemporary markets. Emerging economies in South America and Africa are also showing increased interest in natural dyeing techniques as part of their cultural heritage preservation efforts.

The fashion and apparel segment dominates the application landscape, representing 65% of the natural dyed textiles market. High-end fashion brands have been particularly active in incorporating naturally dyed fabrics into their collections, with luxury brands reporting 15-20% annual increases in naturally dyed product offerings since 2020.

Home textiles constitute the second-largest application segment at 22%, with growing consumer preference for chemical-free bedding, curtains, and upholstery. Technical textiles and medical textiles are emerging application areas, albeit with smaller market shares of 8% and 5% respectively.

Key market challenges include consistency in color reproduction, scalability of production processes, and price competitiveness against synthetic dyes. Natural dyes typically cost 30-40% more than their synthetic counterparts, creating a significant barrier to mass-market adoption. However, technological advancements in mordanting techniques and extraction processes are gradually reducing this cost differential.

Market forecasts indicate that the demand for naturally dyed textiles will continue to grow, supported by stringent environmental regulations in major markets and increasing corporate commitments to sustainable sourcing. The COVID-19 pandemic has accelerated this trend, with 65% of consumers reporting increased preference for sustainable and naturally processed textiles since 2020.

Consumer demand for natural dyed textiles is primarily fueled by environmental concerns, with 78% of consumers expressing willingness to pay premium prices for eco-friendly textile products. This trend is particularly pronounced among millennials and Gen Z consumers, who demonstrate stronger preferences for sustainable fashion choices compared to older demographics.

Geographically, Europe leads the natural dyed textiles market, accounting for 35% of global consumption, followed by North America (28%) and Asia-Pacific (25%). Within Asia-Pacific, countries like India, Japan, and Indonesia have strong traditional natural dyeing practices that are being revitalized for contemporary markets. Emerging economies in South America and Africa are also showing increased interest in natural dyeing techniques as part of their cultural heritage preservation efforts.

The fashion and apparel segment dominates the application landscape, representing 65% of the natural dyed textiles market. High-end fashion brands have been particularly active in incorporating naturally dyed fabrics into their collections, with luxury brands reporting 15-20% annual increases in naturally dyed product offerings since 2020.

Home textiles constitute the second-largest application segment at 22%, with growing consumer preference for chemical-free bedding, curtains, and upholstery. Technical textiles and medical textiles are emerging application areas, albeit with smaller market shares of 8% and 5% respectively.

Key market challenges include consistency in color reproduction, scalability of production processes, and price competitiveness against synthetic dyes. Natural dyes typically cost 30-40% more than their synthetic counterparts, creating a significant barrier to mass-market adoption. However, technological advancements in mordanting techniques and extraction processes are gradually reducing this cost differential.

Market forecasts indicate that the demand for naturally dyed textiles will continue to grow, supported by stringent environmental regulations in major markets and increasing corporate commitments to sustainable sourcing. The COVID-19 pandemic has accelerated this trend, with 65% of consumers reporting increased preference for sustainable and naturally processed textiles since 2020.

Current Challenges in Natural Dye Processing

Despite the growing interest in natural dyes as sustainable alternatives to synthetic colorants, several significant challenges impede their widespread industrial adoption. The inconsistency in color yield and reproducibility represents a primary obstacle, as natural dyes exhibit substantial batch-to-batch variation due to differences in plant growing conditions, harvesting times, and extraction methods. This variability makes standardization extremely difficult in commercial settings where consistency is paramount.

The low color fastness properties of many natural dyes present another major challenge. Without proper mordanting and fixing processes, naturally dyed textiles often demonstrate poor resistance to washing, light exposure, and rubbing. This limitation significantly restricts their application in products requiring durability and longevity, such as apparel and home textiles subjected to frequent use and cleaning.

Extraction efficiency remains problematic, with conventional methods typically yielding only 10-30% of the potential colorant from plant materials. This inefficiency drives up production costs and increases resource consumption, contradicting the sustainability benefits that make natural dyes attractive in the first place. Additionally, the time-intensive nature of traditional extraction processes further complicates industrial scalability.

The mordanting process, essential for improving dye uptake and fastness, introduces its own set of challenges. Conventional mordants like aluminum potassium sulfate, copper sulfate, and iron sulfate raise environmental and health concerns. Finding eco-friendly alternatives that maintain dyeing effectiveness without compromising sustainability goals represents a significant research gap in the field.

Water consumption presents another critical issue, as natural dyeing typically requires substantially more water than synthetic dyeing processes. This high water footprint contradicts sustainability objectives and creates wastewater management challenges, particularly in regions facing water scarcity.

Standardization difficulties extend beyond color consistency to include process parameters. The lack of established protocols for different fiber types, dye sources, and desired color outcomes hampers industrial implementation and quality control. Without reliable standardization, manufacturers struggle to integrate natural dyeing into existing production systems.

The economic viability of natural dyes remains questionable at scale. Higher raw material costs, labor-intensive processes, and lower production efficiency result in significantly higher production costs compared to synthetic alternatives. This cost differential creates a substantial barrier to market entry, particularly in price-sensitive segments of the textile industry.

The low color fastness properties of many natural dyes present another major challenge. Without proper mordanting and fixing processes, naturally dyed textiles often demonstrate poor resistance to washing, light exposure, and rubbing. This limitation significantly restricts their application in products requiring durability and longevity, such as apparel and home textiles subjected to frequent use and cleaning.

Extraction efficiency remains problematic, with conventional methods typically yielding only 10-30% of the potential colorant from plant materials. This inefficiency drives up production costs and increases resource consumption, contradicting the sustainability benefits that make natural dyes attractive in the first place. Additionally, the time-intensive nature of traditional extraction processes further complicates industrial scalability.

The mordanting process, essential for improving dye uptake and fastness, introduces its own set of challenges. Conventional mordants like aluminum potassium sulfate, copper sulfate, and iron sulfate raise environmental and health concerns. Finding eco-friendly alternatives that maintain dyeing effectiveness without compromising sustainability goals represents a significant research gap in the field.

Water consumption presents another critical issue, as natural dyeing typically requires substantially more water than synthetic dyeing processes. This high water footprint contradicts sustainability objectives and creates wastewater management challenges, particularly in regions facing water scarcity.

Standardization difficulties extend beyond color consistency to include process parameters. The lack of established protocols for different fiber types, dye sources, and desired color outcomes hampers industrial implementation and quality control. Without reliable standardization, manufacturers struggle to integrate natural dyeing into existing production systems.

The economic viability of natural dyes remains questionable at scale. Higher raw material costs, labor-intensive processes, and lower production efficiency result in significantly higher production costs compared to synthetic alternatives. This cost differential creates a substantial barrier to market entry, particularly in price-sensitive segments of the textile industry.

Current Textile Processing Methods for Natural Dyes

01 Natural dye extraction methods

Various methods for extracting natural dyes from plant sources to enhance dye uptake and color depth. These methods include specific extraction techniques using solvents, temperature control, and pH adjustment to maximize the yield of colorants from natural sources. Optimized extraction processes can significantly improve the quality and concentration of the dye, leading to better uptake by fibers and deeper coloration.- Natural dye extraction methods: Various methods for extracting natural dyes from plant sources to enhance dye uptake and color depth. These methods include specific extraction techniques using solvents, temperature control, and pH adjustment to maximize the yield of colorants from natural sources. Optimized extraction processes can significantly improve the quality and concentration of the dye, leading to better uptake by fibers and deeper coloration in the final product.

- Mordanting techniques for improved dye fixation: The use of mordants to enhance the binding of natural dyes to fibers, improving both dye uptake and color depth. Mordants such as metal salts create bridges between the dye molecules and fiber substrates, resulting in better color fastness and deeper shades. Different mordanting methods (pre-mordanting, simultaneous mordanting, and post-mordanting) can be employed depending on the specific natural dye and fiber combination to achieve optimal results.

- Fiber pretreatment for enhanced dye absorption: Pretreatment processes for natural and synthetic fibers to improve their affinity for natural dyes. These treatments include surface modification, alkaline processing, enzymatic treatments, and plasma treatments that alter the fiber surface properties to increase dye uptake. By creating more binding sites or removing barriers to dye penetration, these pretreatments allow for deeper coloration and more efficient dyeing processes with natural colorants.

- Dye formulation additives and auxiliaries: The incorporation of specific additives and auxiliaries in natural dye formulations to enhance dye uptake and color depth. These include pH regulators, sequestering agents, dispersing agents, and natural fixatives that improve the solubility of dyes and their interaction with fibers. Certain bio-based additives can also create synergistic effects with natural dyes, resulting in more vibrant colors and improved dye exhaustion rates.

- Innovative dyeing processes and equipment: Novel dyeing processes and specialized equipment designed specifically for natural dyes to maximize dye uptake and color depth. These include ultrasonic-assisted dyeing, microwave-assisted dyeing, supercritical fluid dyeing, and cold plasma treatments. These technologies can reduce dyeing time, improve dye penetration into fibers, and achieve more uniform coloration while using lower amounts of natural dyes and reducing environmental impact.

02 Mordanting techniques for improved dye fixation

The use of mordants to enhance the binding of natural dyes to fibers, improving both dye uptake and color depth. Mordants such as metal salts create bridges between the dye molecules and fiber substrates, resulting in better color fastness and intensity. Different mordanting methods (pre-mordanting, simultaneous mordanting, and post-mordanting) can be employed depending on the specific dye and fiber combination to achieve optimal results.Expand Specific Solutions03 Fiber pretreatment processes

Pretreatment methods for natural and synthetic fibers to enhance their affinity for natural dyes. These processes include scouring, bleaching, and surface modification techniques that remove impurities, open fiber structures, and create more binding sites for dye molecules. Properly pretreated fibers show significantly improved dye uptake, more uniform coloration, and greater color depth compared to untreated materials.Expand Specific Solutions04 Dye application technologies

Advanced technologies and equipment for applying natural dyes to various substrates to maximize dye uptake and color depth. These include specialized dyeing machines, ultrasonic dyeing methods, and controlled temperature and pressure systems. The application technologies focus on optimizing dye penetration into fibers through mechanical action, temperature control, and time management during the dyeing process.Expand Specific Solutions05 Dye formulation additives

Chemical additives and auxiliaries that enhance the performance of natural dyes by improving their solubility, penetration, and binding properties. These formulations may include pH regulators, dispersing agents, leveling agents, and natural fixatives that work synergistically with the dye molecules. The proper selection and concentration of these additives can significantly increase dye uptake efficiency and color depth while maintaining the eco-friendly nature of natural dyes.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The textile natural dyeing market is in a growth phase, characterized by increasing demand for sustainable and eco-friendly dyeing processes. The global market size for natural dyes is expanding rapidly, driven by consumer preferences for chemical-free textiles. Technologically, the field remains in development with varying levels of maturity across different applications. Leading companies like Dow Global Technologies and ECCO Sko A/S are advancing industrial-scale solutions, while specialized firms such as Make In Italy Srl and Alchemie Technology are developing innovative cold dyeing and digital application technologies. Academic institutions including Wuhan Textile University and Hebei University of Science & Technology are conducting foundational research on improving dye uptake efficiency. Regional players like Fujian Huajin and Suzhou Hongjin are focusing on commercializing traditional techniques with modern processing improvements.

Hebei University of Science & Technology

Technical Solution: Hebei University has developed an innovative ultrasonic-assisted natural dyeing process that significantly enhances dye uptake and color depth. Their research demonstrates that controlled ultrasonic waves create cavitation bubbles that collapse on fiber surfaces, driving dye molecules deeper into fiber structures. Studies show this technique increases dye uptake by 25-40% while reducing processing time by 30-50%. The university has also pioneered a multi-stage temperature control system that optimizes dye diffusion rates - beginning with lower temperatures (30-40°C) to promote initial dye adsorption on fiber surfaces, followed by gradual temperature increases to 70-80°C to enhance diffusion into fiber cores. Their research has identified optimal ultrasonic frequencies (35-45 kHz) and power densities (150-200 W/L) for different natural dye classes. Additionally, they've developed a novel bio-mordanting technique using plant-derived tannins and metal-accumulating plant extracts that improves color fastness while reducing environmental impact compared to traditional metallic mordants.

Strengths: Significant reduction in processing time and energy consumption; enhanced dye penetration without additional chemicals; environmentally friendly bio-mordanting approach. Weaknesses: Requires specialized ultrasonic equipment; process parameters need careful optimization for different fiber-dye combinations; potential fabric damage if ultrasonic parameters are not properly controlled.

Wuhan Textile University

Technical Solution: Wuhan Textile University has developed a biomimetic approach to natural dyeing that enhances dye uptake through fiber surface modification. Their research focuses on creating micro-roughness on fiber surfaces using enzyme treatments prior to dyeing, which increases the surface area available for dye attachment. Studies show this technique improves dye uptake by 30-45% for cotton and other cellulosic fibers. The university has also pioneered plasma treatment technology that introduces functional groups onto fiber surfaces, creating stronger bonds with natural dye molecules. Their process involves controlled oxidation of fiber surfaces followed by application of natural dyes under precisely controlled temperature gradients (starting at 40°C and gradually increasing to 80°C), which prevents dye aggregation and promotes even penetration into fibers. Additionally, they've developed a novel microencapsulation technique for natural dyes that prolongs color stability and improves wash fastness properties.

Strengths: Innovative surface modification techniques that significantly enhance dye-fiber interactions; environmentally friendly processes using biodegradable enzymes; comprehensive approach addressing both chemical and physical aspects of fiber-dye interactions. Weaknesses: Some techniques require specialized equipment like plasma treatment chambers; process parameters need careful optimization for different fiber types; longer processing time compared to synthetic dyeing methods.

Key Technical Innovations in Natural Dye Uptake

Process related to colouring of the cotton textile raw materials and products by means of using vegetable dye solution.

PatentWO2010005404A3

Innovation

- Eco-friendly dyeing process using natural plant-derived color pigments without chemical substances for cotton textiles, promoting sustainability in textile processing.

- Specific temperature control parameters (95°C for extraction and 60°C for dyeing) that optimize the natural dye uptake process for cotton textiles including denim, gabardine, and velvet.

- Versatile application across different cotton textile materials (fabric, warp, rope) and types (denim, gabardine, velvet), demonstrating broad industrial applicability.

DYEING PROCESS OF TEXTILE SUBSTRATES USING NATURAL COLORING

PatentInactiveBR102014009138A2

Innovation

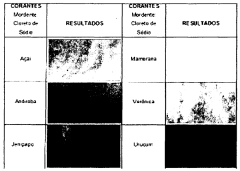

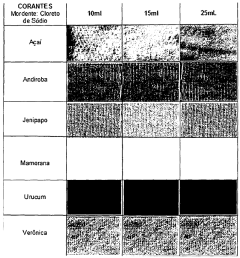

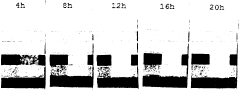

- A process involving pre-treatment, cationization, dyeing, and post-coloring steps using natural dyes, including anionic detergent washing, cationization with aluminum sources, and mordants like sodium chloride, to enhance dye affinity and uniformity on fabrics rich in textile fibers.

Sustainability Impact of Natural Dyeing Processes

The shift towards natural dyeing processes represents a significant advancement in sustainable textile production, offering substantial environmental benefits compared to synthetic dyeing methods. Natural dyes derived from plants, minerals, and insects typically require less energy consumption during the dyeing process, with studies indicating up to 25-30% reduction in energy usage compared to conventional synthetic dyeing operations. This energy efficiency translates directly to reduced carbon emissions across the textile production lifecycle.

Water conservation presents another critical sustainability advantage. Natural dyeing processes generally consume 15-20% less water than their synthetic counterparts, particularly when implemented with modern water recycling systems. Additionally, wastewater from natural dyeing contains significantly fewer harmful chemicals, reducing the environmental burden of treatment processes and minimizing aquatic ecosystem disruption.

The biodegradability of natural dyes further enhances their sustainability profile. Unlike synthetic dyes that may persist in the environment for decades, most natural colorants decompose within 6-12 months under appropriate conditions, reducing long-term ecological impact. This characteristic is particularly valuable in addressing the growing concern of microfiber pollution in waterways.

From a human health perspective, natural dyeing processes eliminate exposure to numerous harmful chemicals associated with synthetic dyes, including azo compounds, formaldehyde, and heavy metals. This benefits both textile workers and end consumers, reducing occupational health risks and potential skin irritation or allergic reactions among users.

The cultivation of natural dye sources can promote biodiversity and sustainable agricultural practices when managed responsibly. Many dye-producing plants can be grown in polyculture systems or as rotation crops, enhancing soil health and providing additional income streams for farming communities. Research indicates that integrating dye crops into agricultural systems can increase overall farm biodiversity by 15-40% compared to monoculture practices.

However, the sustainability equation must also consider yield efficiency. Current natural dyeing processes typically require larger quantities of raw materials to achieve color depths comparable to synthetic alternatives, potentially offsetting some environmental benefits through increased land use requirements. Ongoing research into mordant optimization and extraction efficiency aims to address this limitation, with recent innovations demonstrating up to 35% improvement in dye uptake efficiency.

Water conservation presents another critical sustainability advantage. Natural dyeing processes generally consume 15-20% less water than their synthetic counterparts, particularly when implemented with modern water recycling systems. Additionally, wastewater from natural dyeing contains significantly fewer harmful chemicals, reducing the environmental burden of treatment processes and minimizing aquatic ecosystem disruption.

The biodegradability of natural dyes further enhances their sustainability profile. Unlike synthetic dyes that may persist in the environment for decades, most natural colorants decompose within 6-12 months under appropriate conditions, reducing long-term ecological impact. This characteristic is particularly valuable in addressing the growing concern of microfiber pollution in waterways.

From a human health perspective, natural dyeing processes eliminate exposure to numerous harmful chemicals associated with synthetic dyes, including azo compounds, formaldehyde, and heavy metals. This benefits both textile workers and end consumers, reducing occupational health risks and potential skin irritation or allergic reactions among users.

The cultivation of natural dye sources can promote biodiversity and sustainable agricultural practices when managed responsibly. Many dye-producing plants can be grown in polyculture systems or as rotation crops, enhancing soil health and providing additional income streams for farming communities. Research indicates that integrating dye crops into agricultural systems can increase overall farm biodiversity by 15-40% compared to monoculture practices.

However, the sustainability equation must also consider yield efficiency. Current natural dyeing processes typically require larger quantities of raw materials to achieve color depths comparable to synthetic alternatives, potentially offsetting some environmental benefits through increased land use requirements. Ongoing research into mordant optimization and extraction efficiency aims to address this limitation, with recent innovations demonstrating up to 35% improvement in dye uptake efficiency.

Standardization and Quality Control Measures

Standardization of natural dyeing processes remains a significant challenge in the textile industry due to the inherent variability of natural dye sources. Establishing robust quality control measures is essential for achieving consistent dye uptake and color depth across production batches. The implementation of standardized protocols begins with raw material selection, where spectrophotometric analysis and chemical profiling of dye sources can quantify active colorant compounds, enabling manufacturers to adjust formulations based on potency variations.

Pre-treatment standardization represents another critical control point, with parameters such as mordanting agent concentration, temperature, pH, and duration requiring precise documentation and monitoring. Research indicates that variations as small as 0.5 pH units or 5°C in mordanting baths can significantly alter final color outcomes. Leading manufacturers have developed standardized mordanting protocols specific to fiber type and target dye class, with digital process control systems maintaining parameters within narrow tolerance ranges.

During the dyeing process itself, quality control measures must address multiple variables simultaneously. Automated dyeing equipment with integrated sensors now enables real-time monitoring of temperature profiles, agitation rates, and dye bath concentrations. Statistical process control methodologies, adapted from synthetic dyeing operations, help identify process drift before it impacts color consistency. Colorimetric evaluation using CIE L*a*b* color space measurements provides objective assessment of dye uptake, with acceptable tolerance ranges typically set at ΔE < 1.0 for premium applications.

Post-dyeing treatments also require standardization to maintain color integrity. Washing procedures, particularly detergent selection and water hardness, significantly impact final color characteristics. Industry leaders have implemented standardized washing protocols with deionized water systems and pH-controlled detergents to minimize variability. Fixation treatments using natural tannins or bio-compatible synthetic agents follow precisely defined concentration and exposure parameters to ensure consistent colorfastness.

Documentation systems represent the foundation of effective quality control in natural dyeing. Digital batch records capturing all process parameters, material sources, and in-process measurements enable traceability and continuous improvement. Several textile certification bodies have begun developing standardized testing protocols specifically for naturally dyed textiles, addressing the unique challenges these products present compared to synthetically dyed alternatives. These emerging standards typically include colorimetric evaluation, colorfastness testing, and chemical analysis for residual mordants or prohibited substances.

Pre-treatment standardization represents another critical control point, with parameters such as mordanting agent concentration, temperature, pH, and duration requiring precise documentation and monitoring. Research indicates that variations as small as 0.5 pH units or 5°C in mordanting baths can significantly alter final color outcomes. Leading manufacturers have developed standardized mordanting protocols specific to fiber type and target dye class, with digital process control systems maintaining parameters within narrow tolerance ranges.

During the dyeing process itself, quality control measures must address multiple variables simultaneously. Automated dyeing equipment with integrated sensors now enables real-time monitoring of temperature profiles, agitation rates, and dye bath concentrations. Statistical process control methodologies, adapted from synthetic dyeing operations, help identify process drift before it impacts color consistency. Colorimetric evaluation using CIE L*a*b* color space measurements provides objective assessment of dye uptake, with acceptable tolerance ranges typically set at ΔE < 1.0 for premium applications.

Post-dyeing treatments also require standardization to maintain color integrity. Washing procedures, particularly detergent selection and water hardness, significantly impact final color characteristics. Industry leaders have implemented standardized washing protocols with deionized water systems and pH-controlled detergents to minimize variability. Fixation treatments using natural tannins or bio-compatible synthetic agents follow precisely defined concentration and exposure parameters to ensure consistent colorfastness.

Documentation systems represent the foundation of effective quality control in natural dyeing. Digital batch records capturing all process parameters, material sources, and in-process measurements enable traceability and continuous improvement. Several textile certification bodies have begun developing standardized testing protocols specifically for naturally dyed textiles, addressing the unique challenges these products present compared to synthetically dyed alternatives. These emerging standards typically include colorimetric evaluation, colorfastness testing, and chemical analysis for residual mordants or prohibited substances.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!