The Evolution of QLED: Key Milestones and Breakthroughs

QLED Technology Background and Objectives

Quantum Dot Light-Emitting Diode (QLED) technology represents a significant advancement in display technology, offering enhanced color accuracy, brightness, and energy efficiency compared to traditional LED displays. The evolution of QLED has been marked by continuous innovation and breakthroughs in materials science and manufacturing processes.

QLED technology originated from the discovery of quantum dots in the 1980s by Russian physicist Alexey Ekimov. These semiconductor nanocrystals exhibit unique optical properties due to quantum confinement effects, allowing for precise control of light emission. The potential application of quantum dots in displays was first recognized in the early 2000s, leading to intensive research and development efforts by academic institutions and industry leaders.

The primary objective of QLED technology development has been to create displays with superior color reproduction, wider color gamut, and higher energy efficiency. Researchers and engineers have focused on optimizing the synthesis of quantum dots, improving their stability, and integrating them effectively into display architectures.

Key milestones in QLED evolution include the development of cadmium-free quantum dots, addressing environmental concerns and regulatory requirements. This breakthrough, achieved in the mid-2010s, paved the way for wider commercial adoption of QLED technology. Another significant advancement was the implementation of quantum dot color conversion films, which allowed for easier integration with existing LCD manufacturing processes.

The evolution of QLED has also been driven by the pursuit of improved quantum yield and color purity. Researchers have made substantial progress in enhancing the efficiency of quantum dots, resulting in displays with higher brightness and lower power consumption. Additionally, efforts have been made to expand the color gamut, with recent QLED displays capable of reproducing over 90% of the Rec. 2020 color space.

Manufacturing scalability has been a crucial focus in QLED development. Innovations in quantum dot synthesis and deposition techniques have enabled mass production of QLED displays, making the technology more accessible to consumers. The introduction of inkjet printing methods for quantum dot deposition has further improved manufacturing efficiency and reduced production costs.

Looking ahead, the objectives for QLED technology include achieving even higher color purity, developing more stable and efficient quantum dots, and exploring new applications beyond traditional displays. Researchers are investigating the potential of QLED in flexible and transparent displays, as well as in lighting applications. The ultimate goal is to establish QLED as a dominant display technology, offering unparalleled visual experiences across various consumer and professional applications.

Market Analysis for QLED Displays

The QLED display market has experienced significant growth and transformation in recent years, driven by technological advancements and increasing consumer demand for high-quality visual experiences. As a subset of the broader display technology market, QLED displays have carved out a substantial niche, particularly in the premium television segment.

Market size estimates for QLED displays indicate robust growth trajectories. The global QLED TV market, which represents the largest application segment for this technology, has been expanding at a compound annual growth rate (CAGR) of over 20% in recent years. This growth is expected to continue, with projections suggesting that the market could reach a value in the tens of billions of dollars by the mid-2020s.

Consumer preferences have been shifting towards larger screen sizes and higher resolutions, both areas where QLED technology excels. The ability of QLED displays to deliver vibrant colors, high brightness, and excellent contrast ratios has positioned them as a strong competitor to OLED technology, particularly in the 55-inch and above category.

Geographically, North America and Asia-Pacific have emerged as the leading markets for QLED displays. The North American market has shown strong adoption rates, driven by consumer willingness to invest in premium display technologies. In Asia-Pacific, countries like China and South Korea have not only become significant consumers but also major producers of QLED displays.

The commercial sector has also begun to recognize the potential of QLED technology. Applications in digital signage, control rooms, and high-end corporate installations are contributing to market growth, albeit at a slower pace compared to the consumer segment.

Market dynamics are heavily influenced by a few key players, with Samsung Electronics leading the pack. Samsung's aggressive marketing and continuous technological improvements have played a crucial role in popularizing QLED displays. Other manufacturers have also entered the market, intensifying competition and driving innovation.

Price trends for QLED displays have shown a gradual decline, making the technology more accessible to a broader consumer base. However, QLED displays still command a premium over conventional LED-LCD displays, positioning them in the upper mid-range to high-end market segments.

Looking ahead, the QLED display market is poised for further expansion. Technological advancements, such as improvements in quantum dot efficiency and the integration of mini-LED backlighting, are expected to enhance performance and potentially reduce production costs. These developments could lead to wider adoption across various price points and application areas.

Current QLED Challenges and Limitations

Despite the remarkable progress in QLED technology, several challenges and limitations persist, hindering its widespread adoption and full potential realization. One of the primary concerns is the stability and longevity of blue quantum dots. Blue QLEDs tend to have shorter lifespans compared to their red and green counterparts, leading to color imbalance and degradation over time. This issue stems from the higher energy requirements of blue light emission, which accelerates the deterioration of the quantum dot structure.

Another significant challenge lies in the efficiency of QLED displays, particularly in terms of power consumption. While QLEDs offer improved color gamut and brightness compared to traditional LED-LCD displays, they still lag behind OLED technology in energy efficiency. This limitation is especially noticeable in mobile devices, where battery life is a critical factor.

The manufacturing process of QLED displays also presents hurdles. The precise deposition of quantum dots and the creation of uniform layers across large areas remain technically challenging and cost-intensive. This complexity in production contributes to higher manufacturing costs, making QLED displays less competitive in price-sensitive markets.

Color accuracy and consistency across different viewing angles continue to be areas of improvement for QLED technology. While advancements have been made, some QLED displays still exhibit color shifts when viewed from extreme angles, potentially impacting the viewing experience in certain scenarios.

Environmental concerns also pose challenges to QLED adoption. The use of cadmium in some quantum dot formulations raises questions about long-term sustainability and regulatory compliance. Although cadmium-free alternatives are being developed, they often come with trade-offs in performance or cost.

The thermal management of QLED displays is another area requiring attention. High brightness levels can lead to increased heat generation, potentially affecting the longevity and performance of the quantum dots. Effective heat dissipation solutions are crucial for maintaining display quality and lifespan.

Lastly, the market competition from other display technologies, particularly OLED, presents a strategic challenge for QLED. As OLED technology continues to improve and decrease in cost, QLED must demonstrate clear advantages to secure its position in the display market. Overcoming these technical and market challenges will be crucial for the continued evolution and success of QLED technology in the coming years.

State-of-the-Art QLED Solutions

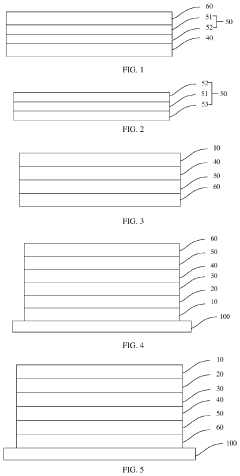

01 QLED structure and composition

QLED devices typically consist of a layer of quantum dots sandwiched between electron and hole transport layers. The quantum dots are usually made of semiconductor nanocrystals, such as cadmium selenide or indium phosphide. The structure and composition of these layers are crucial for optimizing the device's performance, including color purity, efficiency, and longevity.- QLED structure and composition: QLED devices typically consist of a quantum dot layer sandwiched between electron and hole transport layers. The quantum dots are usually made of semiconductor nanocrystals that emit light when electrically excited. The composition and structure of these layers are crucial for device performance, including efficiency and color purity.

- Quantum dot synthesis and optimization: The synthesis of quantum dots is a critical aspect of QLED technology. Various methods are employed to create quantum dots with specific size, shape, and composition to achieve desired optical properties. Optimization of quantum dot materials can lead to improved color gamut, brightness, and efficiency in QLED displays.

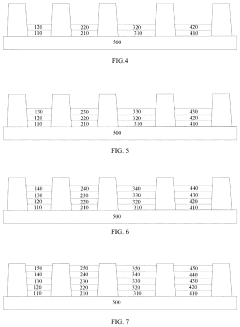

- QLED display manufacturing techniques: Manufacturing processes for QLED displays involve several steps, including quantum dot deposition, patterning, and encapsulation. Advanced techniques such as inkjet printing, photolithography, and transfer printing are used to create high-resolution QLED displays with uniform performance across the panel.

- Color conversion and enhancement in QLEDs: QLED technology often employs color conversion techniques to achieve a wide color gamut. This may involve using blue LEDs as a backlight source and converting the light to other colors using quantum dots. Various methods are used to enhance color purity and efficiency in this conversion process.

- QLED device stability and lifetime improvement: Improving the stability and lifetime of QLED devices is a key area of research. This involves developing new materials and structures to prevent degradation of quantum dots and other components under operational conditions. Encapsulation techniques and the use of barrier layers are common approaches to enhance device longevity.

02 Quantum dot synthesis and processing

The synthesis and processing of quantum dots play a vital role in QLED technology. This includes methods for producing quantum dots with precise size control, surface modification techniques to enhance stability and performance, and processes for incorporating quantum dots into device structures. Innovations in these areas can lead to improved QLED efficiency and color quality.Expand Specific Solutions03 QLED display applications

QLED technology is widely applied in display applications, including televisions, monitors, and mobile devices. These applications leverage the high color purity and brightness of quantum dots to achieve superior image quality. Advancements in this area focus on improving color gamut, contrast ratio, and energy efficiency of QLED displays.Expand Specific Solutions04 QLED lighting solutions

Beyond displays, QLED technology is being developed for lighting applications. This includes the use of quantum dots in LED light bulbs and fixtures to produce high-quality white light or tunable color lighting. Research in this area aims to improve the color rendering index, energy efficiency, and longevity of QLED lighting solutions.Expand Specific Solutions05 QLED manufacturing and scalability

Improving the manufacturing processes and scalability of QLED technology is crucial for its widespread adoption. This includes developing cost-effective production methods, enhancing the uniformity and yield of large-area QLED panels, and creating novel patterning techniques for high-resolution displays. Advancements in these areas aim to make QLED technology more competitive in the market.Expand Specific Solutions

Major QLED Industry Players

The QLED technology market is in a growth phase, with increasing adoption and continuous innovation. The global QLED market size is expanding rapidly, driven by demand for high-quality displays in various applications. Technologically, QLED is maturing but still evolving, with companies like BOE Technology Group, Sharp Corp., and TCL China Star Optoelectronics leading advancements. These firms, along with others like Hisense Visual Technology and Huawei Technologies, are pushing boundaries in color accuracy, brightness, and energy efficiency. Universities such as Zhejiang University and The Hong Kong University of Science & Technology contribute to fundamental research, while companies like Guangdong Juhua Printing Display Technology focus on manufacturing innovations, collectively driving the technology forward.

BOE Technology Group Co., Ltd.

Sharp Corp.

Key QLED Patents and Innovations

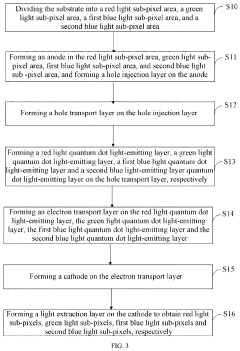

- A display device comprising a plurality of pixels, each including a red light sub-pixel, a green light sub-pixel, a first blue light sub-pixel, and a second blue light sub-pixel, where the first blue light sub-pixel is configured to emit light at high brightness and the second blue light sub-pixel is configured to emit light at low brightness, with the first blue light sub-pixel having high efficiency and the second blue light sub-pixel having a long lifetime, allowing for independent control based on brightness requirements.

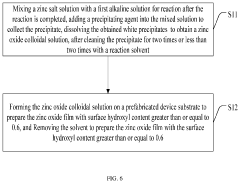

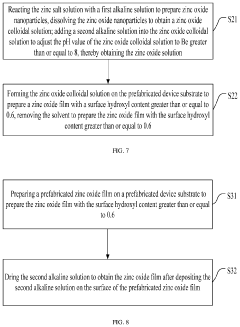

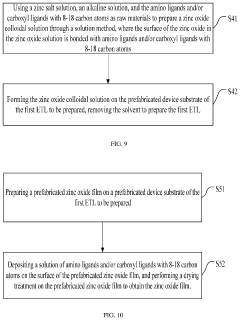

- A QLED device structure utilizing a zinc oxide electron transport layer with a surface hydroxyl content greater than or equal to 0.6 or modified with amino ligands and carboxyl ligands, which reduces electron mobility and injection efficiency, achieving carrier balance without the need for additional barrier layers.

QLED Manufacturing Processes

The manufacturing processes of QLED (Quantum Dot Light Emitting Diode) displays have undergone significant evolution since their inception. Initially, the production of quantum dots was a complex and costly process, limiting their commercial viability. However, advancements in synthesis techniques have dramatically improved both the quality and scalability of quantum dot production.

One of the key milestones in QLED manufacturing was the development of solution-based processing methods. This breakthrough allowed for the deposition of quantum dots onto substrates using techniques such as inkjet printing and spin coating. These methods not only reduced production costs but also enabled the creation of larger display panels with improved uniformity.

Another critical advancement was the refinement of quantum dot encapsulation techniques. Early QLEDs suffered from degradation due to exposure to oxygen and moisture. The introduction of advanced barrier films and hermetic sealing processes significantly enhanced the longevity and stability of QLED displays, making them more suitable for consumer electronics.

The integration of quantum dots into existing LCD manufacturing lines marked a pivotal moment in QLED production. This compatibility allowed display manufacturers to leverage their existing infrastructure, facilitating a smoother transition to QLED technology. The process typically involves adding a quantum dot enhancement film (QDEF) layer to the LCD stack, which converts blue LED backlighting into pure red and green light.

Recent years have seen the emergence of electroluminescent QLED manufacturing techniques. Unlike photoluminescent QLEDs that rely on LED backlighting, these direct-emission QLEDs generate light when an electric current is applied directly to the quantum dot layer. This approach promises even greater energy efficiency and color purity, though it presents new challenges in terms of quantum dot stability and charge injection.

Advancements in material science have also played a crucial role in QLED manufacturing. The development of cadmium-free quantum dots has addressed environmental concerns and regulatory requirements, particularly in markets with strict hazardous substance regulations. These new materials, often based on indium phosphide, have enabled QLED manufacturers to expand their global reach.

As QLED technology continues to mature, manufacturing processes are becoming increasingly automated and precise. The use of advanced robotics and AI-driven quality control systems has significantly improved production yields and consistency. These innovations are crucial for meeting the growing demand for high-quality, large-format displays in both consumer and professional markets.

Environmental Impact of QLED Technology

The environmental impact of QLED technology has become an increasingly important consideration as the technology continues to evolve and gain market share. QLED displays offer several environmental advantages over traditional LED and OLED technologies, particularly in terms of energy efficiency and longevity.

One of the key environmental benefits of QLED technology is its improved energy efficiency. QLEDs consume less power compared to conventional LED displays, resulting in reduced energy consumption and lower carbon emissions over the lifetime of the device. This efficiency is primarily due to the quantum dot layer, which enhances color accuracy and brightness without requiring additional power input.

The longevity of QLED displays also contributes to their positive environmental impact. With a lifespan typically exceeding that of OLED displays, QLEDs reduce the frequency of device replacement and, consequently, electronic waste generation. This extended lifespan is particularly significant in the context of large-scale commercial applications, where frequent replacements can lead to substantial environmental burdens.

However, the production of quantum dots, a crucial component of QLED technology, raises some environmental concerns. Traditional quantum dots often contain heavy metals such as cadmium, which can pose risks to both human health and the environment if not properly managed during manufacturing and disposal processes. In response to these concerns, the industry has been developing cadmium-free quantum dots, which aim to mitigate these potential environmental hazards.

The manufacturing process of QLED displays also presents opportunities for environmental improvement. As the technology matures, manufacturers are exploring more sustainable production methods, including the use of recycled materials and the implementation of energy-efficient manufacturing processes. These efforts aim to reduce the overall carbon footprint associated with QLED production.

End-of-life considerations for QLED displays are another critical aspect of their environmental impact. The industry is increasingly focusing on developing effective recycling methods for quantum dot materials and other components of QLED displays. Proper recycling not only reduces electronic waste but also allows for the recovery of valuable materials, contributing to a more circular economy in the electronics sector.

In conclusion, while QLED technology offers significant environmental benefits in terms of energy efficiency and longevity, ongoing research and development efforts are crucial to address remaining environmental challenges, particularly in the areas of quantum dot production and end-of-life management. As the technology continues to evolve, it is likely that its environmental profile will further improve, solidifying its position as a more sustainable display technology option.