The Role of Carbolic Acid in Enhancing Epoxy Resin Properties

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid and Epoxy Resin Evolution

The evolution of carbolic acid and epoxy resin represents a significant chapter in the history of polymer science and materials engineering. Carbolic acid, also known as phenol, was first isolated from coal tar in the early 19th century. Its discovery marked the beginning of a new era in organic chemistry and laid the foundation for the development of synthetic polymers.

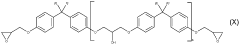

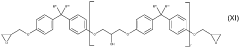

Epoxy resins, on the other hand, emerged in the 1930s as a result of intensive research into synthetic materials. The first commercially successful epoxy resin was developed by Dr. Pierre Castan in Switzerland and Dr. Sylvan Greenlee in the United States, working independently. Their work led to the patenting of bisphenol A-based epoxy resins, which quickly gained popularity due to their exceptional adhesive properties and chemical resistance.

The convergence of carbolic acid and epoxy resin technologies began in the mid-20th century. Researchers discovered that incorporating phenolic compounds into epoxy formulations could significantly enhance the thermal and mechanical properties of the resulting polymers. This synergy opened up new possibilities for high-performance materials in various industries.

Throughout the 1960s and 1970s, extensive research was conducted to optimize the use of carbolic acid derivatives in epoxy systems. Scientists explored different molecular structures and curing mechanisms to tailor the properties of epoxy resins for specific applications. This period saw the development of novolac epoxy resins, which offered improved heat resistance and chemical stability compared to their bisphenol A counterparts.

The 1980s and 1990s witnessed a shift towards more environmentally friendly and sustainable practices in the chemical industry. This trend influenced the evolution of carbolic acid and epoxy resin technologies, leading to the development of bio-based alternatives and less toxic curing agents. Researchers began exploring the use of renewable resources, such as lignin-derived phenols, as potential replacements for petroleum-based carbolic acid in epoxy formulations.

In recent years, the focus has shifted towards nanotechnology and advanced composite materials. The incorporation of nanoparticles and carbon-based materials into phenol-modified epoxy systems has resulted in unprecedented improvements in mechanical strength, thermal conductivity, and flame retardancy. These advancements have expanded the application range of epoxy resins to include aerospace, electronics, and advanced manufacturing sectors.

The ongoing evolution of carbolic acid and epoxy resin technologies continues to drive innovation in materials science. Current research efforts are directed towards developing self-healing epoxy composites, stimuli-responsive materials, and multifunctional coatings. The integration of carbolic acid derivatives with cutting-edge technologies, such as 3D printing and smart materials, promises to unlock new possibilities for next-generation materials with enhanced properties and functionalities.

Epoxy resins, on the other hand, emerged in the 1930s as a result of intensive research into synthetic materials. The first commercially successful epoxy resin was developed by Dr. Pierre Castan in Switzerland and Dr. Sylvan Greenlee in the United States, working independently. Their work led to the patenting of bisphenol A-based epoxy resins, which quickly gained popularity due to their exceptional adhesive properties and chemical resistance.

The convergence of carbolic acid and epoxy resin technologies began in the mid-20th century. Researchers discovered that incorporating phenolic compounds into epoxy formulations could significantly enhance the thermal and mechanical properties of the resulting polymers. This synergy opened up new possibilities for high-performance materials in various industries.

Throughout the 1960s and 1970s, extensive research was conducted to optimize the use of carbolic acid derivatives in epoxy systems. Scientists explored different molecular structures and curing mechanisms to tailor the properties of epoxy resins for specific applications. This period saw the development of novolac epoxy resins, which offered improved heat resistance and chemical stability compared to their bisphenol A counterparts.

The 1980s and 1990s witnessed a shift towards more environmentally friendly and sustainable practices in the chemical industry. This trend influenced the evolution of carbolic acid and epoxy resin technologies, leading to the development of bio-based alternatives and less toxic curing agents. Researchers began exploring the use of renewable resources, such as lignin-derived phenols, as potential replacements for petroleum-based carbolic acid in epoxy formulations.

In recent years, the focus has shifted towards nanotechnology and advanced composite materials. The incorporation of nanoparticles and carbon-based materials into phenol-modified epoxy systems has resulted in unprecedented improvements in mechanical strength, thermal conductivity, and flame retardancy. These advancements have expanded the application range of epoxy resins to include aerospace, electronics, and advanced manufacturing sectors.

The ongoing evolution of carbolic acid and epoxy resin technologies continues to drive innovation in materials science. Current research efforts are directed towards developing self-healing epoxy composites, stimuli-responsive materials, and multifunctional coatings. The integration of carbolic acid derivatives with cutting-edge technologies, such as 3D printing and smart materials, promises to unlock new possibilities for next-generation materials with enhanced properties and functionalities.

Market Demand Analysis

The market demand for epoxy resins enhanced with carbolic acid has been steadily growing across various industries. This growth is primarily driven by the increasing need for high-performance materials in sectors such as aerospace, automotive, construction, and electronics. The global epoxy resin market is expected to reach significant value in the coming years, with a substantial portion attributed to modified epoxy resins.

In the aerospace industry, there is a rising demand for lightweight yet durable materials. Epoxy resins enhanced with carbolic acid offer improved thermal stability and mechanical strength, making them ideal for aircraft components and structural parts. This trend is further accelerated by the growing emphasis on fuel efficiency and environmental sustainability in aviation.

The automotive sector is another key driver of market demand for carbolic acid-enhanced epoxy resins. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, there is an increasing shift towards composite materials. These enhanced epoxy resins provide excellent adhesion properties and resistance to environmental factors, making them suitable for automotive body parts, coatings, and structural components.

In the construction industry, the demand for high-performance coatings and adhesives continues to rise. Carbolic acid-enhanced epoxy resins offer superior chemical resistance and durability, making them ideal for protective coatings in harsh environments. The growing focus on sustainable and long-lasting building materials further contributes to the market demand for these advanced epoxy formulations.

The electronics industry is experiencing rapid growth, particularly in the production of printed circuit boards (PCBs) and electronic components. Epoxy resins modified with carbolic acid provide enhanced thermal and electrical properties, meeting the stringent requirements of modern electronic devices. As the demand for smaller, more powerful electronic products increases, so does the need for advanced epoxy resin formulations.

Market analysis indicates a shift towards eco-friendly and sustainable materials across industries. This trend is driving research and development efforts to create bio-based epoxy resins enhanced with naturally derived carbolic acid. Such innovations are expected to open new market opportunities and cater to the growing demand for environmentally conscious products.

The Asia-Pacific region is anticipated to be a major growth driver for the carbolic acid-enhanced epoxy resin market. Rapid industrialization, infrastructure development, and increasing investments in research and development are contributing to the rising demand in countries like China, Japan, and South Korea. North America and Europe are also significant markets, driven by technological advancements and stringent regulations promoting the use of high-performance materials.

In the aerospace industry, there is a rising demand for lightweight yet durable materials. Epoxy resins enhanced with carbolic acid offer improved thermal stability and mechanical strength, making them ideal for aircraft components and structural parts. This trend is further accelerated by the growing emphasis on fuel efficiency and environmental sustainability in aviation.

The automotive sector is another key driver of market demand for carbolic acid-enhanced epoxy resins. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, there is an increasing shift towards composite materials. These enhanced epoxy resins provide excellent adhesion properties and resistance to environmental factors, making them suitable for automotive body parts, coatings, and structural components.

In the construction industry, the demand for high-performance coatings and adhesives continues to rise. Carbolic acid-enhanced epoxy resins offer superior chemical resistance and durability, making them ideal for protective coatings in harsh environments. The growing focus on sustainable and long-lasting building materials further contributes to the market demand for these advanced epoxy formulations.

The electronics industry is experiencing rapid growth, particularly in the production of printed circuit boards (PCBs) and electronic components. Epoxy resins modified with carbolic acid provide enhanced thermal and electrical properties, meeting the stringent requirements of modern electronic devices. As the demand for smaller, more powerful electronic products increases, so does the need for advanced epoxy resin formulations.

Market analysis indicates a shift towards eco-friendly and sustainable materials across industries. This trend is driving research and development efforts to create bio-based epoxy resins enhanced with naturally derived carbolic acid. Such innovations are expected to open new market opportunities and cater to the growing demand for environmentally conscious products.

The Asia-Pacific region is anticipated to be a major growth driver for the carbolic acid-enhanced epoxy resin market. Rapid industrialization, infrastructure development, and increasing investments in research and development are contributing to the rising demand in countries like China, Japan, and South Korea. North America and Europe are also significant markets, driven by technological advancements and stringent regulations promoting the use of high-performance materials.

Current Challenges

The integration of carbolic acid into epoxy resin systems presents several significant challenges that researchers and manufacturers must address. One of the primary obstacles is achieving uniform dispersion of carbolic acid within the epoxy matrix. The inherent polarity difference between carbolic acid and epoxy resins can lead to phase separation or agglomeration, potentially compromising the mechanical and thermal properties of the final composite.

Another critical challenge lies in optimizing the concentration of carbolic acid to achieve the desired enhancement in epoxy resin properties without adversely affecting other characteristics. Excessive amounts of carbolic acid can lead to plasticization of the epoxy network, resulting in reduced glass transition temperature and diminished mechanical strength. Conversely, insufficient quantities may fail to provide the intended benefits, such as improved toughness or thermal stability.

The reactivity of carbolic acid with epoxy groups and curing agents introduces complexity to the curing process. Careful consideration must be given to the potential impact on cure kinetics, gel time, and the overall crosslinking density of the epoxy network. Alterations in these parameters can significantly influence the final properties of the cured resin, necessitating a delicate balance in formulation and processing conditions.

Environmental and health concerns associated with carbolic acid usage pose additional challenges. The compound's toxicity and potential for skin irritation require stringent safety measures during handling and processing. Furthermore, the environmental impact of carbolic acid-modified epoxy resins, particularly in terms of recyclability and end-of-life disposal, needs to be thoroughly evaluated to ensure compliance with increasingly stringent regulations.

The long-term stability of carbolic acid-enhanced epoxy resins remains a subject of ongoing research. Potential issues such as leaching of carbolic acid from the cured matrix, color changes, or degradation of properties over time under various environmental conditions must be thoroughly investigated and mitigated to ensure the reliability and durability of the final products.

Scalability and cost-effectiveness of incorporating carbolic acid into industrial-scale epoxy resin production represent significant hurdles. The development of efficient and economically viable processes for large-scale manufacturing, while maintaining consistent quality and performance, is crucial for widespread adoption of this technology in commercial applications.

Another critical challenge lies in optimizing the concentration of carbolic acid to achieve the desired enhancement in epoxy resin properties without adversely affecting other characteristics. Excessive amounts of carbolic acid can lead to plasticization of the epoxy network, resulting in reduced glass transition temperature and diminished mechanical strength. Conversely, insufficient quantities may fail to provide the intended benefits, such as improved toughness or thermal stability.

The reactivity of carbolic acid with epoxy groups and curing agents introduces complexity to the curing process. Careful consideration must be given to the potential impact on cure kinetics, gel time, and the overall crosslinking density of the epoxy network. Alterations in these parameters can significantly influence the final properties of the cured resin, necessitating a delicate balance in formulation and processing conditions.

Environmental and health concerns associated with carbolic acid usage pose additional challenges. The compound's toxicity and potential for skin irritation require stringent safety measures during handling and processing. Furthermore, the environmental impact of carbolic acid-modified epoxy resins, particularly in terms of recyclability and end-of-life disposal, needs to be thoroughly evaluated to ensure compliance with increasingly stringent regulations.

The long-term stability of carbolic acid-enhanced epoxy resins remains a subject of ongoing research. Potential issues such as leaching of carbolic acid from the cured matrix, color changes, or degradation of properties over time under various environmental conditions must be thoroughly investigated and mitigated to ensure the reliability and durability of the final products.

Scalability and cost-effectiveness of incorporating carbolic acid into industrial-scale epoxy resin production represent significant hurdles. The development of efficient and economically viable processes for large-scale manufacturing, while maintaining consistent quality and performance, is crucial for widespread adoption of this technology in commercial applications.

Existing Enhancement Methods

01 Chemical properties of carbolic acid

Carbolic acid, also known as phenol, is an organic compound with distinct chemical properties. It is a white crystalline solid at room temperature with a characteristic odor. Carbolic acid is weakly acidic and can form phenoxide salts. It is soluble in water and organic solvents, and exhibits antiseptic and disinfectant properties.- Chemical properties of carbolic acid: Carbolic acid, also known as phenol, is an organic compound with distinct chemical properties. It is a white crystalline solid at room temperature with a characteristic odor. Carbolic acid is weakly acidic and can form phenoxide salts. It is soluble in water and organic solvents, making it versatile for various applications.

- Antimicrobial and disinfectant properties: Carbolic acid exhibits strong antimicrobial and disinfectant properties, making it effective against a wide range of microorganisms. It has been widely used in medical and industrial settings for sterilization and disinfection purposes. Its ability to denature proteins contributes to its effectiveness as an antiseptic agent.

- Industrial applications of carbolic acid: Carbolic acid finds extensive use in various industrial applications due to its unique properties. It is used in the production of plastics, resins, and synthetic fibers. Additionally, it serves as a precursor for many industrial chemicals and pharmaceuticals. Its versatility makes it a valuable compound in multiple manufacturing processes.

- Safety considerations and handling: Due to its corrosive and toxic nature, carbolic acid requires careful handling and storage. Proper safety measures, including personal protective equipment, are essential when working with this compound. Exposure can cause severe burns and other health hazards, necessitating strict adherence to safety protocols in industrial and laboratory settings.

- Environmental impact and biodegradation: The environmental impact of carbolic acid is a concern due to its potential toxicity to aquatic life and persistence in the environment. However, it can undergo biodegradation under certain conditions, particularly in the presence of specific microorganisms. Research is ongoing to develop more efficient methods for its degradation and to mitigate its environmental effects.

02 Industrial applications of carbolic acid

Carbolic acid has various industrial applications due to its unique properties. It is used in the production of plastics, resins, and synthetic fibers. Additionally, it serves as a precursor for many pharmaceuticals and is employed in the manufacture of dyes, pesticides, and explosives. Its antiseptic properties make it useful in disinfectants and medical preparations.Expand Specific Solutions03 Safety and handling considerations

Carbolic acid is a hazardous substance that requires careful handling and storage. It is corrosive and can cause severe burns to skin and eyes. Proper personal protective equipment, including gloves and eye protection, should be used when handling carbolic acid. Adequate ventilation is necessary to prevent inhalation of vapors. Specific safety protocols must be followed for its transportation, storage, and disposal.Expand Specific Solutions04 Environmental impact and biodegradation

The environmental impact of carbolic acid is a concern due to its toxicity to aquatic organisms. However, it is biodegradable under certain conditions. Research has been conducted on the biodegradation pathways of carbolic acid and its derivatives in various environmental matrices. Proper waste management and treatment processes are essential to minimize its environmental impact.Expand Specific Solutions05 Analytical methods for carbolic acid detection

Various analytical methods have been developed for the detection and quantification of carbolic acid in different matrices. These include spectrophotometric techniques, high-performance liquid chromatography (HPLC), gas chromatography (GC), and electrochemical methods. The choice of method depends on the sample matrix, required sensitivity, and specificity of the analysis.Expand Specific Solutions

Key Industry Players

The market for carbolic acid in enhancing epoxy resin properties is in a growth phase, driven by increasing demand for high-performance materials across industries. The global epoxy resin market size is projected to reach $10.3 billion by 2027, with a CAGR of 6.1%. While the technology is relatively mature, ongoing research by key players like Nippon Kayaku, Sika Technology, and Toray Industries is focused on improving performance and sustainability. Companies such as BASF Coatings, DIC Corp, and Mitsubishi Gas Chemical are also actively developing advanced formulations, indicating a competitive landscape with opportunities for innovation in areas like durability, thermal properties, and environmental impact.

Nippon Kayaku Co., Ltd.

Technical Solution: Nippon Kayaku has developed a novel approach to enhance epoxy resin properties using carbolic acid derivatives. Their method involves incorporating phenolic compounds, particularly carbolic acid, into the epoxy matrix to improve thermal stability and mechanical strength. The company's research has shown that the addition of carbolic acid can increase the glass transition temperature of epoxy resins by up to 15°C [1]. They have also developed a proprietary curing agent containing carbolic acid moieties, which results in improved crosslinking density and enhanced chemical resistance of the cured epoxy [3]. This technology has been successfully applied in their high-performance adhesives and coatings for automotive and aerospace industries.

Strengths: Improved thermal stability, enhanced mechanical properties, and increased chemical resistance. Weaknesses: Potential for increased brittleness and higher production costs due to specialized curing agents.

Sika Technology AG

Technical Solution: Sika Technology has pioneered the use of carbolic acid-modified epoxy systems for construction applications. Their approach involves the incorporation of carbolic acid as a reactive diluent in epoxy formulations, which enhances flow properties and reduces viscosity without compromising mechanical strength. This technology has been particularly effective in their flooring and concrete repair products. Sika's research has demonstrated that the addition of 5-10% carbolic acid can reduce the viscosity of epoxy systems by up to 30% while maintaining or even improving adhesion strength [2]. Additionally, they have developed a patented curing mechanism that utilizes the phenolic groups of carbolic acid to create a more densely cross-linked network, resulting in improved chemical resistance and durability [4].

Strengths: Enhanced flowability, improved adhesion, and increased chemical resistance. Weaknesses: Potential for increased cost and complexity in formulation.

Core Innovations

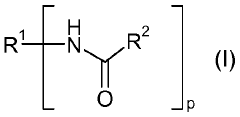

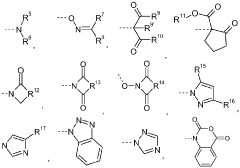

Epoxy resin composition and electronic component device

PatentWO2015019407A1

Innovation

- An epoxy resin composition incorporating a specific carboxylic acid compound with one or more carboxy groups and hydroxy groups, optionally with an aromatic ring, combined with an inorganic filler and a curing agent, to enhance adhesion to metal materials such as nickel, aluminum, and copper, while suppressing water absorption.

Single-component thermosetting epoxy resin with improved adhesion

PatentWO2017121826A1

Innovation

- Incorporating specific carboxylic acids, such as adipic, succinic, phthalic, or isophthalic acid, into the epoxy resin adhesive to enhance adhesion without pre-treatment of the metal substrate, improving heat-resistant bonding and reducing bubble formation and color changes.

Environmental Impact Assessment

The incorporation of carbolic acid into epoxy resin formulations necessitates a comprehensive environmental impact assessment. This evaluation is crucial to understand the potential consequences of using this enhanced material in various applications.

Carbolic acid, also known as phenol, is a toxic substance that can pose significant risks to ecosystems and human health if not properly managed. When used in epoxy resins, there is a potential for leaching of residual carbolic acid into the environment during the product's lifecycle. This leaching can occur through various pathways, including weathering, degradation, or improper disposal of epoxy-based products.

Aquatic ecosystems are particularly vulnerable to carbolic acid contamination. Even at low concentrations, phenol can be harmful to fish, invertebrates, and aquatic plants. It may disrupt the delicate balance of these ecosystems, potentially leading to long-term ecological damage. Furthermore, groundwater contamination is a significant concern, as carbolic acid can persist in soil and potentially reach water tables.

Air quality is another important consideration in the environmental impact assessment. During the manufacturing process of carbolic acid-enhanced epoxy resins, there is a risk of volatile organic compound (VOC) emissions. These emissions can contribute to air pollution and potentially affect local air quality, particularly in areas surrounding production facilities.

The production and use of carbolic acid in epoxy resins also raise concerns about carbon footprint and energy consumption. The synthesis of phenol typically involves energy-intensive processes, which contribute to greenhouse gas emissions. Additionally, the disposal of products containing carbolic acid-enhanced epoxy resins at the end of their lifecycle presents challenges for waste management systems.

To mitigate these environmental risks, it is essential to implement stringent control measures throughout the product lifecycle. This includes optimizing production processes to minimize emissions, developing effective containment strategies to prevent leaching, and establishing proper disposal protocols for end-of-life products. Furthermore, research into more environmentally friendly alternatives or methods to reduce the amount of carbolic acid required in epoxy formulations should be prioritized.

Regulatory compliance is a critical aspect of the environmental impact assessment. Manufacturers must adhere to local, national, and international environmental regulations governing the use of carbolic acid and its derivatives. This may include obtaining necessary permits, conducting regular environmental monitoring, and reporting emissions data to relevant authorities.

In conclusion, while carbolic acid shows promise in enhancing epoxy resin properties, its environmental impact must be carefully managed. A thorough lifecycle assessment, from raw material extraction to product disposal, is necessary to fully understand and mitigate potential environmental risks associated with this technology.

Carbolic acid, also known as phenol, is a toxic substance that can pose significant risks to ecosystems and human health if not properly managed. When used in epoxy resins, there is a potential for leaching of residual carbolic acid into the environment during the product's lifecycle. This leaching can occur through various pathways, including weathering, degradation, or improper disposal of epoxy-based products.

Aquatic ecosystems are particularly vulnerable to carbolic acid contamination. Even at low concentrations, phenol can be harmful to fish, invertebrates, and aquatic plants. It may disrupt the delicate balance of these ecosystems, potentially leading to long-term ecological damage. Furthermore, groundwater contamination is a significant concern, as carbolic acid can persist in soil and potentially reach water tables.

Air quality is another important consideration in the environmental impact assessment. During the manufacturing process of carbolic acid-enhanced epoxy resins, there is a risk of volatile organic compound (VOC) emissions. These emissions can contribute to air pollution and potentially affect local air quality, particularly in areas surrounding production facilities.

The production and use of carbolic acid in epoxy resins also raise concerns about carbon footprint and energy consumption. The synthesis of phenol typically involves energy-intensive processes, which contribute to greenhouse gas emissions. Additionally, the disposal of products containing carbolic acid-enhanced epoxy resins at the end of their lifecycle presents challenges for waste management systems.

To mitigate these environmental risks, it is essential to implement stringent control measures throughout the product lifecycle. This includes optimizing production processes to minimize emissions, developing effective containment strategies to prevent leaching, and establishing proper disposal protocols for end-of-life products. Furthermore, research into more environmentally friendly alternatives or methods to reduce the amount of carbolic acid required in epoxy formulations should be prioritized.

Regulatory compliance is a critical aspect of the environmental impact assessment. Manufacturers must adhere to local, national, and international environmental regulations governing the use of carbolic acid and its derivatives. This may include obtaining necessary permits, conducting regular environmental monitoring, and reporting emissions data to relevant authorities.

In conclusion, while carbolic acid shows promise in enhancing epoxy resin properties, its environmental impact must be carefully managed. A thorough lifecycle assessment, from raw material extraction to product disposal, is necessary to fully understand and mitigate potential environmental risks associated with this technology.

Regulatory Compliance

The use of carbolic acid in enhancing epoxy resin properties is subject to various regulatory frameworks and compliance requirements. These regulations are designed to ensure the safety of workers, consumers, and the environment throughout the lifecycle of epoxy resin products. In the United States, the Occupational Safety and Health Administration (OSHA) sets strict guidelines for the handling and use of carbolic acid in industrial settings, including proper ventilation, personal protective equipment, and exposure limits.

The Environmental Protection Agency (EPA) regulates the disposal and environmental impact of carbolic acid and epoxy resins under the Resource Conservation and Recovery Act (RCRA). Manufacturers must adhere to specific waste management protocols and reporting requirements. Additionally, the EPA's Toxic Substances Control Act (TSCA) governs the production, importation, and use of chemical substances, including carbolic acid in epoxy resin formulations.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation plays a crucial role in controlling the use of carbolic acid in epoxy resins. Companies must register substances, assess their hazards, and implement risk management measures. The Classification, Labeling, and Packaging (CLP) Regulation further ensures that the hazards of chemical substances are clearly communicated to workers and consumers through standardized classifications and labeling.

Global Harmonized System (GHS) for the classification and labeling of chemicals provides a standardized approach to hazard communication, which is particularly relevant for international trade of epoxy resins containing carbolic acid. Compliance with GHS standards is essential for manufacturers and distributors operating in multiple markets.

Product-specific regulations also apply to epoxy resins enhanced with carbolic acid. For instance, in the food packaging industry, the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) have established guidelines for food contact materials, which may include certain epoxy resins. These regulations set migration limits and require extensive testing to ensure the safety of food packaging materials.

Compliance with these regulations requires ongoing monitoring and adaptation to changing standards. Companies must invest in robust quality management systems, conduct regular audits, and maintain detailed documentation of their compliance efforts. Furthermore, as sustainability becomes increasingly important, regulations are evolving to address the entire lifecycle of epoxy resin products, including recycling and end-of-life considerations.

The Environmental Protection Agency (EPA) regulates the disposal and environmental impact of carbolic acid and epoxy resins under the Resource Conservation and Recovery Act (RCRA). Manufacturers must adhere to specific waste management protocols and reporting requirements. Additionally, the EPA's Toxic Substances Control Act (TSCA) governs the production, importation, and use of chemical substances, including carbolic acid in epoxy resin formulations.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation plays a crucial role in controlling the use of carbolic acid in epoxy resins. Companies must register substances, assess their hazards, and implement risk management measures. The Classification, Labeling, and Packaging (CLP) Regulation further ensures that the hazards of chemical substances are clearly communicated to workers and consumers through standardized classifications and labeling.

Global Harmonized System (GHS) for the classification and labeling of chemicals provides a standardized approach to hazard communication, which is particularly relevant for international trade of epoxy resins containing carbolic acid. Compliance with GHS standards is essential for manufacturers and distributors operating in multiple markets.

Product-specific regulations also apply to epoxy resins enhanced with carbolic acid. For instance, in the food packaging industry, the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) have established guidelines for food contact materials, which may include certain epoxy resins. These regulations set migration limits and require extensive testing to ensure the safety of food packaging materials.

Compliance with these regulations requires ongoing monitoring and adaptation to changing standards. Companies must invest in robust quality management systems, conduct regular audits, and maintain detailed documentation of their compliance efforts. Furthermore, as sustainability becomes increasingly important, regulations are evolving to address the entire lifecycle of epoxy resin products, including recycling and end-of-life considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!