The Role of Carbolic Acid in Textile Industry Antimicrobial Treatments

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid in Textiles: Background and Objectives

Carbolic acid, also known as phenol, has a long and significant history in the textile industry, particularly in the realm of antimicrobial treatments. This organic compound, first isolated from coal tar in the 19th century, has been a cornerstone in the development of antimicrobial solutions for textiles due to its potent bactericidal properties.

The evolution of carbolic acid's use in textiles can be traced back to the early 20th century when the need for hygienic fabrics became increasingly apparent. Initially, its application was primarily focused on medical textiles and military uniforms, where preventing the spread of infections was crucial. Over time, the scope of its use expanded to encompass a wider range of textile products, including sportswear, home textiles, and industrial fabrics.

The primary objective of incorporating carbolic acid into textile treatments has been to impart durable antimicrobial properties to fabrics. This serves multiple purposes, including odor control, prevention of microbial degradation, and enhancement of overall hygiene. As the textile industry has evolved, so too have the methods of applying carbolic acid and its derivatives to fabrics, with a focus on improving efficacy, durability, and safety.

In recent years, the role of carbolic acid in textile antimicrobial treatments has been subject to increased scrutiny and innovation. Environmental concerns and stricter regulations have prompted research into more sustainable and eco-friendly alternatives. However, the fundamental principles established through the use of carbolic acid continue to inform current antimicrobial strategies in the textile industry.

The ongoing technological advancements aim to address several key challenges. These include enhancing the longevity of antimicrobial effects, reducing the environmental impact of treatments, and ensuring the safety of end-users. Additionally, there is a growing emphasis on developing multifunctional treatments that combine antimicrobial properties with other desirable fabric characteristics, such as moisture-wicking or UV protection.

As we look towards the future, the role of carbolic acid in textile antimicrobial treatments is likely to evolve further. While traditional applications may decrease due to environmental and health considerations, the principles and knowledge gained from its use continue to drive innovation in the field. The goal remains to create textiles that not only protect against microbial threats but also meet the increasing demands for sustainability and performance in the modern textile industry.

The evolution of carbolic acid's use in textiles can be traced back to the early 20th century when the need for hygienic fabrics became increasingly apparent. Initially, its application was primarily focused on medical textiles and military uniforms, where preventing the spread of infections was crucial. Over time, the scope of its use expanded to encompass a wider range of textile products, including sportswear, home textiles, and industrial fabrics.

The primary objective of incorporating carbolic acid into textile treatments has been to impart durable antimicrobial properties to fabrics. This serves multiple purposes, including odor control, prevention of microbial degradation, and enhancement of overall hygiene. As the textile industry has evolved, so too have the methods of applying carbolic acid and its derivatives to fabrics, with a focus on improving efficacy, durability, and safety.

In recent years, the role of carbolic acid in textile antimicrobial treatments has been subject to increased scrutiny and innovation. Environmental concerns and stricter regulations have prompted research into more sustainable and eco-friendly alternatives. However, the fundamental principles established through the use of carbolic acid continue to inform current antimicrobial strategies in the textile industry.

The ongoing technological advancements aim to address several key challenges. These include enhancing the longevity of antimicrobial effects, reducing the environmental impact of treatments, and ensuring the safety of end-users. Additionally, there is a growing emphasis on developing multifunctional treatments that combine antimicrobial properties with other desirable fabric characteristics, such as moisture-wicking or UV protection.

As we look towards the future, the role of carbolic acid in textile antimicrobial treatments is likely to evolve further. While traditional applications may decrease due to environmental and health considerations, the principles and knowledge gained from its use continue to drive innovation in the field. The goal remains to create textiles that not only protect against microbial threats but also meet the increasing demands for sustainability and performance in the modern textile industry.

Market Analysis for Antimicrobial Textiles

The global market for antimicrobial textiles has been experiencing significant growth in recent years, driven by increasing awareness of hygiene and health concerns. This trend has been further accelerated by the COVID-19 pandemic, which has heightened the demand for products with antimicrobial properties across various sectors, including healthcare, sportswear, and home textiles.

The healthcare sector remains the largest consumer of antimicrobial textiles, with hospitals and medical facilities seeking to reduce the risk of hospital-acquired infections. The sportswear industry has also shown substantial growth in the adoption of antimicrobial textiles, as consumers increasingly prioritize odor-control and hygiene in their athletic apparel.

In terms of regional markets, North America and Europe currently dominate the antimicrobial textile market, owing to stringent regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing disposable income, and growing health consciousness among consumers.

The use of carbolic acid, also known as phenol, in antimicrobial treatments for textiles is part of a broader trend towards more effective and sustainable antimicrobial solutions. While traditional antimicrobial agents like silver and triclosan have been widely used, concerns about environmental impact and bacterial resistance have led to increased interest in alternative compounds.

Carbolic acid-based treatments offer several advantages, including broad-spectrum antimicrobial activity, durability, and cost-effectiveness. These properties make them particularly attractive for applications in healthcare textiles and protective clothing. However, the market adoption of carbolic acid treatments faces challenges related to potential skin irritation and environmental concerns associated with phenolic compounds.

The antimicrobial textile market is highly competitive, with key players continuously investing in research and development to improve product efficacy and sustainability. This has led to the emergence of new technologies and formulations, including nanotechnology-based solutions and bio-based antimicrobial agents.

Consumer preferences are shifting towards more sustainable and eco-friendly antimicrobial treatments, creating opportunities for innovative solutions that balance effectiveness with environmental responsibility. This trend is likely to shape the future development of antimicrobial textile treatments, including those based on carbolic acid and its derivatives.

The healthcare sector remains the largest consumer of antimicrobial textiles, with hospitals and medical facilities seeking to reduce the risk of hospital-acquired infections. The sportswear industry has also shown substantial growth in the adoption of antimicrobial textiles, as consumers increasingly prioritize odor-control and hygiene in their athletic apparel.

In terms of regional markets, North America and Europe currently dominate the antimicrobial textile market, owing to stringent regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing disposable income, and growing health consciousness among consumers.

The use of carbolic acid, also known as phenol, in antimicrobial treatments for textiles is part of a broader trend towards more effective and sustainable antimicrobial solutions. While traditional antimicrobial agents like silver and triclosan have been widely used, concerns about environmental impact and bacterial resistance have led to increased interest in alternative compounds.

Carbolic acid-based treatments offer several advantages, including broad-spectrum antimicrobial activity, durability, and cost-effectiveness. These properties make them particularly attractive for applications in healthcare textiles and protective clothing. However, the market adoption of carbolic acid treatments faces challenges related to potential skin irritation and environmental concerns associated with phenolic compounds.

The antimicrobial textile market is highly competitive, with key players continuously investing in research and development to improve product efficacy and sustainability. This has led to the emergence of new technologies and formulations, including nanotechnology-based solutions and bio-based antimicrobial agents.

Consumer preferences are shifting towards more sustainable and eco-friendly antimicrobial treatments, creating opportunities for innovative solutions that balance effectiveness with environmental responsibility. This trend is likely to shape the future development of antimicrobial textile treatments, including those based on carbolic acid and its derivatives.

Current Challenges in Textile Antimicrobial Treatments

The textile industry faces several significant challenges in implementing effective antimicrobial treatments, particularly concerning the use of carbolic acid. One of the primary issues is the increasing resistance of microorganisms to traditional antimicrobial agents. This resistance development necessitates the continuous search for new, more potent antimicrobial compounds or innovative treatment methods.

Environmental concerns pose another major challenge. The use of carbolic acid and other synthetic antimicrobial agents can lead to water pollution and soil contamination when released into the environment through textile processing effluents. This has led to stricter regulations and a growing demand for more eco-friendly alternatives, putting pressure on manufacturers to develop sustainable antimicrobial solutions.

The durability of antimicrobial treatments remains a persistent challenge. Many current treatments lose their effectiveness after repeated washing or prolonged use, reducing the longevity of the textile's antimicrobial properties. This issue is particularly critical in applications such as medical textiles and protective clothing, where consistent antimicrobial performance is crucial.

Safety concerns for both consumers and textile workers present another significant challenge. Carbolic acid and some other antimicrobial agents can cause skin irritation or allergic reactions in sensitive individuals. Ensuring the safety of these treatments while maintaining their efficacy is a delicate balance that researchers and manufacturers must continually address.

The cost-effectiveness of antimicrobial treatments is an ongoing concern for the industry. Implementing advanced antimicrobial technologies often increases production costs, which can be challenging to justify in a competitive market. Manufacturers must find ways to optimize the application process and reduce the overall cost of antimicrobial treatments without compromising their effectiveness.

Regulatory compliance adds another layer of complexity to the challenges faced by the textile industry. Different countries and regions have varying regulations regarding the use of antimicrobial agents in textiles. Navigating these diverse regulatory landscapes while maintaining global market access requires significant resources and adaptability from manufacturers.

Lastly, the textile industry faces challenges in achieving uniform antimicrobial performance across different fabric types and structures. The effectiveness of treatments can vary depending on the textile's composition, weave, and finish. Developing versatile antimicrobial solutions that can be applied consistently across a wide range of textile products remains an ongoing challenge for researchers and manufacturers in the industry.

Environmental concerns pose another major challenge. The use of carbolic acid and other synthetic antimicrobial agents can lead to water pollution and soil contamination when released into the environment through textile processing effluents. This has led to stricter regulations and a growing demand for more eco-friendly alternatives, putting pressure on manufacturers to develop sustainable antimicrobial solutions.

The durability of antimicrobial treatments remains a persistent challenge. Many current treatments lose their effectiveness after repeated washing or prolonged use, reducing the longevity of the textile's antimicrobial properties. This issue is particularly critical in applications such as medical textiles and protective clothing, where consistent antimicrobial performance is crucial.

Safety concerns for both consumers and textile workers present another significant challenge. Carbolic acid and some other antimicrobial agents can cause skin irritation or allergic reactions in sensitive individuals. Ensuring the safety of these treatments while maintaining their efficacy is a delicate balance that researchers and manufacturers must continually address.

The cost-effectiveness of antimicrobial treatments is an ongoing concern for the industry. Implementing advanced antimicrobial technologies often increases production costs, which can be challenging to justify in a competitive market. Manufacturers must find ways to optimize the application process and reduce the overall cost of antimicrobial treatments without compromising their effectiveness.

Regulatory compliance adds another layer of complexity to the challenges faced by the textile industry. Different countries and regions have varying regulations regarding the use of antimicrobial agents in textiles. Navigating these diverse regulatory landscapes while maintaining global market access requires significant resources and adaptability from manufacturers.

Lastly, the textile industry faces challenges in achieving uniform antimicrobial performance across different fabric types and structures. The effectiveness of treatments can vary depending on the textile's composition, weave, and finish. Developing versatile antimicrobial solutions that can be applied consistently across a wide range of textile products remains an ongoing challenge for researchers and manufacturers in the industry.

Existing Carbolic Acid-based Antimicrobial Solutions

01 Antimicrobial properties of carbolic acid

Carbolic acid, also known as phenol, exhibits strong antimicrobial properties. It is effective against a wide range of microorganisms, including bacteria, fungi, and viruses. Its ability to disrupt cell membranes and denature proteins makes it a potent disinfectant and antiseptic agent.- Antimicrobial properties of carbolic acid: Carbolic acid, also known as phenol, exhibits strong antimicrobial properties. It is effective against a wide range of microorganisms, including bacteria, fungi, and viruses. Its ability to disrupt cell membranes and denature proteins makes it a potent disinfectant and antiseptic agent.

- Carbolic acid in medical and healthcare applications: Due to its antimicrobial properties, carbolic acid is used in various medical and healthcare applications. It is incorporated into disinfectants, antiseptics, and sterilizing solutions for medical instruments and surfaces. Its use extends to personal care products and wound treatments.

- Formulations and compositions containing carbolic acid: Carbolic acid is often combined with other ingredients to enhance its antimicrobial efficacy or to create specialized formulations. These compositions may include other disinfectants, surfactants, or additives to improve stability, effectiveness, or application properties.

- Industrial and environmental applications: The antimicrobial properties of carbolic acid are utilized in various industrial and environmental applications. It is used in water treatment, industrial cleaning, and as a preservative in certain products. Its effectiveness in controlling microbial growth makes it valuable in these sectors.

- Safety considerations and alternatives: While carbolic acid is an effective antimicrobial agent, its use is associated with safety concerns due to its corrosive and toxic nature. Research has focused on developing safer alternatives or modified formulations that maintain antimicrobial efficacy while reducing potential risks.

02 Carbolic acid in medical and healthcare applications

The antimicrobial properties of carbolic acid make it valuable in various medical and healthcare applications. It is used in disinfectants, surgical instruments sterilization, and as an antiseptic in wound care. Its effectiveness in killing pathogens contributes to infection control in healthcare settings.Expand Specific Solutions03 Carbolic acid in personal care and hygiene products

Carbolic acid is incorporated into personal care and hygiene products due to its antimicrobial properties. It can be found in soaps, mouthwashes, and other cleansing products. The addition of carbolic acid helps to enhance the product's ability to kill harmful microorganisms and maintain personal hygiene.Expand Specific Solutions04 Carbolic acid in industrial and environmental applications

The antimicrobial properties of carbolic acid are utilized in various industrial and environmental applications. It is used in water treatment, as a preservative in industrial products, and in the formulation of disinfectants for surfaces and equipment. Its broad-spectrum activity makes it effective in controlling microbial growth in diverse settings.Expand Specific Solutions05 Synergistic effects of carbolic acid with other antimicrobial agents

Carbolic acid can be combined with other antimicrobial agents to enhance its effectiveness. These combinations can lead to synergistic effects, improving the overall antimicrobial activity and broadening the spectrum of action. Such combinations are used in various applications to achieve more potent and comprehensive antimicrobial protection.Expand Specific Solutions

Key Players in Antimicrobial Textile Industry

The antimicrobial treatment market in the textile industry using carbolic acid is in a growth phase, driven by increasing demand for hygienic textiles. The market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Henkel, DuPont, and BASF leading innovation. These firms are developing more effective and sustainable antimicrobial solutions, focusing on improving efficacy while reducing environmental impact. Smaller players like Microban Products Co. and Applied Silver, Inc. are also contributing to technological advancements, particularly in specialized applications. The competitive landscape is characterized by a mix of established chemical giants and niche players, with ongoing research at institutions like Zhejiang Sci-Tech University and Ghent University further driving innovation in this sector.

Microban Products Co.

Technical Solution: Microban has developed advanced antimicrobial treatments incorporating carbolic acid derivatives for textile applications. Their technology involves integrating phenolic compounds into fabric fibers during the manufacturing process, creating a durable antimicrobial barrier. This treatment has shown efficacy against a wide range of microorganisms, including bacteria, fungi, and algae[1]. Microban's carbolic acid-based solutions have demonstrated long-lasting antimicrobial activity, maintaining effectiveness for up to 50 wash cycles[2]. The company has also focused on developing eco-friendly formulations that comply with stringent environmental regulations while maintaining high antimicrobial performance[3].

Strengths: Long-lasting antimicrobial efficacy, broad-spectrum activity, and eco-friendly formulations. Weaknesses: Potential for skin irritation in sensitive individuals, higher production costs compared to conventional treatments.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered the use of carbolic acid derivatives in textile antimicrobial treatments through their Silvadur™ technology. This innovative approach combines the antimicrobial properties of phenolic compounds with silver ions to create a synergistic effect[4]. The treatment is applied to textiles using a unique polymer delivery system, ensuring even distribution and strong adhesion to fabric fibers. DuPont's carbolic acid-based antimicrobial solution has shown exceptional efficacy against odor-causing bacteria, with studies demonstrating a 99.9% reduction in bacterial growth after 24 hours[5]. The company has also focused on developing low-leaching formulations to minimize environmental impact and extend the treatment's durability[6].

Strengths: Synergistic antimicrobial action, high efficacy against odor-causing bacteria, and low environmental impact. Weaknesses: Higher cost due to the inclusion of silver ions, potential for reduced effectiveness in high-pH environments.

Innovations in Carbolic Acid Antimicrobial Applications

Antimicrobial synthetic textile and a method for manufacturing thereof

PatentWO2024115816A1

Innovation

- A method involving the use of polycarboxylic acids, specifically citric acid, as an antimicrobial finish on synthetic textiles, where the acid is cured in the presence of a catalyst like sodium hypophosphite, forming crosslinked or polymerized molecules that provide a durable and non-leaching antimicrobial layer.

Use of nitrogen-containing complexing agents for deodorization and antimicrobial treatment of the skin and textile fibre materials

PatentInactiveUS6391325B1

Innovation

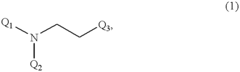

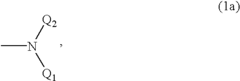

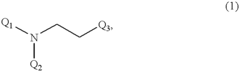

- Nitrogen-containing complexing agents, such as ethylenediaminetetraacetic acid (EDTA), nitrilotriacetic acid (NTA), and ethylenediaminedisuccinic acid (EDDS), are used for their antimicrobial properties to treat skin and textile fibers, formulated into body care compositions and detergents, and can be synthesized chemically or microbiologically to ensure optically pure forms.

Environmental Impact of Carbolic Acid Treatments

The use of carbolic acid in textile industry antimicrobial treatments has raised significant environmental concerns. While effective in controlling microbial growth, the widespread application of this chemical compound has potential negative impacts on ecosystems and human health.

One of the primary environmental issues associated with carbolic acid treatments is water pollution. Textile manufacturing processes often result in the release of wastewater containing residual carbolic acid. When discharged into water bodies, this can lead to the contamination of aquatic ecosystems. The presence of carbolic acid in water can be toxic to various aquatic organisms, disrupting the natural balance of these environments and potentially causing long-term ecological damage.

Soil contamination is another environmental concern. Carbolic acid can leach into the soil from treated textiles or through improper disposal of manufacturing waste. This contamination can negatively affect soil microorganisms, which play crucial roles in nutrient cycling and soil health. Furthermore, it may impact plant growth and potentially enter the food chain through agricultural products grown in affected areas.

The production and use of carbolic acid also contribute to air pollution. Volatile organic compounds (VOCs) released during the manufacturing and application processes can contribute to the formation of ground-level ozone and smog. These air quality issues can have far-reaching effects on both human health and the environment, particularly in areas with high concentrations of textile manufacturing facilities.

The persistence of carbolic acid in the environment is a significant concern. Unlike some other antimicrobial agents, carbolic acid does not readily biodegrade, leading to its accumulation in ecosystems over time. This persistence increases the potential for long-term environmental impacts and makes remediation efforts more challenging and costly.

From a broader perspective, the environmental footprint of carbolic acid treatments extends to resource consumption and energy use. The production of carbolic acid requires significant energy inputs and raw materials, contributing to overall industrial carbon emissions and resource depletion. This aspect of environmental impact is often overlooked but is crucial when considering the sustainability of textile industry practices.

In response to these environmental concerns, there is growing pressure on the textile industry to adopt more sustainable antimicrobial treatments. This has led to increased research into eco-friendly alternatives and the development of stricter regulations governing the use and disposal of carbolic acid in textile manufacturing processes. As awareness of environmental issues continues to grow, the industry faces the challenge of balancing effective antimicrobial protection with environmental responsibility.

One of the primary environmental issues associated with carbolic acid treatments is water pollution. Textile manufacturing processes often result in the release of wastewater containing residual carbolic acid. When discharged into water bodies, this can lead to the contamination of aquatic ecosystems. The presence of carbolic acid in water can be toxic to various aquatic organisms, disrupting the natural balance of these environments and potentially causing long-term ecological damage.

Soil contamination is another environmental concern. Carbolic acid can leach into the soil from treated textiles or through improper disposal of manufacturing waste. This contamination can negatively affect soil microorganisms, which play crucial roles in nutrient cycling and soil health. Furthermore, it may impact plant growth and potentially enter the food chain through agricultural products grown in affected areas.

The production and use of carbolic acid also contribute to air pollution. Volatile organic compounds (VOCs) released during the manufacturing and application processes can contribute to the formation of ground-level ozone and smog. These air quality issues can have far-reaching effects on both human health and the environment, particularly in areas with high concentrations of textile manufacturing facilities.

The persistence of carbolic acid in the environment is a significant concern. Unlike some other antimicrobial agents, carbolic acid does not readily biodegrade, leading to its accumulation in ecosystems over time. This persistence increases the potential for long-term environmental impacts and makes remediation efforts more challenging and costly.

From a broader perspective, the environmental footprint of carbolic acid treatments extends to resource consumption and energy use. The production of carbolic acid requires significant energy inputs and raw materials, contributing to overall industrial carbon emissions and resource depletion. This aspect of environmental impact is often overlooked but is crucial when considering the sustainability of textile industry practices.

In response to these environmental concerns, there is growing pressure on the textile industry to adopt more sustainable antimicrobial treatments. This has led to increased research into eco-friendly alternatives and the development of stricter regulations governing the use and disposal of carbolic acid in textile manufacturing processes. As awareness of environmental issues continues to grow, the industry faces the challenge of balancing effective antimicrobial protection with environmental responsibility.

Regulatory Framework for Antimicrobial Textiles

The regulatory framework for antimicrobial textiles plays a crucial role in ensuring the safe and effective use of carbolic acid and other antimicrobial agents in the textile industry. Various governmental bodies and international organizations have established guidelines and standards to govern the production, testing, and marketing of antimicrobial textiles.

In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial agents used in textiles under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). Manufacturers must register their products with the EPA and provide data demonstrating efficacy and safety. The Food and Drug Administration (FDA) also oversees antimicrobial textiles that make medical claims, ensuring compliance with relevant regulations.

The European Union has implemented the Biocidal Products Regulation (BPR), which covers antimicrobial treatments in textiles. This regulation requires manufacturers to obtain authorization for active substances and biocidal products before they can be placed on the market. The BPR aims to harmonize the European market while ensuring a high level of protection for human health and the environment.

In Asia, countries like Japan and South Korea have their own regulatory frameworks. Japan's Ministry of Health, Labour and Welfare oversees the regulation of antimicrobial textiles, while South Korea's Ministry of Food and Drug Safety manages the approval process for such products.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, have developed specific test methods and performance standards for antimicrobial textiles. These standards help ensure consistency in testing procedures and provide benchmarks for product performance across different markets.

The regulatory landscape also addresses environmental concerns associated with antimicrobial treatments. Many countries have implemented restrictions on certain chemicals, including some forms of carbolic acid, due to potential environmental impacts. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, for instance, imposes strict controls on the use of hazardous substances in textiles.

Labeling requirements form another critical aspect of the regulatory framework. In many jurisdictions, manufacturers must provide clear and accurate information about the antimicrobial properties of their textiles, including any limitations or potential risks associated with their use.

As the textile industry continues to innovate, regulatory bodies are adapting their frameworks to address new technologies and emerging concerns. This includes the development of regulations for nanotechnology-based antimicrobial treatments and the ongoing evaluation of long-term health and environmental impacts of various antimicrobial agents used in textiles.

In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial agents used in textiles under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). Manufacturers must register their products with the EPA and provide data demonstrating efficacy and safety. The Food and Drug Administration (FDA) also oversees antimicrobial textiles that make medical claims, ensuring compliance with relevant regulations.

The European Union has implemented the Biocidal Products Regulation (BPR), which covers antimicrobial treatments in textiles. This regulation requires manufacturers to obtain authorization for active substances and biocidal products before they can be placed on the market. The BPR aims to harmonize the European market while ensuring a high level of protection for human health and the environment.

In Asia, countries like Japan and South Korea have their own regulatory frameworks. Japan's Ministry of Health, Labour and Welfare oversees the regulation of antimicrobial textiles, while South Korea's Ministry of Food and Drug Safety manages the approval process for such products.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, have developed specific test methods and performance standards for antimicrobial textiles. These standards help ensure consistency in testing procedures and provide benchmarks for product performance across different markets.

The regulatory landscape also addresses environmental concerns associated with antimicrobial treatments. Many countries have implemented restrictions on certain chemicals, including some forms of carbolic acid, due to potential environmental impacts. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, for instance, imposes strict controls on the use of hazardous substances in textiles.

Labeling requirements form another critical aspect of the regulatory framework. In many jurisdictions, manufacturers must provide clear and accurate information about the antimicrobial properties of their textiles, including any limitations or potential risks associated with their use.

As the textile industry continues to innovate, regulatory bodies are adapting their frameworks to address new technologies and emerging concerns. This includes the development of regulations for nanotechnology-based antimicrobial treatments and the ongoing evaluation of long-term health and environmental impacts of various antimicrobial agents used in textiles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!