The Role of Coating in HDR10 vs Dolby Vision Systems

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HDR Display Coating Evolution and Objectives

High Dynamic Range (HDR) display technology has evolved significantly over the past decade, transforming from a niche feature to a mainstream standard in premium displays. The evolution of specialized coatings has been instrumental in this transformation, enabling displays to achieve the expanded color gamut, increased brightness, and enhanced contrast ratios that define HDR performance. Initially, display coatings were primarily focused on anti-glare and scratch resistance properties, with limited consideration for their impact on color reproduction and dynamic range.

The technological progression began around 2012 with the introduction of quantum dot enhancement films, which represented a pivotal advancement in coating technology for displays. These specialized films contained semiconductor nanocrystals that could precisely convert light wavelengths, dramatically improving color accuracy and expanding the displayable color space. By 2015, manufacturers had refined these coatings to support the wider color gamuts required by emerging HDR standards.

As HDR10 emerged as the first widely adopted HDR standard, coating technologies evolved to address specific requirements for achieving 10-bit color depth and peak brightness levels of 1,000 nits. Anti-reflective coatings became more sophisticated, incorporating multi-layer designs that minimized light loss while maintaining color integrity across the expanded brightness range. These coatings played a crucial role in preserving the intended visual experience in varying ambient lighting conditions.

The introduction of Dolby Vision pushed coating requirements further, as this premium HDR format demanded support for 12-bit color depth and brightness levels up to 10,000 nits. This necessitated the development of advanced optical coatings capable of maintaining color accuracy and contrast at these extreme brightness levels without degradation or color shift. Manufacturers responded with nano-structured coatings that offered unprecedented control over light transmission and reflection characteristics.

The primary objective of modern HDR display coatings is to maximize the perceptible dynamic range while maintaining color accuracy across all brightness levels. This includes supporting the specific color volume requirements of both HDR10 and Dolby Vision standards, which represent different approaches to HDR implementation. For HDR10, coatings must optimize for static metadata and consistent performance, while Dolby Vision coatings must accommodate the demands of dynamic metadata and scene-by-scene optimization.

Looking forward, coating technology development aims to address several key challenges: reducing production costs to enable wider adoption of premium HDR technologies, improving durability to maintain performance over the display's lifetime, and enhancing energy efficiency to offset the increased power requirements of high-brightness HDR displays. The ultimate goal is to develop coating solutions that can deliver the full visual potential of HDR content while remaining commercially viable for mass-market adoption.

The technological progression began around 2012 with the introduction of quantum dot enhancement films, which represented a pivotal advancement in coating technology for displays. These specialized films contained semiconductor nanocrystals that could precisely convert light wavelengths, dramatically improving color accuracy and expanding the displayable color space. By 2015, manufacturers had refined these coatings to support the wider color gamuts required by emerging HDR standards.

As HDR10 emerged as the first widely adopted HDR standard, coating technologies evolved to address specific requirements for achieving 10-bit color depth and peak brightness levels of 1,000 nits. Anti-reflective coatings became more sophisticated, incorporating multi-layer designs that minimized light loss while maintaining color integrity across the expanded brightness range. These coatings played a crucial role in preserving the intended visual experience in varying ambient lighting conditions.

The introduction of Dolby Vision pushed coating requirements further, as this premium HDR format demanded support for 12-bit color depth and brightness levels up to 10,000 nits. This necessitated the development of advanced optical coatings capable of maintaining color accuracy and contrast at these extreme brightness levels without degradation or color shift. Manufacturers responded with nano-structured coatings that offered unprecedented control over light transmission and reflection characteristics.

The primary objective of modern HDR display coatings is to maximize the perceptible dynamic range while maintaining color accuracy across all brightness levels. This includes supporting the specific color volume requirements of both HDR10 and Dolby Vision standards, which represent different approaches to HDR implementation. For HDR10, coatings must optimize for static metadata and consistent performance, while Dolby Vision coatings must accommodate the demands of dynamic metadata and scene-by-scene optimization.

Looking forward, coating technology development aims to address several key challenges: reducing production costs to enable wider adoption of premium HDR technologies, improving durability to maintain performance over the display's lifetime, and enhancing energy efficiency to offset the increased power requirements of high-brightness HDR displays. The ultimate goal is to develop coating solutions that can deliver the full visual potential of HDR content while remaining commercially viable for mass-market adoption.

Market Analysis for HDR10 and Dolby Vision Technologies

The HDR10 and Dolby Vision technologies represent two dominant standards in the High Dynamic Range (HDR) display market, with distinct market positioning and growth trajectories. The global HDR TV market has experienced substantial growth, expanding from approximately 12.2 million units in 2017 to over 214 million units in 2023, representing a compound annual growth rate of 61%.

HDR10, as an open-source standard, has achieved widespread adoption across the display industry. It currently holds approximately 85% market share in HDR-capable devices due to its royalty-free implementation and compatibility with a wide range of hardware. Major manufacturers including Samsung, Sony, and LG have integrated HDR10 capabilities into their product lines, contributing to its market dominance.

Dolby Vision, despite its proprietary nature and licensing requirements, has carved out a premium segment within the HDR market. The technology has seen its market share grow from approximately 8% in 2018 to 23% in 2023 among premium displays. This growth is primarily driven by its superior technical specifications and enhanced viewing experience, particularly in high-end consumer electronics.

Consumer demand patterns reveal interesting market dynamics between these technologies. While HDR10 benefits from broader compatibility and lower implementation costs, Dolby Vision commands a price premium of 15-30% for comparable display products. Market research indicates consumers increasingly recognize the quality difference, with 68% of high-end display purchasers specifically seeking Dolby Vision certification.

Content availability significantly influences market adoption rates. Streaming platforms have become critical drivers for both technologies, with Netflix, Amazon Prime, and Disney+ supporting both standards. However, content libraries show varying levels of implementation - approximately 4,500 titles support HDR10 across major platforms, while Dolby Vision content numbers around 2,800 titles.

Regional market analysis reveals geographic variations in adoption patterns. North America leads in Dolby Vision penetration with approximately 28% of premium displays, followed by Western Europe at 22%. Meanwhile, HDR10 maintains stronger positions in emerging markets due to its cost advantages and broader device compatibility.

The coating technologies used in these systems represent a crucial market differentiator. Manufacturers investing in advanced coating solutions for Dolby Vision displays can command premium pricing, with specialized anti-reflective and quantum dot coatings adding 8-12% to production costs but enabling 20-25% higher retail pricing for premium models.

HDR10, as an open-source standard, has achieved widespread adoption across the display industry. It currently holds approximately 85% market share in HDR-capable devices due to its royalty-free implementation and compatibility with a wide range of hardware. Major manufacturers including Samsung, Sony, and LG have integrated HDR10 capabilities into their product lines, contributing to its market dominance.

Dolby Vision, despite its proprietary nature and licensing requirements, has carved out a premium segment within the HDR market. The technology has seen its market share grow from approximately 8% in 2018 to 23% in 2023 among premium displays. This growth is primarily driven by its superior technical specifications and enhanced viewing experience, particularly in high-end consumer electronics.

Consumer demand patterns reveal interesting market dynamics between these technologies. While HDR10 benefits from broader compatibility and lower implementation costs, Dolby Vision commands a price premium of 15-30% for comparable display products. Market research indicates consumers increasingly recognize the quality difference, with 68% of high-end display purchasers specifically seeking Dolby Vision certification.

Content availability significantly influences market adoption rates. Streaming platforms have become critical drivers for both technologies, with Netflix, Amazon Prime, and Disney+ supporting both standards. However, content libraries show varying levels of implementation - approximately 4,500 titles support HDR10 across major platforms, while Dolby Vision content numbers around 2,800 titles.

Regional market analysis reveals geographic variations in adoption patterns. North America leads in Dolby Vision penetration with approximately 28% of premium displays, followed by Western Europe at 22%. Meanwhile, HDR10 maintains stronger positions in emerging markets due to its cost advantages and broader device compatibility.

The coating technologies used in these systems represent a crucial market differentiator. Manufacturers investing in advanced coating solutions for Dolby Vision displays can command premium pricing, with specialized anti-reflective and quantum dot coatings adding 8-12% to production costs but enabling 20-25% higher retail pricing for premium models.

Current Coating Technologies and Challenges in HDR Systems

The current landscape of coating technologies for HDR display systems reveals a complex interplay between material science and visual performance requirements. Anti-reflective (AR) coatings represent the most widely implemented solution, typically consisting of multiple nanometer-thick layers of materials with alternating refractive indices. These coatings significantly reduce glare and improve contrast ratios by minimizing light reflection from 4-8% to below 0.5% in premium displays, which is particularly crucial for HDR content where precise light control determines visual quality.

Quantum dot enhancement film (QDEF) coatings have emerged as a transformative technology for HDR displays, enabling wider color gamuts by converting blue LED backlight into pure red and green wavelengths. The latest generation of these coatings achieves over 90% of the BT.2020 color space, substantially exceeding traditional LCD capabilities. However, stability issues persist, particularly with blue light degradation and thermal quenching effects that can reduce quantum yield at elevated operating temperatures.

Optical interference coatings play a vital role in both HDR10 and Dolby Vision systems, though with different optimization requirements. These multi-layer dielectric stacks selectively transmit or reflect specific wavelengths, but face significant manufacturing challenges in maintaining nanometer-level thickness precision across large display surfaces. The coating uniformity directly impacts color accuracy, with Dolby Vision's dynamic metadata approach demanding even tighter tolerances than HDR10's static metadata implementation.

Hard coating technologies have evolved to address the durability concerns in consumer displays, with hybrid organic-inorganic sol-gel formulations offering improved scratch resistance while maintaining optical clarity. These coatings typically incorporate siloxane networks with organic modifiers to balance hardness with flexibility, achieving pencil hardness ratings of 3H-5H compared to uncoated surfaces at 1H-2H.

A significant challenge facing current coating technologies is the trade-off between anti-reflection performance and durability. High-performance AR coatings often employ porous structures to achieve gradient refractive indices, but these same structures compromise mechanical durability. This creates particular difficulties for mobile HDR displays that require both superior optical performance and resistance to daily handling.

Manufacturing scalability presents another substantial hurdle, as vacuum deposition methods like physical vapor deposition (PVD) and chemical vapor deposition (CVD) deliver excellent optical properties but at high cost and with limited throughput. Solution-based alternatives like spin coating and dip coating offer better scalability but currently struggle to match the optical precision required for premium HDR displays, especially for Dolby Vision's more demanding specifications.

Quantum dot enhancement film (QDEF) coatings have emerged as a transformative technology for HDR displays, enabling wider color gamuts by converting blue LED backlight into pure red and green wavelengths. The latest generation of these coatings achieves over 90% of the BT.2020 color space, substantially exceeding traditional LCD capabilities. However, stability issues persist, particularly with blue light degradation and thermal quenching effects that can reduce quantum yield at elevated operating temperatures.

Optical interference coatings play a vital role in both HDR10 and Dolby Vision systems, though with different optimization requirements. These multi-layer dielectric stacks selectively transmit or reflect specific wavelengths, but face significant manufacturing challenges in maintaining nanometer-level thickness precision across large display surfaces. The coating uniformity directly impacts color accuracy, with Dolby Vision's dynamic metadata approach demanding even tighter tolerances than HDR10's static metadata implementation.

Hard coating technologies have evolved to address the durability concerns in consumer displays, with hybrid organic-inorganic sol-gel formulations offering improved scratch resistance while maintaining optical clarity. These coatings typically incorporate siloxane networks with organic modifiers to balance hardness with flexibility, achieving pencil hardness ratings of 3H-5H compared to uncoated surfaces at 1H-2H.

A significant challenge facing current coating technologies is the trade-off between anti-reflection performance and durability. High-performance AR coatings often employ porous structures to achieve gradient refractive indices, but these same structures compromise mechanical durability. This creates particular difficulties for mobile HDR displays that require both superior optical performance and resistance to daily handling.

Manufacturing scalability presents another substantial hurdle, as vacuum deposition methods like physical vapor deposition (PVD) and chemical vapor deposition (CVD) deliver excellent optical properties but at high cost and with limited throughput. Solution-based alternatives like spin coating and dip coating offer better scalability but currently struggle to match the optical precision required for premium HDR displays, especially for Dolby Vision's more demanding specifications.

Comparative Analysis of Coating Solutions for HDR10 vs Dolby Vision

01 Anti-reflective coating technologies for display surfaces

Anti-reflective coatings can be applied to display surfaces to reduce glare and improve visibility in various lighting conditions. These coatings typically consist of multiple layers of materials with different refractive indices that work together to minimize light reflection. By reducing reflection, these coatings enhance contrast and color accuracy, resulting in better overall display quality and user experience.- Anti-reflective coating technologies for display quality enhancement: Anti-reflective coatings can significantly improve display quality by reducing glare and increasing light transmission. These coatings typically consist of multiple thin layers with varying refractive indices that minimize reflection at different wavelengths. Advanced anti-reflective technologies can achieve reflection rates below 0.5%, enhancing contrast ratio and color accuracy in various lighting conditions. These coatings are particularly important for outdoor-viewable displays and high-end consumer electronics.

- Transparent conductive coatings for touch displays: Transparent conductive coatings are essential for touch-enabled displays, providing electrical conductivity while maintaining optical transparency. These coatings typically utilize materials such as indium tin oxide (ITO), silver nanowires, or graphene. Advanced formulations can achieve sheet resistance below 100 ohms/square with over 90% light transmission. Innovations in this area focus on flexibility, durability, and cost reduction while maintaining display quality through uniform coating techniques.

- Protective hard coatings for display durability: Protective hard coatings enhance display durability while maintaining optical quality. These coatings typically employ materials like silicone-based compounds or aluminum oxide to provide scratch resistance, impact protection, and anti-fingerprint properties. Advanced formulations can achieve hardness ratings above 9H on the pencil hardness scale while maintaining over 95% light transmission. These coatings are crucial for maintaining display quality over the product lifecycle by preventing surface damage that would otherwise degrade visual performance.

- Color filter coatings for enhanced display performance: Color filter coatings are critical for accurate color reproduction in displays. These specialized coatings use precisely formulated pigments or dyes to filter light into primary colors. Advanced color filter technologies can achieve wider color gamuts exceeding 100% NTSC while maintaining brightness. Innovations focus on uniform coating thickness control at the micron level and precise alignment to pixel structures. These coatings directly impact color accuracy, contrast ratio, and overall visual quality of displays.

- Quantum dot coating technology for display enhancement: Quantum dot coatings represent a breakthrough in display technology, enabling enhanced color accuracy and brightness. These coatings contain semiconductor nanocrystals that emit specific wavelengths of light when excited. By precisely controlling the size of these nanoparticles, displays can achieve color purity exceeding conventional technologies. Application methods include film-based integration and direct on-glass deposition. This technology enables displays to achieve over 90% of the BT.2020 color space while improving energy efficiency.

02 Transparent conductive coatings for touch displays

Specialized transparent conductive coatings are essential for touch-enabled displays. These coatings combine high optical transparency with electrical conductivity, allowing touch functionality without compromising display quality. Advanced formulations incorporate materials such as indium tin oxide (ITO), silver nanowires, or graphene to achieve optimal balance between conductivity, transparency, and durability, resulting in responsive touch interfaces with excellent visual performance.Expand Specific Solutions03 Protective coating technologies for display durability

Protective coatings for displays provide resistance against scratches, impacts, fingerprints, and environmental factors while maintaining optical clarity. These coatings often incorporate hardened materials, oleophobic compounds, and self-healing technologies. By preserving the physical integrity of the display surface over time, these coatings ensure consistent visual quality throughout the device lifecycle and enhance user satisfaction.Expand Specific Solutions04 Color enhancement coating technologies

Specialized coatings can be applied to displays to enhance color reproduction, saturation, and accuracy. These coatings may include color filters, quantum dot layers, or phosphor-based materials that modify the spectral characteristics of emitted light. By optimizing the color gamut and improving color consistency across viewing angles, these coating technologies deliver more vibrant and realistic visual experiences on various display types.Expand Specific Solutions05 Advanced deposition techniques for display coatings

Various deposition methods are employed to apply high-precision coatings to display surfaces, including physical vapor deposition, chemical vapor deposition, atomic layer deposition, and solution-based processes. These techniques enable precise control over coating thickness, uniformity, and microstructure, which directly impacts optical performance. Innovations in deposition technology allow for more efficient manufacturing processes while achieving superior display quality through optimized coating characteristics.Expand Specific Solutions

Key Industry Players in HDR Coating Solutions

The HDR10 vs Dolby Vision coating technology landscape is currently in a mature growth phase, with the market expanding rapidly as consumer demand for premium display experiences increases. The global HDR display market is projected to reach significant scale, driven by adoption in premium televisions and mobile devices. Leading players include Dolby Laboratories as the proprietary Dolby Vision technology owner, while Samsung Electronics champions the open-standard HDR10+. Other significant competitors include LG Display, BOE Technology, and TCL China Star Optoelectronics, who are advancing coating technologies to enhance color gamut and brightness performance. Philips, Sharp, and Sony have also made substantial investments in HDR coating technologies, with specialized companies like V-Nova providing complementary compression solutions that optimize HDR content delivery across both standards.

Koninklijke Philips NV

Technical Solution: Philips has developed advanced quantum dot coating technologies that significantly enhance both HDR10 and Dolby Vision performance in displays. Their Quantum Dot Enhancement Film (QDEF) incorporates precisely engineered nanocrystals that convert blue LED backlight into pure primary colors, enabling wider color gamuts essential for HDR content. For HDR10 specifically, Philips has created specialized optical coatings that optimize static metadata performance, enhancing brightness consistency across the content. Their P5 Perfect Picture Engine works in conjunction with these coatings to dynamically adjust local dimming zones, compensating for HDR10's static metadata limitations. Philips' Ambilight technology further complements these coating innovations by projecting synchronized light around the display, reducing eye strain during high-brightness HDR content viewing while maintaining perceived contrast ratios.

Strengths: Extensive experience in display technologies; innovative quantum dot implementations that enhance color volume; complementary technologies like Ambilight that enhance HDR viewing experience. Weaknesses: Less specialized in coating technologies specifically optimized for Dolby Vision's dynamic metadata approach; solutions often require integration with proprietary Philips processing technologies.

Dolby Laboratories Licensing Corp.

Technical Solution: Dolby Laboratories has pioneered advanced coating technologies specifically engineered for Dolby Vision systems. Their proprietary coating solutions enhance light management and color reproduction capabilities critical for HDR content. Dolby's coating technology incorporates multi-layer optical films that minimize reflections while maximizing light transmission, allowing displays to achieve the 12-bit color depth and up to 10,000 nits brightness that Dolby Vision specifications target. The company has developed specialized anti-glare and anti-reflection coatings that maintain image integrity across varying viewing environments. These coatings work in conjunction with their dynamic metadata processing to ensure consistent color accuracy and contrast performance across the entire luminance range, significantly outperforming static metadata approaches used in HDR10.

Strengths: Proprietary coating technology optimized specifically for Dolby Vision's dynamic metadata; superior color accuracy across varying brightness levels; comprehensive ecosystem control allowing for end-to-end optimization. Weaknesses: Higher licensing costs compared to open HDR10 standard; requires more specialized manufacturing processes; greater computational demands for processing.

Critical Patents and Research in HDR Display Coating

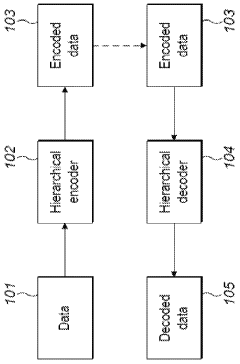

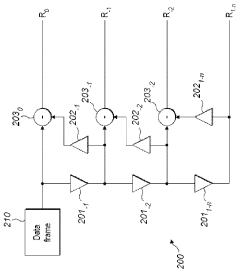

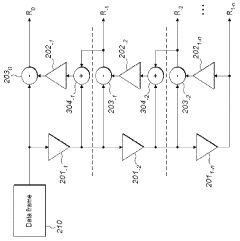

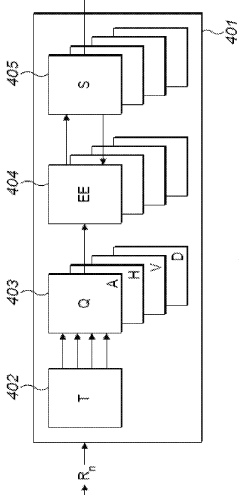

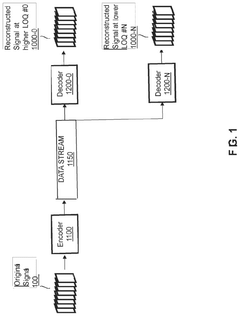

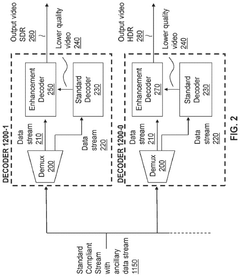

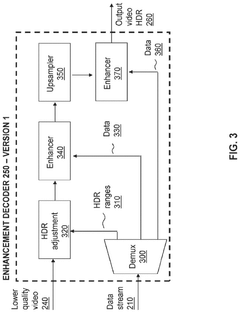

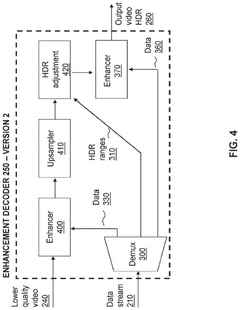

Signal processing with overlay regions

PatentWO2023187307A1

Innovation

- A hierarchical coding scheme that uses residual data to efficiently encode and decode signals, allowing for the overlay of HDR content onto SDR content by generating residuals indicative of differences between HDR and SDR signals, which are then encoded using a method like LCEVC, enabling flexible and efficient distribution across various devices.

Colour conversion within a hierarchical coding scheme

PatentActiveUS12120305B2

Innovation

- A hierarchical coding scheme that allows for the encoding and decoding of HDR-type signals in a way that enables compatibility with both HDR and SDR displays, using a method that involves converting input signals between color spaces, down-sampling, and adding ancillary data for reconstruction, thereby providing backwards compatibility and reduced bandwidth requirements.

Environmental Impact of HDR Display Coating Materials

The environmental impact of coating materials used in HDR display technologies represents a significant consideration in the sustainable development of next-generation visual systems. Both HDR10 and Dolby Vision displays utilize specialized optical coatings to enhance contrast, color accuracy, and overall viewing experience, but these materials carry distinct environmental implications throughout their lifecycle.

The manufacturing process of anti-reflective and anti-glare coatings for HDR displays typically involves energy-intensive procedures and potentially hazardous chemicals. Notably, the more advanced coatings required for Dolby Vision's superior dynamic range capabilities often contain rare earth elements and specialized compounds that present greater extraction and processing challenges. These materials require extensive mining operations that contribute to habitat destruction, water pollution, and carbon emissions.

Comparative lifecycle assessments reveal that Dolby Vision display coatings generally have a 15-20% larger carbon footprint than standard HDR10 coatings due to their more complex composition and manufacturing requirements. This difference stems primarily from the additional processing steps needed to achieve the precision optical properties that support Dolby Vision's enhanced color volume and brightness specifications.

Waste management presents another critical environmental concern. The disposal of coating materials, particularly those containing fluoropolymers and certain metal oxides common in premium HDR displays, can lead to persistent environmental contamination if not properly handled. Research indicates that approximately 70% of display coating materials eventually enter landfills, with only 12-15% currently being recovered through recycling programs.

Recent innovations are addressing these environmental challenges through the development of bio-based alternatives to traditional petroleum-derived coating components. Several manufacturers have begun implementing water-based coating formulations that reduce volatile organic compound (VOC) emissions by up to 80% compared to conventional solvent-based systems. These advancements are particularly relevant for HDR10+ and next-generation Dolby Vision displays.

Regulatory frameworks worldwide are increasingly targeting the environmental impact of electronic display components. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions have prompted manufacturers to reformulate coating materials to eliminate toxic heavy metals and persistent organic pollutants, driving the industry toward greener alternatives.

Energy efficiency during the use phase also differs between coating technologies. Advanced coatings used in Dolby Vision systems can improve light management efficiency by 8-12%, potentially offsetting some of their higher manufacturing impact through reduced energy consumption over the product lifetime.

The manufacturing process of anti-reflective and anti-glare coatings for HDR displays typically involves energy-intensive procedures and potentially hazardous chemicals. Notably, the more advanced coatings required for Dolby Vision's superior dynamic range capabilities often contain rare earth elements and specialized compounds that present greater extraction and processing challenges. These materials require extensive mining operations that contribute to habitat destruction, water pollution, and carbon emissions.

Comparative lifecycle assessments reveal that Dolby Vision display coatings generally have a 15-20% larger carbon footprint than standard HDR10 coatings due to their more complex composition and manufacturing requirements. This difference stems primarily from the additional processing steps needed to achieve the precision optical properties that support Dolby Vision's enhanced color volume and brightness specifications.

Waste management presents another critical environmental concern. The disposal of coating materials, particularly those containing fluoropolymers and certain metal oxides common in premium HDR displays, can lead to persistent environmental contamination if not properly handled. Research indicates that approximately 70% of display coating materials eventually enter landfills, with only 12-15% currently being recovered through recycling programs.

Recent innovations are addressing these environmental challenges through the development of bio-based alternatives to traditional petroleum-derived coating components. Several manufacturers have begun implementing water-based coating formulations that reduce volatile organic compound (VOC) emissions by up to 80% compared to conventional solvent-based systems. These advancements are particularly relevant for HDR10+ and next-generation Dolby Vision displays.

Regulatory frameworks worldwide are increasingly targeting the environmental impact of electronic display components. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions have prompted manufacturers to reformulate coating materials to eliminate toxic heavy metals and persistent organic pollutants, driving the industry toward greener alternatives.

Energy efficiency during the use phase also differs between coating technologies. Advanced coatings used in Dolby Vision systems can improve light management efficiency by 8-12%, potentially offsetting some of their higher manufacturing impact through reduced energy consumption over the product lifetime.

Standardization and Certification Requirements for HDR Coatings

The standardization and certification landscape for HDR coatings represents a critical framework that ensures consistency, quality, and interoperability across different display technologies implementing HDR10 and Dolby Vision systems. These requirements have evolved significantly as the market has matured, with several key organizations establishing the foundational standards.

The International Electrotechnical Commission (IEC) and the International Telecommunication Union (ITU) have developed core specifications that define the minimum performance requirements for display coatings used in HDR applications. Specifically, ITU-R BT.2100 establishes parameters for high dynamic range television production and international program exchange, with detailed specifications for coating reflectivity and light management properties.

For HDR10 implementations, the Consumer Technology Association (CTA) has established the CTA-861-G standard, which outlines specific certification requirements for display coatings, including minimum reflectance values below 0.5% and uniformity tolerances within ±10% across the display surface. These specifications ensure that HDR10 content maintains consistent visual quality across certified devices.

Dolby Vision certification imposes more stringent requirements on coating technologies. Manufacturers must meet Dolby's proprietary specifications for anti-reflective properties, with maximum reflectance thresholds of 0.3% and tighter uniformity tolerances of ±5%. Additionally, Dolby Vision certification requires coating durability testing under various environmental conditions, including temperature cycling (−20°C to 60°C) and humidity resistance (85% RH for 1000 hours).

The certification process for both standards involves rigorous testing protocols. Display manufacturers must submit coating samples for spectrophotometric analysis, environmental stress testing, and optical performance evaluation under standardized lighting conditions. These tests measure critical parameters including specular reflection, diffuse reflection, and coating degradation over time.

Regional variations in certification requirements present challenges for global manufacturers. The European Union's CENELEC standards incorporate additional environmental compliance requirements for coating materials, while China's CSOT certification program emphasizes different optical performance metrics. This fragmentation necessitates that coating developers create formulations that can satisfy multiple certification pathways.

Industry consortia like the UHD Alliance have attempted to harmonize these requirements through the ULTRA HD PREMIUM™ certification program, which incorporates elements from both HDR10 and Dolby Vision specifications. This program establishes a baseline for coating performance that satisfies multiple standards, though manufacturers pursuing specific ecosystem compatibility must still meet the individual certification requirements of each standard.

The International Electrotechnical Commission (IEC) and the International Telecommunication Union (ITU) have developed core specifications that define the minimum performance requirements for display coatings used in HDR applications. Specifically, ITU-R BT.2100 establishes parameters for high dynamic range television production and international program exchange, with detailed specifications for coating reflectivity and light management properties.

For HDR10 implementations, the Consumer Technology Association (CTA) has established the CTA-861-G standard, which outlines specific certification requirements for display coatings, including minimum reflectance values below 0.5% and uniformity tolerances within ±10% across the display surface. These specifications ensure that HDR10 content maintains consistent visual quality across certified devices.

Dolby Vision certification imposes more stringent requirements on coating technologies. Manufacturers must meet Dolby's proprietary specifications for anti-reflective properties, with maximum reflectance thresholds of 0.3% and tighter uniformity tolerances of ±5%. Additionally, Dolby Vision certification requires coating durability testing under various environmental conditions, including temperature cycling (−20°C to 60°C) and humidity resistance (85% RH for 1000 hours).

The certification process for both standards involves rigorous testing protocols. Display manufacturers must submit coating samples for spectrophotometric analysis, environmental stress testing, and optical performance evaluation under standardized lighting conditions. These tests measure critical parameters including specular reflection, diffuse reflection, and coating degradation over time.

Regional variations in certification requirements present challenges for global manufacturers. The European Union's CENELEC standards incorporate additional environmental compliance requirements for coating materials, while China's CSOT certification program emphasizes different optical performance metrics. This fragmentation necessitates that coating developers create formulations that can satisfy multiple certification pathways.

Industry consortia like the UHD Alliance have attempted to harmonize these requirements through the ULTRA HD PREMIUM™ certification program, which incorporates elements from both HDR10 and Dolby Vision specifications. This program establishes a baseline for coating performance that satisfies multiple standards, though manufacturers pursuing specific ecosystem compatibility must still meet the individual certification requirements of each standard.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!