The Role of Nanotechnology in QLED Evolution

JUN 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QLED Nanotechnology Background and Objectives

Quantum dot light-emitting diode (QLED) technology has emerged as a promising advancement in display technology, offering superior color performance and energy efficiency compared to traditional LED displays. The evolution of QLED technology is intrinsically linked to the field of nanotechnology, which has played a pivotal role in its development and continues to drive innovation in this domain.

The journey of QLED technology began in the early 1990s with the discovery of quantum dots, nanoscale semiconductor particles that exhibit unique optical and electronic properties. These quantum dots, typically ranging from 2 to 10 nanometers in size, can be precisely tuned to emit specific colors of light when excited, making them ideal for display applications. The ability to control the size and composition of quantum dots at the nanoscale has been crucial in achieving the wide color gamut and high color purity that QLED displays are known for.

As research in nanotechnology progressed, so did the understanding and manipulation of quantum dots. The early 2000s saw significant advancements in quantum dot synthesis techniques, allowing for better control over their size distribution and surface properties. This led to improved quantum yield and stability, addressing some of the initial challenges faced by QLED technology.

The primary objective of nanotechnology in QLED evolution has been to enhance the performance and efficiency of these displays. This includes improving color accuracy, increasing brightness, extending device lifespan, and reducing power consumption. Nanotechnology has enabled the development of more efficient quantum dot materials, better encapsulation methods to protect quantum dots from degradation, and novel device architectures that optimize charge injection and light extraction.

One of the key areas where nanotechnology has made a significant impact is in the development of quantum dot synthesis methods. Solution-based processes, such as hot-injection and microfluidic techniques, have been refined to produce highly uniform quantum dots with precise control over their size and composition. These advancements have directly translated to improvements in display performance, allowing for more accurate color reproduction and higher efficiency.

Furthermore, nanotechnology has facilitated the integration of quantum dots into display manufacturing processes. Techniques such as photolithography and inkjet printing have been adapted to work with quantum dot materials, enabling the production of high-resolution QLED displays at scale. This has been crucial in moving QLED technology from laboratory demonstrations to commercial products.

Looking ahead, the role of nanotechnology in QLED evolution is expected to expand further. Researchers are exploring new quantum dot materials, such as perovskite quantum dots, which promise even better color performance and stability. Additionally, nanotechnology is driving the development of quantum dot-based blue emitters, which could potentially replace the current blue LED backlights used in QLED displays, leading to true self-emissive QLED technology.

The journey of QLED technology began in the early 1990s with the discovery of quantum dots, nanoscale semiconductor particles that exhibit unique optical and electronic properties. These quantum dots, typically ranging from 2 to 10 nanometers in size, can be precisely tuned to emit specific colors of light when excited, making them ideal for display applications. The ability to control the size and composition of quantum dots at the nanoscale has been crucial in achieving the wide color gamut and high color purity that QLED displays are known for.

As research in nanotechnology progressed, so did the understanding and manipulation of quantum dots. The early 2000s saw significant advancements in quantum dot synthesis techniques, allowing for better control over their size distribution and surface properties. This led to improved quantum yield and stability, addressing some of the initial challenges faced by QLED technology.

The primary objective of nanotechnology in QLED evolution has been to enhance the performance and efficiency of these displays. This includes improving color accuracy, increasing brightness, extending device lifespan, and reducing power consumption. Nanotechnology has enabled the development of more efficient quantum dot materials, better encapsulation methods to protect quantum dots from degradation, and novel device architectures that optimize charge injection and light extraction.

One of the key areas where nanotechnology has made a significant impact is in the development of quantum dot synthesis methods. Solution-based processes, such as hot-injection and microfluidic techniques, have been refined to produce highly uniform quantum dots with precise control over their size and composition. These advancements have directly translated to improvements in display performance, allowing for more accurate color reproduction and higher efficiency.

Furthermore, nanotechnology has facilitated the integration of quantum dots into display manufacturing processes. Techniques such as photolithography and inkjet printing have been adapted to work with quantum dot materials, enabling the production of high-resolution QLED displays at scale. This has been crucial in moving QLED technology from laboratory demonstrations to commercial products.

Looking ahead, the role of nanotechnology in QLED evolution is expected to expand further. Researchers are exploring new quantum dot materials, such as perovskite quantum dots, which promise even better color performance and stability. Additionally, nanotechnology is driving the development of quantum dot-based blue emitters, which could potentially replace the current blue LED backlights used in QLED displays, leading to true self-emissive QLED technology.

QLED Market Demand Analysis

The QLED (Quantum Dot Light-Emitting Diode) market has experienced significant growth in recent years, driven by increasing demand for high-quality displays in various consumer electronics and professional applications. As nanotechnology plays a crucial role in QLED evolution, the market demand for these advanced displays continues to expand rapidly.

The consumer electronics sector, particularly the television industry, has been a major driver of QLED market growth. Consumers are increasingly seeking larger screens with higher resolution, improved color accuracy, and enhanced brightness. QLED technology, enabled by nanotechnology advancements, offers superior color gamut, better energy efficiency, and longer lifespan compared to traditional LED displays. This has led to a surge in demand for QLED TVs, with major manufacturers investing heavily in research and development to improve QLED performance and reduce production costs.

Beyond televisions, the QLED market is expanding into other consumer electronics segments, including smartphones, tablets, and laptops. The demand for vibrant, energy-efficient displays in mobile devices is driving the adoption of QLED technology in these products. As manufacturers strive to differentiate their offerings in a competitive market, QLED displays provide a compelling selling point for premium devices.

In the professional and commercial sectors, QLED technology is gaining traction in applications such as digital signage, control room displays, and high-end monitors for creative professionals. The superior color accuracy and brightness of QLED displays make them ideal for these demanding environments, where image quality and reliability are paramount.

The automotive industry represents another growing market for QLED technology. As vehicles become more technologically advanced, there is an increasing demand for high-quality displays for infotainment systems, digital dashboards, and heads-up displays. QLED technology's ability to deliver bright, clear images even in challenging lighting conditions makes it particularly well-suited for automotive applications.

The healthcare sector is also emerging as a potential growth area for QLED displays. Medical imaging equipment, surgical displays, and diagnostic monitors can benefit from the improved color accuracy and contrast offered by QLED technology, potentially leading to more accurate diagnoses and improved patient outcomes.

As nanotechnology continues to advance, enabling further improvements in QLED performance and manufacturing processes, the market demand is expected to grow substantially in the coming years. Industry analysts project strong growth rates for the QLED market, with some estimates suggesting a compound annual growth rate (CAGR) in the double digits over the next five to ten years.

However, challenges remain in terms of production costs and competition from other display technologies such as OLED. The ability of manufacturers to leverage nanotechnology advancements to reduce costs and improve performance will be crucial in determining the long-term market demand for QLED displays across various industries and applications.

The consumer electronics sector, particularly the television industry, has been a major driver of QLED market growth. Consumers are increasingly seeking larger screens with higher resolution, improved color accuracy, and enhanced brightness. QLED technology, enabled by nanotechnology advancements, offers superior color gamut, better energy efficiency, and longer lifespan compared to traditional LED displays. This has led to a surge in demand for QLED TVs, with major manufacturers investing heavily in research and development to improve QLED performance and reduce production costs.

Beyond televisions, the QLED market is expanding into other consumer electronics segments, including smartphones, tablets, and laptops. The demand for vibrant, energy-efficient displays in mobile devices is driving the adoption of QLED technology in these products. As manufacturers strive to differentiate their offerings in a competitive market, QLED displays provide a compelling selling point for premium devices.

In the professional and commercial sectors, QLED technology is gaining traction in applications such as digital signage, control room displays, and high-end monitors for creative professionals. The superior color accuracy and brightness of QLED displays make them ideal for these demanding environments, where image quality and reliability are paramount.

The automotive industry represents another growing market for QLED technology. As vehicles become more technologically advanced, there is an increasing demand for high-quality displays for infotainment systems, digital dashboards, and heads-up displays. QLED technology's ability to deliver bright, clear images even in challenging lighting conditions makes it particularly well-suited for automotive applications.

The healthcare sector is also emerging as a potential growth area for QLED displays. Medical imaging equipment, surgical displays, and diagnostic monitors can benefit from the improved color accuracy and contrast offered by QLED technology, potentially leading to more accurate diagnoses and improved patient outcomes.

As nanotechnology continues to advance, enabling further improvements in QLED performance and manufacturing processes, the market demand is expected to grow substantially in the coming years. Industry analysts project strong growth rates for the QLED market, with some estimates suggesting a compound annual growth rate (CAGR) in the double digits over the next five to ten years.

However, challenges remain in terms of production costs and competition from other display technologies such as OLED. The ability of manufacturers to leverage nanotechnology advancements to reduce costs and improve performance will be crucial in determining the long-term market demand for QLED displays across various industries and applications.

Nanotechnology in QLED: Current Status and Challenges

Nanotechnology has emerged as a pivotal force in the evolution of Quantum Dot Light-Emitting Diode (QLED) technology, revolutionizing display and lighting industries. The current status of nanotechnology in QLED development is characterized by significant advancements, yet it also faces notable challenges that require innovative solutions.

One of the primary areas where nanotechnology has made substantial progress is in the synthesis and optimization of quantum dots. Researchers have successfully developed methods to produce highly uniform and stable quantum dots with precise control over their size, shape, and composition. These advancements have led to improved color purity, enhanced efficiency, and increased longevity of QLED devices.

However, despite these achievements, several challenges persist in the field. One major hurdle is the issue of quantum dot stability. While significant improvements have been made, quantum dots still suffer from degradation over time, particularly when exposed to high temperatures or intense light. This degradation can lead to color shifts and reduced device performance, limiting the long-term reliability of QLED displays.

Another challenge lies in the development of blue quantum dots. While red and green quantum dots have reached a high level of efficiency and stability, blue quantum dots continue to lag behind. The difficulty in producing stable and efficient blue emitters has hindered the overall performance of QLED displays, as blue light is crucial for achieving a full-color spectrum.

The integration of quantum dots into device structures also presents ongoing challenges. Researchers are working on developing more efficient and cost-effective methods for incorporating quantum dots into LED architectures. This includes exploring new deposition techniques and investigating novel materials for charge transport layers that can enhance the overall performance of QLED devices.

Environmental concerns and regulatory requirements pose additional challenges to the widespread adoption of QLED technology. Many quantum dots contain heavy metals, such as cadmium, which are subject to strict regulations in various countries. As a result, there is a growing focus on developing cadmium-free quantum dots that can match or exceed the performance of their cadmium-based counterparts.

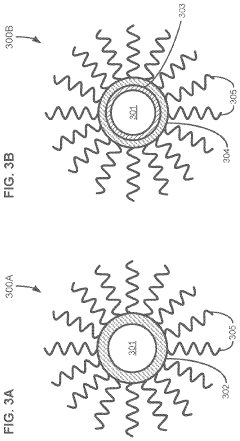

Despite these challenges, the field of nanotechnology in QLED continues to advance rapidly. Researchers are exploring new materials and structures, such as perovskite quantum dots and core-shell nanostructures, to overcome current limitations. Additionally, efforts are being made to improve manufacturing processes, making QLED technology more scalable and cost-effective for mass production.

One of the primary areas where nanotechnology has made substantial progress is in the synthesis and optimization of quantum dots. Researchers have successfully developed methods to produce highly uniform and stable quantum dots with precise control over their size, shape, and composition. These advancements have led to improved color purity, enhanced efficiency, and increased longevity of QLED devices.

However, despite these achievements, several challenges persist in the field. One major hurdle is the issue of quantum dot stability. While significant improvements have been made, quantum dots still suffer from degradation over time, particularly when exposed to high temperatures or intense light. This degradation can lead to color shifts and reduced device performance, limiting the long-term reliability of QLED displays.

Another challenge lies in the development of blue quantum dots. While red and green quantum dots have reached a high level of efficiency and stability, blue quantum dots continue to lag behind. The difficulty in producing stable and efficient blue emitters has hindered the overall performance of QLED displays, as blue light is crucial for achieving a full-color spectrum.

The integration of quantum dots into device structures also presents ongoing challenges. Researchers are working on developing more efficient and cost-effective methods for incorporating quantum dots into LED architectures. This includes exploring new deposition techniques and investigating novel materials for charge transport layers that can enhance the overall performance of QLED devices.

Environmental concerns and regulatory requirements pose additional challenges to the widespread adoption of QLED technology. Many quantum dots contain heavy metals, such as cadmium, which are subject to strict regulations in various countries. As a result, there is a growing focus on developing cadmium-free quantum dots that can match or exceed the performance of their cadmium-based counterparts.

Despite these challenges, the field of nanotechnology in QLED continues to advance rapidly. Researchers are exploring new materials and structures, such as perovskite quantum dots and core-shell nanostructures, to overcome current limitations. Additionally, efforts are being made to improve manufacturing processes, making QLED technology more scalable and cost-effective for mass production.

Current Nanotechnology Solutions in QLED

01 Quantum dot structure improvements

Advancements in quantum dot structures for QLED devices, including core-shell configurations, multi-layered structures, and novel materials to enhance efficiency and color purity. These improvements aim to optimize light emission and reduce energy loss in quantum dot layers.- Quantum dot structure improvements: Advancements in QLED technology focus on enhancing the quantum dot structure. This includes developing new materials, optimizing the size and shape of quantum dots, and improving their stability and efficiency. These improvements lead to better color purity, brightness, and overall performance of QLED displays.

- Light-emitting layer enhancements: Evolution in QLED technology involves improvements in the light-emitting layer. This includes developing new quantum dot compositions, enhancing the electron transport layer, and optimizing the hole transport layer. These advancements result in improved luminescence efficiency, color gamut, and device longevity.

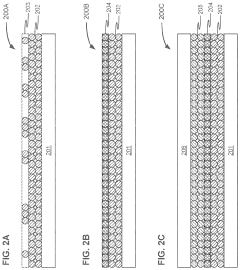

- Manufacturing process innovations: QLED evolution encompasses advancements in manufacturing processes. This includes developing new deposition techniques, improving patterning methods, and enhancing encapsulation technologies. These innovations lead to more efficient production, better uniformity, and increased scalability of QLED displays.

- Integration with other display technologies: QLED technology is evolving through integration with other display technologies. This includes combining quantum dots with OLED, micro-LED, or traditional LCD technologies. These hybrid approaches aim to leverage the strengths of multiple technologies, resulting in displays with improved performance, energy efficiency, and versatility.

- Application-specific QLED developments: The evolution of QLED technology includes developments tailored for specific applications. This involves optimizing QLED displays for use in various devices such as televisions, smartphones, automotive displays, and wearable technology. These application-specific advancements focus on meeting unique requirements like flexibility, durability, or power efficiency for different use cases.

02 QLED device architecture enhancements

Innovations in QLED device architectures, such as improved electron and hole transport layers, novel electrode designs, and optimized quantum dot placement. These enhancements focus on increasing overall device performance, efficiency, and longevity.Expand Specific Solutions03 Color tuning and light management

Techniques for precise color tuning and light management in QLED displays, including methods for achieving wider color gamuts, improved color accuracy, and enhanced brightness control. This involves optimizing quantum dot compositions and implementing advanced optical designs.Expand Specific Solutions04 Manufacturing and scalability improvements

Advancements in QLED manufacturing processes and scalability, including new deposition techniques, patterning methods, and large-scale production strategies. These improvements aim to reduce costs and increase the commercial viability of QLED technology.Expand Specific Solutions05 Integration with other technologies

Exploration of QLED integration with other display and lighting technologies, such as micro-LED, OLED, and traditional LED. This includes hybrid approaches and novel applications that leverage the unique properties of quantum dots in various device configurations.Expand Specific Solutions

Key Players in QLED Nanotechnology

The nanotechnology-driven QLED evolution is in a rapid growth phase, with the market size expanding significantly due to increasing demand for high-quality displays. The technology's maturity is advancing, with key players like BOE Technology Group, Sharp Corp., and TCL China Star Optoelectronics leading innovation. Universities such as Zhejiang University and Hong Kong University of Science & Technology contribute to fundamental research, while companies like Nanosys, Inc. focus on commercialization. The competitive landscape is diverse, featuring established electronics giants, specialized nanotechnology firms, and academic institutions, all striving to enhance QLED performance through nanoscale advancements.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a proprietary QLED technology that utilizes nanotechnology to enhance quantum dot performance. Their approach involves encapsulating quantum dots in a nano-scale protective layer, which improves stability and longevity. This nano-encapsulation technique allows for better control of quantum dot size and distribution, resulting in more precise color reproduction and higher luminance efficiency. BOE's QLED panels also incorporate a nano-structured light management layer that optimizes light extraction and reduces reflection, leading to improved contrast and viewing angles.

Strengths: Enhanced color accuracy, improved stability, and better energy efficiency. Weaknesses: Higher production costs and potential challenges in scaling up production.

Sharp Corp.

Technical Solution: Sharp has developed a novel QLED technology that leverages nanotechnology to create highly efficient and stable quantum dots. Their approach involves using a nano-scale core-shell structure for quantum dots, where the core is surrounded by multiple protective layers at the nanometer scale. This multi-layer nanostructure enhances quantum yield and protects the quantum dots from environmental degradation. Sharp's QLED displays also incorporate a nano-patterned optical film that improves light extraction efficiency and color purity. Additionally, they have developed a nano-composite material for the quantum dot color conversion layer, which allows for better dispersion and thermal management of quantum dots.

Strengths: Excellent color gamut, high brightness, and improved longevity. Weaknesses: Complex manufacturing process and potential for higher costs.

Core Nanotech Innovations for QLED

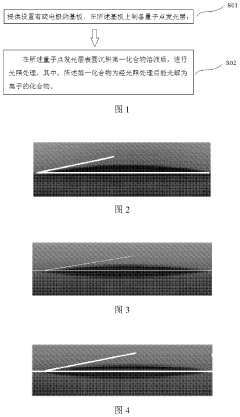

QLED and manufacturing method thereof

PatentActiveUS20220081313A1

Innovation

- A QLED manufacturing method involving the use of a first compound solution that photodegrades into ions under illumination, applied to the quantum dot light emitting layer, which reduces the contact angle and improves the compatibility between layers, enhancing the flatness and luminous efficiency of the QLED.

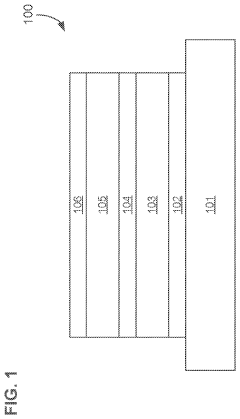

Light-emitting apparatus with improved charge transport layer

PatentPendingUS20240237387A9

Innovation

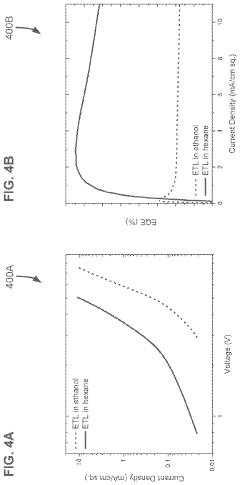

- Incorporating a metal-oxide nanoparticle-based electron transport layer with specific solvent polarity and size characteristics, deposited using solution processes like spin coating or inkjet printing, to improve charge balance and injection efficiency in QLEDs.

Environmental Impact of QLED Nanotechnology

The environmental impact of QLED nanotechnology is a critical consideration as this technology continues to evolve and gain prominence in the display industry. While QLEDs offer significant advantages in terms of energy efficiency and color performance, their production and disposal processes raise important environmental concerns.

One of the primary environmental challenges associated with QLED nanotechnology is the use of heavy metals, particularly cadmium, in the quantum dot materials. Although the amount of cadmium used in each display is minimal, the cumulative effect of widespread adoption could lead to increased environmental contamination if not properly managed. This has prompted research into cadmium-free alternatives, such as indium phosphide-based quantum dots, which show promise in reducing the environmental footprint of QLED production.

The manufacturing process of QLEDs also presents environmental challenges. The synthesis of quantum dots often involves the use of toxic solvents and precursors, which can contribute to air and water pollution if not carefully controlled. Additionally, the high-precision manufacturing techniques required for QLED production can be energy-intensive, potentially offsetting some of the energy savings achieved during the product's use phase.

End-of-life disposal of QLED displays is another area of environmental concern. The complex nature of these devices, combining organic materials, quantum dots, and traditional electronic components, makes recycling challenging. Improper disposal can lead to the release of harmful substances into the environment, including heavy metals and persistent organic pollutants.

However, it's important to note that QLED technology also offers potential environmental benefits. The improved energy efficiency of QLED displays compared to traditional LED and OLED technologies can lead to significant reductions in energy consumption over the product's lifetime. This efficiency gain could translate to lower greenhouse gas emissions associated with powering these devices.

Furthermore, the long lifespan of QLED displays may contribute to a reduction in electronic waste generation. As these displays maintain their performance characteristics for longer periods, consumers may need to replace their devices less frequently, potentially decreasing the overall environmental impact of display production and disposal.

Ongoing research in nanotechnology is focused on developing more environmentally friendly quantum dot materials and production processes. This includes exploring bio-based quantum dots, improving manufacturing efficiency, and designing for easier recycling and material recovery at the end of a product's life cycle.

One of the primary environmental challenges associated with QLED nanotechnology is the use of heavy metals, particularly cadmium, in the quantum dot materials. Although the amount of cadmium used in each display is minimal, the cumulative effect of widespread adoption could lead to increased environmental contamination if not properly managed. This has prompted research into cadmium-free alternatives, such as indium phosphide-based quantum dots, which show promise in reducing the environmental footprint of QLED production.

The manufacturing process of QLEDs also presents environmental challenges. The synthesis of quantum dots often involves the use of toxic solvents and precursors, which can contribute to air and water pollution if not carefully controlled. Additionally, the high-precision manufacturing techniques required for QLED production can be energy-intensive, potentially offsetting some of the energy savings achieved during the product's use phase.

End-of-life disposal of QLED displays is another area of environmental concern. The complex nature of these devices, combining organic materials, quantum dots, and traditional electronic components, makes recycling challenging. Improper disposal can lead to the release of harmful substances into the environment, including heavy metals and persistent organic pollutants.

However, it's important to note that QLED technology also offers potential environmental benefits. The improved energy efficiency of QLED displays compared to traditional LED and OLED technologies can lead to significant reductions in energy consumption over the product's lifetime. This efficiency gain could translate to lower greenhouse gas emissions associated with powering these devices.

Furthermore, the long lifespan of QLED displays may contribute to a reduction in electronic waste generation. As these displays maintain their performance characteristics for longer periods, consumers may need to replace their devices less frequently, potentially decreasing the overall environmental impact of display production and disposal.

Ongoing research in nanotechnology is focused on developing more environmentally friendly quantum dot materials and production processes. This includes exploring bio-based quantum dots, improving manufacturing efficiency, and designing for easier recycling and material recovery at the end of a product's life cycle.

Intellectual Property Landscape in QLED Nanotech

The intellectual property landscape in QLED nanotechnology is characterized by a complex web of patents and proprietary technologies held by various industry players. Major technology companies and research institutions have been actively filing patents related to quantum dot light-emitting diode (QLED) technologies, with a particular focus on nanomaterials and fabrication processes.

Key patent holders in the QLED nanotech space include Samsung, LG, Sony, and Nanosys. These companies have secured numerous patents covering quantum dot synthesis, deposition techniques, and device architectures. Samsung, for instance, holds patents on quantum dot color conversion layers and methods for improving QLED efficiency. LG has patented innovative quantum dot compositions and manufacturing processes for enhanced stability and performance.

The patent landscape also reveals a growing interest in cadmium-free quantum dots, driven by environmental concerns and regulatory pressures. Companies like Nanoco and Nanosys have made significant strides in this area, patenting novel indium phosphide-based quantum dot formulations and associated manufacturing techniques.

Another notable trend in QLED nanotech patents is the focus on improving quantum dot stability and longevity. Patents in this area cover encapsulation methods, surface treatments, and composite materials designed to protect quantum dots from degradation and enhance their operational lifetime in QLED devices.

Fabrication processes for QLED displays have also been a hotbed of patent activity. Companies have sought to protect innovations in quantum dot deposition techniques, including inkjet printing, photolithography, and transfer printing methods. These patents aim to enable more efficient and cost-effective manufacturing of large-scale QLED displays.

The intellectual property landscape extends beyond display technologies, with patents covering QLED applications in lighting, sensors, and photovoltaics. This diversification reflects the broad potential of QLED nanotechnology across multiple industries.

As the QLED market continues to grow, patent disputes and licensing agreements have become increasingly common. Cross-licensing deals between major players have emerged as a strategy to navigate the complex patent landscape and facilitate technology development.

Looking ahead, emerging areas of patent activity in QLED nanotech include quantum dot-enhanced microLED displays, perovskite quantum dots, and advanced quantum dot synthesis techniques. These trends suggest ongoing innovation and competition in the field, with intellectual property playing a crucial role in shaping the future of QLED technology.

Key patent holders in the QLED nanotech space include Samsung, LG, Sony, and Nanosys. These companies have secured numerous patents covering quantum dot synthesis, deposition techniques, and device architectures. Samsung, for instance, holds patents on quantum dot color conversion layers and methods for improving QLED efficiency. LG has patented innovative quantum dot compositions and manufacturing processes for enhanced stability and performance.

The patent landscape also reveals a growing interest in cadmium-free quantum dots, driven by environmental concerns and regulatory pressures. Companies like Nanoco and Nanosys have made significant strides in this area, patenting novel indium phosphide-based quantum dot formulations and associated manufacturing techniques.

Another notable trend in QLED nanotech patents is the focus on improving quantum dot stability and longevity. Patents in this area cover encapsulation methods, surface treatments, and composite materials designed to protect quantum dots from degradation and enhance their operational lifetime in QLED devices.

Fabrication processes for QLED displays have also been a hotbed of patent activity. Companies have sought to protect innovations in quantum dot deposition techniques, including inkjet printing, photolithography, and transfer printing methods. These patents aim to enable more efficient and cost-effective manufacturing of large-scale QLED displays.

The intellectual property landscape extends beyond display technologies, with patents covering QLED applications in lighting, sensors, and photovoltaics. This diversification reflects the broad potential of QLED nanotechnology across multiple industries.

As the QLED market continues to grow, patent disputes and licensing agreements have become increasingly common. Cross-licensing deals between major players have emerged as a strategy to navigate the complex patent landscape and facilitate technology development.

Looking ahead, emerging areas of patent activity in QLED nanotech include quantum dot-enhanced microLED displays, perovskite quantum dots, and advanced quantum dot synthesis techniques. These trends suggest ongoing innovation and competition in the field, with intellectual property playing a crucial role in shaping the future of QLED technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!