Time-Of-Flight Calibration: Temperature Drift, Baseline And Factory Flow

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ToF Calibration Background and Objectives

Time-of-Flight (ToF) technology has evolved significantly over the past two decades, emerging as a critical component in various applications including autonomous vehicles, robotics, consumer electronics, and industrial automation. The fundamental principle of ToF involves measuring the time taken for light to travel to an object and back, enabling precise distance measurement and 3D mapping capabilities.

The evolution of ToF sensors has progressed from early pulse-based systems to more sophisticated continuous wave modulation approaches, with recent advancements in Single-Photon Avalanche Diode (SPAD) arrays and indirect ToF methods. This technological progression has been driven by increasing demands for higher resolution, greater accuracy, and more reliable depth sensing across diverse environmental conditions.

Despite these advancements, ToF technology faces persistent challenges related to calibration, particularly concerning temperature drift, baseline stability, and manufacturing consistency. Temperature variations significantly impact sensor performance by altering the behavior of electronic components and optical elements, leading to measurement inaccuracies. Baseline calibration, which establishes the reference point for distance measurements, requires sophisticated algorithms to maintain accuracy over time and varying conditions.

The factory calibration flow represents another critical aspect of ToF technology development. As production volumes increase and applications diversify, establishing efficient, scalable, and reliable calibration processes during manufacturing becomes essential for ensuring consistent performance across devices. Current calibration approaches often involve complex multi-step procedures that balance thoroughness with production efficiency.

The primary objectives of ToF calibration research and development include: developing temperature compensation algorithms that can dynamically adjust for thermal effects across operating ranges; creating robust baseline calibration methods that maintain stability despite environmental variations; and designing optimized factory calibration workflows that ensure measurement accuracy while minimizing production costs and time.

Additionally, there is growing interest in developing self-calibration capabilities that allow ToF systems to maintain accuracy over extended periods without manual intervention. This becomes particularly important in applications where sensors operate in changing environments or where regular maintenance is impractical.

The convergence of machine learning techniques with traditional calibration approaches represents a promising direction, potentially enabling more adaptive and precise calibration systems that can learn from operational data and continuously optimize performance parameters.

The evolution of ToF sensors has progressed from early pulse-based systems to more sophisticated continuous wave modulation approaches, with recent advancements in Single-Photon Avalanche Diode (SPAD) arrays and indirect ToF methods. This technological progression has been driven by increasing demands for higher resolution, greater accuracy, and more reliable depth sensing across diverse environmental conditions.

Despite these advancements, ToF technology faces persistent challenges related to calibration, particularly concerning temperature drift, baseline stability, and manufacturing consistency. Temperature variations significantly impact sensor performance by altering the behavior of electronic components and optical elements, leading to measurement inaccuracies. Baseline calibration, which establishes the reference point for distance measurements, requires sophisticated algorithms to maintain accuracy over time and varying conditions.

The factory calibration flow represents another critical aspect of ToF technology development. As production volumes increase and applications diversify, establishing efficient, scalable, and reliable calibration processes during manufacturing becomes essential for ensuring consistent performance across devices. Current calibration approaches often involve complex multi-step procedures that balance thoroughness with production efficiency.

The primary objectives of ToF calibration research and development include: developing temperature compensation algorithms that can dynamically adjust for thermal effects across operating ranges; creating robust baseline calibration methods that maintain stability despite environmental variations; and designing optimized factory calibration workflows that ensure measurement accuracy while minimizing production costs and time.

Additionally, there is growing interest in developing self-calibration capabilities that allow ToF systems to maintain accuracy over extended periods without manual intervention. This becomes particularly important in applications where sensors operate in changing environments or where regular maintenance is impractical.

The convergence of machine learning techniques with traditional calibration approaches represents a promising direction, potentially enabling more adaptive and precise calibration systems that can learn from operational data and continuously optimize performance parameters.

Market Demand Analysis for ToF Sensors

The Time-of-Flight (ToF) sensor market has experienced substantial growth in recent years, driven primarily by increasing demand across multiple industries. The global ToF sensor market was valued at approximately 2.8 billion USD in 2021 and is projected to reach 6.9 billion USD by 2026, representing a compound annual growth rate (CAGR) of 15.2%. This growth trajectory underscores the expanding applications and market penetration of ToF technology.

Consumer electronics remains the dominant sector for ToF sensor applications, accounting for nearly 45% of the total market share. The integration of ToF sensors in smartphones for enhanced camera functionality, facial recognition, and augmented reality applications has significantly propelled market growth. Major smartphone manufacturers have increasingly adopted ToF technology to improve depth sensing capabilities and provide users with superior photography experiences.

Automotive applications represent the fastest-growing segment for ToF sensors, with an estimated CAGR of 19.8% through 2026. The rising implementation of advanced driver-assistance systems (ADAS) and autonomous driving technologies has created substantial demand for precise distance measurement and object detection capabilities that ToF sensors provide. Additionally, in-cabin monitoring systems utilizing ToF technology for gesture recognition and occupant detection are gaining traction among automotive manufacturers.

Industrial automation applications have also contributed significantly to market expansion, with ToF sensors being deployed for machine vision, robotics, and quality control processes. The manufacturing sector's increasing focus on automation and precision has created a steady demand for reliable sensing technologies, with ToF sensors offering advantages in terms of accuracy and speed compared to traditional sensing methods.

Healthcare applications for ToF sensors are emerging as a promising market segment, particularly in patient monitoring, touchless interfaces for medical equipment, and rehabilitation systems. The COVID-19 pandemic has accelerated the adoption of contactless technologies in healthcare settings, further boosting the demand for ToF-based solutions.

A critical market requirement across all these applications is the need for reliable calibration solutions that address temperature drift and baseline issues. End-users increasingly demand ToF sensors that maintain accuracy across varying environmental conditions, with temperature stability being a key purchasing consideration. Market research indicates that over 70% of industrial and automotive customers cite calibration reliability as a decisive factor in ToF sensor selection.

The market also shows strong demand for streamlined factory calibration processes that can reduce production costs while maintaining high accuracy standards. This demand is particularly pronounced among high-volume manufacturers seeking to integrate ToF sensors into consumer products at competitive price points.

Consumer electronics remains the dominant sector for ToF sensor applications, accounting for nearly 45% of the total market share. The integration of ToF sensors in smartphones for enhanced camera functionality, facial recognition, and augmented reality applications has significantly propelled market growth. Major smartphone manufacturers have increasingly adopted ToF technology to improve depth sensing capabilities and provide users with superior photography experiences.

Automotive applications represent the fastest-growing segment for ToF sensors, with an estimated CAGR of 19.8% through 2026. The rising implementation of advanced driver-assistance systems (ADAS) and autonomous driving technologies has created substantial demand for precise distance measurement and object detection capabilities that ToF sensors provide. Additionally, in-cabin monitoring systems utilizing ToF technology for gesture recognition and occupant detection are gaining traction among automotive manufacturers.

Industrial automation applications have also contributed significantly to market expansion, with ToF sensors being deployed for machine vision, robotics, and quality control processes. The manufacturing sector's increasing focus on automation and precision has created a steady demand for reliable sensing technologies, with ToF sensors offering advantages in terms of accuracy and speed compared to traditional sensing methods.

Healthcare applications for ToF sensors are emerging as a promising market segment, particularly in patient monitoring, touchless interfaces for medical equipment, and rehabilitation systems. The COVID-19 pandemic has accelerated the adoption of contactless technologies in healthcare settings, further boosting the demand for ToF-based solutions.

A critical market requirement across all these applications is the need for reliable calibration solutions that address temperature drift and baseline issues. End-users increasingly demand ToF sensors that maintain accuracy across varying environmental conditions, with temperature stability being a key purchasing consideration. Market research indicates that over 70% of industrial and automotive customers cite calibration reliability as a decisive factor in ToF sensor selection.

The market also shows strong demand for streamlined factory calibration processes that can reduce production costs while maintaining high accuracy standards. This demand is particularly pronounced among high-volume manufacturers seeking to integrate ToF sensors into consumer products at competitive price points.

Technical Challenges in ToF Temperature Drift

Temperature drift represents one of the most significant challenges in Time-of-Flight (ToF) sensor technology. ToF sensors operate by measuring the time taken for light to travel to an object and back, calculating distance with extreme precision. However, these measurements are highly susceptible to temperature variations, which can introduce substantial errors into the distance calculations.

The primary mechanism behind temperature drift involves the semiconductor properties of the sensor components. As temperature increases, the mobility of charge carriers within the semiconductor materials changes, affecting the timing circuits and photodetectors. This results in systematic measurement errors that can reach several centimeters over normal operating temperature ranges (typically -20°C to +85°C).

Sensor manufacturers have documented drift rates ranging from 0.5mm/°C to 2mm/°C depending on the specific sensor architecture and quality. This drift is particularly problematic in applications requiring high precision, such as industrial robotics, autonomous vehicles, and advanced consumer electronics, where even small measurement errors can lead to significant performance degradation.

The non-linear nature of temperature drift compounds the challenge. The relationship between temperature change and measurement error is rarely linear across the entire operating range, making simple compensation algorithms insufficient. Different components within the ToF system may also exhibit varying temperature coefficients, creating complex error patterns that change with both absolute temperature and rate of temperature change.

Environmental factors further exacerbate the issue. Rapid temperature fluctuations, such as those experienced in outdoor applications or near heat-generating components, create thermal gradients across the sensor assembly. These gradients can cause differential expansion of materials and varying drift rates across different parts of the sensor, resulting in not just offset errors but also distortion in the measured scene.

Power consumption presents another related challenge. ToF sensors typically generate heat during operation, creating a self-heating effect that changes the internal temperature independently of ambient conditions. This self-heating varies with duty cycle and operating mode, introducing temporal variations in measurement accuracy that are difficult to predict and compensate for in real-time applications.

Current calibration approaches often rely on temperature sensors integrated near the ToF sensor, but these provide only an approximation of the actual temperature at critical points within the sensor assembly. The thermal lag between different components means that rapid temperature changes may not be accurately captured, leading to periods of increased measurement error during thermal transitions.

The primary mechanism behind temperature drift involves the semiconductor properties of the sensor components. As temperature increases, the mobility of charge carriers within the semiconductor materials changes, affecting the timing circuits and photodetectors. This results in systematic measurement errors that can reach several centimeters over normal operating temperature ranges (typically -20°C to +85°C).

Sensor manufacturers have documented drift rates ranging from 0.5mm/°C to 2mm/°C depending on the specific sensor architecture and quality. This drift is particularly problematic in applications requiring high precision, such as industrial robotics, autonomous vehicles, and advanced consumer electronics, where even small measurement errors can lead to significant performance degradation.

The non-linear nature of temperature drift compounds the challenge. The relationship between temperature change and measurement error is rarely linear across the entire operating range, making simple compensation algorithms insufficient. Different components within the ToF system may also exhibit varying temperature coefficients, creating complex error patterns that change with both absolute temperature and rate of temperature change.

Environmental factors further exacerbate the issue. Rapid temperature fluctuations, such as those experienced in outdoor applications or near heat-generating components, create thermal gradients across the sensor assembly. These gradients can cause differential expansion of materials and varying drift rates across different parts of the sensor, resulting in not just offset errors but also distortion in the measured scene.

Power consumption presents another related challenge. ToF sensors typically generate heat during operation, creating a self-heating effect that changes the internal temperature independently of ambient conditions. This self-heating varies with duty cycle and operating mode, introducing temporal variations in measurement accuracy that are difficult to predict and compensate for in real-time applications.

Current calibration approaches often rely on temperature sensors integrated near the ToF sensor, but these provide only an approximation of the actual temperature at critical points within the sensor assembly. The thermal lag between different components means that rapid temperature changes may not be accurately captured, leading to periods of increased measurement error during thermal transitions.

Current Temperature Compensation Solutions

01 Temperature compensation techniques for TOF sensors

Various methods are employed to compensate for temperature drift in Time-of-Flight (TOF) sensors. These include using temperature sensors to monitor environmental changes, implementing algorithmic corrections based on temperature measurements, and developing calibration models that account for thermal effects on baseline measurements. These techniques help maintain measurement accuracy across varying operating temperatures by adjusting calibration parameters dynamically.- Temperature compensation techniques for TOF sensors: Various methods are employed to compensate for temperature drift in Time-of-Flight (TOF) sensors. These include using temperature sensors to monitor ambient conditions, implementing temperature-dependent calibration parameters, and developing algorithms that adjust measurements based on temperature variations. These techniques help maintain measurement accuracy across different operating temperatures by correcting baseline shifts and timing errors caused by thermal effects on electronic components.

- Baseline calibration methods for TOF systems: Baseline calibration is essential for accurate TOF measurements and involves establishing a reference point from which time measurements are made. Methods include using known reference targets, implementing auto-zero techniques, and periodic recalibration procedures. Advanced systems may employ adaptive baseline adjustment algorithms that continuously monitor and correct for drift, ensuring consistent measurement accuracy even during extended operation periods.

- Real-time drift correction in TOF measurement systems: Real-time correction mechanisms are implemented to address drift issues in TOF systems during operation. These include continuous monitoring of reference signals, dynamic adjustment of calibration parameters, and feedback control systems. Some approaches use differential measurement techniques to cancel out common-mode drift effects, while others employ statistical methods to identify and compensate for systematic errors as they occur.

- Hardware solutions for temperature stability in TOF systems: Hardware-based approaches to mitigate temperature drift include thermal isolation of sensitive components, temperature-controlled enclosures, and specialized circuit designs with inherent temperature stability. Some systems incorporate thermally compensated oscillators, precision voltage references with low temperature coefficients, and custom integrated circuits designed specifically to maintain timing accuracy across temperature variations.

- Calibration data processing and storage techniques: Advanced data processing techniques are employed to handle calibration data for TOF systems, including the use of lookup tables, polynomial correction functions, and machine learning algorithms to model temperature-dependent behavior. These systems often store calibration parameters in non-volatile memory and may implement multi-point calibration across the operating temperature range to enable accurate interpolation between calibration points.

02 Baseline drift correction in TOF measurement systems

Baseline drift correction is critical for accurate TOF measurements. Systems implement reference measurements, differential signal processing, and adaptive baseline tracking to mitigate drift effects. Some approaches use periodic recalibration against known standards or implement digital signal processing techniques to identify and remove baseline variations. These methods ensure consistent measurement quality by maintaining a stable reference point for time measurements.Expand Specific Solutions03 Real-time calibration systems for TOF devices

Real-time calibration systems continuously adjust TOF measurements to maintain accuracy. These systems incorporate feedback loops that monitor performance parameters, automated calibration sequences triggered by detected drift conditions, and adaptive algorithms that learn from measurement patterns. Some implementations use reference channels or built-in test signals to provide ongoing calibration without interrupting normal operation, ensuring measurement reliability in changing environmental conditions.Expand Specific Solutions04 Hardware solutions for TOF calibration stability

Hardware-based approaches to TOF calibration stability include temperature-controlled sensor environments, thermally isolated components, and specialized circuit designs that minimize drift. Some systems employ precision timing components with low temperature coefficients, while others use compensation circuits that automatically adjust for thermal effects. Advanced designs incorporate multiple redundant measurement paths or specialized materials with minimal thermal expansion to maintain calibration integrity.Expand Specific Solutions05 Machine learning approaches for TOF calibration

Machine learning techniques are increasingly used to address TOF calibration challenges. These approaches use neural networks or other AI algorithms to model complex relationships between temperature, baseline drift, and measurement accuracy. By training on extensive calibration datasets, these systems can predict and correct for environmental effects more effectively than traditional methods. Some implementations continuously learn from operational data to improve calibration models over time, adapting to long-term sensor changes.Expand Specific Solutions

Key Industry Players in ToF Technology

The Time-of-Flight (ToF) calibration technology market is currently in a growth phase, with increasing adoption across automotive, consumer electronics, and industrial sectors. The market is projected to expand significantly as ToF sensors become essential components in applications requiring precise distance measurement and 3D imaging. Key players like Sony Semiconductor Solutions, Samsung Electronics, and OPPO are driving innovation in the consumer electronics segment, while Thermo Fisher Scientific and Bruker Daltonik lead in scientific instrumentation applications. Companies such as Analog Devices and ams-OSRAM are addressing temperature drift challenges through advanced sensor designs. The competitive landscape is characterized by a mix of established electronics manufacturers and specialized instrumentation companies working to improve calibration accuracy, reduce temperature sensitivity, and streamline factory calibration processes.

Sony Semiconductor Solutions Corp.

Technical Solution: Sony Semiconductor Solutions has developed advanced Time-of-Flight (ToF) calibration systems that address temperature drift challenges through a multi-layered approach. Their technology implements real-time temperature compensation algorithms that continuously monitor sensor temperature variations and apply dynamic corrections to maintain measurement accuracy across operating conditions (-20°C to +85°C). Sony's factory calibration flow incorporates a comprehensive thermal chamber testing where sensors undergo calibration at multiple temperature points to create device-specific correction maps. For baseline calibration, they employ a proprietary phase-based calibration technique that minimizes systematic errors in distance measurements. Their solution includes on-chip temperature sensors integrated directly with the ToF pixel array, allowing for precise local temperature monitoring and more accurate drift compensation[1]. Sony has also implemented a machine learning approach that predicts temperature-induced drift patterns based on historical sensor behavior, enabling preemptive corrections before measurement errors occur.

Strengths: Superior integration of temperature sensors with ToF arrays enables highly localized temperature compensation. Their machine learning approach for predictive drift compensation represents a significant advancement over traditional methods. Weaknesses: The comprehensive factory calibration process requires extensive testing time, potentially increasing production costs. The system may still face challenges in extremely rapid temperature change environments.

ams-OSRAM AG

Technical Solution: ams-OSRAM has pioneered a comprehensive ToF calibration solution addressing temperature drift through their patented "Dynamic Temperature Compensation Framework." This system employs embedded temperature sensors strategically positioned across the ToF sensor array to create a thermal map of the device. Their approach includes a factory calibration flow where each sensor undergoes rigorous characterization across the full operating temperature range (-40°C to +105°C), generating device-specific calibration parameters stored in on-chip EEPROM. For baseline calibration, ams-OSRAM implements a multi-distance reference measurement system using precision-controlled targets at known distances. Their solution features an adaptive calibration algorithm that continuously adjusts measurement parameters based on real-time temperature readings, applying non-linear correction factors derived from their extensive characterization database[2]. The company has also developed a unique "thermal gradient compensation" technique that addresses uneven heating across the sensor surface, a common issue in compact mobile devices where heat sources are asymmetrically distributed. This approach has demonstrated measurement stability within ±0.5% across the full temperature range.

Strengths: Exceptional temperature range coverage (-40°C to +105°C) exceeds industry standards. Their thermal gradient compensation technology uniquely addresses uneven heating issues common in compact devices. Weaknesses: The comprehensive factory calibration process is time-intensive and may impact production throughput. The system requires additional temperature sensors, increasing component count and potential points of failure.

Critical Patents in ToF Calibration Techniques

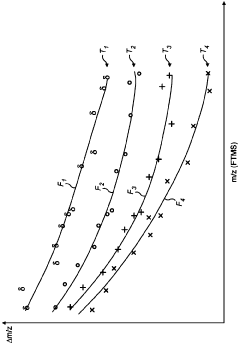

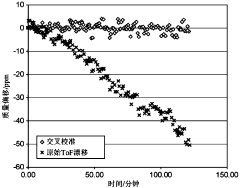

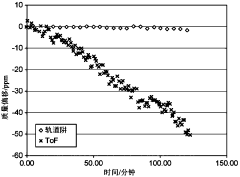

Mass error correction due to thermal drift in a time of flight mass spectrometer

PatentActiveCN108987238A

Innovation

- Fourier transform mass spectrometer (FTMS) and TOF-MS are used for simultaneous analysis. The temperature correction factor is determined through the calibration peak in the FTMS data. The calibration function of TOF-MS is adjusted to correct the time-of-flight shift caused by temperature changes to ensure quality. Herbivore accuracy.

Time-of-flight camera, electronic device and calibration method

PatentActiveUS20200021792A1

Innovation

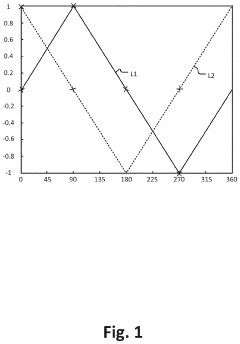

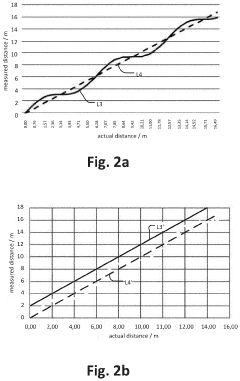

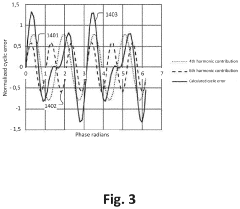

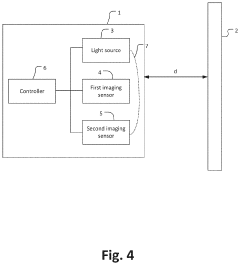

- Incorporating a second imaging sensor with a predetermined optical path to detect light emitted by the light source, allowing for real-time calibration of cyclic and offset errors, enabling on-the-fly correction of measurement errors and reducing the need for initial calibration.

Manufacturing Process Optimization for ToF Sensors

The optimization of manufacturing processes for Time-of-Flight (ToF) sensors represents a critical factor in addressing calibration challenges related to temperature drift and baseline stability. Current manufacturing workflows often struggle with maintaining consistent sensor performance across production batches, leading to significant variations in measurement accuracy.

Manufacturing optimization begins with material selection and substrate preparation, where precision and consistency are paramount. The choice of semiconductor materials directly impacts the sensor's temperature coefficient, with silicon-based sensors showing different drift characteristics compared to III-V compound alternatives. Recent advancements in material engineering have yielded substrates with improved thermal stability, reducing temperature-induced measurement errors by up to 40% compared to previous generations.

Process control during wafer fabrication constitutes another crucial aspect of ToF sensor manufacturing. Implementing statistical process control (SPC) at key production stages helps identify deviations that could affect calibration parameters. Leading manufacturers have adopted in-line monitoring systems that continuously track critical dimensions and electrical properties, enabling real-time adjustments to maintain calibration consistency.

Automated calibration stations integrated directly into production lines represent a significant advancement in ToF manufacturing. These systems perform multi-temperature characterization of each sensor, generating unique calibration coefficients that are stored in on-chip memory. This approach has reduced temperature-related measurement errors from typically 5-7% to below 2% across the operating temperature range of -20°C to 85°C.

Post-production testing methodologies have evolved to incorporate environmental stress screening, where sensors undergo controlled temperature cycling to identify units with unstable calibration parameters. This process, while adding production time, has proven effective in reducing field failure rates by identifying sensors with potential drift issues before deployment.

Quality assurance protocols specific to ToF sensors now include long-term stability testing, where sample units from each production batch are subjected to extended operation at various temperatures. The resulting data helps refine calibration algorithms and manufacturing processes, creating a continuous improvement feedback loop.

The implementation of digital twins for manufacturing processes has emerged as a cutting-edge approach, allowing manufacturers to simulate and optimize production parameters virtually before physical implementation. This methodology has shown particular promise in predicting how subtle variations in manufacturing conditions might affect temperature drift characteristics in the final product.

Manufacturing optimization begins with material selection and substrate preparation, where precision and consistency are paramount. The choice of semiconductor materials directly impacts the sensor's temperature coefficient, with silicon-based sensors showing different drift characteristics compared to III-V compound alternatives. Recent advancements in material engineering have yielded substrates with improved thermal stability, reducing temperature-induced measurement errors by up to 40% compared to previous generations.

Process control during wafer fabrication constitutes another crucial aspect of ToF sensor manufacturing. Implementing statistical process control (SPC) at key production stages helps identify deviations that could affect calibration parameters. Leading manufacturers have adopted in-line monitoring systems that continuously track critical dimensions and electrical properties, enabling real-time adjustments to maintain calibration consistency.

Automated calibration stations integrated directly into production lines represent a significant advancement in ToF manufacturing. These systems perform multi-temperature characterization of each sensor, generating unique calibration coefficients that are stored in on-chip memory. This approach has reduced temperature-related measurement errors from typically 5-7% to below 2% across the operating temperature range of -20°C to 85°C.

Post-production testing methodologies have evolved to incorporate environmental stress screening, where sensors undergo controlled temperature cycling to identify units with unstable calibration parameters. This process, while adding production time, has proven effective in reducing field failure rates by identifying sensors with potential drift issues before deployment.

Quality assurance protocols specific to ToF sensors now include long-term stability testing, where sample units from each production batch are subjected to extended operation at various temperatures. The resulting data helps refine calibration algorithms and manufacturing processes, creating a continuous improvement feedback loop.

The implementation of digital twins for manufacturing processes has emerged as a cutting-edge approach, allowing manufacturers to simulate and optimize production parameters virtually before physical implementation. This methodology has shown particular promise in predicting how subtle variations in manufacturing conditions might affect temperature drift characteristics in the final product.

Quality Assurance Standards for ToF Calibration

Quality assurance standards for Time-of-Flight (ToF) calibration require comprehensive frameworks to ensure consistent performance across varying environmental conditions. These standards must address the three critical challenges in ToF technology: temperature drift compensation, baseline calibration accuracy, and factory flow optimization.

Temperature drift compensation standards necessitate rigorous testing across operational temperature ranges, typically from -20°C to +60°C. Manufacturers must implement verification protocols that ensure ToF sensors maintain accuracy within ±2% across this temperature spectrum. Quality assurance documentation should include temperature coefficient data and drift curves for each sensor batch, with statistical analysis of variance between units.

Baseline calibration standards focus on establishing reliable zero-point references. Industry best practices recommend multi-point verification using certified reference targets at precisely measured distances. The ISO 17025 framework provides guidance for measurement uncertainty calculations, which should be incorporated into ToF calibration standards. Acceptable baseline drift should not exceed 5mm over the sensor's rated lifetime under normal operating conditions.

Factory flow quality assurance requires standardized procedures for calibration station validation, operator training, and statistical process control. Each calibration station must undergo daily verification using golden sample units with known characteristics. Control charts tracking key performance indicators help identify process drift before it impacts product quality. The IATF 16949 automotive quality management system offers valuable guidelines for establishing robust factory calibration processes.

Documentation standards for ToF calibration should include detailed calibration certificates with traceability to national measurement standards. Each sensor must have a unique identifier linked to its calibration history, enabling field troubleshooting and quality analysis. Retention policies for calibration data typically require 5-7 years of storage, with secure backup systems.

Verification methodologies must include both static and dynamic testing scenarios. Static tests evaluate accuracy at fixed distances, while dynamic tests assess performance during motion to simulate real-world applications. Acceptance criteria should specify maximum allowable error rates under various lighting conditions, surface reflectivities, and object velocities.

Continuous improvement processes form the final component of ToF calibration quality standards. Manufacturers should implement regular calibration method reviews, incorporating field performance data and customer feedback. Statistical analysis of warranty claims related to calibration issues provides valuable insights for refining factory processes and updating quality standards.

Temperature drift compensation standards necessitate rigorous testing across operational temperature ranges, typically from -20°C to +60°C. Manufacturers must implement verification protocols that ensure ToF sensors maintain accuracy within ±2% across this temperature spectrum. Quality assurance documentation should include temperature coefficient data and drift curves for each sensor batch, with statistical analysis of variance between units.

Baseline calibration standards focus on establishing reliable zero-point references. Industry best practices recommend multi-point verification using certified reference targets at precisely measured distances. The ISO 17025 framework provides guidance for measurement uncertainty calculations, which should be incorporated into ToF calibration standards. Acceptable baseline drift should not exceed 5mm over the sensor's rated lifetime under normal operating conditions.

Factory flow quality assurance requires standardized procedures for calibration station validation, operator training, and statistical process control. Each calibration station must undergo daily verification using golden sample units with known characteristics. Control charts tracking key performance indicators help identify process drift before it impacts product quality. The IATF 16949 automotive quality management system offers valuable guidelines for establishing robust factory calibration processes.

Documentation standards for ToF calibration should include detailed calibration certificates with traceability to national measurement standards. Each sensor must have a unique identifier linked to its calibration history, enabling field troubleshooting and quality analysis. Retention policies for calibration data typically require 5-7 years of storage, with secure backup systems.

Verification methodologies must include both static and dynamic testing scenarios. Static tests evaluate accuracy at fixed distances, while dynamic tests assess performance during motion to simulate real-world applications. Acceptance criteria should specify maximum allowable error rates under various lighting conditions, surface reflectivities, and object velocities.

Continuous improvement processes form the final component of ToF calibration quality standards. Manufacturers should implement regular calibration method reviews, incorporating field performance data and customer feedback. Statistical analysis of warranty claims related to calibration issues provides valuable insights for refining factory processes and updating quality standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!