Time-Of-Flight Safety And Compliance: Laser Classes, IEC And FDA

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ToF Technology Background and Safety Objectives

Time-of-Flight (ToF) technology has evolved significantly since its inception in the early 1970s, initially developed for military applications such as range finding and target identification. The fundamental principle of ToF involves measuring the time taken for light to travel to an object and back, enabling precise distance calculation. Over the past decade, this technology has transitioned from specialized military use to widespread commercial applications, including autonomous vehicles, robotics, consumer electronics, and industrial automation.

The evolution of ToF technology has been marked by several key milestones. Early systems utilized basic pulse-based methods with limited resolution. The introduction of continuous wave modulation techniques in the 1990s significantly improved accuracy. Recent advancements in semiconductor manufacturing have enabled the miniaturization of ToF sensors, making them suitable for integration into portable devices and expanding their application scope dramatically.

As ToF systems increasingly incorporate laser emitters to achieve greater precision and range, safety considerations have become paramount. These systems must balance performance requirements with strict safety standards to protect users and bystanders from potential eye and skin hazards associated with laser radiation. The primary safety objective is to ensure that ToF systems operate within established safety thresholds while maintaining functional effectiveness.

International safety standards for laser-based systems are primarily governed by two regulatory frameworks: the International Electrotechnical Commission (IEC) standards, particularly IEC 60825, and the U.S. Food and Drug Administration (FDA) regulations. These frameworks classify lasers into distinct categories based on their potential to cause harm, with classifications ranging from Class 1 (safe under all conditions of normal use) to Class 4 (high power lasers requiring stringent safety measures).

For commercial ToF applications, achieving Class 1 or Class 1M certification is typically the target, as these classifications permit operation without additional safety controls in consumer environments. The technical challenge lies in designing systems that maintain measurement accuracy and range while remaining within these lower risk classifications.

Current technical objectives in the field focus on developing ToF systems that automatically adjust laser power based on environmental conditions and usage scenarios, implementing fail-safe mechanisms that prevent accidental exposure to harmful radiation levels, and creating comprehensive testing protocols that verify compliance across all operational modes and conditions.

As the adoption of ToF technology continues to accelerate across industries, establishing clear safety guidelines and compliance frameworks becomes increasingly critical to ensure responsible deployment and public acceptance of these powerful sensing systems.

The evolution of ToF technology has been marked by several key milestones. Early systems utilized basic pulse-based methods with limited resolution. The introduction of continuous wave modulation techniques in the 1990s significantly improved accuracy. Recent advancements in semiconductor manufacturing have enabled the miniaturization of ToF sensors, making them suitable for integration into portable devices and expanding their application scope dramatically.

As ToF systems increasingly incorporate laser emitters to achieve greater precision and range, safety considerations have become paramount. These systems must balance performance requirements with strict safety standards to protect users and bystanders from potential eye and skin hazards associated with laser radiation. The primary safety objective is to ensure that ToF systems operate within established safety thresholds while maintaining functional effectiveness.

International safety standards for laser-based systems are primarily governed by two regulatory frameworks: the International Electrotechnical Commission (IEC) standards, particularly IEC 60825, and the U.S. Food and Drug Administration (FDA) regulations. These frameworks classify lasers into distinct categories based on their potential to cause harm, with classifications ranging from Class 1 (safe under all conditions of normal use) to Class 4 (high power lasers requiring stringent safety measures).

For commercial ToF applications, achieving Class 1 or Class 1M certification is typically the target, as these classifications permit operation without additional safety controls in consumer environments. The technical challenge lies in designing systems that maintain measurement accuracy and range while remaining within these lower risk classifications.

Current technical objectives in the field focus on developing ToF systems that automatically adjust laser power based on environmental conditions and usage scenarios, implementing fail-safe mechanisms that prevent accidental exposure to harmful radiation levels, and creating comprehensive testing protocols that verify compliance across all operational modes and conditions.

As the adoption of ToF technology continues to accelerate across industries, establishing clear safety guidelines and compliance frameworks becomes increasingly critical to ensure responsible deployment and public acceptance of these powerful sensing systems.

Market Demand for Safe ToF Applications

The Time-of-Flight (ToF) sensing market is experiencing robust growth driven by increasing demand for safe, compliant applications across multiple industries. Current market projections indicate the global ToF sensor market will reach approximately $6.9 billion by 2025, growing at a CAGR of around 17% from 2020. This growth is primarily fueled by the expanding adoption of ToF technology in consumer electronics, automotive safety systems, industrial automation, and healthcare applications.

In the consumer electronics sector, smartphone manufacturers are increasingly integrating ToF sensors for enhanced facial recognition, augmented reality experiences, and improved camera functionality. Market research indicates that over 45% of premium smartphones shipped in 2022 incorporated some form of ToF sensing technology, with this percentage expected to increase as manufacturers seek competitive differentiation.

The automotive industry represents another significant market driver, with ToF sensors being deployed in advanced driver-assistance systems (ADAS) and autonomous driving technologies. Safety regulations in major markets including the EU, North America, and Japan are mandating increasingly sophisticated sensing capabilities in vehicles, creating a regulatory push for ToF technology adoption. Industry analysts project that by 2024, approximately 30% of new vehicles will incorporate ToF sensors for various safety applications.

Industrial automation applications are also creating substantial demand for safety-compliant ToF systems. Manufacturing facilities are implementing ToF sensors for precise object detection, worker safety monitoring, and quality control processes. The market for industrial ToF applications is expected to grow at 20% annually through 2025, driven by Industry 4.0 initiatives and workplace safety regulations.

Healthcare applications represent an emerging but rapidly growing segment, with ToF technology being utilized in patient monitoring, touchless interfaces in sterile environments, and rehabilitation systems. The COVID-19 pandemic has accelerated adoption of contactless technologies in healthcare settings, with the healthcare ToF market segment projected to double in size between 2021 and 2025.

A critical market requirement across all these sectors is compliance with international safety standards, particularly regarding laser emissions. End-users increasingly demand Class 1 laser-based ToF solutions that eliminate the need for special safety measures while maintaining performance. This has created a competitive advantage for manufacturers who can deliver high-performance ToF systems that meet the most stringent IEC and FDA safety classifications, particularly in consumer and healthcare applications where user exposure is common.

In the consumer electronics sector, smartphone manufacturers are increasingly integrating ToF sensors for enhanced facial recognition, augmented reality experiences, and improved camera functionality. Market research indicates that over 45% of premium smartphones shipped in 2022 incorporated some form of ToF sensing technology, with this percentage expected to increase as manufacturers seek competitive differentiation.

The automotive industry represents another significant market driver, with ToF sensors being deployed in advanced driver-assistance systems (ADAS) and autonomous driving technologies. Safety regulations in major markets including the EU, North America, and Japan are mandating increasingly sophisticated sensing capabilities in vehicles, creating a regulatory push for ToF technology adoption. Industry analysts project that by 2024, approximately 30% of new vehicles will incorporate ToF sensors for various safety applications.

Industrial automation applications are also creating substantial demand for safety-compliant ToF systems. Manufacturing facilities are implementing ToF sensors for precise object detection, worker safety monitoring, and quality control processes. The market for industrial ToF applications is expected to grow at 20% annually through 2025, driven by Industry 4.0 initiatives and workplace safety regulations.

Healthcare applications represent an emerging but rapidly growing segment, with ToF technology being utilized in patient monitoring, touchless interfaces in sterile environments, and rehabilitation systems. The COVID-19 pandemic has accelerated adoption of contactless technologies in healthcare settings, with the healthcare ToF market segment projected to double in size between 2021 and 2025.

A critical market requirement across all these sectors is compliance with international safety standards, particularly regarding laser emissions. End-users increasingly demand Class 1 laser-based ToF solutions that eliminate the need for special safety measures while maintaining performance. This has created a competitive advantage for manufacturers who can deliver high-performance ToF systems that meet the most stringent IEC and FDA safety classifications, particularly in consumer and healthcare applications where user exposure is common.

Current Regulatory Landscape and Technical Challenges

The Time-of-Flight (ToF) technology landscape is currently governed by a complex web of international and regional regulatory frameworks. The International Electrotechnical Commission (IEC) has established the IEC 60825 standard series, which serves as the global benchmark for laser product safety. This standard classifies lasers into seven categories (1, 1M, 1C, 2, 2M, 3R, 3B, and 4) based on their potential to cause harm to eyes and skin. For ToF applications, most systems utilize Class 1 or Class 2 lasers to ensure safety in consumer and commercial environments.

In the United States, the Food and Drug Administration (FDA) regulates laser products through the Center for Devices and Radiological Health (CDRH), implementing standards based on the Federal Laser Product Performance Standard (FLPPS) in 21 CFR 1040.10 and 1040.11. While largely harmonized with IEC standards, the FDA maintains some distinct requirements, creating compliance challenges for global manufacturers who must navigate both frameworks simultaneously.

The European Union enforces laser safety through the EN 60825-1 standard, which is derived from IEC 60825 but includes region-specific modifications. Additionally, ToF systems must comply with broader regulatory frameworks such as CE marking requirements and the Radio Equipment Directive (RED) when integrated with wireless capabilities.

Technical challenges in regulatory compliance center around several key areas. First, the miniaturization trend in ToF sensors creates difficulties in implementing adequate safety features while maintaining compact form factors. Engineers must design sophisticated power monitoring circuits and automatic shut-off mechanisms that fit within increasingly smaller devices.

Second, the dynamic nature of ToF applications, particularly in automotive LIDAR and mobile devices, presents challenges in maintaining compliance across varying operational conditions. Systems must adapt laser output based on environmental factors while ensuring they never exceed safety thresholds.

Third, the integration of ToF technology into consumer products introduces the challenge of "reasonably foreseeable misuse" considerations. Manufacturers must anticipate potential misuse scenarios and implement safeguards accordingly, which often requires complex sensing and control systems.

Fourth, the regulatory landscape itself presents a moving target. Standards are periodically updated to address emerging technologies and applications, requiring manufacturers to maintain vigilance and adaptability in their compliance strategies. The recent updates to IEC 60825-1 (Edition 3.0) introduced new considerations for pulsed lasers commonly used in ToF systems.

Finally, testing and certification procedures for ToF systems present significant technical hurdles. Accurate measurement of ultrashort laser pulses typical in ToF applications requires specialized equipment and expertise, while the validation of safety systems under all operating conditions demands extensive testing protocols.

In the United States, the Food and Drug Administration (FDA) regulates laser products through the Center for Devices and Radiological Health (CDRH), implementing standards based on the Federal Laser Product Performance Standard (FLPPS) in 21 CFR 1040.10 and 1040.11. While largely harmonized with IEC standards, the FDA maintains some distinct requirements, creating compliance challenges for global manufacturers who must navigate both frameworks simultaneously.

The European Union enforces laser safety through the EN 60825-1 standard, which is derived from IEC 60825 but includes region-specific modifications. Additionally, ToF systems must comply with broader regulatory frameworks such as CE marking requirements and the Radio Equipment Directive (RED) when integrated with wireless capabilities.

Technical challenges in regulatory compliance center around several key areas. First, the miniaturization trend in ToF sensors creates difficulties in implementing adequate safety features while maintaining compact form factors. Engineers must design sophisticated power monitoring circuits and automatic shut-off mechanisms that fit within increasingly smaller devices.

Second, the dynamic nature of ToF applications, particularly in automotive LIDAR and mobile devices, presents challenges in maintaining compliance across varying operational conditions. Systems must adapt laser output based on environmental factors while ensuring they never exceed safety thresholds.

Third, the integration of ToF technology into consumer products introduces the challenge of "reasonably foreseeable misuse" considerations. Manufacturers must anticipate potential misuse scenarios and implement safeguards accordingly, which often requires complex sensing and control systems.

Fourth, the regulatory landscape itself presents a moving target. Standards are periodically updated to address emerging technologies and applications, requiring manufacturers to maintain vigilance and adaptability in their compliance strategies. The recent updates to IEC 60825-1 (Edition 3.0) introduced new considerations for pulsed lasers commonly used in ToF systems.

Finally, testing and certification procedures for ToF systems present significant technical hurdles. Accurate measurement of ultrashort laser pulses typical in ToF applications requires specialized equipment and expertise, while the validation of safety systems under all operating conditions demands extensive testing protocols.

Existing ToF Safety Compliance Solutions

01 Safety standards and compliance for ToF systems

Time-of-Flight technology implementations must adhere to specific safety standards and regulatory compliance requirements. These include eye safety considerations for laser-based ToF systems, electromagnetic compatibility standards, and certification requirements across different jurisdictions. Compliance frameworks ensure that ToF devices operate within safe emission levels and meet international safety protocols, particularly important in consumer electronics and automotive applications.- Safety standards and compliance for Time-of-Flight systems: Time-of-Flight technology implementations must adhere to specific safety standards and regulatory compliance frameworks. These include radiation safety limits, electromagnetic compatibility requirements, and industry-specific certifications. Compliance with these standards ensures that ToF systems operate safely in various environments without causing harm to users or interference with other electronic systems. Regulatory bodies have established guidelines for manufacturers to follow during development and deployment of ToF-based products.

- Eye safety considerations in ToF sensor deployment: Time-of-Flight sensors often utilize infrared lasers or LEDs that must be carefully designed to ensure eye safety. Manufacturers implement power limitations, beam divergence techniques, and automatic shutdown mechanisms to prevent potential eye damage from prolonged exposure. These safety features are particularly important in consumer applications where users may be in close proximity to the sensors. The design must balance performance requirements with strict adherence to international eye safety standards for optical radiation.

- Security and privacy compliance for ToF data: Time-of-Flight systems capture spatial and sometimes biometric data that requires proper security and privacy protection measures. Implementations must include data encryption, secure storage protocols, and user consent mechanisms to comply with privacy regulations such as GDPR and CCPA. The processing of depth information, especially in applications involving facial recognition or body tracking, necessitates robust security frameworks to prevent unauthorized access and protect sensitive personal information.

- Automotive safety applications of ToF technology: Time-of-Flight sensors are increasingly deployed in automotive safety systems, requiring compliance with specific vehicle safety standards. These applications include obstacle detection, pedestrian recognition, and driver monitoring systems that enhance vehicle safety. The technology must meet stringent reliability requirements, function under diverse environmental conditions, and integrate with existing vehicle safety systems. Certification processes ensure that ToF-based automotive systems perform consistently in critical safety scenarios.

- Industrial safety implementations using ToF sensors: In industrial environments, Time-of-Flight technology is utilized for machine safety, worker protection, and hazardous area monitoring. These implementations must comply with industrial safety standards and often require intrinsic safety certifications for use in potentially explosive atmospheres. ToF sensors enable precise distance measurement and object detection for collision avoidance in automated systems and robotics. The technology provides real-time monitoring capabilities that help prevent workplace accidents and ensure compliance with occupational safety regulations.

02 Automotive ToF safety applications

Time-of-Flight technology is extensively used in automotive safety systems, providing critical distance measurement capabilities for collision avoidance, autonomous driving, and driver assistance features. These systems incorporate fail-safe mechanisms, redundancy protocols, and real-time monitoring to ensure reliable operation under various environmental conditions. The technology enables precise object detection and classification, contributing to overall vehicle safety compliance with transportation regulations.Expand Specific Solutions03 Security and privacy compliance for ToF data

Time-of-Flight systems collect spatial and sometimes biometric data, raising important security and privacy considerations. Implementations must include data protection measures, encryption protocols, and compliance with privacy regulations such as GDPR. These systems often incorporate anonymization techniques for collected data, secure storage mechanisms, and controlled access to sensitive information, particularly in applications involving human monitoring or identification.Expand Specific Solutions04 Industrial safety applications of ToF technology

In industrial environments, Time-of-Flight technology provides critical safety functions including human-machine interaction boundaries, hazardous area monitoring, and emergency detection systems. These implementations must comply with industrial safety standards, workplace regulations, and machine safety directives. The technology enables precise distance measurement for safety zones, personnel detection, and automated emergency responses in manufacturing and processing facilities.Expand Specific Solutions05 Medical and healthcare ToF compliance

Time-of-Flight technology in medical and healthcare applications faces stringent regulatory requirements for patient safety, data accuracy, and clinical validation. These systems must comply with medical device regulations, biocompatibility standards, and healthcare data protection laws. Applications include non-invasive monitoring, patient positioning systems, and diagnostic imaging tools, all requiring specific certifications and safety validations before clinical deployment.Expand Specific Solutions

Key Industry Players in ToF Technology

Time-of-Flight (ToF) safety and compliance is evolving in a rapidly growing market, with increasing adoption across automotive, consumer electronics, and industrial sectors. The market is in a growth phase, expected to reach significant scale as ToF technology becomes essential for depth sensing applications. Technologically, the field is maturing with companies at different development stages. Industry leaders like Sony Semiconductor Solutions, ams-OSRAM, and Infineon Technologies have established mature laser safety protocols compliant with IEC and FDA standards. Meanwhile, emerging players such as RoboSense, Hesai Technology, and MicroVision are advancing innovative approaches to balance performance with safety requirements. Mobile technology companies including OPPO and Google are integrating ToF sensors into consumer devices while ensuring compliance with Class 1 laser safety standards essential for consumer applications.

Guangdong OPPO Mobile Telecommunications Corp., Ltd.

Technical Solution: OPPO has developed sophisticated ToF camera systems for mobile devices with comprehensive safety compliance features. Their approach focuses on miniaturized ToF modules that maintain Class 1 laser safety classification according to IEC 60825-1 standards while delivering high-precision depth sensing capabilities. OPPO's technology implements multiple safety mechanisms, including hardware-level current limiting circuits, temperature compensation systems, and proprietary firmware that continuously monitors laser emission parameters. Their mobile ToF sensors incorporate specialized optical designs that distribute laser energy across wider fields of view, reducing point energy density while maintaining measurement accuracy. OPPO has established rigorous testing protocols that verify compliance with both IEC international standards and FDA requirements, enabling global deployment of their devices. Their latest generation ToF systems feature dynamic power adjustment capabilities that optimize performance based on ambient conditions while ensuring operation remains within Class 1 safety limits. OPPO's compliance strategy includes comprehensive documentation and certification processes, with particular attention to consumer device safety requirements that often exceed minimum regulatory standards. Their integrated approach addresses both normal operation and potential fault conditions, with redundant safety mechanisms that can disable laser emission if any abnormal behavior is detected.

Strengths: OPPO's solutions are highly optimized for mobile device integration, with extremely compact form factors that maintain safety compliance. Their systems benefit from the company's extensive experience with global consumer electronics regulations and certification processes. Weaknesses: The miniaturized form factor and strict power limitations for consumer devices may restrict maximum range and precision compared to larger industrial systems, and the focus on consumer applications may limit suitability for more demanding industrial environments.

MicroVision, Inc.

Technical Solution: MicroVision has pioneered laser beam scanning (LBS) technology for ToF applications with a strong focus on safety compliance. Their MAVIN LiDAR system utilizes a sophisticated Class 1 laser safety architecture that incorporates multiple redundant safety monitoring circuits to ensure compliance with IEC 60825-1:2014 standards. The system employs a proprietary Automatic Power Control (APC) mechanism that continuously monitors and adjusts laser output power to maintain eye-safe operation across varying temperatures and conditions. MicroVision's approach includes frequency modulation techniques that distribute laser energy across multiple wavelengths, reducing peak power while maintaining detection range and accuracy. Their compliance strategy encompasses both IEC international standards and FDA requirements under 21 CFR 1040.10, with comprehensive testing protocols that verify performance under normal operation and fault conditions. MicroVision has implemented a "safety first" design philosophy where their systems include hardware-level safety interlocks that can disable laser emission within microseconds if any anomalous behavior is detected, ensuring that even in failure modes, the system remains within Class 1 laser safety parameters.

Strengths: MicroVision's technology achieves high performance while maintaining strict safety compliance through innovative beam scanning and power control methods. Their systems feature multiple redundant safety mechanisms and have successfully obtained both IEC certification and FDA clearance. Weaknesses: The sophisticated safety architecture increases component count and system complexity, potentially affecting reliability in harsh environments. The power limitations necessary for maintaining Class 1 compliance may restrict maximum operational range compared to higher-powered systems.

Critical Laser Classification Systems Analysis

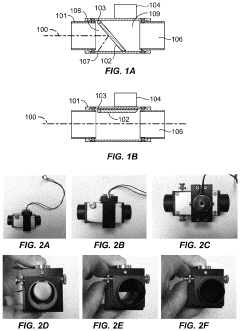

Fail safe beam shutter devices and systems

PatentActiveUS12007552B2

Innovation

- The development of electromagnetic radiation beam shutter apparatuses with a 'trap-door' design, where a shutter is held open by an electromagnet and automatically falls into a closed position upon loss of power, using a ferromagnetic material and pivotally attached to the housing, ensuring fail-safe closure and preventing accidental exposure.

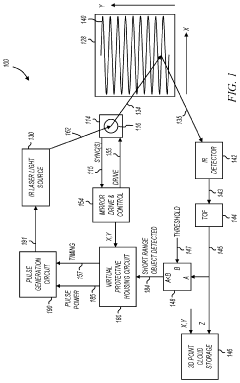

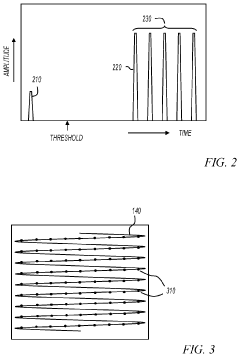

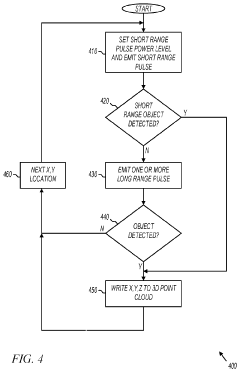

Eye-safe scanning lidar with virtual protective housing

PatentActiveUS12019188B2

Innovation

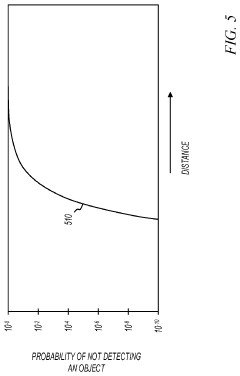

- The implementation of a virtual protective housing system that dynamically manages emission levels by emitting short range pulses to ensure eye safety at close distances and switching to long range pulses when necessary, using a combination of pulse generation, time-of-flight measurement, and comparator circuits to adjust pulse energy and timing based on detected objects and thresholds.

International Harmonization of Safety Standards

The global landscape of laser safety standards has evolved significantly over the past decades, with major regulatory bodies working towards harmonization of requirements across different regions. The International Electrotechnical Commission (IEC) and the U.S. Food and Drug Administration (FDA) represent two of the most influential organizations in establishing safety standards for Time-of-Flight (ToF) and other laser-based technologies.

The IEC, through its standard IEC 60825, has established a framework that has become the foundation for laser safety regulations worldwide. This standard classifies lasers into distinct categories (Classes 1, 1M, 2, 2M, 3R, 3B, and 4) based on their potential to cause harm, with Class 1 being the safest and Class 4 presenting significant hazards. Many countries have adopted these classifications directly into their national regulations.

The FDA's Center for Devices and Radiological Health (CDRH) maintains its own regulatory framework through 21 CFR 1040.10 and 1040.11. Historically, these regulations differed from IEC standards in several aspects, creating compliance challenges for manufacturers targeting global markets. However, the FDA's Laser Notice No. 50 (LN50) has been instrumental in aligning U.S. requirements more closely with international standards.

Recent developments have shown significant progress in harmonization efforts. The 2019 update to LN50 further reduced discrepancies between FDA and IEC requirements, particularly regarding risk assessment methodologies and acceptable exposure limits. This convergence has simplified the certification process for ToF system manufacturers, reducing the need for market-specific design modifications.

The European Union's incorporation of IEC standards through the EN 60825 series has created a consistent regulatory environment across Europe. Similarly, Asian markets including Japan, South Korea, and China have increasingly aligned their national standards with IEC frameworks, though certain region-specific requirements remain in place.

Despite progress, challenges to complete harmonization persist. Different implementation timelines for updated standards, varying enforcement mechanisms, and country-specific documentation requirements continue to create compliance complexities. Additionally, emerging applications of ToF technology in autonomous vehicles, robotics, and consumer electronics have prompted regulatory bodies to consider specialized provisions that may temporarily diverge before new harmonized approaches are established.

For manufacturers of ToF systems, navigating this evolving landscape requires maintaining awareness of both harmonized requirements and regional variations. Establishing compliance strategies that address the most stringent requirements across target markets often provides the most efficient path to global market access.

The IEC, through its standard IEC 60825, has established a framework that has become the foundation for laser safety regulations worldwide. This standard classifies lasers into distinct categories (Classes 1, 1M, 2, 2M, 3R, 3B, and 4) based on their potential to cause harm, with Class 1 being the safest and Class 4 presenting significant hazards. Many countries have adopted these classifications directly into their national regulations.

The FDA's Center for Devices and Radiological Health (CDRH) maintains its own regulatory framework through 21 CFR 1040.10 and 1040.11. Historically, these regulations differed from IEC standards in several aspects, creating compliance challenges for manufacturers targeting global markets. However, the FDA's Laser Notice No. 50 (LN50) has been instrumental in aligning U.S. requirements more closely with international standards.

Recent developments have shown significant progress in harmonization efforts. The 2019 update to LN50 further reduced discrepancies between FDA and IEC requirements, particularly regarding risk assessment methodologies and acceptable exposure limits. This convergence has simplified the certification process for ToF system manufacturers, reducing the need for market-specific design modifications.

The European Union's incorporation of IEC standards through the EN 60825 series has created a consistent regulatory environment across Europe. Similarly, Asian markets including Japan, South Korea, and China have increasingly aligned their national standards with IEC frameworks, though certain region-specific requirements remain in place.

Despite progress, challenges to complete harmonization persist. Different implementation timelines for updated standards, varying enforcement mechanisms, and country-specific documentation requirements continue to create compliance complexities. Additionally, emerging applications of ToF technology in autonomous vehicles, robotics, and consumer electronics have prompted regulatory bodies to consider specialized provisions that may temporarily diverge before new harmonized approaches are established.

For manufacturers of ToF systems, navigating this evolving landscape requires maintaining awareness of both harmonized requirements and regional variations. Establishing compliance strategies that address the most stringent requirements across target markets often provides the most efficient path to global market access.

Risk Assessment Methodologies for ToF Systems

Risk assessment for Time-of-Flight (ToF) systems requires structured methodologies to ensure compliance with laser safety standards established by the International Electrotechnical Commission (IEC) and the Food and Drug Administration (FDA). These methodologies typically begin with hazard identification, where potential risks associated with laser emissions from ToF sensors are systematically cataloged based on wavelength, power output, and exposure scenarios.

Quantitative risk assessment follows, employing mathematical models to calculate Maximum Permissible Exposure (MPE) limits for different user scenarios. This involves determining Accessible Emission Limits (AELs) and comparing them against established thresholds for various laser classifications. For ToF systems, which commonly utilize Class 1 or Class 1M lasers, calculations must account for factors such as beam divergence, pulse characteristics, and potential for ocular focusing.

Failure Mode and Effects Analysis (FMEA) represents another critical methodology, examining potential failure points within ToF systems that could lead to increased laser emission or compromised safety features. This includes evaluation of control circuit malfunctions, optical component degradation, and environmental factors that might affect beam characteristics over the product lifecycle.

Scenario-based risk assessment complements these approaches by modeling real-world usage patterns. For ToF systems in consumer electronics, this might include analyzing risks during normal operation, maintenance, and foreseeable misuse scenarios. Special attention is given to vulnerable populations such as children or individuals with photosensitivity conditions.

Temporal risk factors must also be evaluated, particularly for pulsed ToF systems where peak power may significantly exceed average power. The IEC 60825 standard provides specific methodologies for calculating exposure limits based on pulse duration, repetition rate, and viewing conditions, all of which must be incorporated into comprehensive risk assessments.

Verification and validation protocols form the final component of ToF risk assessment methodologies. These include physical testing under controlled conditions, computational modeling to predict beam behavior in various environments, and documentation procedures that demonstrate compliance with relevant standards. Third-party certification often serves as an additional layer of verification, particularly for consumer products entering regulated markets.

Quantitative risk assessment follows, employing mathematical models to calculate Maximum Permissible Exposure (MPE) limits for different user scenarios. This involves determining Accessible Emission Limits (AELs) and comparing them against established thresholds for various laser classifications. For ToF systems, which commonly utilize Class 1 or Class 1M lasers, calculations must account for factors such as beam divergence, pulse characteristics, and potential for ocular focusing.

Failure Mode and Effects Analysis (FMEA) represents another critical methodology, examining potential failure points within ToF systems that could lead to increased laser emission or compromised safety features. This includes evaluation of control circuit malfunctions, optical component degradation, and environmental factors that might affect beam characteristics over the product lifecycle.

Scenario-based risk assessment complements these approaches by modeling real-world usage patterns. For ToF systems in consumer electronics, this might include analyzing risks during normal operation, maintenance, and foreseeable misuse scenarios. Special attention is given to vulnerable populations such as children or individuals with photosensitivity conditions.

Temporal risk factors must also be evaluated, particularly for pulsed ToF systems where peak power may significantly exceed average power. The IEC 60825 standard provides specific methodologies for calculating exposure limits based on pulse duration, repetition rate, and viewing conditions, all of which must be incorporated into comprehensive risk assessments.

Verification and validation protocols form the final component of ToF risk assessment methodologies. These include physical testing under controlled conditions, computational modeling to predict beam behavior in various environments, and documentation procedures that demonstrate compliance with relevant standards. Third-party certification often serves as an additional layer of verification, particularly for consumer products entering regulated markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!