Time-Of-Flight Materials And Surfaces: Dark/Glossy Targets And Errors

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TOF Sensing Technology Background and Objectives

Time-of-Flight (ToF) sensing technology has evolved significantly over the past three decades, transforming from laboratory experiments to mainstream commercial applications. Initially developed for scientific measurements in the 1980s, ToF technology gained momentum in the early 2000s with the introduction of solid-state sensors capable of measuring the time taken for light to travel to an object and back. This principle enables accurate distance measurement and 3D mapping of environments, making it invaluable across multiple industries.

The evolution of ToF technology has been marked by continuous improvements in sensor resolution, accuracy, and miniaturization. Early systems utilized bulky equipment with limited resolution, while modern ToF sensors can be integrated into compact devices with millimeter-level precision. This progression has been driven by advancements in complementary metal-oxide-semiconductor (CMOS) technology, which has enabled the development of highly integrated, power-efficient ToF sensor arrays.

Current market trends indicate a growing demand for ToF technology in consumer electronics, automotive systems, industrial automation, and healthcare applications. The integration of ToF sensors in smartphones for enhanced photography, facial recognition, and augmented reality experiences represents a significant market driver. Similarly, the automotive industry's push toward autonomous driving has accelerated the development of high-performance ToF systems for obstacle detection and navigation.

Despite these advancements, ToF technology faces significant challenges when dealing with certain materials and surface properties. Dark objects absorb a substantial portion of the emitted light, resulting in weak return signals and measurement inaccuracies. Conversely, glossy or highly reflective surfaces can cause specular reflections, leading to false readings or "hot pixels" in the sensor data. These material-dependent errors represent a critical limitation in ToF technology's universal applicability.

The primary objective of current ToF research is to overcome these material-related challenges through both hardware and software innovations. Hardware approaches focus on increasing light source power, improving sensor sensitivity, and developing multi-spectral illumination systems. Software solutions include advanced signal processing algorithms, machine learning techniques for error compensation, and fusion with complementary sensing modalities such as structured light or stereo vision.

Looking forward, the technology roadmap for ToF sensing aims to achieve robust performance across all material types and surface conditions, enabling truly universal 3D sensing capabilities. This goal aligns with broader industry trends toward more intelligent, context-aware systems that can perceive and interact with their physical environment with human-like or superior perception abilities.

The evolution of ToF technology has been marked by continuous improvements in sensor resolution, accuracy, and miniaturization. Early systems utilized bulky equipment with limited resolution, while modern ToF sensors can be integrated into compact devices with millimeter-level precision. This progression has been driven by advancements in complementary metal-oxide-semiconductor (CMOS) technology, which has enabled the development of highly integrated, power-efficient ToF sensor arrays.

Current market trends indicate a growing demand for ToF technology in consumer electronics, automotive systems, industrial automation, and healthcare applications. The integration of ToF sensors in smartphones for enhanced photography, facial recognition, and augmented reality experiences represents a significant market driver. Similarly, the automotive industry's push toward autonomous driving has accelerated the development of high-performance ToF systems for obstacle detection and navigation.

Despite these advancements, ToF technology faces significant challenges when dealing with certain materials and surface properties. Dark objects absorb a substantial portion of the emitted light, resulting in weak return signals and measurement inaccuracies. Conversely, glossy or highly reflective surfaces can cause specular reflections, leading to false readings or "hot pixels" in the sensor data. These material-dependent errors represent a critical limitation in ToF technology's universal applicability.

The primary objective of current ToF research is to overcome these material-related challenges through both hardware and software innovations. Hardware approaches focus on increasing light source power, improving sensor sensitivity, and developing multi-spectral illumination systems. Software solutions include advanced signal processing algorithms, machine learning techniques for error compensation, and fusion with complementary sensing modalities such as structured light or stereo vision.

Looking forward, the technology roadmap for ToF sensing aims to achieve robust performance across all material types and surface conditions, enabling truly universal 3D sensing capabilities. This goal aligns with broader industry trends toward more intelligent, context-aware systems that can perceive and interact with their physical environment with human-like or superior perception abilities.

Market Applications and Demand Analysis for TOF Sensors

The Time-of-Flight (ToF) sensor market has experienced significant growth in recent years, driven by increasing demand across multiple industries. The global ToF sensor market was valued at approximately $2.8 billion in 2021 and is projected to reach $6.9 billion by 2026, representing a compound annual growth rate of 19.8%. This growth trajectory is primarily fueled by the expanding applications in consumer electronics, automotive systems, industrial automation, and healthcare sectors.

In the consumer electronics segment, ToF sensors have become integral components in smartphones for enhanced facial recognition, augmented reality applications, and improved camera autofocus capabilities. Major smartphone manufacturers have incorporated ToF technology to enable more immersive user experiences and advanced photography features. The gaming industry has also embraced ToF sensors for motion tracking and gesture recognition, creating more interactive gaming environments.

The automotive sector represents another significant market for ToF sensors, particularly with the advancement of advanced driver-assistance systems (ADAS) and autonomous vehicles. ToF sensors provide crucial depth perception capabilities for obstacle detection, pedestrian recognition, and parking assistance. As vehicle automation levels increase, the demand for more sophisticated ToF sensors capable of handling various environmental conditions, including challenging surfaces like dark or glossy objects, continues to rise.

Industrial automation applications utilize ToF sensors for precise object detection, robotic guidance, and quality control processes. The ability to accurately measure distances and create detailed 3D maps of environments has made ToF technology invaluable in manufacturing settings. However, industrial environments often present challenging surfaces, including dark, reflective, or irregularly shaped objects, which can cause measurement errors and require specialized ToF solutions.

Healthcare and medical applications represent an emerging market for ToF sensors, with applications in patient monitoring, touchless interfaces in surgical environments, and rehabilitation therapy. The non-contact nature of ToF sensing makes it particularly valuable in healthcare settings where hygiene is paramount.

Despite the growing market demand, ToF technology faces challenges when dealing with certain materials and surfaces. Dark objects that absorb infrared light and highly reflective or glossy surfaces that cause specular reflections can significantly reduce measurement accuracy. These technical limitations have created market opportunities for companies developing advanced ToF sensors with improved performance on problematic surfaces.

The market is witnessing increased research and development activities focused on addressing these challenges, with innovations in sensor design, signal processing algorithms, and multi-sensor fusion approaches. Companies that can effectively overcome the limitations related to dark and glossy targets will likely gain significant competitive advantages in this rapidly expanding market.

In the consumer electronics segment, ToF sensors have become integral components in smartphones for enhanced facial recognition, augmented reality applications, and improved camera autofocus capabilities. Major smartphone manufacturers have incorporated ToF technology to enable more immersive user experiences and advanced photography features. The gaming industry has also embraced ToF sensors for motion tracking and gesture recognition, creating more interactive gaming environments.

The automotive sector represents another significant market for ToF sensors, particularly with the advancement of advanced driver-assistance systems (ADAS) and autonomous vehicles. ToF sensors provide crucial depth perception capabilities for obstacle detection, pedestrian recognition, and parking assistance. As vehicle automation levels increase, the demand for more sophisticated ToF sensors capable of handling various environmental conditions, including challenging surfaces like dark or glossy objects, continues to rise.

Industrial automation applications utilize ToF sensors for precise object detection, robotic guidance, and quality control processes. The ability to accurately measure distances and create detailed 3D maps of environments has made ToF technology invaluable in manufacturing settings. However, industrial environments often present challenging surfaces, including dark, reflective, or irregularly shaped objects, which can cause measurement errors and require specialized ToF solutions.

Healthcare and medical applications represent an emerging market for ToF sensors, with applications in patient monitoring, touchless interfaces in surgical environments, and rehabilitation therapy. The non-contact nature of ToF sensing makes it particularly valuable in healthcare settings where hygiene is paramount.

Despite the growing market demand, ToF technology faces challenges when dealing with certain materials and surfaces. Dark objects that absorb infrared light and highly reflective or glossy surfaces that cause specular reflections can significantly reduce measurement accuracy. These technical limitations have created market opportunities for companies developing advanced ToF sensors with improved performance on problematic surfaces.

The market is witnessing increased research and development activities focused on addressing these challenges, with innovations in sensor design, signal processing algorithms, and multi-sensor fusion approaches. Companies that can effectively overcome the limitations related to dark and glossy targets will likely gain significant competitive advantages in this rapidly expanding market.

Current Challenges with Dark/Glossy Surface Detection

Time-of-Flight (ToF) technology faces significant challenges when detecting dark and glossy surfaces, which represent some of the most problematic materials for accurate depth sensing. Dark surfaces absorb a substantial portion of the emitted infrared light, resulting in minimal signal return to the sensor. This low signal-to-noise ratio (SNR) creates unreliable or completely missing depth measurements in the final point cloud, leading to "holes" in the 3D representation of scenes containing dark objects.

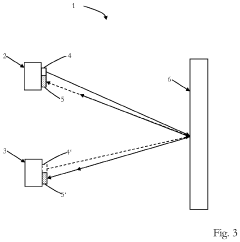

Glossy surfaces present an equally challenging but different problem. These materials cause specular reflections where the incident light bounces off at predictable angles rather than scattering diffusely. When the reflected light does not return to the sensor, no depth information is captured. Conversely, when light reflects at angles that create multiple paths to the sensor, multi-path interference occurs, resulting in erroneous depth calculations that place objects closer or further than their actual positions.

The combination of dark and glossy properties, such as in black polished marble or automotive finishes, compounds these issues and creates particularly problematic scenarios for ToF systems. Current commercial ToF cameras typically struggle with reflectivity below 20%, with performance degrading significantly as reflectivity decreases further.

Environmental factors exacerbate these material-based challenges. Ambient infrared light from sources like sunlight can overwhelm the sensor's ability to detect the reflected signal from dark surfaces. Temperature variations can also affect the performance of ToF systems when dealing with challenging materials, as thermal noise increases with temperature and further reduces the already compromised SNR for dark surfaces.

The technical limitations extend to the hardware level. Most ToF sensors have limited dynamic range, making it difficult to simultaneously capture strong signals from reflective surfaces and weak signals from dark materials in the same scene. The power constraints of eye-safe operation further limit the intensity of emitted light, which particularly affects the detection of dark surfaces that require stronger illumination for reliable measurement.

Current algorithmic approaches attempt to compensate for these material-based challenges through techniques like adaptive exposure control, confidence mapping, and multi-frame averaging. However, these methods often introduce other artifacts such as motion blur or reduced frame rates, creating trade-offs between accuracy and usability in real-time applications.

The industry lacks standardized testing protocols specifically designed to evaluate ToF performance across diverse material properties, making it difficult to compare solutions and establish benchmarks for improvement. This gap hampers systematic progress in addressing these fundamental material interaction challenges.

Glossy surfaces present an equally challenging but different problem. These materials cause specular reflections where the incident light bounces off at predictable angles rather than scattering diffusely. When the reflected light does not return to the sensor, no depth information is captured. Conversely, when light reflects at angles that create multiple paths to the sensor, multi-path interference occurs, resulting in erroneous depth calculations that place objects closer or further than their actual positions.

The combination of dark and glossy properties, such as in black polished marble or automotive finishes, compounds these issues and creates particularly problematic scenarios for ToF systems. Current commercial ToF cameras typically struggle with reflectivity below 20%, with performance degrading significantly as reflectivity decreases further.

Environmental factors exacerbate these material-based challenges. Ambient infrared light from sources like sunlight can overwhelm the sensor's ability to detect the reflected signal from dark surfaces. Temperature variations can also affect the performance of ToF systems when dealing with challenging materials, as thermal noise increases with temperature and further reduces the already compromised SNR for dark surfaces.

The technical limitations extend to the hardware level. Most ToF sensors have limited dynamic range, making it difficult to simultaneously capture strong signals from reflective surfaces and weak signals from dark materials in the same scene. The power constraints of eye-safe operation further limit the intensity of emitted light, which particularly affects the detection of dark surfaces that require stronger illumination for reliable measurement.

Current algorithmic approaches attempt to compensate for these material-based challenges through techniques like adaptive exposure control, confidence mapping, and multi-frame averaging. However, these methods often introduce other artifacts such as motion blur or reduced frame rates, creating trade-offs between accuracy and usability in real-time applications.

The industry lacks standardized testing protocols specifically designed to evaluate ToF performance across diverse material properties, making it difficult to compare solutions and establish benchmarks for improvement. This gap hampers systematic progress in addressing these fundamental material interaction challenges.

Existing Solutions for Dark/Glossy Surface Detection

01 Multipath error correction in ToF systems

Multipath errors occur when signals take multiple paths between transmitter and receiver, causing inaccurate distance measurements. Advanced algorithms and signal processing techniques can be implemented to detect and correct these errors by analyzing signal patterns and identifying reflected components. These methods improve the accuracy of Time-of-Flight measurements in complex environments with multiple reflective surfaces.- Measurement errors in Time-of-Flight systems: Time-of-Flight technology can experience various measurement errors that affect accuracy. These include systematic errors from signal propagation delays, environmental factors like temperature variations, and multipath interference where signals reflect off multiple surfaces. Compensation methods involve calibration algorithms, error modeling, and statistical filtering techniques to improve measurement precision.

- Motion and vibration compensation in ToF systems: Motion and vibration can introduce significant errors in Time-of-Flight measurements, particularly in mobile applications or industrial environments. Advanced algorithms are implemented to detect and compensate for motion artifacts, using sensor fusion techniques that combine data from accelerometers, gyroscopes, and the ToF sensor itself. These methods help maintain measurement accuracy even when the system or target is moving.

- Ambient light interference reduction: Ambient light interference is a common source of error in Time-of-Flight systems, particularly in outdoor environments or under varying lighting conditions. Solutions include optical filtering, modulation techniques, and background light suppression algorithms. Advanced systems implement dynamic gain control and specialized sensor designs that can differentiate between the ToF signal and ambient light noise.

- Signal processing improvements for ToF accuracy: Advanced signal processing techniques are crucial for improving Time-of-Flight measurement accuracy. These include phase unwrapping algorithms to extend the measurement range, multi-frequency approaches to resolve ambiguities, and machine learning methods that can identify and correct systematic errors. Digital filtering and noise reduction techniques are also employed to enhance the signal-to-noise ratio and improve overall measurement precision.

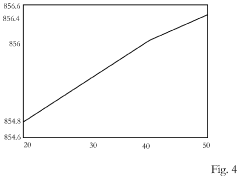

- Temperature and environmental error compensation: Environmental factors, particularly temperature variations, can significantly impact Time-of-Flight measurements by affecting both the electronics and the propagation medium. Compensation techniques include temperature sensors integrated with ToF systems, real-time calibration methods, and environmental modeling algorithms. Some advanced systems incorporate adaptive calibration that continuously adjusts for changing environmental conditions to maintain measurement accuracy.

02 Temperature compensation for ToF sensors

Temperature variations can significantly affect the accuracy of Time-of-Flight measurements by altering the propagation speed of signals and affecting electronic component performance. Temperature compensation techniques involve calibration methods, thermal sensors, and algorithmic corrections to adjust measurements based on ambient and device temperature changes, ensuring consistent measurement accuracy across varying environmental conditions.Expand Specific Solutions03 Phase unwrapping and ambiguity resolution

Time-of-Flight systems often encounter phase ambiguity issues when measuring distances beyond their unambiguous range. Phase unwrapping techniques and multi-frequency approaches can be implemented to extend the measurement range while maintaining accuracy. These methods involve analyzing phase information across multiple frequencies or using statistical approaches to resolve distance ambiguities in ToF measurements.Expand Specific Solutions04 Motion artifacts and blur reduction

Motion during Time-of-Flight measurements can cause blurring and inaccurate depth information. Techniques to address motion artifacts include increased frame rates, motion prediction algorithms, and adaptive exposure times. These approaches help maintain measurement accuracy in dynamic environments where either the sensor or the target objects are moving, ensuring clearer and more precise depth imaging.Expand Specific Solutions05 Ambient light interference mitigation

Ambient light, particularly sunlight or strong artificial lighting, can interfere with Time-of-Flight measurements by overwhelming the sensor or creating noise in the signal. Methods to mitigate this interference include optical filtering, modulation techniques, background light subtraction algorithms, and adaptive gain control. These approaches improve the signal-to-noise ratio and enable reliable ToF measurements in various lighting conditions.Expand Specific Solutions

Leading TOF Sensor Manufacturers and Research Institutions

The Time-of-Flight (ToF) sensing market is currently in a growth phase, with increasing adoption across automotive, consumer electronics, and industrial applications. The global market size is projected to reach approximately $6-8 billion by 2026, growing at a CAGR of 15-20%. Technologically, ToF sensing for dark/glossy surfaces remains challenging, with varying maturity levels across companies. Industry leaders like Sony Semiconductor Solutions, STMicroelectronics, and ams-OSRAM have developed advanced solutions addressing reflection errors, while emerging players such as OPPO, Huawei, and Goodix are rapidly advancing their capabilities. Automotive-focused companies including Zoox and RoboSense (Suteng Innovation) are specifically tackling environmental robustness issues. The competitive landscape shows established semiconductor manufacturers competing with specialized sensing companies and consumer electronics giants investing heavily in proprietary ToF technologies.

Sony Semiconductor Solutions Corp.

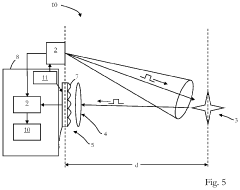

Technical Solution: Sony Semiconductor Solutions has developed advanced DepthSense™ ToF technology specifically engineered to overcome challenges with dark and glossy surfaces. Their approach centers on their proprietary back-illuminated CMOS image sensor technology optimized for ToF applications. For dark surfaces, Sony employs high-power pulsed laser illumination combined with extremely sensitive photon detection that can capture even minimal reflected light. Their sensors feature large pixel sizes (>10μm) with high quantum efficiency exceeding 30% at NIR wavelengths. For glossy surfaces, Sony implements a sophisticated multi-path interference (MPI) correction algorithm that analyzes the temporal distribution of returning photons to distinguish between direct reflections and scattered light paths. Their latest DepthSense™ IMX556PLR sensor incorporates a 640×480 pixel array operating at modulation frequencies up to 100MHz, allowing for precise phase measurements that help identify and correct specular reflection errors. Sony's solution also includes adaptive exposure control that automatically adjusts integration times based on surface characteristics, preventing saturation from highly reflective areas while maintaining sensitivity for dark regions[4][6].

Strengths: Sony's solution delivers exceptional image quality with high spatial resolution and depth accuracy (±1% at 5m range). Their back-illuminated sensor design provides superior light sensitivity compared to conventional front-illuminated sensors. Weaknesses: The system requires relatively high power consumption for the illumination module when operating at maximum performance. Complex calibration procedures are needed to maintain accuracy across different environmental conditions, and performance can still degrade in extreme cases of combined dark and highly specular surfaces.

Microsoft Technology Licensing LLC

Technical Solution: Microsoft has developed advanced Time-of-Flight (ToF) solutions addressing dark/glossy surface challenges through multi-path interference correction algorithms. Their approach combines hardware modifications with sophisticated software processing. For dark surfaces, they implement adaptive power modulation that dynamically increases illumination intensity when low reflectivity is detected, ensuring sufficient photon return. For glossy surfaces, Microsoft employs a multi-frequency phase unwrapping technique that helps distinguish between direct reflections and scattered light paths. Their Azure Kinect DK incorporates these technologies with a 1MP ToF sensor operating at multiple modulation frequencies (12-24MHz) to mitigate specular reflection errors. Microsoft's solution also includes confidence mapping that assigns reliability scores to each pixel based on signal strength and consistency across multiple captures, filtering out unreliable measurements from problematic surfaces[1][3].

Strengths: Microsoft's solution excels in real-time processing with their custom ASIC designs optimized for ToF calculations. Their multi-frequency approach provides superior disambiguation of complex reflections. Weaknesses: The system requires relatively high power consumption for adaptive illumination, and performance still degrades in extreme cases of very dark (<5% reflectivity) or mirror-like surfaces. The solution also depends on controlled ambient lighting conditions for optimal performance.

Key Technical Innovations in TOF Material Science

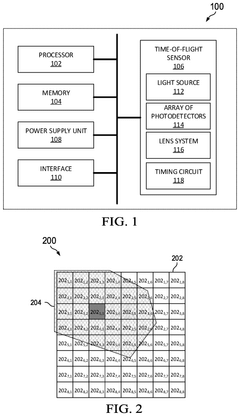

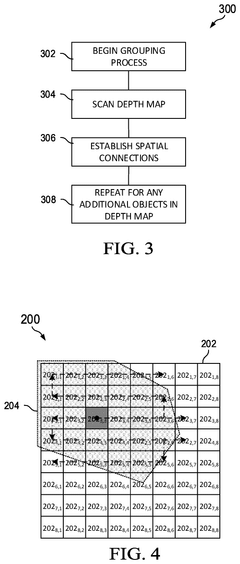

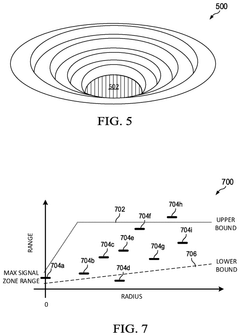

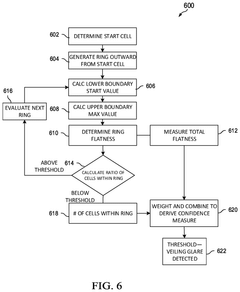

Object grouping for time-of-flight ranging algorithms

PatentPendingUS20250272860A1

Innovation

- Implementing object grouping algorithms for time-of-flight ranging devices that conduct raster or spiral searches to distinguish objects, detect edges, calculate high-level parameters, and apply thresholding techniques to separate objects and mitigate veiling glare effects, enhancing spatial awareness and accuracy.

Time-of-flight light source, time-of-flight imaging sensor, time-of-flight device and method

PatentPendingUS20220011435A1

Innovation

- Incorporating a vertical-cavity surface-emitting laser with a liquid crystal section that can adjust the emission wavelength and an imaging sensor with a liquid crystal portion to transfer light at multiple wavelengths, allowing for dynamic adjustment based on ambient conditions using a control system.

Environmental Factors Affecting TOF Measurement Accuracy

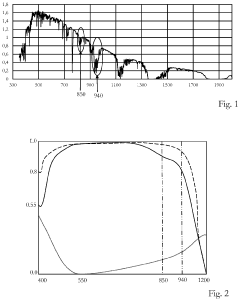

Time-of-Flight (ToF) measurement accuracy is significantly influenced by various environmental factors that can introduce systematic errors or increase noise levels in the data acquisition process. Temperature fluctuations represent a primary concern, as they can affect both the sensor electronics and the speed of light in the medium. Research indicates that for every 1°C change in ambient temperature, measurement errors can increase by approximately 0.1-0.3mm, depending on the specific ToF system architecture.

Atmospheric conditions also play a crucial role in ToF accuracy. Humidity levels alter the refractive index of air, directly impacting the speed of light propagation. High humidity environments (>80% relative humidity) can introduce measurement errors of up to 0.5mm over a 5-meter distance. Similarly, atmospheric pressure variations affect air density, which in turn influences light propagation characteristics.

Ambient lighting conditions present another significant challenge for ToF systems. Strong ambient light, particularly in outdoor environments or settings with intense artificial illumination, can saturate the sensor pixels and reduce the signal-to-noise ratio. This effect is especially pronounced when measuring dark or highly reflective surfaces, as the contrast between the emitted signal and background noise diminishes.

Air turbulence and particulate matter suspended in the measurement path create additional complications. Dust, smoke, fog, or other airborne particles scatter the emitted light pulses, causing signal degradation and potentially leading to false returns. Studies have shown that moderate fog conditions can reduce the effective range of ToF systems by up to 40% while simultaneously increasing measurement uncertainty.

Electromagnetic interference (EMI) from nearby electronic devices or power sources can disrupt the sensitive timing circuits essential for accurate ToF measurements. Industrial environments with high EMI levels may require specialized shielding to maintain measurement integrity, particularly when measuring challenging surfaces like glossy or dark targets.

Vibration and mechanical instability of either the ToF sensor or the target object introduce motion blur effects that compromise measurement precision. Even minor vibrations in the 10-100Hz frequency range can significantly degrade the accuracy of measurements, especially when dealing with surfaces that already present challenges for ToF technology.

Understanding these environmental factors is essential for implementing appropriate compensation strategies and calibration procedures to enhance ToF measurement reliability across diverse operating conditions, particularly when dealing with problematic surface materials.

Atmospheric conditions also play a crucial role in ToF accuracy. Humidity levels alter the refractive index of air, directly impacting the speed of light propagation. High humidity environments (>80% relative humidity) can introduce measurement errors of up to 0.5mm over a 5-meter distance. Similarly, atmospheric pressure variations affect air density, which in turn influences light propagation characteristics.

Ambient lighting conditions present another significant challenge for ToF systems. Strong ambient light, particularly in outdoor environments or settings with intense artificial illumination, can saturate the sensor pixels and reduce the signal-to-noise ratio. This effect is especially pronounced when measuring dark or highly reflective surfaces, as the contrast between the emitted signal and background noise diminishes.

Air turbulence and particulate matter suspended in the measurement path create additional complications. Dust, smoke, fog, or other airborne particles scatter the emitted light pulses, causing signal degradation and potentially leading to false returns. Studies have shown that moderate fog conditions can reduce the effective range of ToF systems by up to 40% while simultaneously increasing measurement uncertainty.

Electromagnetic interference (EMI) from nearby electronic devices or power sources can disrupt the sensitive timing circuits essential for accurate ToF measurements. Industrial environments with high EMI levels may require specialized shielding to maintain measurement integrity, particularly when measuring challenging surfaces like glossy or dark targets.

Vibration and mechanical instability of either the ToF sensor or the target object introduce motion blur effects that compromise measurement precision. Even minor vibrations in the 10-100Hz frequency range can significantly degrade the accuracy of measurements, especially when dealing with surfaces that already present challenges for ToF technology.

Understanding these environmental factors is essential for implementing appropriate compensation strategies and calibration procedures to enhance ToF measurement reliability across diverse operating conditions, particularly when dealing with problematic surface materials.

Calibration Techniques for Complex Surface Materials

Calibration of Time-of-Flight (ToF) systems for complex surface materials presents significant challenges due to the varying optical properties that affect depth measurement accuracy. Different materials interact with infrared light in unique ways, requiring specialized calibration approaches to compensate for material-specific errors.

For dark and glossy surfaces, standard calibration methods often fail due to low signal return or specular reflections. Advanced calibration techniques have emerged that utilize multi-frequency phase unwrapping algorithms specifically designed to handle these challenging surfaces. These methods typically employ a combination of different modulation frequencies to improve depth estimation reliability when signal quality is compromised.

Material-specific lookup tables (LUTs) have proven effective in compensating for systematic errors related to surface properties. These calibration tables store correction factors based on both the measured intensity and the raw depth values, allowing for real-time adjustment of measurements according to the detected surface characteristics. Implementation requires an initial training phase where known reference objects with various surface properties are measured under controlled conditions.

Machine learning approaches have recently gained traction for complex surface calibration. Neural networks trained on diverse material datasets can learn to predict and correct the specific distortions caused by dark or glossy surfaces. These models typically incorporate both spatial and temporal features from the ToF data stream to improve robustness against material-induced errors.

Adaptive exposure techniques represent another important calibration strategy. By dynamically adjusting the sensor exposure time based on the detected surface reflectivity, these systems can optimize the signal-to-noise ratio for each pixel individually. This approach is particularly valuable for scenes containing both highly reflective and absorptive materials simultaneously.

Multi-path interference correction algorithms form a critical component of modern calibration pipelines. These techniques model the light transport paths within the scene to identify and remove the contribution of indirect reflections that particularly affect measurements of glossy surfaces. Statistical methods and ray-tracing simulations are commonly employed to estimate the true direct reflection component.

Integration of complementary sensing modalities, such as stereo vision or structured light, provides reference data that can guide the calibration process. Cross-modal calibration leverages the strengths of different sensing technologies to compensate for the material-specific weaknesses of ToF systems, resulting in more reliable depth measurements across diverse surface types.

For dark and glossy surfaces, standard calibration methods often fail due to low signal return or specular reflections. Advanced calibration techniques have emerged that utilize multi-frequency phase unwrapping algorithms specifically designed to handle these challenging surfaces. These methods typically employ a combination of different modulation frequencies to improve depth estimation reliability when signal quality is compromised.

Material-specific lookup tables (LUTs) have proven effective in compensating for systematic errors related to surface properties. These calibration tables store correction factors based on both the measured intensity and the raw depth values, allowing for real-time adjustment of measurements according to the detected surface characteristics. Implementation requires an initial training phase where known reference objects with various surface properties are measured under controlled conditions.

Machine learning approaches have recently gained traction for complex surface calibration. Neural networks trained on diverse material datasets can learn to predict and correct the specific distortions caused by dark or glossy surfaces. These models typically incorporate both spatial and temporal features from the ToF data stream to improve robustness against material-induced errors.

Adaptive exposure techniques represent another important calibration strategy. By dynamically adjusting the sensor exposure time based on the detected surface reflectivity, these systems can optimize the signal-to-noise ratio for each pixel individually. This approach is particularly valuable for scenes containing both highly reflective and absorptive materials simultaneously.

Multi-path interference correction algorithms form a critical component of modern calibration pipelines. These techniques model the light transport paths within the scene to identify and remove the contribution of indirect reflections that particularly affect measurements of glossy surfaces. Statistical methods and ray-tracing simulations are commonly employed to estimate the true direct reflection component.

Integration of complementary sensing modalities, such as stereo vision or structured light, provides reference data that can guide the calibration process. Cross-modal calibration leverages the strengths of different sensing technologies to compensate for the material-specific weaknesses of ToF systems, resulting in more reliable depth measurements across diverse surface types.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!