Understanding Silicone Rubber's Acoustic Insulation Properties

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acoustic Insulation Goals

The primary goal of understanding silicone rubber's acoustic insulation properties is to enhance noise reduction capabilities in various applications, ranging from industrial machinery to consumer electronics. This objective is driven by the increasing demand for quieter environments in both professional and personal settings.

One key aim is to quantify and optimize the sound transmission loss (STL) of silicone rubber across a wide frequency spectrum. This involves determining the material's ability to attenuate airborne sound waves, particularly in the low to mid-frequency ranges where many common noise sources occur. Researchers seek to achieve a minimum STL of 20-30 dB in the 250-1000 Hz range, with higher values at higher frequencies.

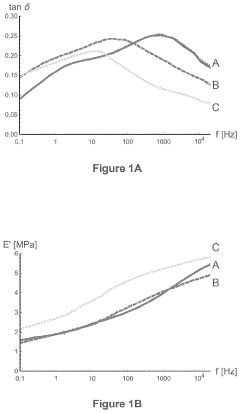

Another critical goal is to improve the damping characteristics of silicone rubber. This involves enhancing its ability to convert vibrational energy into heat, thereby reducing structure-borne noise. Researchers aim to increase the material's loss factor, targeting values above 0.1 across a broad temperature range, which would significantly outperform many traditional elastomers.

Developing silicone rubber composites with enhanced acoustic properties is also a primary objective. This includes incorporating fillers or creating multi-layer structures to achieve better sound absorption and insulation. The goal is to create materials that can provide effective acoustic insulation while maintaining other desirable properties of silicone rubber, such as flexibility, durability, and temperature resistance.

Researchers are also focusing on understanding the relationship between the molecular structure of silicone rubber and its acoustic properties. This includes studying how factors such as crosslink density, chain length, and the presence of functional groups affect sound transmission and absorption. The aim is to develop predictive models that can guide the design of silicone rubbers with tailored acoustic properties for specific applications.

Another important goal is to investigate the long-term stability of silicone rubber's acoustic properties under various environmental conditions. This includes assessing the impact of temperature fluctuations, humidity, UV exposure, and mechanical stress on the material's sound insulation performance over time. The objective is to develop formulations that maintain their acoustic properties for extended periods, ideally matching or exceeding the service life of the applications they are used in.

Finally, there is a growing emphasis on developing environmentally friendly silicone rubber formulations with excellent acoustic properties. This aligns with the broader trend towards sustainable materials in various industries. The goal is to create bio-based or recyclable silicone rubbers that offer comparable or superior acoustic insulation to traditional formulations, thereby addressing both performance and environmental concerns.

One key aim is to quantify and optimize the sound transmission loss (STL) of silicone rubber across a wide frequency spectrum. This involves determining the material's ability to attenuate airborne sound waves, particularly in the low to mid-frequency ranges where many common noise sources occur. Researchers seek to achieve a minimum STL of 20-30 dB in the 250-1000 Hz range, with higher values at higher frequencies.

Another critical goal is to improve the damping characteristics of silicone rubber. This involves enhancing its ability to convert vibrational energy into heat, thereby reducing structure-borne noise. Researchers aim to increase the material's loss factor, targeting values above 0.1 across a broad temperature range, which would significantly outperform many traditional elastomers.

Developing silicone rubber composites with enhanced acoustic properties is also a primary objective. This includes incorporating fillers or creating multi-layer structures to achieve better sound absorption and insulation. The goal is to create materials that can provide effective acoustic insulation while maintaining other desirable properties of silicone rubber, such as flexibility, durability, and temperature resistance.

Researchers are also focusing on understanding the relationship between the molecular structure of silicone rubber and its acoustic properties. This includes studying how factors such as crosslink density, chain length, and the presence of functional groups affect sound transmission and absorption. The aim is to develop predictive models that can guide the design of silicone rubbers with tailored acoustic properties for specific applications.

Another important goal is to investigate the long-term stability of silicone rubber's acoustic properties under various environmental conditions. This includes assessing the impact of temperature fluctuations, humidity, UV exposure, and mechanical stress on the material's sound insulation performance over time. The objective is to develop formulations that maintain their acoustic properties for extended periods, ideally matching or exceeding the service life of the applications they are used in.

Finally, there is a growing emphasis on developing environmentally friendly silicone rubber formulations with excellent acoustic properties. This aligns with the broader trend towards sustainable materials in various industries. The goal is to create bio-based or recyclable silicone rubbers that offer comparable or superior acoustic insulation to traditional formulations, thereby addressing both performance and environmental concerns.

Market Demand Analysis

The market demand for acoustic insulation materials, particularly silicone rubber-based solutions, has been steadily growing across various industries. This surge is primarily driven by the increasing awareness of noise pollution and its adverse effects on human health and productivity. The construction sector, especially in urban areas, shows a significant demand for effective sound insulation materials to create quieter living and working environments.

In the automotive industry, there's a rising need for lightweight yet efficient acoustic insulation materials to enhance passenger comfort while meeting stringent fuel efficiency standards. Silicone rubber's unique properties make it an attractive option for this application. The aerospace sector also demonstrates a growing interest in advanced acoustic insulation materials to improve cabin comfort and reduce external noise in aircraft.

The industrial machinery and equipment market is another key driver for acoustic insulation materials. As regulations regarding workplace noise levels become more stringent, manufacturers are seeking innovative solutions to reduce machinery noise. Silicone rubber-based acoustic insulation offers potential advantages in this area due to its durability and resistance to harsh environments.

Consumer electronics is an emerging market for acoustic insulation materials. With the proliferation of smart home devices and the increasing importance of audio quality in portable electronics, there's a growing demand for materials that can effectively manage sound within compact spaces.

The healthcare sector presents a niche but promising market for acoustic insulation. Hospitals and medical facilities are increasingly recognizing the importance of noise reduction in patient recovery and staff well-being. Silicone rubber's hygienic properties make it particularly suitable for healthcare applications.

Market analysts project the global acoustic insulation market to experience substantial growth in the coming years. This growth is attributed to urbanization, stringent noise pollution regulations, and increasing investments in infrastructure development. The Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization and urban development in countries like China and India.

As environmental concerns gain prominence, there's a growing demand for eco-friendly acoustic insulation materials. This trend presents both a challenge and an opportunity for silicone rubber-based solutions, as manufacturers explore ways to enhance the material's sustainability profile while maintaining its acoustic performance.

In the automotive industry, there's a rising need for lightweight yet efficient acoustic insulation materials to enhance passenger comfort while meeting stringent fuel efficiency standards. Silicone rubber's unique properties make it an attractive option for this application. The aerospace sector also demonstrates a growing interest in advanced acoustic insulation materials to improve cabin comfort and reduce external noise in aircraft.

The industrial machinery and equipment market is another key driver for acoustic insulation materials. As regulations regarding workplace noise levels become more stringent, manufacturers are seeking innovative solutions to reduce machinery noise. Silicone rubber-based acoustic insulation offers potential advantages in this area due to its durability and resistance to harsh environments.

Consumer electronics is an emerging market for acoustic insulation materials. With the proliferation of smart home devices and the increasing importance of audio quality in portable electronics, there's a growing demand for materials that can effectively manage sound within compact spaces.

The healthcare sector presents a niche but promising market for acoustic insulation. Hospitals and medical facilities are increasingly recognizing the importance of noise reduction in patient recovery and staff well-being. Silicone rubber's hygienic properties make it particularly suitable for healthcare applications.

Market analysts project the global acoustic insulation market to experience substantial growth in the coming years. This growth is attributed to urbanization, stringent noise pollution regulations, and increasing investments in infrastructure development. The Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization and urban development in countries like China and India.

As environmental concerns gain prominence, there's a growing demand for eco-friendly acoustic insulation materials. This trend presents both a challenge and an opportunity for silicone rubber-based solutions, as manufacturers explore ways to enhance the material's sustainability profile while maintaining its acoustic performance.

Current Challenges

The current challenges in understanding silicone rubber's acoustic insulation properties are multifaceted and complex. One of the primary obstacles is the lack of comprehensive data on the material's behavior across a wide range of frequencies and environmental conditions. While silicone rubber has shown promising acoustic insulation capabilities, its performance can vary significantly depending on factors such as temperature, humidity, and pressure.

Another significant challenge lies in accurately modeling and predicting the acoustic properties of silicone rubber. The material's viscoelastic nature makes it difficult to develop precise mathematical models that can account for its dynamic behavior under different acoustic loads. This complexity hinders the ability to optimize silicone rubber formulations for specific acoustic applications without extensive experimental testing.

The manufacturing process of silicone rubber also presents challenges in achieving consistent acoustic properties. Variations in curing conditions, additives, and molecular structure can lead to inconsistencies in the final product's acoustic performance. This variability makes it challenging for engineers to design reliable acoustic insulation solutions using silicone rubber, as the material's properties may not be uniform across different batches or production runs.

Furthermore, there is a need for improved testing methodologies to evaluate silicone rubber's acoustic insulation properties accurately. Current standardized testing procedures may not fully capture the material's unique characteristics, particularly its behavior at high frequencies or under complex acoustic environments. This limitation hampers the ability to compare silicone rubber's performance with other acoustic insulation materials effectively.

The long-term durability and stability of silicone rubber's acoustic properties also remain a concern. While the material is known for its resilience, the effects of aging, exposure to various chemicals, and prolonged acoustic stress on its insulation capabilities are not fully understood. This uncertainty poses challenges for applications requiring sustained acoustic performance over extended periods.

Additionally, the integration of silicone rubber into composite acoustic insulation systems presents its own set of challenges. Optimizing the interaction between silicone rubber and other materials to achieve synergistic acoustic effects requires a deep understanding of interface dynamics and material compatibility. The lack of comprehensive research in this area limits the potential for developing advanced, multi-material acoustic solutions.

Lastly, the cost-effectiveness of silicone rubber as an acoustic insulation material remains a challenge for widespread adoption. While its unique properties offer advantages in certain applications, the material's higher cost compared to traditional acoustic insulators can be prohibitive for large-scale implementation. Balancing the acoustic performance benefits with economic considerations is an ongoing challenge for researchers and industry professionals alike.

Another significant challenge lies in accurately modeling and predicting the acoustic properties of silicone rubber. The material's viscoelastic nature makes it difficult to develop precise mathematical models that can account for its dynamic behavior under different acoustic loads. This complexity hinders the ability to optimize silicone rubber formulations for specific acoustic applications without extensive experimental testing.

The manufacturing process of silicone rubber also presents challenges in achieving consistent acoustic properties. Variations in curing conditions, additives, and molecular structure can lead to inconsistencies in the final product's acoustic performance. This variability makes it challenging for engineers to design reliable acoustic insulation solutions using silicone rubber, as the material's properties may not be uniform across different batches or production runs.

Furthermore, there is a need for improved testing methodologies to evaluate silicone rubber's acoustic insulation properties accurately. Current standardized testing procedures may not fully capture the material's unique characteristics, particularly its behavior at high frequencies or under complex acoustic environments. This limitation hampers the ability to compare silicone rubber's performance with other acoustic insulation materials effectively.

The long-term durability and stability of silicone rubber's acoustic properties also remain a concern. While the material is known for its resilience, the effects of aging, exposure to various chemicals, and prolonged acoustic stress on its insulation capabilities are not fully understood. This uncertainty poses challenges for applications requiring sustained acoustic performance over extended periods.

Additionally, the integration of silicone rubber into composite acoustic insulation systems presents its own set of challenges. Optimizing the interaction between silicone rubber and other materials to achieve synergistic acoustic effects requires a deep understanding of interface dynamics and material compatibility. The lack of comprehensive research in this area limits the potential for developing advanced, multi-material acoustic solutions.

Lastly, the cost-effectiveness of silicone rubber as an acoustic insulation material remains a challenge for widespread adoption. While its unique properties offer advantages in certain applications, the material's higher cost compared to traditional acoustic insulators can be prohibitive for large-scale implementation. Balancing the acoustic performance benefits with economic considerations is an ongoing challenge for researchers and industry professionals alike.

Existing Solutions

01 Composition of silicone rubber for acoustic insulation

Silicone rubber compositions are formulated with specific additives to enhance acoustic insulation properties. These compositions may include fillers, crosslinking agents, and other modifiers to improve sound absorption and damping characteristics. The resulting material offers excellent acoustic insulation while maintaining the desirable properties of silicone rubber, such as flexibility and durability.- Composition of silicone rubber for acoustic insulation: Silicone rubber compositions are formulated with specific additives to enhance acoustic insulation properties. These compositions may include fillers, cross-linking agents, and other modifiers to improve sound absorption and damping characteristics. The resulting material offers excellent acoustic insulation while maintaining the desirable properties of silicone rubber, such as flexibility and durability.

- Structural design of silicone rubber acoustic insulation panels: Acoustic insulation panels made from silicone rubber are designed with specific structural features to maximize sound absorption and isolation. These designs may include layered structures, honeycomb patterns, or variable thickness profiles. The structural design aims to create air pockets and sound-absorbing surfaces that effectively reduce noise transmission across a wide frequency range.

- Integration of silicone rubber acoustic insulation in electronic devices: Silicone rubber acoustic insulation is incorporated into various electronic devices to reduce noise emission and improve sound quality. This application is particularly relevant in smartphones, laptops, and other portable devices where space is limited. The silicone rubber insulation helps to isolate internal components, preventing unwanted vibrations and enhancing overall acoustic performance.

- Manufacturing processes for silicone rubber acoustic insulation: Specialized manufacturing processes are developed to produce silicone rubber acoustic insulation materials with optimal performance. These processes may include molding techniques, extrusion methods, or advanced curing procedures. The focus is on creating consistent and high-quality insulation materials that maintain their acoustic properties over time and under various environmental conditions.

- Application of silicone rubber acoustic insulation in automotive industry: Silicone rubber acoustic insulation finds extensive use in the automotive sector for reducing cabin noise and improving passenger comfort. It is applied in various parts of vehicles, including door panels, engine compartments, and flooring. The material's ability to withstand high temperatures and resist degradation makes it particularly suitable for automotive applications, where it can effectively dampen vibrations and absorb sound across a wide range of frequencies.

02 Multilayer structures incorporating silicone rubber for acoustic insulation

Acoustic insulation systems often utilize multilayer structures that incorporate silicone rubber layers. These structures may combine silicone rubber with other materials such as foams, fabrics, or rigid substrates to create composite systems with enhanced sound absorption and transmission loss properties. The layered approach allows for tailored acoustic performance across different frequency ranges.Expand Specific Solutions03 Silicone rubber foams for acoustic applications

Silicone rubber foams are developed specifically for acoustic insulation purposes. These foams combine the benefits of silicone rubber with a cellular structure that provides excellent sound absorption. The foam structure can be engineered to target specific frequency ranges and achieve desired acoustic properties while maintaining the inherent advantages of silicone materials.Expand Specific Solutions04 Surface modifications of silicone rubber for improved acoustic performance

Various surface modification techniques are applied to silicone rubber to enhance its acoustic insulation properties. These may include texturing, patterning, or applying specialized coatings to the silicone rubber surface. Such modifications can improve sound scattering, absorption, or reflection, leading to better overall acoustic insulation performance.Expand Specific Solutions05 Integration of silicone rubber in acoustic insulation systems

Silicone rubber is integrated into various acoustic insulation systems and products. This includes its use in automotive applications, building materials, electronic devices, and industrial equipment. The material's versatility allows for custom-shaped components and seamless integration with other materials, providing effective noise reduction solutions across diverse applications.Expand Specific Solutions

Key Industry Players

The acoustic insulation properties of silicone rubber are gaining attention in a competitive landscape characterized by evolving market dynamics. The industry is in a growth phase, with increasing demand for noise reduction solutions across various sectors. The global market for acoustic materials is expanding, driven by stringent noise regulations and growing awareness of sound pollution. Technologically, silicone rubber's acoustic properties are still being explored, with companies like Shin-Etsu Chemical, Dow Silicones, and Wacker Chemie leading research efforts. These firms, along with others like Momentive Performance Materials and Henkel, are investing in R&D to enhance silicone rubber's acoustic performance, indicating a moderate level of technological maturity with significant potential for innovation and market growth.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced silicone rubber compounds specifically engineered for acoustic insulation. Their technology focuses on optimizing the molecular structure of silicone rubber to enhance its sound-damping properties. The company utilizes a proprietary cross-linking process that creates a network of silicone polymers with varying chain lengths, resulting in improved acoustic absorption across a wide frequency range[1]. Additionally, Shin-Etsu has incorporated micro-voids and specialized fillers into their silicone rubber formulations, which further enhance sound attenuation by creating multiple interfaces for sound wave reflection and dissipation[2].

Strengths: Superior acoustic performance across a broad frequency spectrum, excellent durability, and resistance to environmental factors. Weaknesses: Potentially higher cost compared to conventional materials, and may require specialized processing techniques.

Dow Silicones Corp.

Technical Solution: Dow Silicones has developed a range of silicone rubber solutions for acoustic insulation, focusing on both passive and active noise control. Their technology incorporates a multi-layered approach, combining different silicone rubber formulations to target specific frequency ranges. The company has introduced nano-structured silicone composites that exhibit enhanced sound absorption properties due to increased surface area and improved impedance matching with air[3]. Dow's research also extends to adaptive silicone materials that can change their acoustic properties in response to external stimuli, allowing for dynamic noise control in various applications[4].

Strengths: Versatile solutions for different acoustic environments, potential for smart and adaptive noise control systems. Weaknesses: Complexity in manufacturing multi-layered systems, potential higher costs for advanced formulations.

Core Innovations

Flexible insulation material

PatentWO2018197062A1

Innovation

- A rubber mixture comprising silicone rubber, hollow microspheres, and fillers such as BaSO4, TiO2, and Al2Si2O5(OH)4, which enhances dielectric properties and allows for better compressibility and porosity, enabling the material to be used in applications like impact sensors.

Silicone rubber formulations with tunable damping properties and method of preparation thereof

PatentActiveUS20220243063A1

Innovation

- Development of a cured silicone rubber with a poly-N1, N2-siloxane polymer and a poly(dimethyl)(diphenyl)siloxane copolymer, where the diphenylsiloxane content is adjusted to achieve a tunable damping coefficient within a specific frequency range, allowing for quick curing at ambient temperature without complex machinery, and using UV radiation for rapid polymerization.

Environmental Impact

The environmental impact of silicone rubber's acoustic insulation properties is a crucial consideration in the context of sustainable development and ecological responsibility. Silicone rubber, known for its excellent sound-dampening capabilities, offers significant advantages in noise reduction applications across various industries. However, its production, use, and disposal have both positive and negative implications for the environment.

From a positive perspective, the durability and longevity of silicone rubber contribute to reduced waste generation. Its resistance to degradation means that silicone rubber acoustic insulation products have extended lifespans, reducing the frequency of replacement and, consequently, the overall environmental footprint associated with manufacturing and disposal. Additionally, the energy-saving potential of effective acoustic insulation can lead to reduced power consumption in buildings and vehicles, indirectly lowering greenhouse gas emissions.

However, the production of silicone rubber involves energy-intensive processes and the use of potentially harmful chemicals. The primary raw material, silica, is typically derived from sand, which requires mining operations that can disrupt local ecosystems. The synthesis of silicone polymers also involves the use of organic solvents and catalysts, some of which may have adverse environmental effects if not properly managed.

End-of-life considerations for silicone rubber acoustic insulation products present another environmental challenge. While silicone rubber is theoretically recyclable, the current infrastructure for recycling these materials is limited. Most silicone rubber products end up in landfills, where they persist for extended periods due to their resistance to biodegradation. This longevity, while beneficial during the product's use phase, becomes problematic in waste management scenarios.

Recent advancements in green chemistry and sustainable manufacturing practices are addressing some of these environmental concerns. Researchers are exploring bio-based alternatives for silicone production, aiming to reduce reliance on petrochemical feedstocks. Additionally, efforts are underway to develop more efficient recycling technologies for silicone rubber, including chemical recycling methods that break down the polymer into reusable components.

The acoustic insulation properties of silicone rubber also contribute to noise pollution reduction, which is increasingly recognized as an environmental issue. By effectively dampening sound, silicone rubber helps create quieter environments, potentially reducing stress on wildlife and improving quality of life in urban areas. This indirect environmental benefit underscores the complex interplay between material properties and ecological impact.

From a positive perspective, the durability and longevity of silicone rubber contribute to reduced waste generation. Its resistance to degradation means that silicone rubber acoustic insulation products have extended lifespans, reducing the frequency of replacement and, consequently, the overall environmental footprint associated with manufacturing and disposal. Additionally, the energy-saving potential of effective acoustic insulation can lead to reduced power consumption in buildings and vehicles, indirectly lowering greenhouse gas emissions.

However, the production of silicone rubber involves energy-intensive processes and the use of potentially harmful chemicals. The primary raw material, silica, is typically derived from sand, which requires mining operations that can disrupt local ecosystems. The synthesis of silicone polymers also involves the use of organic solvents and catalysts, some of which may have adverse environmental effects if not properly managed.

End-of-life considerations for silicone rubber acoustic insulation products present another environmental challenge. While silicone rubber is theoretically recyclable, the current infrastructure for recycling these materials is limited. Most silicone rubber products end up in landfills, where they persist for extended periods due to their resistance to biodegradation. This longevity, while beneficial during the product's use phase, becomes problematic in waste management scenarios.

Recent advancements in green chemistry and sustainable manufacturing practices are addressing some of these environmental concerns. Researchers are exploring bio-based alternatives for silicone production, aiming to reduce reliance on petrochemical feedstocks. Additionally, efforts are underway to develop more efficient recycling technologies for silicone rubber, including chemical recycling methods that break down the polymer into reusable components.

The acoustic insulation properties of silicone rubber also contribute to noise pollution reduction, which is increasingly recognized as an environmental issue. By effectively dampening sound, silicone rubber helps create quieter environments, potentially reducing stress on wildlife and improving quality of life in urban areas. This indirect environmental benefit underscores the complex interplay between material properties and ecological impact.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and application of silicone rubber for acoustic insulation purposes. As the demand for noise reduction solutions continues to grow across various industries, manufacturers and end-users must navigate a complex landscape of standards and regulations to ensure their products meet legal requirements and performance expectations.

In the United States, the Occupational Safety and Health Administration (OSHA) sets guidelines for workplace noise exposure, which indirectly influences the development of acoustic insulation materials. The National Institute for Occupational Safety and Health (NIOSH) also provides recommendations for noise exposure limits, further shaping the regulatory environment. These standards often drive the need for improved acoustic insulation materials, including those based on silicone rubber.

The European Union has established the Environmental Noise Directive (END) to address noise pollution, which impacts the design and implementation of acoustic insulation solutions. Additionally, the EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation affects the production and use of silicone rubber, ensuring that potentially harmful substances are properly managed throughout the material's lifecycle.

In the automotive industry, regulations such as the Federal Motor Vehicle Safety Standards (FMVSS) in the United States and the United Nations Economic Commission for Europe (UNECE) regulations in Europe set specific requirements for vehicle noise levels. These standards directly influence the development and application of silicone rubber acoustic insulation in vehicles.

For building and construction applications, various national and international building codes incorporate acoustic performance requirements. For instance, the International Building Code (IBC) in the United States includes provisions for sound transmission and insulation. Similarly, the European Standard EN ISO 717 provides guidelines for rating sound insulation in buildings, which can impact the use of silicone rubber-based acoustic solutions.

Manufacturers must also consider environmental regulations when developing silicone rubber acoustic insulation products. Many countries have implemented restrictions on volatile organic compounds (VOCs) and other potentially harmful emissions, which can affect the formulation and production processes of silicone rubber materials.

As the understanding of silicone rubber's acoustic insulation properties continues to evolve, it is essential for researchers and manufacturers to stay informed about emerging regulations and standards. This includes monitoring updates to existing guidelines and participating in industry discussions that may shape future regulatory frameworks. By maintaining compliance with current regulations and anticipating future requirements, companies can ensure their silicone rubber acoustic insulation products remain competitive and legally viable in the global market.

In the United States, the Occupational Safety and Health Administration (OSHA) sets guidelines for workplace noise exposure, which indirectly influences the development of acoustic insulation materials. The National Institute for Occupational Safety and Health (NIOSH) also provides recommendations for noise exposure limits, further shaping the regulatory environment. These standards often drive the need for improved acoustic insulation materials, including those based on silicone rubber.

The European Union has established the Environmental Noise Directive (END) to address noise pollution, which impacts the design and implementation of acoustic insulation solutions. Additionally, the EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation affects the production and use of silicone rubber, ensuring that potentially harmful substances are properly managed throughout the material's lifecycle.

In the automotive industry, regulations such as the Federal Motor Vehicle Safety Standards (FMVSS) in the United States and the United Nations Economic Commission for Europe (UNECE) regulations in Europe set specific requirements for vehicle noise levels. These standards directly influence the development and application of silicone rubber acoustic insulation in vehicles.

For building and construction applications, various national and international building codes incorporate acoustic performance requirements. For instance, the International Building Code (IBC) in the United States includes provisions for sound transmission and insulation. Similarly, the European Standard EN ISO 717 provides guidelines for rating sound insulation in buildings, which can impact the use of silicone rubber-based acoustic solutions.

Manufacturers must also consider environmental regulations when developing silicone rubber acoustic insulation products. Many countries have implemented restrictions on volatile organic compounds (VOCs) and other potentially harmful emissions, which can affect the formulation and production processes of silicone rubber materials.

As the understanding of silicone rubber's acoustic insulation properties continues to evolve, it is essential for researchers and manufacturers to stay informed about emerging regulations and standards. This includes monitoring updates to existing guidelines and participating in industry discussions that may shape future regulatory frameworks. By maintaining compliance with current regulations and anticipating future requirements, companies can ensure their silicone rubber acoustic insulation products remain competitive and legally viable in the global market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!