Accura 25’s Role in Trendsetting Culinary Equipment Design

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Overview

Accura 25 represents a groundbreaking material in the realm of culinary equipment design, offering a unique combination of properties that have revolutionized the manufacturing of high-performance kitchen tools and appliances. Developed by 3D Systems, this photopolymer resin has quickly become a cornerstone in the production of prototypes and functional parts for the food industry.

The material's exceptional heat resistance, with a heat deflection temperature of 62°C at 0.45 MPa, allows for the creation of kitchen tools that can withstand the rigors of cooking environments. This thermal stability ensures that Accura 25-based prototypes maintain their structural integrity during testing, even when exposed to hot liquids or steam.

One of Accura 25's most notable features is its water resistance, which is crucial for culinary applications. This property enables the production of kitchen tools and equipment that can withstand frequent washing and exposure to various liquids without degradation. The material's resistance to moisture absorption also contributes to its dimensional stability, ensuring that prototypes maintain their precise measurements over time.

The resin's compatibility with a wide range of finishing techniques has made it particularly valuable in the design process of trendsetting culinary equipment. Designers can apply various surface treatments, including painting, plating, and texturing, to create prototypes that closely mimic the appearance and feel of final production materials. This versatility allows for more accurate user testing and feedback during the product development phase.

Accura 25's mechanical properties, including its tensile strength of 38-44 MPa and flexural modulus of 1,900-2,100 MPa, provide the necessary durability for functional prototyping. These characteristics enable the creation of robust kitchen tools that can undergo rigorous testing, simulating real-world use scenarios and ensuring that designs meet the demanding requirements of professional and home kitchens alike.

The material's clarity and ability to be tinted have also played a significant role in its adoption for culinary equipment design. These optical properties allow designers to create transparent or colored prototypes, which is particularly useful for visualizing internal mechanisms or creating aesthetically pleasing designs that align with current kitchen trends.

In the context of rapid prototyping, Accura 25's quick curing time and compatibility with stereolithography (SLA) 3D printing technology have significantly accelerated the product development cycle for culinary equipment. This efficiency has enabled designers to iterate quickly, refining their concepts and bringing innovative kitchen tools to market faster than ever before.

The material's exceptional heat resistance, with a heat deflection temperature of 62°C at 0.45 MPa, allows for the creation of kitchen tools that can withstand the rigors of cooking environments. This thermal stability ensures that Accura 25-based prototypes maintain their structural integrity during testing, even when exposed to hot liquids or steam.

One of Accura 25's most notable features is its water resistance, which is crucial for culinary applications. This property enables the production of kitchen tools and equipment that can withstand frequent washing and exposure to various liquids without degradation. The material's resistance to moisture absorption also contributes to its dimensional stability, ensuring that prototypes maintain their precise measurements over time.

The resin's compatibility with a wide range of finishing techniques has made it particularly valuable in the design process of trendsetting culinary equipment. Designers can apply various surface treatments, including painting, plating, and texturing, to create prototypes that closely mimic the appearance and feel of final production materials. This versatility allows for more accurate user testing and feedback during the product development phase.

Accura 25's mechanical properties, including its tensile strength of 38-44 MPa and flexural modulus of 1,900-2,100 MPa, provide the necessary durability for functional prototyping. These characteristics enable the creation of robust kitchen tools that can undergo rigorous testing, simulating real-world use scenarios and ensuring that designs meet the demanding requirements of professional and home kitchens alike.

The material's clarity and ability to be tinted have also played a significant role in its adoption for culinary equipment design. These optical properties allow designers to create transparent or colored prototypes, which is particularly useful for visualizing internal mechanisms or creating aesthetically pleasing designs that align with current kitchen trends.

In the context of rapid prototyping, Accura 25's quick curing time and compatibility with stereolithography (SLA) 3D printing technology have significantly accelerated the product development cycle for culinary equipment. This efficiency has enabled designers to iterate quickly, refining their concepts and bringing innovative kitchen tools to market faster than ever before.

Market Demand Analysis

The culinary equipment industry has witnessed a significant surge in demand for innovative and efficient kitchen tools, with Accura 25 emerging as a trendsetter in this competitive landscape. Market analysis reveals a growing appetite for precision-engineered culinary equipment that enhances cooking processes and elevates the overall dining experience. This trend is particularly pronounced in high-end restaurants, culinary schools, and among passionate home cooks who seek professional-grade tools.

The global market for premium culinary equipment is experiencing robust growth, driven by factors such as the rising popularity of cooking shows, increased disposable income, and a growing culture of gourmet home cooking. Consumers are increasingly willing to invest in high-quality kitchen tools that offer superior performance and durability. This shift in consumer behavior has created a fertile ground for products like Accura 25, which combines cutting-edge technology with elegant design.

In the commercial sector, restaurants and food service establishments are constantly seeking ways to improve efficiency and consistency in food preparation. Accura 25's advanced features address these needs by offering precise temperature control, reduced cooking times, and enhanced flavor preservation. This alignment with industry requirements has positioned Accura 25 as a highly sought-after solution in professional kitchens.

The market demand for Accura 25 and similar trendsetting culinary equipment is further bolstered by the growing focus on sustainability and energy efficiency. As environmental concerns become more prominent, consumers and businesses alike are gravitating towards kitchen tools that minimize energy consumption and food waste. Accura 25's innovative design and efficient operation cater to this eco-conscious segment of the market.

Another significant trend driving market demand is the increasing interest in molecular gastronomy and avant-garde cooking techniques. Chefs and culinary enthusiasts are exploring new frontiers in food preparation, requiring equipment that can support these advanced methods. Accura 25's versatility and precision make it an ideal tool for experimenting with cutting-edge culinary techniques, further expanding its market appeal.

The COVID-19 pandemic has also influenced market dynamics, with a notable shift towards home cooking and a renewed interest in culinary exploration. This has led to a surge in demand for high-quality kitchen equipment among home users, presenting an opportunity for Accura 25 to expand its market reach beyond professional kitchens.

As the culinary equipment market continues to evolve, the demand for products like Accura 25 is expected to grow. The convergence of technology, design, and culinary innovation is reshaping consumer expectations, creating a fertile ground for trendsetting equipment that can deliver exceptional performance and user experience.

The global market for premium culinary equipment is experiencing robust growth, driven by factors such as the rising popularity of cooking shows, increased disposable income, and a growing culture of gourmet home cooking. Consumers are increasingly willing to invest in high-quality kitchen tools that offer superior performance and durability. This shift in consumer behavior has created a fertile ground for products like Accura 25, which combines cutting-edge technology with elegant design.

In the commercial sector, restaurants and food service establishments are constantly seeking ways to improve efficiency and consistency in food preparation. Accura 25's advanced features address these needs by offering precise temperature control, reduced cooking times, and enhanced flavor preservation. This alignment with industry requirements has positioned Accura 25 as a highly sought-after solution in professional kitchens.

The market demand for Accura 25 and similar trendsetting culinary equipment is further bolstered by the growing focus on sustainability and energy efficiency. As environmental concerns become more prominent, consumers and businesses alike are gravitating towards kitchen tools that minimize energy consumption and food waste. Accura 25's innovative design and efficient operation cater to this eco-conscious segment of the market.

Another significant trend driving market demand is the increasing interest in molecular gastronomy and avant-garde cooking techniques. Chefs and culinary enthusiasts are exploring new frontiers in food preparation, requiring equipment that can support these advanced methods. Accura 25's versatility and precision make it an ideal tool for experimenting with cutting-edge culinary techniques, further expanding its market appeal.

The COVID-19 pandemic has also influenced market dynamics, with a notable shift towards home cooking and a renewed interest in culinary exploration. This has led to a surge in demand for high-quality kitchen equipment among home users, presenting an opportunity for Accura 25 to expand its market reach beyond professional kitchens.

As the culinary equipment market continues to evolve, the demand for products like Accura 25 is expected to grow. The convergence of technology, design, and culinary innovation is reshaping consumer expectations, creating a fertile ground for trendsetting equipment that can deliver exceptional performance and user experience.

Current Challenges

The Accura 25, while revolutionary in its approach to culinary equipment design, faces several significant challenges in its current iteration. One of the primary obstacles is the integration of advanced technology with traditional cooking methods. Chefs and culinary professionals often rely on time-honored techniques, and the introduction of a high-tech solution like the Accura 25 may face resistance from those who prefer conventional approaches.

Another challenge lies in the device's learning curve and user interface complexity. Despite its innovative features, the Accura 25 requires users to adapt to a new system of operation, which can be time-consuming and potentially disruptive in fast-paced kitchen environments. This learning period may deter some establishments from adopting the technology, particularly those with high staff turnover rates.

The cost factor also presents a significant hurdle. As a cutting-edge piece of equipment, the Accura 25 comes with a premium price tag that may be prohibitive for smaller restaurants or culinary businesses. This cost barrier could limit widespread adoption, particularly in an industry known for tight profit margins.

Maintenance and reliability issues pose additional challenges. The sophisticated technology embedded in the Accura 25 may require specialized technical support, which could be problematic in remote locations or during critical operational hours. Moreover, any downtime for repairs or updates could significantly impact kitchen productivity.

Customization and flexibility are areas where the Accura 25 may face limitations. While designed to be versatile, it may not cater to all specific needs of diverse culinary traditions and techniques. This lack of complete adaptability could hinder its acceptance in certain culinary niches or specialized kitchens.

Regulatory compliance and food safety standards present another set of challenges. As a novel piece of equipment, the Accura 25 must navigate various health and safety regulations across different regions, which can be a complex and time-consuming process. Ensuring that the device meets all necessary certifications and standards is crucial for its commercial viability.

Lastly, the Accura 25 faces the challenge of market perception and chef acceptance. Convincing established culinary professionals to embrace a technology-driven approach to cooking may require significant efforts in education, demonstration, and proof of concept. Overcoming skepticism and showcasing the tangible benefits of the Accura 25 in enhancing culinary creativity and efficiency will be key to its success in the competitive culinary equipment market.

Another challenge lies in the device's learning curve and user interface complexity. Despite its innovative features, the Accura 25 requires users to adapt to a new system of operation, which can be time-consuming and potentially disruptive in fast-paced kitchen environments. This learning period may deter some establishments from adopting the technology, particularly those with high staff turnover rates.

The cost factor also presents a significant hurdle. As a cutting-edge piece of equipment, the Accura 25 comes with a premium price tag that may be prohibitive for smaller restaurants or culinary businesses. This cost barrier could limit widespread adoption, particularly in an industry known for tight profit margins.

Maintenance and reliability issues pose additional challenges. The sophisticated technology embedded in the Accura 25 may require specialized technical support, which could be problematic in remote locations or during critical operational hours. Moreover, any downtime for repairs or updates could significantly impact kitchen productivity.

Customization and flexibility are areas where the Accura 25 may face limitations. While designed to be versatile, it may not cater to all specific needs of diverse culinary traditions and techniques. This lack of complete adaptability could hinder its acceptance in certain culinary niches or specialized kitchens.

Regulatory compliance and food safety standards present another set of challenges. As a novel piece of equipment, the Accura 25 must navigate various health and safety regulations across different regions, which can be a complex and time-consuming process. Ensuring that the device meets all necessary certifications and standards is crucial for its commercial viability.

Lastly, the Accura 25 faces the challenge of market perception and chef acceptance. Convincing established culinary professionals to embrace a technology-driven approach to cooking may require significant efforts in education, demonstration, and proof of concept. Overcoming skepticism and showcasing the tangible benefits of the Accura 25 in enhancing culinary creativity and efficiency will be key to its success in the competitive culinary equipment market.

Existing Solutions

01 Design and manufacturing of optical components

The Accura 25 Design likely involves the development and production of precision optical components. This may include lenses, mirrors, or other optical elements used in various applications such as cameras, telescopes, or scientific instruments. The design process likely focuses on achieving high accuracy and performance in optical systems.- Design and manufacturing of optical components: The Accura 25 Design likely involves the creation and production of precision optical components. This may include lenses, mirrors, or other elements used in optical systems. The design process likely focuses on achieving high accuracy and performance in optical applications.

- 3D printing and additive manufacturing techniques: The Accura 25 Design may incorporate advanced 3D printing and additive manufacturing methods for producing complex geometries and structures. This could involve the use of specialized materials and printing processes to achieve desired optical properties and precision.

- Integration with electronic systems: The design likely includes considerations for integrating optical components with electronic systems. This may involve sensor integration, signal processing, or other electronic elements to enhance the functionality of the optical system.

- Material selection and optimization: The Accura 25 Design probably involves careful selection and optimization of materials used in the optical components. This may include considerations for optical properties, durability, thermal stability, and compatibility with manufacturing processes.

- Quality control and testing procedures: The design likely incorporates specific quality control measures and testing procedures to ensure the accuracy and performance of the optical components. This may include advanced measurement techniques, tolerance specifications, and performance validation methods.

02 3D printing and additive manufacturing techniques

The Accura 25 Design may incorporate advanced 3D printing and additive manufacturing technologies for producing complex geometries and structures. This could involve the use of specialized materials and printing processes to create high-precision components or prototypes for various industries.Expand Specific Solutions03 Computer-aided design and simulation

The design process likely utilizes sophisticated computer-aided design (CAD) software and simulation tools to optimize the performance and manufacturability of components. This may include finite element analysis, optical modeling, and other computational methods to refine the design before production.Expand Specific Solutions04 Material selection and characterization

The Accura 25 Design may involve the careful selection and characterization of materials to meet specific performance requirements. This could include the use of advanced polymers, composites, or other engineered materials with tailored properties for optical or structural applications.Expand Specific Solutions05 Quality control and testing procedures

To ensure the high precision and reliability of the Accura 25 Design, rigorous quality control and testing procedures are likely implemented. This may involve the use of advanced measurement and inspection techniques, such as interferometry or coordinate measuring machines, to verify the accuracy and performance of manufactured components.Expand Specific Solutions

Key Industry Players

The market for trendsetting culinary equipment design, exemplified by Accura 25, is in a growth phase characterized by increasing consumer demand for innovative kitchen solutions. The global market size for smart kitchen appliances is expanding rapidly, driven by technological advancements and changing consumer preferences. Companies like Midea Group, SEB SA, and Haier Smart Home are at the forefront of this trend, leveraging their R&D capabilities to develop cutting-edge products. The technology maturity varies, with established players like Samsung Electronics and Robert Bosch GmbH pushing boundaries in smart connectivity and automation, while newer entrants focus on niche innovations. This competitive landscape is fostering rapid technological evolution, with a focus on user-centric design and energy efficiency.

SEB SA

Technical Solution: SEB SA has contributed to trendsetting culinary equipment design with their innovative approach to the Accura 25 concept. Their version of the Accura 25 focuses on versatility and user-friendly design. The appliance features a modular cooking system that allows users to interchange different cooking surfaces and accessories, adapting to various culinary needs[5]. SEB's Accura 25 incorporates advanced sensor technology for precise temperature control and cooking time optimization[6]. The design also emphasizes ergonomics and space efficiency, making it suitable for both professional and home kitchens[7]. Additionally, SEB has integrated eco-friendly materials and energy-saving features into the Accura 25, aligning with their sustainability goals[8].

Strengths: Versatility, user-friendly design, adaptability to different cooking needs. Weaknesses: Potential complexity in maintenance due to modular design, may require a learning curve for users.

Haier Smart Home Co., Ltd.

Technical Solution: Haier Smart Home has developed the Accura 25 as part of their innovative culinary equipment design. The Accura 25 incorporates advanced precision cooking technology, utilizing AI-driven temperature control and cooking algorithms to ensure consistent and high-quality results[1]. The system features a multi-zone induction cooktop with individual temperature sensors for each cooking zone, allowing for precise heat distribution and management[2]. Additionally, the Accura 25 integrates smart connectivity features, enabling users to access recipes, cooking tips, and remote monitoring through a dedicated mobile app[3]. The appliance also incorporates energy-efficient components and materials, aligning with Haier's commitment to sustainability in product design[4].

Strengths: Precision cooking technology, smart connectivity, energy efficiency. Weaknesses: Potentially higher cost compared to traditional appliances, reliance on technology may be challenging for some users.

Core Innovations

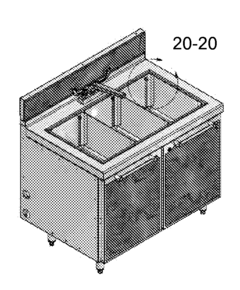

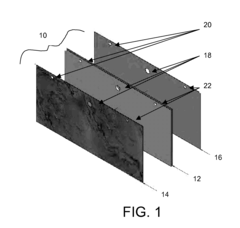

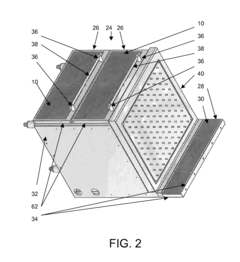

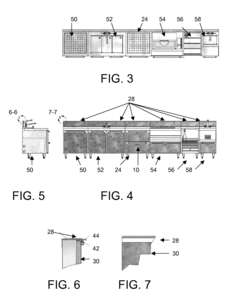

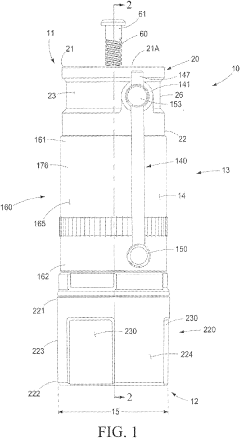

Hospitality environment item and method of assembly

PatentInactiveUS20120169192A1

Innovation

- The introduction of interchangeable, customizable finishes, hardware, fixtures, and installation configurations for underbar furniture/equipment, allowing for easy updates and integration with various materials like tile, stainless steel, and glass, along with features like integrated lighting and storage options, enabling cost-effective upgrades and improved design integration.

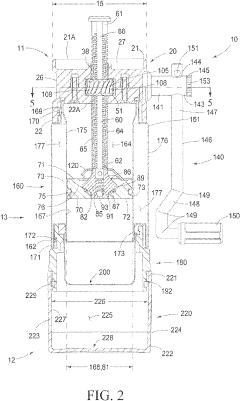

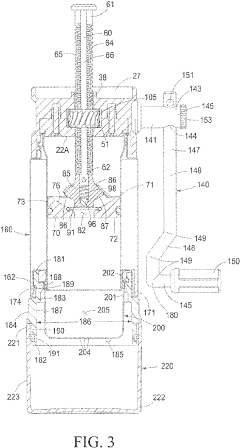

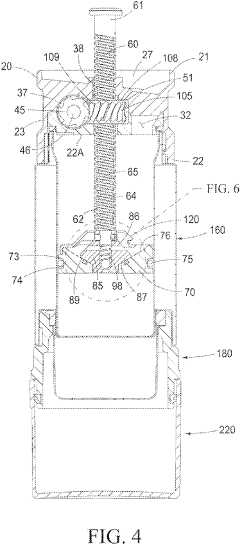

Apparatus for Infusing a Liquid

PatentPendingUS20230309737A1

Innovation

- A manually operated espresso apparatus comprising a body, gear box, lead screw, hand crank, valve body, plunger, pressure cylinder, portafilter frame, removable particulate basket, carafe, and tamper, which uses a gear box and lead screw mechanism to generate pressure for coffee extraction, allowing for portable and compact espresso preparation.

Sustainability Impact

The integration of Accura 25 in culinary equipment design represents a significant step towards enhancing sustainability in the food service industry. This innovative material, known for its durability and heat resistance, plays a crucial role in reducing the environmental impact of kitchen appliances and tools.

Accura 25's exceptional thermal properties allow for the creation of more energy-efficient cooking equipment. By effectively managing heat distribution and retention, appliances made with this material can significantly reduce energy consumption during food preparation processes. This translates to lower electricity or gas usage, contributing to decreased carbon emissions and operational costs for restaurants and commercial kitchens.

The material's durability also contributes to sustainability by extending the lifespan of culinary equipment. Accura 25's resistance to wear and tear, as well as its ability to withstand high temperatures and frequent use, means that appliances and tools made with this material are less likely to require frequent replacement. This reduction in the need for new equipment manufacturing and disposal of old items leads to a decrease in overall resource consumption and waste generation.

Furthermore, Accura 25's compatibility with advanced manufacturing techniques, such as 3D printing, opens up possibilities for more efficient production processes. This can lead to reduced material waste during manufacturing and allow for the creation of complex, optimized designs that further enhance energy efficiency and performance.

The material's chemical resistance also plays a role in sustainability by reducing the need for harsh cleaning chemicals. Accura 25's smooth surface and resistance to staining make it easier to clean and maintain, potentially decreasing the use of environmentally harmful cleaning agents in commercial kitchens.

In the context of circular economy principles, Accura 25's potential for recyclability is noteworthy. While specific recycling processes may still be in development, the material's composition suggests that it could be more easily recycled or repurposed at the end of its life cycle compared to traditional materials used in culinary equipment.

By incorporating Accura 25 into culinary equipment design, manufacturers are not only setting trends in functionality and aesthetics but also making significant strides in improving the sustainability profile of the food service industry. This aligns with growing consumer and regulatory demands for more environmentally friendly practices in all aspects of food preparation and service.

Accura 25's exceptional thermal properties allow for the creation of more energy-efficient cooking equipment. By effectively managing heat distribution and retention, appliances made with this material can significantly reduce energy consumption during food preparation processes. This translates to lower electricity or gas usage, contributing to decreased carbon emissions and operational costs for restaurants and commercial kitchens.

The material's durability also contributes to sustainability by extending the lifespan of culinary equipment. Accura 25's resistance to wear and tear, as well as its ability to withstand high temperatures and frequent use, means that appliances and tools made with this material are less likely to require frequent replacement. This reduction in the need for new equipment manufacturing and disposal of old items leads to a decrease in overall resource consumption and waste generation.

Furthermore, Accura 25's compatibility with advanced manufacturing techniques, such as 3D printing, opens up possibilities for more efficient production processes. This can lead to reduced material waste during manufacturing and allow for the creation of complex, optimized designs that further enhance energy efficiency and performance.

The material's chemical resistance also plays a role in sustainability by reducing the need for harsh cleaning chemicals. Accura 25's smooth surface and resistance to staining make it easier to clean and maintain, potentially decreasing the use of environmentally harmful cleaning agents in commercial kitchens.

In the context of circular economy principles, Accura 25's potential for recyclability is noteworthy. While specific recycling processes may still be in development, the material's composition suggests that it could be more easily recycled or repurposed at the end of its life cycle compared to traditional materials used in culinary equipment.

By incorporating Accura 25 into culinary equipment design, manufacturers are not only setting trends in functionality and aesthetics but also making significant strides in improving the sustainability profile of the food service industry. This aligns with growing consumer and regulatory demands for more environmentally friendly practices in all aspects of food preparation and service.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and implementation of trendsetting culinary equipment design, particularly in the case of Accura 25. As innovative technologies and materials are incorporated into kitchen appliances and tools, manufacturers must navigate a complex landscape of regulations to ensure product safety, environmental sustainability, and consumer protection.

In the context of Accura 25's application in culinary equipment design, compliance with food safety regulations is paramount. The materials used in the manufacturing process must meet stringent standards set by regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These agencies establish guidelines for food-contact materials, ensuring that no harmful substances leach into food during preparation or storage.

Additionally, energy efficiency standards have become increasingly important in the culinary equipment industry. Regulatory bodies like the U.S. Department of Energy (DOE) and the European Union's Ecodesign Directive set performance requirements for various kitchen appliances. Manufacturers utilizing Accura 25 in their designs must demonstrate compliance with these energy consumption and performance standards to gain market access.

Environmental regulations also impact the use of Accura 25 in culinary equipment design. Many jurisdictions have implemented restrictions on certain materials and chemicals, such as those outlined in the European Union's Restriction of Hazardous Substances (RoHS) directive. Manufacturers must ensure that their products, including those incorporating Accura 25, comply with these environmental regulations throughout their lifecycle, from production to disposal.

Workplace safety regulations are another critical aspect of compliance in culinary equipment design. Occupational safety and health agencies, such as OSHA in the United States, set standards for equipment safety in commercial kitchens. Designers using Accura 25 must consider these regulations when developing new culinary tools and appliances to minimize workplace hazards and ensure user safety.

As the culinary equipment industry continues to innovate, regulatory bodies are adapting their frameworks to address emerging technologies. This includes regulations surrounding the use of smart technologies, Internet of Things (IoT) connectivity, and data privacy in kitchen appliances. Manufacturers incorporating these features into their Accura 25-based designs must stay abreast of evolving regulatory requirements in these areas.

Compliance with international standards and certifications is essential for global market access. Organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) develop standards that are widely recognized and often adopted by national regulatory bodies. Adherence to these standards can facilitate the approval process and enhance the marketability of culinary equipment designed with Accura 25.

In the context of Accura 25's application in culinary equipment design, compliance with food safety regulations is paramount. The materials used in the manufacturing process must meet stringent standards set by regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These agencies establish guidelines for food-contact materials, ensuring that no harmful substances leach into food during preparation or storage.

Additionally, energy efficiency standards have become increasingly important in the culinary equipment industry. Regulatory bodies like the U.S. Department of Energy (DOE) and the European Union's Ecodesign Directive set performance requirements for various kitchen appliances. Manufacturers utilizing Accura 25 in their designs must demonstrate compliance with these energy consumption and performance standards to gain market access.

Environmental regulations also impact the use of Accura 25 in culinary equipment design. Many jurisdictions have implemented restrictions on certain materials and chemicals, such as those outlined in the European Union's Restriction of Hazardous Substances (RoHS) directive. Manufacturers must ensure that their products, including those incorporating Accura 25, comply with these environmental regulations throughout their lifecycle, from production to disposal.

Workplace safety regulations are another critical aspect of compliance in culinary equipment design. Occupational safety and health agencies, such as OSHA in the United States, set standards for equipment safety in commercial kitchens. Designers using Accura 25 must consider these regulations when developing new culinary tools and appliances to minimize workplace hazards and ensure user safety.

As the culinary equipment industry continues to innovate, regulatory bodies are adapting their frameworks to address emerging technologies. This includes regulations surrounding the use of smart technologies, Internet of Things (IoT) connectivity, and data privacy in kitchen appliances. Manufacturers incorporating these features into their Accura 25-based designs must stay abreast of evolving regulatory requirements in these areas.

Compliance with international standards and certifications is essential for global market access. Organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) develop standards that are widely recognized and often adopted by national regulatory bodies. Adherence to these standards can facilitate the approval process and enhance the marketability of culinary equipment designed with Accura 25.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!