Advanced Coating for Improved Heat Dissipation in 454 Big Blocks

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Dissipation Challenges in 454 Big Blocks

The 454 Big Block engine, renowned for its power and performance, faces significant heat dissipation challenges that can impact its efficiency and longevity. These challenges stem from the engine's large displacement and high-performance nature, which generate substantial heat during operation. The primary areas of concern include the cylinder heads, exhaust valves, and combustion chambers, where temperatures can reach extreme levels.

One of the main heat dissipation challenges is the thermal stress on cylinder heads. The 454 Big Block's large bore size and high compression ratios result in intense heat generation within the combustion chambers. This heat must be efficiently transferred away from the cylinder heads to prevent warping, cracking, or other forms of thermal damage. The traditional cooling passages in the engine block and heads may struggle to dissipate heat quickly enough, especially during high-load or prolonged high-rpm operations.

Another critical area is the exhaust valves, which are subjected to the hottest gases in the engine. The large valve sizes in the 454 Big Block, while beneficial for airflow, also present a significant heat management challenge. Insufficient cooling of these valves can lead to premature wear, valve seat recession, or even valve failure in extreme cases.

The combustion chambers themselves pose a unique heat dissipation challenge. The large volume of fuel-air mixture ignited in each cycle produces intense heat that must be managed effectively. Hotspots in the combustion chamber can lead to pre-ignition or detonation, severely impacting engine performance and potentially causing damage.

The engine's oil system also plays a crucial role in heat dissipation. The 454 Big Block's high-performance nature puts additional stress on the oil, which must not only lubricate but also aid in cooling various engine components. Ensuring adequate oil flow and cooling capacity is essential for maintaining optimal engine temperatures.

Furthermore, the sheer size and weight of the 454 Big Block engine create challenges in terms of overall vehicle heat management. The engine's mass retains heat, potentially leading to underhood temperature issues that can affect other vehicle systems and components.

Addressing these heat dissipation challenges is crucial for maximizing the performance and reliability of the 454 Big Block engine. Advanced coating technologies offer promising solutions to enhance heat dissipation, protect critical components, and improve overall thermal management in these powerful engines.

One of the main heat dissipation challenges is the thermal stress on cylinder heads. The 454 Big Block's large bore size and high compression ratios result in intense heat generation within the combustion chambers. This heat must be efficiently transferred away from the cylinder heads to prevent warping, cracking, or other forms of thermal damage. The traditional cooling passages in the engine block and heads may struggle to dissipate heat quickly enough, especially during high-load or prolonged high-rpm operations.

Another critical area is the exhaust valves, which are subjected to the hottest gases in the engine. The large valve sizes in the 454 Big Block, while beneficial for airflow, also present a significant heat management challenge. Insufficient cooling of these valves can lead to premature wear, valve seat recession, or even valve failure in extreme cases.

The combustion chambers themselves pose a unique heat dissipation challenge. The large volume of fuel-air mixture ignited in each cycle produces intense heat that must be managed effectively. Hotspots in the combustion chamber can lead to pre-ignition or detonation, severely impacting engine performance and potentially causing damage.

The engine's oil system also plays a crucial role in heat dissipation. The 454 Big Block's high-performance nature puts additional stress on the oil, which must not only lubricate but also aid in cooling various engine components. Ensuring adequate oil flow and cooling capacity is essential for maintaining optimal engine temperatures.

Furthermore, the sheer size and weight of the 454 Big Block engine create challenges in terms of overall vehicle heat management. The engine's mass retains heat, potentially leading to underhood temperature issues that can affect other vehicle systems and components.

Addressing these heat dissipation challenges is crucial for maximizing the performance and reliability of the 454 Big Block engine. Advanced coating technologies offer promising solutions to enhance heat dissipation, protect critical components, and improve overall thermal management in these powerful engines.

Market Demand for Enhanced Engine Cooling

The market demand for enhanced engine cooling in 454 Big Blocks has been steadily increasing due to the growing emphasis on performance and efficiency in the automotive industry. As vehicles become more powerful and compact, the need for effective heat dissipation becomes paramount. The 454 Big Block engine, known for its high output and robust design, is particularly susceptible to heat-related issues, making it a prime target for advanced cooling solutions.

In recent years, there has been a significant shift towards high-performance vehicles, both in the consumer market and in motorsports. This trend has led to a surge in demand for engines that can deliver exceptional power while maintaining optimal operating temperatures. The 454 Big Block, with its large displacement and potential for high horsepower, fits perfectly into this niche. However, its tendency to generate substantial heat during operation has created a pressing need for innovative cooling technologies.

The aftermarket parts industry has responded to this demand by developing a range of products aimed at improving heat dissipation in these engines. From advanced radiators and high-flow water pumps to specialized coolants, the market offers various solutions. However, there is a growing recognition that these traditional approaches may not be sufficient to meet the increasingly stringent performance requirements of modern high-output engines.

This gap in the market has created an opportunity for advanced coating technologies that can directly address the heat dissipation challenges of the 454 Big Block. The potential benefits of such coatings, including improved thermal efficiency, reduced engine wear, and enhanced overall performance, have generated significant interest among engine builders, performance enthusiasts, and racing teams.

Market research indicates that the global automotive thermal management system market, which includes advanced cooling solutions, is expected to grow substantially in the coming years. This growth is driven not only by the performance sector but also by the broader automotive industry's push towards more efficient and environmentally friendly vehicles. The demand for advanced coatings that can improve heat dissipation in high-performance engines like the 454 Big Block is a significant part of this larger trend.

Furthermore, the increasing focus on sustainability and fuel efficiency in the automotive sector has indirectly boosted the demand for enhanced engine cooling solutions. By improving heat dissipation, these technologies can contribute to better fuel economy and reduced emissions, aligning with both consumer preferences and regulatory requirements.

The market for advanced cooling solutions in 454 Big Blocks is not limited to new engines. There is also a substantial retrofit market, as owners of existing vehicles seek to upgrade their engines with the latest heat dissipation technologies. This dual market – new installations and retrofits – further expands the potential for advanced coating solutions.

In recent years, there has been a significant shift towards high-performance vehicles, both in the consumer market and in motorsports. This trend has led to a surge in demand for engines that can deliver exceptional power while maintaining optimal operating temperatures. The 454 Big Block, with its large displacement and potential for high horsepower, fits perfectly into this niche. However, its tendency to generate substantial heat during operation has created a pressing need for innovative cooling technologies.

The aftermarket parts industry has responded to this demand by developing a range of products aimed at improving heat dissipation in these engines. From advanced radiators and high-flow water pumps to specialized coolants, the market offers various solutions. However, there is a growing recognition that these traditional approaches may not be sufficient to meet the increasingly stringent performance requirements of modern high-output engines.

This gap in the market has created an opportunity for advanced coating technologies that can directly address the heat dissipation challenges of the 454 Big Block. The potential benefits of such coatings, including improved thermal efficiency, reduced engine wear, and enhanced overall performance, have generated significant interest among engine builders, performance enthusiasts, and racing teams.

Market research indicates that the global automotive thermal management system market, which includes advanced cooling solutions, is expected to grow substantially in the coming years. This growth is driven not only by the performance sector but also by the broader automotive industry's push towards more efficient and environmentally friendly vehicles. The demand for advanced coatings that can improve heat dissipation in high-performance engines like the 454 Big Block is a significant part of this larger trend.

Furthermore, the increasing focus on sustainability and fuel efficiency in the automotive sector has indirectly boosted the demand for enhanced engine cooling solutions. By improving heat dissipation, these technologies can contribute to better fuel economy and reduced emissions, aligning with both consumer preferences and regulatory requirements.

The market for advanced cooling solutions in 454 Big Blocks is not limited to new engines. There is also a substantial retrofit market, as owners of existing vehicles seek to upgrade their engines with the latest heat dissipation technologies. This dual market – new installations and retrofits – further expands the potential for advanced coating solutions.

Current Coating Technologies and Limitations

Current coating technologies for heat dissipation in 454 Big Blocks have made significant strides in recent years, yet they still face several limitations. The most commonly used coatings include ceramic thermal barrier coatings (TBCs), metallic thermal spray coatings, and polymer-based thermal management coatings. Each of these technologies offers unique advantages but also comes with specific drawbacks.

Ceramic TBCs, typically composed of materials like yttria-stabilized zirconia (YSZ), provide excellent thermal insulation and can withstand high temperatures. However, they often suffer from poor adhesion to metal substrates and are prone to spallation under thermal cycling conditions. This can lead to coating failure and reduced engine performance over time.

Metallic thermal spray coatings, such as those based on MCrAlY alloys (where M represents nickel, cobalt, or a combination), offer good oxidation resistance and thermal conductivity. These coatings can be applied using various techniques like plasma spraying or high-velocity oxy-fuel (HVOF) spraying. While they provide better adhesion compared to ceramic coatings, they may not offer the same level of thermal insulation and can be susceptible to corrosion in certain environments.

Polymer-based thermal management coatings have gained attention due to their ease of application and flexibility. These coatings often incorporate thermally conductive fillers like boron nitride or aluminum oxide. While they can be effective for moderate temperature applications, they generally lack the high-temperature capabilities required for 454 Big Blocks operating under extreme conditions.

A significant limitation across all current coating technologies is the challenge of maintaining consistent thickness and uniformity, especially on complex engine geometries. This can lead to variations in thermal performance and potential hot spots within the engine block. Additionally, the durability of these coatings under prolonged exposure to high temperatures, thermal cycling, and mechanical stresses remains a concern.

Another limitation is the trade-off between thermal insulation and heat dissipation. While some coatings excel at insulating the engine components from extreme temperatures, they may inadvertently impede the necessary heat dissipation, potentially leading to overheating issues in other areas of the engine.

The application process for many of these coatings can be complex and time-consuming, often requiring specialized equipment and skilled technicians. This can increase production costs and limit the widespread adoption of advanced coating technologies in mass-produced engines.

Furthermore, the environmental impact and regulatory compliance of certain coating materials and processes pose challenges. Some high-performance coatings may contain materials that are subject to increasing environmental scrutiny, necessitating the development of more sustainable alternatives.

Ceramic TBCs, typically composed of materials like yttria-stabilized zirconia (YSZ), provide excellent thermal insulation and can withstand high temperatures. However, they often suffer from poor adhesion to metal substrates and are prone to spallation under thermal cycling conditions. This can lead to coating failure and reduced engine performance over time.

Metallic thermal spray coatings, such as those based on MCrAlY alloys (where M represents nickel, cobalt, or a combination), offer good oxidation resistance and thermal conductivity. These coatings can be applied using various techniques like plasma spraying or high-velocity oxy-fuel (HVOF) spraying. While they provide better adhesion compared to ceramic coatings, they may not offer the same level of thermal insulation and can be susceptible to corrosion in certain environments.

Polymer-based thermal management coatings have gained attention due to their ease of application and flexibility. These coatings often incorporate thermally conductive fillers like boron nitride or aluminum oxide. While they can be effective for moderate temperature applications, they generally lack the high-temperature capabilities required for 454 Big Blocks operating under extreme conditions.

A significant limitation across all current coating technologies is the challenge of maintaining consistent thickness and uniformity, especially on complex engine geometries. This can lead to variations in thermal performance and potential hot spots within the engine block. Additionally, the durability of these coatings under prolonged exposure to high temperatures, thermal cycling, and mechanical stresses remains a concern.

Another limitation is the trade-off between thermal insulation and heat dissipation. While some coatings excel at insulating the engine components from extreme temperatures, they may inadvertently impede the necessary heat dissipation, potentially leading to overheating issues in other areas of the engine.

The application process for many of these coatings can be complex and time-consuming, often requiring specialized equipment and skilled technicians. This can increase production costs and limit the widespread adoption of advanced coating technologies in mass-produced engines.

Furthermore, the environmental impact and regulatory compliance of certain coating materials and processes pose challenges. Some high-performance coatings may contain materials that are subject to increasing environmental scrutiny, necessitating the development of more sustainable alternatives.

Existing Advanced Coating Solutions

01 Advanced thermal management coatings

Innovative coating technologies are developed to enhance heat dissipation in electronic devices and components. These coatings are designed to efficiently transfer heat away from critical areas, improving overall thermal management and device performance. The advanced coatings may incorporate materials with high thermal conductivity or utilize novel structures to maximize heat transfer.- Nanostructured coatings for enhanced heat dissipation: Advanced coatings with nanostructured materials are used to improve heat dissipation in electronic devices. These coatings can be applied to various surfaces to increase thermal conductivity and promote efficient heat transfer. The nanostructures create a larger surface area for heat exchange, enhancing overall cooling performance.

- Phase change materials in thermal management coatings: Incorporating phase change materials (PCMs) into coatings provides advanced heat dissipation capabilities. These materials absorb and release thermal energy during phase transitions, helping to regulate temperature and improve heat management in various applications, including electronics and building materials.

- Graphene-based coatings for superior thermal conductivity: Graphene-based coatings offer exceptional thermal conductivity properties for advanced heat dissipation. These ultra-thin coatings can be applied to various substrates to enhance heat transfer and improve overall thermal management in electronic devices and other heat-sensitive applications.

- Multi-layer coating systems for optimized heat dissipation: Advanced multi-layer coating systems are designed to optimize heat dissipation through a combination of materials with different thermal properties. These systems can include layers for heat spreading, insulation, and emission, providing a comprehensive approach to thermal management in various industries.

- Self-healing thermal coatings for long-term performance: Self-healing thermal coatings are developed to maintain long-term heat dissipation performance. These advanced coatings can repair minor damages and maintain their thermal properties over time, ensuring consistent heat management in challenging environments and extending the lifespan of coated components.

02 Nanostructured coatings for heat dissipation

Nanostructured coatings are employed to significantly improve heat dissipation capabilities. These coatings utilize nanomaterials or nanostructures to create large surface areas for enhanced heat transfer. The nanostructured design allows for efficient heat conduction and radiation, making them particularly effective for applications requiring high thermal management performance.Expand Specific Solutions03 Phase change material coatings

Coatings incorporating phase change materials (PCMs) are developed for advanced heat dissipation. These coatings utilize the latent heat absorption properties of PCMs to regulate temperature and manage heat flow. During temperature fluctuations, the PCMs in the coating change phase, absorbing or releasing heat, thereby maintaining a more stable thermal environment for the coated components.Expand Specific Solutions04 Multi-layer thermal management coatings

Advanced multi-layer coating systems are designed for optimized heat dissipation. These coatings combine different materials and structures in multiple layers, each serving a specific thermal management function. The layered approach allows for tailored heat transfer properties, such as directional heat flow or selective heat reflection, resulting in improved overall thermal performance.Expand Specific Solutions05 Smart coatings with adaptive thermal properties

Innovative smart coatings with adaptive thermal properties are developed for advanced heat dissipation. These coatings can dynamically adjust their thermal characteristics in response to environmental changes or external stimuli. The adaptive nature of these coatings allows for optimized heat management across varying operating conditions, enhancing the overall efficiency and reliability of thermal systems.Expand Specific Solutions

Key Players in Advanced Coating Industry

The advanced coating technology for improved heat dissipation in 454 Big Blocks is in a competitive and evolving market. The industry is in a growth phase, driven by increasing demand for high-performance engines and thermal management solutions. The market size is expanding, with potential applications in automotive, aerospace, and industrial sectors. Technologically, the field is advancing rapidly, with companies like Siemens AG, Toyota Motor Corp., and Applied Materials, Inc. leading innovation. These firms, along with specialized players such as Xu Yang Thermal Conduction Co., Ltd., are investing in R&D to develop more efficient and durable coatings. The technology's maturity varies, with some established solutions and ongoing research for next-generation materials and application methods.

Siemens AG

Technical Solution: Siemens has developed an advanced thermal management coating system applicable to high-performance engines like the 454 Big Block. Their solution utilizes a combination of thermal spraying and laser cladding techniques to create a multi-functional coating. The base layer consists of a nickel-based superalloy with embedded ceramic particles, providing both thermal resistance and structural integrity. This is followed by a middle layer of functionally graded material (FGM) that gradually transitions from metal to ceramic, minimizing thermal expansion mismatches. The top layer is a nanostructured zirconia-based thermal barrier coating, deposited using suspension plasma spraying for enhanced porosity control and thermal insulation[7][9]. Siemens' coating system also incorporates smart sensors within the layers, allowing for real-time monitoring of coating integrity and engine thermal conditions, enabling predictive maintenance and optimized engine performance.

Strengths: Multi-functional coating with integrated sensors for real-time monitoring. Excellent thermal insulation and structural integrity. Weaknesses: Complex manufacturing process and potentially high initial implementation costs.

Toyota Motor Corp.

Technical Solution: Toyota has developed an innovative thermal management coating system for high-performance engines, including applications suitable for the 454 Big Block. Their approach combines a ceramic matrix composite (CMC) coating with an advanced thermal barrier coating (TBC). The CMC layer, composed of silicon carbide fibers in a silicon carbide matrix, provides exceptional heat resistance and mechanical strength. On top of this, Toyota applies a yttria-stabilized zirconia TBC using electron beam physical vapor deposition (EB-PVD), creating a columnar microstructure that enhances strain tolerance and thermal cycling resistance[4][6]. This dual-layer system not only improves heat dissipation but also reduces thermal stress on engine components. Toyota's coating technology also incorporates self-healing properties, where minor cracks can be repaired during engine operation, extending the coating's lifespan and maintaining its thermal performance over time.

Strengths: Excellent heat resistance, mechanical strength, and self-healing properties. Weaknesses: Potentially high production costs and complexity in large-scale manufacturing.

Innovative Coating Materials and Techniques

Coating material or paint having improved heat transfer and heat-transferring surface having a coating that is produced using the coating material

PatentWO2008107734A1

Innovation

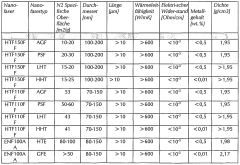

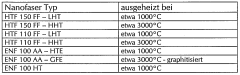

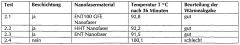

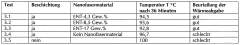

- A coating material comprising a lacquer base with nanofibers, such as ENF-100-HT, HTP-150F-LHT, and HTP-110FF-LHT, which enhances heat transfer by increasing the effective surface area through a finely structured surface, improving both radiative and convective heat dissipation while providing surface protection.

Coating material or paint having improved heat transfer and heat-transferring surface having a coating that is produced using the coating material

PatentInactiveEP2129727A1

Innovation

- A coating material comprising a lacquer base with nanofibers, such as ENF-100-HT, HTP-150F-LHT, and HTP-110FF-LHT, which enhances heat transfer by increasing the effective surface area through radiation and convection, while also providing surface protection against corrosion.

Environmental Impact of Coating Technologies

The environmental impact of coating technologies used in advanced heat dissipation systems for 454 Big Blocks is a critical consideration in the automotive industry. These coatings, while improving engine performance and efficiency, can have both positive and negative effects on the environment throughout their lifecycle.

One of the primary environmental benefits of advanced heat dissipation coatings is the potential reduction in fuel consumption. By improving heat transfer and thermal efficiency, these coatings allow engines to operate at higher temperatures with less energy loss. This increased efficiency translates to lower fuel consumption and, consequently, reduced greenhouse gas emissions. Over the lifetime of a vehicle, this can result in a significant decrease in carbon footprint.

However, the production process of these advanced coatings often involves the use of specialized materials and energy-intensive manufacturing techniques. Some coating materials may include rare earth elements or other scarce resources, raising concerns about resource depletion and the environmental impact of mining activities. The manufacturing process may also generate hazardous waste or emissions that require careful management and disposal.

During the use phase, the durability and longevity of the coating play a crucial role in its environmental impact. High-quality coatings that maintain their performance over extended periods can reduce the need for engine maintenance or replacement, thereby minimizing waste generation and resource consumption associated with repairs or engine rebuilds.

End-of-life considerations are also important when assessing the environmental impact of these coatings. The recyclability of coated engine components may be affected by the presence of advanced coatings, potentially complicating the recycling process or reducing the recyclable content of the engine block. Some coating materials may require special handling or disposal procedures to prevent environmental contamination.

Advancements in coating technologies are continually addressing these environmental concerns. Research is focused on developing more environmentally friendly coating materials and application processes. Bio-based or recyclable coating materials are being explored as alternatives to traditional petroleum-based products. Additionally, improvements in application techniques aim to reduce overspray and waste, minimizing the environmental footprint of the coating process.

The automotive industry is also investigating the potential for these coatings to enable the use of alternative materials in engine construction. For instance, the enhanced heat dissipation properties might allow for the use of lighter materials in engine blocks, contributing to overall vehicle weight reduction and improved fuel efficiency.

In conclusion, while advanced coatings for improved heat dissipation in 454 Big Blocks offer significant environmental benefits through increased engine efficiency, their overall environmental impact must be carefully considered across the entire lifecycle. Continued research and development in this field are essential to maximize the positive environmental effects while mitigating potential negative impacts.

One of the primary environmental benefits of advanced heat dissipation coatings is the potential reduction in fuel consumption. By improving heat transfer and thermal efficiency, these coatings allow engines to operate at higher temperatures with less energy loss. This increased efficiency translates to lower fuel consumption and, consequently, reduced greenhouse gas emissions. Over the lifetime of a vehicle, this can result in a significant decrease in carbon footprint.

However, the production process of these advanced coatings often involves the use of specialized materials and energy-intensive manufacturing techniques. Some coating materials may include rare earth elements or other scarce resources, raising concerns about resource depletion and the environmental impact of mining activities. The manufacturing process may also generate hazardous waste or emissions that require careful management and disposal.

During the use phase, the durability and longevity of the coating play a crucial role in its environmental impact. High-quality coatings that maintain their performance over extended periods can reduce the need for engine maintenance or replacement, thereby minimizing waste generation and resource consumption associated with repairs or engine rebuilds.

End-of-life considerations are also important when assessing the environmental impact of these coatings. The recyclability of coated engine components may be affected by the presence of advanced coatings, potentially complicating the recycling process or reducing the recyclable content of the engine block. Some coating materials may require special handling or disposal procedures to prevent environmental contamination.

Advancements in coating technologies are continually addressing these environmental concerns. Research is focused on developing more environmentally friendly coating materials and application processes. Bio-based or recyclable coating materials are being explored as alternatives to traditional petroleum-based products. Additionally, improvements in application techniques aim to reduce overspray and waste, minimizing the environmental footprint of the coating process.

The automotive industry is also investigating the potential for these coatings to enable the use of alternative materials in engine construction. For instance, the enhanced heat dissipation properties might allow for the use of lighter materials in engine blocks, contributing to overall vehicle weight reduction and improved fuel efficiency.

In conclusion, while advanced coatings for improved heat dissipation in 454 Big Blocks offer significant environmental benefits through increased engine efficiency, their overall environmental impact must be carefully considered across the entire lifecycle. Continued research and development in this field are essential to maximize the positive environmental effects while mitigating potential negative impacts.

Performance Testing and Validation Methods

Performance testing and validation methods for advanced coatings designed to improve heat dissipation in 454 Big Block engines require a comprehensive approach to ensure reliability and effectiveness. These methods typically involve a combination of laboratory tests and real-world simulations to assess the coating's performance under various conditions.

One of the primary testing methods is thermal conductivity measurement. This involves using specialized equipment such as a guarded hot plate apparatus or a laser flash analyzer to determine the coating's ability to transfer heat. The thermal conductivity values obtained are compared to baseline measurements of uncoated engine components to quantify the improvement in heat dissipation.

Durability testing is another crucial aspect of performance validation. This includes thermal cycling tests, where coated components are subjected to repeated heating and cooling cycles to simulate real-world engine operation. The coating's adhesion, thermal expansion behavior, and resistance to cracking or delamination are closely monitored throughout these cycles.

Corrosion resistance testing is also essential, as engine components are exposed to various corrosive substances during operation. Salt spray tests and immersion tests in simulated engine coolants and oils are conducted to evaluate the coating's protective properties and long-term durability.

Engine dynamometer testing provides valuable data on the coating's performance in a controlled, yet realistic environment. Coated engine components are installed in a test engine, which is then run through various load and speed conditions while monitoring parameters such as engine temperature, oil temperature, and overall thermal efficiency.

Field testing in actual vehicles represents the ultimate validation method. This involves installing coated components in test vehicles and subjecting them to rigorous driving conditions, including high-speed runs, towing, and extended idling. Data logging systems are used to capture real-time temperature and performance metrics during these tests.

Microscopic analysis techniques, such as scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS), are employed to examine the coating's structure and composition before and after testing. This helps in understanding any changes or degradation that may occur during use and informs potential improvements to the coating formulation or application process.

Computational fluid dynamics (CFD) simulations complement physical testing by providing insights into heat flow patterns and thermal management within the engine. These simulations can be validated against experimental data and used to optimize coating designs and application strategies.

Standardized testing protocols, such as those developed by SAE International or ASTM, are often incorporated into the validation process to ensure consistency and comparability of results across different coating technologies and engine designs.

One of the primary testing methods is thermal conductivity measurement. This involves using specialized equipment such as a guarded hot plate apparatus or a laser flash analyzer to determine the coating's ability to transfer heat. The thermal conductivity values obtained are compared to baseline measurements of uncoated engine components to quantify the improvement in heat dissipation.

Durability testing is another crucial aspect of performance validation. This includes thermal cycling tests, where coated components are subjected to repeated heating and cooling cycles to simulate real-world engine operation. The coating's adhesion, thermal expansion behavior, and resistance to cracking or delamination are closely monitored throughout these cycles.

Corrosion resistance testing is also essential, as engine components are exposed to various corrosive substances during operation. Salt spray tests and immersion tests in simulated engine coolants and oils are conducted to evaluate the coating's protective properties and long-term durability.

Engine dynamometer testing provides valuable data on the coating's performance in a controlled, yet realistic environment. Coated engine components are installed in a test engine, which is then run through various load and speed conditions while monitoring parameters such as engine temperature, oil temperature, and overall thermal efficiency.

Field testing in actual vehicles represents the ultimate validation method. This involves installing coated components in test vehicles and subjecting them to rigorous driving conditions, including high-speed runs, towing, and extended idling. Data logging systems are used to capture real-time temperature and performance metrics during these tests.

Microscopic analysis techniques, such as scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS), are employed to examine the coating's structure and composition before and after testing. This helps in understanding any changes or degradation that may occur during use and informs potential improvements to the coating formulation or application process.

Computational fluid dynamics (CFD) simulations complement physical testing by providing insights into heat flow patterns and thermal management within the engine. These simulations can be validated against experimental data and used to optimize coating designs and application strategies.

Standardized testing protocols, such as those developed by SAE International or ASTM, are often incorporated into the validation process to ensure consistency and comparability of results across different coating technologies and engine designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!