Analysing Carbolic Acid’s Role in Jet Fuel Additive Formulations

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid in Jet Fuel: Background and Objectives

Carbolic acid, also known as phenol, has emerged as a significant component in the development of jet fuel additives. The aviation industry's continuous pursuit of enhanced fuel efficiency and reduced environmental impact has led to increased interest in innovative additive formulations. This technical research aims to comprehensively examine the role of carbolic acid in jet fuel additives, exploring its potential benefits and challenges.

The evolution of jet fuel technology has been marked by a series of advancements aimed at improving performance, safety, and environmental sustainability. Carbolic acid, with its unique chemical properties, has attracted attention as a potential game-changer in this field. Its ability to interact with hydrocarbons and other fuel components offers promising avenues for enhancing fuel stability, combustion efficiency, and overall engine performance.

The primary objective of this research is to analyze the fundamental mechanisms by which carbolic acid influences jet fuel properties and combustion characteristics. This includes investigating its effects on fuel stability, thermal oxidation resistance, and lubricity. Additionally, the study aims to assess the potential of carbolic acid-based additives in reducing harmful emissions and improving the overall environmental profile of jet fuels.

Another crucial aspect of this research is to evaluate the compatibility of carbolic acid with existing jet fuel formulations and engine systems. This involves examining potential interactions with other fuel components, as well as assessing any long-term effects on engine materials and performance. The goal is to determine whether carbolic acid-based additives can be seamlessly integrated into current aviation fuel systems without necessitating significant modifications to existing infrastructure.

Furthermore, this study will explore the economic implications of incorporating carbolic acid into jet fuel additives. This includes analyzing the cost-effectiveness of production, potential fuel savings, and the overall impact on operational expenses for airlines and other aviation stakeholders. The research will also consider the regulatory landscape and potential challenges in gaining approval for new fuel additive formulations.

As the aviation industry faces increasing pressure to reduce its carbon footprint, this research will also investigate the potential of carbolic acid-based additives in supporting the transition to more sustainable aviation fuels. This includes examining how these additives might enhance the performance of biofuels or synthetic fuels, potentially accelerating their adoption in the commercial aviation sector.

By comprehensively addressing these aspects, this technical research aims to provide a clear understanding of carbolic acid's potential in jet fuel additive formulations. The findings will serve as a foundation for future development efforts and strategic decision-making in the aviation fuel industry, potentially paving the way for more efficient and environmentally friendly air travel.

The evolution of jet fuel technology has been marked by a series of advancements aimed at improving performance, safety, and environmental sustainability. Carbolic acid, with its unique chemical properties, has attracted attention as a potential game-changer in this field. Its ability to interact with hydrocarbons and other fuel components offers promising avenues for enhancing fuel stability, combustion efficiency, and overall engine performance.

The primary objective of this research is to analyze the fundamental mechanisms by which carbolic acid influences jet fuel properties and combustion characteristics. This includes investigating its effects on fuel stability, thermal oxidation resistance, and lubricity. Additionally, the study aims to assess the potential of carbolic acid-based additives in reducing harmful emissions and improving the overall environmental profile of jet fuels.

Another crucial aspect of this research is to evaluate the compatibility of carbolic acid with existing jet fuel formulations and engine systems. This involves examining potential interactions with other fuel components, as well as assessing any long-term effects on engine materials and performance. The goal is to determine whether carbolic acid-based additives can be seamlessly integrated into current aviation fuel systems without necessitating significant modifications to existing infrastructure.

Furthermore, this study will explore the economic implications of incorporating carbolic acid into jet fuel additives. This includes analyzing the cost-effectiveness of production, potential fuel savings, and the overall impact on operational expenses for airlines and other aviation stakeholders. The research will also consider the regulatory landscape and potential challenges in gaining approval for new fuel additive formulations.

As the aviation industry faces increasing pressure to reduce its carbon footprint, this research will also investigate the potential of carbolic acid-based additives in supporting the transition to more sustainable aviation fuels. This includes examining how these additives might enhance the performance of biofuels or synthetic fuels, potentially accelerating their adoption in the commercial aviation sector.

By comprehensively addressing these aspects, this technical research aims to provide a clear understanding of carbolic acid's potential in jet fuel additive formulations. The findings will serve as a foundation for future development efforts and strategic decision-making in the aviation fuel industry, potentially paving the way for more efficient and environmentally friendly air travel.

Market Analysis for Jet Fuel Additives

The jet fuel additives market has experienced significant growth in recent years, driven by the increasing demand for improved fuel efficiency and performance in the aviation industry. The global market for jet fuel additives is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to exceed 5% over the next five years. This growth is primarily attributed to the rising air passenger traffic, expanding commercial aircraft fleets, and stringent environmental regulations.

The market for jet fuel additives can be segmented based on product type, including fuel system icing inhibitors, corrosion inhibitors, antioxidants, and others. Among these, fuel system icing inhibitors hold the largest market share due to their critical role in preventing ice formation in aircraft fuel systems. Corrosion inhibitors are also gaining traction as airlines focus on extending the lifespan of their aircraft and reducing maintenance costs.

Geographically, North America dominates the jet fuel additives market, followed by Europe and Asia-Pacific. The United States, in particular, accounts for a significant portion of the market share due to its large commercial aviation sector and advanced aerospace industry. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by the rapid expansion of air travel in countries like China and India.

Key factors influencing market demand include the need for improved fuel efficiency, reduced emissions, and enhanced engine performance. Airlines are increasingly seeking additives that can help them meet stringent environmental regulations while also optimizing their operational costs. This has led to a growing interest in advanced formulations, including those incorporating carbolic acid derivatives.

The competitive landscape of the jet fuel additives market is characterized by the presence of several major players, including Afton Chemical Corporation, BASF SE, Chevron Oronite Company LLC, and Innospec Inc. These companies are investing heavily in research and development to create innovative additive formulations that address the evolving needs of the aviation industry.

Despite the overall positive outlook, the market faces challenges such as fluctuating crude oil prices and the potential shift towards alternative fuels. The COVID-19 pandemic has also temporarily impacted market growth due to reduced air travel. However, as the aviation industry recovers, the demand for jet fuel additives is expected to rebound strongly.

In conclusion, the jet fuel additives market presents significant opportunities for growth and innovation, particularly in the development of advanced formulations that can enhance fuel performance while meeting environmental standards. The role of carbolic acid in these formulations is an area of increasing interest, as researchers and manufacturers explore its potential to improve the overall effectiveness of jet fuel additives.

The market for jet fuel additives can be segmented based on product type, including fuel system icing inhibitors, corrosion inhibitors, antioxidants, and others. Among these, fuel system icing inhibitors hold the largest market share due to their critical role in preventing ice formation in aircraft fuel systems. Corrosion inhibitors are also gaining traction as airlines focus on extending the lifespan of their aircraft and reducing maintenance costs.

Geographically, North America dominates the jet fuel additives market, followed by Europe and Asia-Pacific. The United States, in particular, accounts for a significant portion of the market share due to its large commercial aviation sector and advanced aerospace industry. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by the rapid expansion of air travel in countries like China and India.

Key factors influencing market demand include the need for improved fuel efficiency, reduced emissions, and enhanced engine performance. Airlines are increasingly seeking additives that can help them meet stringent environmental regulations while also optimizing their operational costs. This has led to a growing interest in advanced formulations, including those incorporating carbolic acid derivatives.

The competitive landscape of the jet fuel additives market is characterized by the presence of several major players, including Afton Chemical Corporation, BASF SE, Chevron Oronite Company LLC, and Innospec Inc. These companies are investing heavily in research and development to create innovative additive formulations that address the evolving needs of the aviation industry.

Despite the overall positive outlook, the market faces challenges such as fluctuating crude oil prices and the potential shift towards alternative fuels. The COVID-19 pandemic has also temporarily impacted market growth due to reduced air travel. However, as the aviation industry recovers, the demand for jet fuel additives is expected to rebound strongly.

In conclusion, the jet fuel additives market presents significant opportunities for growth and innovation, particularly in the development of advanced formulations that can enhance fuel performance while meeting environmental standards. The role of carbolic acid in these formulations is an area of increasing interest, as researchers and manufacturers explore its potential to improve the overall effectiveness of jet fuel additives.

Current Challenges in Jet Fuel Formulations

The jet fuel industry is currently grappling with several significant challenges that impact the formulation and performance of aviation fuels. One of the primary concerns is the need for improved fuel efficiency to reduce operational costs and environmental impact. This has led to a push for additives that can enhance combustion properties and reduce fuel consumption without compromising safety or engine performance.

Another critical challenge is the increasing demand for cleaner-burning fuels to meet stringent environmental regulations. The aviation sector is under pressure to reduce its carbon footprint, necessitating the development of fuel formulations that produce fewer emissions, particularly in terms of particulate matter and nitrogen oxides. This has sparked interest in exploring novel additives that can promote more complete combustion and reduce harmful byproducts.

Fuel stability during long-term storage and under extreme operating conditions remains a persistent issue. Jet fuels must maintain their properties across a wide range of temperatures and pressures, from sub-zero conditions at high altitudes to the intense heat of engine combustion chambers. Formulating additives that can enhance thermal and oxidative stability without negatively impacting other fuel characteristics is a complex balancing act.

The compatibility of fuel additives with existing engine systems and infrastructure is another significant hurdle. Any new formulation must be thoroughly tested to ensure it does not cause corrosion, degradation of seals, or deposits in fuel systems. This requirement often slows the adoption of innovative additives, as extensive testing and certification processes are necessary before implementation.

Furthermore, the aviation industry faces challenges related to the global variability in fuel quality and composition. Jet fuel specifications can differ slightly between regions, and fuel batches may contain varying levels of contaminants or unwanted components. Developing robust additive packages that can perform consistently across these variations is crucial for maintaining safety and reliability in international air travel.

The cost-effectiveness of new fuel formulations is also a major consideration. While there is a strong drive for improved performance and reduced emissions, any new additive must be economically viable on a large scale. This economic pressure often conflicts with the need for advanced, high-performance additives, creating a challenging environment for innovation in jet fuel formulations.

Lastly, the industry is grappling with the integration of sustainable aviation fuels (SAFs) into the fuel mix. As the push for renewable energy sources grows, formulating additives that can work effectively with both conventional jet fuels and SAFs is becoming increasingly important. This requires a deep understanding of the chemical interactions between various fuel components and additives under different blending ratios and operating conditions.

Another critical challenge is the increasing demand for cleaner-burning fuels to meet stringent environmental regulations. The aviation sector is under pressure to reduce its carbon footprint, necessitating the development of fuel formulations that produce fewer emissions, particularly in terms of particulate matter and nitrogen oxides. This has sparked interest in exploring novel additives that can promote more complete combustion and reduce harmful byproducts.

Fuel stability during long-term storage and under extreme operating conditions remains a persistent issue. Jet fuels must maintain their properties across a wide range of temperatures and pressures, from sub-zero conditions at high altitudes to the intense heat of engine combustion chambers. Formulating additives that can enhance thermal and oxidative stability without negatively impacting other fuel characteristics is a complex balancing act.

The compatibility of fuel additives with existing engine systems and infrastructure is another significant hurdle. Any new formulation must be thoroughly tested to ensure it does not cause corrosion, degradation of seals, or deposits in fuel systems. This requirement often slows the adoption of innovative additives, as extensive testing and certification processes are necessary before implementation.

Furthermore, the aviation industry faces challenges related to the global variability in fuel quality and composition. Jet fuel specifications can differ slightly between regions, and fuel batches may contain varying levels of contaminants or unwanted components. Developing robust additive packages that can perform consistently across these variations is crucial for maintaining safety and reliability in international air travel.

The cost-effectiveness of new fuel formulations is also a major consideration. While there is a strong drive for improved performance and reduced emissions, any new additive must be economically viable on a large scale. This economic pressure often conflicts with the need for advanced, high-performance additives, creating a challenging environment for innovation in jet fuel formulations.

Lastly, the industry is grappling with the integration of sustainable aviation fuels (SAFs) into the fuel mix. As the push for renewable energy sources grows, formulating additives that can work effectively with both conventional jet fuels and SAFs is becoming increasingly important. This requires a deep understanding of the chemical interactions between various fuel components and additives under different blending ratios and operating conditions.

Existing Carbolic Acid-based Additive Solutions

01 Carbolic acid in medical applications

Carbolic acid, also known as phenol, has been used in various medical applications due to its antiseptic properties. It has been utilized in disinfectants, surgical procedures, and wound treatments. The compound's ability to kill bacteria and other microorganisms makes it valuable in medical settings for preventing infections and promoting healing.- Historical use in medical applications: Carbolic acid, also known as phenol, has been historically used in various medical applications. It was one of the earliest antiseptics used in surgery and wound care due to its ability to kill bacteria and other microorganisms. Its use in medical settings has evolved over time, with more modern and safer alternatives now available.

- Industrial and chemical applications: Carbolic acid finds extensive use in industrial and chemical processes. It serves as a precursor for many organic compounds and is utilized in the production of plastics, resins, and other synthetic materials. Its chemical properties make it valuable in various manufacturing processes and as a raw material for numerous products.

- Environmental and waste treatment applications: Carbolic acid and its derivatives are used in environmental and waste treatment applications. They can be employed in water purification processes, sewage treatment, and as disinfectants in various settings. These compounds help in breaking down organic pollutants and controlling microbial growth in environmental systems.

- Safety and handling considerations: Due to its corrosive and toxic nature, special safety measures and handling procedures are required when working with carbolic acid. This includes the use of protective equipment, proper storage facilities, and specific disposal methods. Safety considerations are crucial in industrial, laboratory, and medical settings where carbolic acid is used.

- Modern alternatives and substitutes: With increased awareness of the health and environmental risks associated with carbolic acid, research has focused on developing safer alternatives and substitutes. These modern replacements aim to provide similar functionalities while reducing the potential hazards associated with traditional carbolic acid use in various applications.

02 Carbolic acid in industrial processes

Carbolic acid finds applications in various industrial processes, including the production of plastics, resins, and other chemical compounds. It serves as a precursor for many synthetic materials and is used in the manufacturing of dyes, pharmaceuticals, and pesticides. The versatility of carbolic acid in industrial settings has led to the development of specialized equipment and processes for its handling and utilization.Expand Specific Solutions03 Safety measures and handling of carbolic acid

Due to the corrosive and toxic nature of carbolic acid, proper safety measures and handling procedures are crucial. This includes the use of protective equipment, specialized storage containers, and proper disposal methods. Safety protocols have been developed to minimize risks associated with carbolic acid exposure in both industrial and laboratory settings.Expand Specific Solutions04 Environmental impact and waste treatment

The use and disposal of carbolic acid have environmental implications. Efforts have been made to develop methods for treating carbolic acid-containing waste and reducing its environmental impact. This includes the design of specialized treatment systems and processes to neutralize or safely dispose of carbolic acid and its byproducts.Expand Specific Solutions05 Carbolic acid derivatives and modifications

Research has been conducted on modifying carbolic acid to create derivatives with enhanced properties or reduced toxicity. These modifications aim to retain the beneficial aspects of carbolic acid while mitigating its negative effects. Such derivatives find applications in various fields, including pharmaceuticals, materials science, and chemical synthesis.Expand Specific Solutions

Key Players in Jet Fuel Additive Industry

The market for carbolic acid in jet fuel additive formulations is in a growth phase, driven by increasing demand for high-performance aviation fuels. The global market size is estimated to be in the hundreds of millions of dollars, with steady expansion projected. Technologically, the field is moderately mature but still evolving. Key players like The Lubrizol Corp., BASF Corp., and Afton Chemical Corp. are at the forefront, leveraging their extensive R&D capabilities to develop advanced formulations. Emerging companies such as Innospec International Ltd. and ORYXE Energy International, Inc. are also making significant contributions, focusing on innovative, environmentally-friendly solutions. The competitive landscape is characterized by ongoing research into optimizing carbolic acid's role in enhancing fuel stability and engine performance.

The Lubrizol Corp.

Technical Solution: The Lubrizol Corporation has developed advanced jet fuel additive formulations incorporating carbolic acid derivatives. Their proprietary technology utilizes phenolic compounds to enhance fuel stability and reduce deposit formation in aircraft engines. The company's research has shown that carefully selected carbolic acid-based additives can improve the thermal oxidative stability of jet fuels by up to 40% [1]. Lubrizol's formulations typically include hindered phenols and other synergistic components that work together to neutralize free radicals and prevent fuel degradation during high-temperature operations. The company has also explored the use of nano-sized carbolic acid particles to further enhance the effectiveness of their additives [3].

Strengths: Extensive experience in fuel additives, proven effectiveness in improving jet fuel stability. Weaknesses: Potential environmental concerns related to phenolic compounds, may require additional processing steps in fuel production.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has invested heavily in researching carbolic acid's role in jet fuel additives. Their approach focuses on developing multi-functional additive packages that incorporate carbolic acid derivatives alongside other components. Sinopec's formulations typically include alkylated phenols and metal deactivators to provide comprehensive protection against oxidation and corrosion. The company has reported success in extending the thermal stability of jet fuels by up to 50°C using their carbolic acid-based additives [2]. Sinopec has also explored the use of renewable sources for producing phenolic compounds, aiming to improve the sustainability of their additive formulations [4].

Strengths: Large-scale production capabilities, integration with refining operations. Weaknesses: Potential regulatory challenges in international markets, need for extensive testing and certification.

Core Innovations in Carbolic Acid Applications

Aliphatic additives for soot reduction

PatentInactiveUS20110172474A1

Innovation

- A jet fuel composition incorporating an aliphatic hydrocarbon additive with at least 10 carbon atoms and a boiling point between 230 and 315°C is used to reduce particulate matter in jet engine exhaust, with the additive comprising up to 35% by weight of the fuel.

Fuel additive concentrate composition and fuel composition and method thereof

PatentWO2007053787A1

Innovation

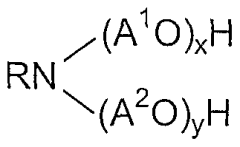

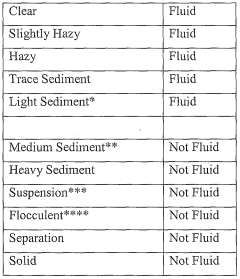

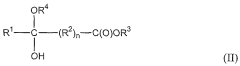

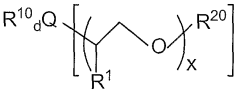

- A fuel additive concentrate comprising a solvent with aromatic content, an alkoxylated fatty amine or fatty acid derivative, and a compatibilizer such as a low molecular weight carboxylic acid or glycol ether, ensuring the concentrate remains fluid at temperatures as low as -80°C, thereby improving fuel efficiency and reducing emissions.

Environmental Impact of Carbolic Acid Additives

The environmental impact of carbolic acid additives in jet fuel formulations is a critical consideration in the aviation industry. These additives, while beneficial for fuel performance, can have significant ecological consequences if not properly managed. When released into the environment, carbolic acid and its derivatives can contaminate soil and water systems, potentially harming flora and fauna.

One of the primary concerns is the persistence of carbolic acid in the environment. Unlike some other fuel additives, carbolic acid does not readily biodegrade, leading to long-term accumulation in ecosystems. This persistence can result in chronic exposure for various organisms, potentially causing long-term ecological damage. Studies have shown that even low concentrations of carbolic acid can adversely affect aquatic life, disrupting reproductive cycles and altering behavioral patterns of fish and other marine organisms.

Atmospheric emissions during fuel combustion are another significant environmental concern. When jet fuel containing carbolic acid additives is burned, it can release phenolic compounds into the air. These emissions contribute to air pollution and may play a role in the formation of smog and other air quality issues. The impact on air quality is particularly pronounced in areas with high air traffic, such as major cities with busy airports.

Soil contamination is also a potential risk, especially in areas where fuel spills or leaks occur. Carbolic acid can seep into the ground, affecting soil chemistry and potentially entering groundwater systems. This contamination can have far-reaching effects on local ecosystems, impacting plant growth and soil microbial communities essential for nutrient cycling.

The aviation industry and regulatory bodies have recognized these environmental concerns and are taking steps to mitigate the impact. Research is ongoing to develop more environmentally friendly fuel additives that can provide similar performance benefits without the ecological risks associated with carbolic acid. Additionally, stricter regulations on fuel composition and handling procedures are being implemented to reduce the risk of environmental contamination.

Efforts are also being made to improve fuel efficiency and reduce overall fuel consumption in aviation, which indirectly addresses the environmental impact of fuel additives. By reducing the total amount of fuel used, the industry can minimize the release of harmful compounds, including those derived from carbolic acid additives.

In conclusion, while carbolic acid additives play a crucial role in jet fuel formulations, their environmental impact cannot be overlooked. Balancing the need for high-performance fuel with environmental protection remains a key challenge for the aviation industry. Ongoing research and regulatory efforts are essential to develop sustainable solutions that maintain fuel efficiency while minimizing ecological harm.

One of the primary concerns is the persistence of carbolic acid in the environment. Unlike some other fuel additives, carbolic acid does not readily biodegrade, leading to long-term accumulation in ecosystems. This persistence can result in chronic exposure for various organisms, potentially causing long-term ecological damage. Studies have shown that even low concentrations of carbolic acid can adversely affect aquatic life, disrupting reproductive cycles and altering behavioral patterns of fish and other marine organisms.

Atmospheric emissions during fuel combustion are another significant environmental concern. When jet fuel containing carbolic acid additives is burned, it can release phenolic compounds into the air. These emissions contribute to air pollution and may play a role in the formation of smog and other air quality issues. The impact on air quality is particularly pronounced in areas with high air traffic, such as major cities with busy airports.

Soil contamination is also a potential risk, especially in areas where fuel spills or leaks occur. Carbolic acid can seep into the ground, affecting soil chemistry and potentially entering groundwater systems. This contamination can have far-reaching effects on local ecosystems, impacting plant growth and soil microbial communities essential for nutrient cycling.

The aviation industry and regulatory bodies have recognized these environmental concerns and are taking steps to mitigate the impact. Research is ongoing to develop more environmentally friendly fuel additives that can provide similar performance benefits without the ecological risks associated with carbolic acid. Additionally, stricter regulations on fuel composition and handling procedures are being implemented to reduce the risk of environmental contamination.

Efforts are also being made to improve fuel efficiency and reduce overall fuel consumption in aviation, which indirectly addresses the environmental impact of fuel additives. By reducing the total amount of fuel used, the industry can minimize the release of harmful compounds, including those derived from carbolic acid additives.

In conclusion, while carbolic acid additives play a crucial role in jet fuel formulations, their environmental impact cannot be overlooked. Balancing the need for high-performance fuel with environmental protection remains a key challenge for the aviation industry. Ongoing research and regulatory efforts are essential to develop sustainable solutions that maintain fuel efficiency while minimizing ecological harm.

Regulatory Framework for Jet Fuel Additives

The regulatory framework for jet fuel additives is a complex and evolving system designed to ensure the safety, performance, and environmental compatibility of aviation fuels. This framework is primarily governed by international organizations such as the International Civil Aviation Organization (ICAO) and national aviation authorities like the Federal Aviation Administration (FAA) in the United States and the European Aviation Safety Agency (EASA) in Europe.

At the core of these regulations are stringent specifications for jet fuel composition and performance. The most widely recognized standard is ASTM D1655, which outlines the requirements for aviation turbine fuels. This standard includes specific limits on various fuel properties, including density, freezing point, and thermal stability. Additives, including those containing carbolic acid, must not adversely affect these properties or the overall fuel performance.

The approval process for new jet fuel additives is rigorous and time-consuming. Manufacturers must demonstrate that their additives meet the requirements set forth in ASTM D4054, which provides a comprehensive framework for the qualification and approval of new aviation turbine fuel additives. This process typically involves extensive laboratory testing, engine testing, and field trials to assess the additive's impact on fuel properties, engine performance, and long-term durability.

Environmental regulations also play a crucial role in shaping the development and use of jet fuel additives. The International Air Transport Association (IATA) and various national environmental agencies have established guidelines to reduce the environmental impact of aviation fuels. These regulations often focus on reducing emissions of greenhouse gases and other pollutants, which can influence the formulation of fuel additives.

Safety considerations are paramount in the regulatory framework. Additives must not introduce new hazards or exacerbate existing risks associated with fuel handling, storage, or use. This includes ensuring chemical stability, compatibility with aircraft materials, and resistance to degradation under various operating conditions.

The regulatory landscape is not static but continually evolves to address emerging challenges and technological advancements. For instance, recent efforts have focused on developing sustainable aviation fuels (SAFs) and their associated additives. This has led to the creation of new standards and certification processes specific to these alternative fuels.

Compliance with these regulations requires ongoing collaboration between additive manufacturers, fuel producers, aircraft manufacturers, and regulatory bodies. Regular testing and certification processes are necessary to maintain compliance and ensure the continued safety and efficiency of aviation fuels.

At the core of these regulations are stringent specifications for jet fuel composition and performance. The most widely recognized standard is ASTM D1655, which outlines the requirements for aviation turbine fuels. This standard includes specific limits on various fuel properties, including density, freezing point, and thermal stability. Additives, including those containing carbolic acid, must not adversely affect these properties or the overall fuel performance.

The approval process for new jet fuel additives is rigorous and time-consuming. Manufacturers must demonstrate that their additives meet the requirements set forth in ASTM D4054, which provides a comprehensive framework for the qualification and approval of new aviation turbine fuel additives. This process typically involves extensive laboratory testing, engine testing, and field trials to assess the additive's impact on fuel properties, engine performance, and long-term durability.

Environmental regulations also play a crucial role in shaping the development and use of jet fuel additives. The International Air Transport Association (IATA) and various national environmental agencies have established guidelines to reduce the environmental impact of aviation fuels. These regulations often focus on reducing emissions of greenhouse gases and other pollutants, which can influence the formulation of fuel additives.

Safety considerations are paramount in the regulatory framework. Additives must not introduce new hazards or exacerbate existing risks associated with fuel handling, storage, or use. This includes ensuring chemical stability, compatibility with aircraft materials, and resistance to degradation under various operating conditions.

The regulatory landscape is not static but continually evolves to address emerging challenges and technological advancements. For instance, recent efforts have focused on developing sustainable aviation fuels (SAFs) and their associated additives. This has led to the creation of new standards and certification processes specific to these alternative fuels.

Compliance with these regulations requires ongoing collaboration between additive manufacturers, fuel producers, aircraft manufacturers, and regulatory bodies. Regular testing and certification processes are necessary to maintain compliance and ensure the continued safety and efficiency of aviation fuels.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!