Analyzing Muriatic Acid's Effectiveness in Cleaning Aerospace Components

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Muriatic Acid Cleaning Background and Objectives

Muriatic acid, also known as hydrochloric acid, has been a staple in industrial cleaning processes for decades. In the aerospace industry, where precision and cleanliness are paramount, the effectiveness of cleaning agents plays a crucial role in maintaining the integrity and performance of components. This technical research report aims to explore the background and objectives of analyzing muriatic acid's effectiveness in cleaning aerospace components.

The aerospace industry demands stringent cleanliness standards due to the critical nature of its operations. Components used in aircraft and spacecraft must be free from contaminants, corrosion, and debris to ensure optimal performance and safety. Over the years, various cleaning methods and agents have been employed, with muriatic acid emerging as a potential solution due to its strong acidic properties and ability to dissolve a wide range of contaminants.

The historical context of using muriatic acid in aerospace cleaning dates back to the mid-20th century when the industry began to recognize the need for more effective cleaning agents. Traditional methods often fell short in removing stubborn deposits and ensuring thorough cleanliness of complex component geometries. Muriatic acid's ability to react with and dissolve metallic oxides, scale, and other inorganic contaminants made it an attractive option for addressing these challenges.

As the aerospace industry has evolved, so too have the materials and manufacturing processes used in component production. This evolution has necessitated a continuous reassessment of cleaning methodologies to ensure compatibility with new materials and to meet increasingly stringent cleanliness requirements. The analysis of muriatic acid's effectiveness in this context aims to determine its suitability for modern aerospace applications and to identify any potential limitations or areas for improvement.

The primary objective of this research is to conduct a comprehensive evaluation of muriatic acid's cleaning efficacy on various aerospace components. This includes assessing its ability to remove different types of contaminants, its impact on material properties, and its overall efficiency compared to alternative cleaning methods. Additionally, the study aims to explore the optimal concentration, application methods, and treatment durations for maximizing cleaning effectiveness while minimizing potential adverse effects on component integrity.

Another crucial aspect of this analysis is to investigate the environmental and safety implications of using muriatic acid in aerospace cleaning processes. As regulatory standards become more stringent, it is essential to evaluate the acid's environmental impact, disposal requirements, and potential health hazards to workers. This assessment will help determine whether muriatic acid cleaning aligns with current and future sustainability goals in the aerospace industry.

Furthermore, this research seeks to identify potential innovations or modifications in muriatic acid cleaning processes that could enhance its effectiveness or mitigate any drawbacks. This may include exploring additives, developing new application techniques, or investigating synergistic effects with other cleaning agents. By doing so, the study aims to contribute to the ongoing technological advancement in aerospace component cleaning and maintenance.

The aerospace industry demands stringent cleanliness standards due to the critical nature of its operations. Components used in aircraft and spacecraft must be free from contaminants, corrosion, and debris to ensure optimal performance and safety. Over the years, various cleaning methods and agents have been employed, with muriatic acid emerging as a potential solution due to its strong acidic properties and ability to dissolve a wide range of contaminants.

The historical context of using muriatic acid in aerospace cleaning dates back to the mid-20th century when the industry began to recognize the need for more effective cleaning agents. Traditional methods often fell short in removing stubborn deposits and ensuring thorough cleanliness of complex component geometries. Muriatic acid's ability to react with and dissolve metallic oxides, scale, and other inorganic contaminants made it an attractive option for addressing these challenges.

As the aerospace industry has evolved, so too have the materials and manufacturing processes used in component production. This evolution has necessitated a continuous reassessment of cleaning methodologies to ensure compatibility with new materials and to meet increasingly stringent cleanliness requirements. The analysis of muriatic acid's effectiveness in this context aims to determine its suitability for modern aerospace applications and to identify any potential limitations or areas for improvement.

The primary objective of this research is to conduct a comprehensive evaluation of muriatic acid's cleaning efficacy on various aerospace components. This includes assessing its ability to remove different types of contaminants, its impact on material properties, and its overall efficiency compared to alternative cleaning methods. Additionally, the study aims to explore the optimal concentration, application methods, and treatment durations for maximizing cleaning effectiveness while minimizing potential adverse effects on component integrity.

Another crucial aspect of this analysis is to investigate the environmental and safety implications of using muriatic acid in aerospace cleaning processes. As regulatory standards become more stringent, it is essential to evaluate the acid's environmental impact, disposal requirements, and potential health hazards to workers. This assessment will help determine whether muriatic acid cleaning aligns with current and future sustainability goals in the aerospace industry.

Furthermore, this research seeks to identify potential innovations or modifications in muriatic acid cleaning processes that could enhance its effectiveness or mitigate any drawbacks. This may include exploring additives, developing new application techniques, or investigating synergistic effects with other cleaning agents. By doing so, the study aims to contribute to the ongoing technological advancement in aerospace component cleaning and maintenance.

Aerospace Industry Demand for Effective Cleaning Solutions

The aerospace industry's demand for effective cleaning solutions has been steadily increasing due to the critical nature of component cleanliness in ensuring safety, performance, and longevity of aircraft and spacecraft. As aerospace technologies advance, the complexity of components and materials used in manufacturing has grown exponentially, necessitating more sophisticated and efficient cleaning methods.

One of the primary drivers for this demand is the stringent regulatory requirements imposed by aviation authorities worldwide. These regulations mandate strict adherence to cleanliness standards to prevent contamination-related failures and ensure optimal performance of aerospace systems. Consequently, manufacturers and maintenance facilities are constantly seeking innovative cleaning solutions that can meet these exacting standards while also improving operational efficiency.

The aerospace industry faces unique challenges in component cleaning due to the diverse range of materials used, including various metals, composites, and advanced alloys. Each material requires specific cleaning approaches to avoid damage while effectively removing contaminants such as oils, greases, carbon deposits, and corrosion products. This complexity has led to a growing market for specialized cleaning agents and processes tailored to aerospace applications.

Environmental concerns and sustainability initiatives have also significantly influenced the demand for cleaning solutions in the aerospace sector. There is a strong push towards adopting more environmentally friendly cleaning agents and processes that reduce the use of hazardous chemicals and minimize waste generation. This trend has spurred research into green cleaning technologies and biodegradable solvents that can match or exceed the performance of traditional cleaning methods.

The global nature of the aerospace industry has further amplified the need for effective cleaning solutions. With supply chains spanning multiple countries and continents, ensuring consistent cleanliness standards across different manufacturing and maintenance facilities has become a significant challenge. This has created a demand for standardized cleaning processes and solutions that can be implemented globally while accommodating local regulatory requirements and environmental conditions.

Moreover, the increasing focus on preventive maintenance and lifecycle cost reduction in the aerospace industry has heightened the importance of effective cleaning solutions. Regular and thorough cleaning of components can significantly extend their operational life, reduce the frequency of replacements, and minimize the risk of in-service failures. As a result, there is a growing emphasis on developing cleaning technologies that not only remove contaminants but also provide protective coatings or treatments to enhance component durability.

The advent of new technologies such as additive manufacturing and advanced composites in aerospace manufacturing has introduced additional complexities in cleaning requirements. These novel materials and production methods often require specialized cleaning approaches to address unique contamination issues and surface characteristics. Consequently, there is an ongoing demand for research and development of cleaning solutions specifically tailored to these emerging technologies.

One of the primary drivers for this demand is the stringent regulatory requirements imposed by aviation authorities worldwide. These regulations mandate strict adherence to cleanliness standards to prevent contamination-related failures and ensure optimal performance of aerospace systems. Consequently, manufacturers and maintenance facilities are constantly seeking innovative cleaning solutions that can meet these exacting standards while also improving operational efficiency.

The aerospace industry faces unique challenges in component cleaning due to the diverse range of materials used, including various metals, composites, and advanced alloys. Each material requires specific cleaning approaches to avoid damage while effectively removing contaminants such as oils, greases, carbon deposits, and corrosion products. This complexity has led to a growing market for specialized cleaning agents and processes tailored to aerospace applications.

Environmental concerns and sustainability initiatives have also significantly influenced the demand for cleaning solutions in the aerospace sector. There is a strong push towards adopting more environmentally friendly cleaning agents and processes that reduce the use of hazardous chemicals and minimize waste generation. This trend has spurred research into green cleaning technologies and biodegradable solvents that can match or exceed the performance of traditional cleaning methods.

The global nature of the aerospace industry has further amplified the need for effective cleaning solutions. With supply chains spanning multiple countries and continents, ensuring consistent cleanliness standards across different manufacturing and maintenance facilities has become a significant challenge. This has created a demand for standardized cleaning processes and solutions that can be implemented globally while accommodating local regulatory requirements and environmental conditions.

Moreover, the increasing focus on preventive maintenance and lifecycle cost reduction in the aerospace industry has heightened the importance of effective cleaning solutions. Regular and thorough cleaning of components can significantly extend their operational life, reduce the frequency of replacements, and minimize the risk of in-service failures. As a result, there is a growing emphasis on developing cleaning technologies that not only remove contaminants but also provide protective coatings or treatments to enhance component durability.

The advent of new technologies such as additive manufacturing and advanced composites in aerospace manufacturing has introduced additional complexities in cleaning requirements. These novel materials and production methods often require specialized cleaning approaches to address unique contamination issues and surface characteristics. Consequently, there is an ongoing demand for research and development of cleaning solutions specifically tailored to these emerging technologies.

Current Challenges in Aerospace Component Cleaning

The aerospace industry faces significant challenges in component cleaning, particularly when dealing with complex and sensitive parts. One of the primary issues is the removal of various contaminants, including oils, greases, carbon deposits, and corrosion products, without damaging the underlying material. These contaminants can accumulate during manufacturing, assembly, or operational use, potentially compromising the performance and safety of aerospace systems.

Traditional cleaning methods often struggle to effectively clean intricate geometries and hard-to-reach areas of aerospace components. This is especially problematic for parts with small crevices, internal passages, or porous surfaces, where contaminants can become deeply embedded. The inability to thoroughly clean these areas can lead to reduced component lifespan, increased maintenance frequency, and potential safety risks.

Another significant challenge is the need for cleaning processes that are compatible with a wide range of materials used in aerospace applications. These materials can include various metals, alloys, composites, and advanced ceramics, each with its own specific chemical sensitivities and cleaning requirements. Finding a universal cleaning solution that is effective across this diverse range of materials while maintaining their structural integrity is a complex task.

Environmental and health concerns also pose challenges in aerospace component cleaning. Many traditional cleaning agents, such as chlorinated solvents, have been phased out due to their harmful environmental impact and potential health risks to workers. This has led to a search for more environmentally friendly and safer alternatives, which must still meet the stringent cleaning standards required in the aerospace industry.

The increasing complexity of aerospace components, driven by advancements in design and manufacturing technologies, further complicates the cleaning process. Modern components often feature intricate designs, multi-material constructions, and advanced surface treatments, all of which require specialized cleaning approaches. Balancing the need for thorough cleaning with the preservation of these advanced features is a delicate and challenging task.

Lastly, the aerospace industry's strict regulatory environment and quality control standards add another layer of complexity to component cleaning. Cleaning processes must not only be effective but also consistently reproducible and well-documented to meet certification requirements. This necessitates the development of robust, validated cleaning protocols that can be reliably implemented across different manufacturing and maintenance facilities.

Traditional cleaning methods often struggle to effectively clean intricate geometries and hard-to-reach areas of aerospace components. This is especially problematic for parts with small crevices, internal passages, or porous surfaces, where contaminants can become deeply embedded. The inability to thoroughly clean these areas can lead to reduced component lifespan, increased maintenance frequency, and potential safety risks.

Another significant challenge is the need for cleaning processes that are compatible with a wide range of materials used in aerospace applications. These materials can include various metals, alloys, composites, and advanced ceramics, each with its own specific chemical sensitivities and cleaning requirements. Finding a universal cleaning solution that is effective across this diverse range of materials while maintaining their structural integrity is a complex task.

Environmental and health concerns also pose challenges in aerospace component cleaning. Many traditional cleaning agents, such as chlorinated solvents, have been phased out due to their harmful environmental impact and potential health risks to workers. This has led to a search for more environmentally friendly and safer alternatives, which must still meet the stringent cleaning standards required in the aerospace industry.

The increasing complexity of aerospace components, driven by advancements in design and manufacturing technologies, further complicates the cleaning process. Modern components often feature intricate designs, multi-material constructions, and advanced surface treatments, all of which require specialized cleaning approaches. Balancing the need for thorough cleaning with the preservation of these advanced features is a delicate and challenging task.

Lastly, the aerospace industry's strict regulatory environment and quality control standards add another layer of complexity to component cleaning. Cleaning processes must not only be effective but also consistently reproducible and well-documented to meet certification requirements. This necessitates the development of robust, validated cleaning protocols that can be reliably implemented across different manufacturing and maintenance facilities.

Existing Muriatic Acid Cleaning Protocols

01 Cleaning and etching applications

Muriatic acid, also known as hydrochloric acid, is highly effective in cleaning and etching various surfaces. It is commonly used for removing rust, scale, and mineral deposits from metal surfaces, concrete, and masonry. The acid's strong corrosive properties make it suitable for preparing surfaces for painting or further treatment.- Cleaning and etching applications: Muriatic acid, also known as hydrochloric acid, is highly effective in cleaning and etching various surfaces. It is commonly used for removing rust, scale, and mineral deposits from metal surfaces, concrete, and masonry. The acid's strong corrosive properties make it suitable for preparing surfaces for painting or further treatment.

- pH adjustment in industrial processes: Muriatic acid is widely used in industrial processes for pH adjustment. Its effectiveness in lowering pH levels makes it valuable in water treatment, chemical manufacturing, and food processing industries. The acid's ability to neutralize alkaline solutions and control acidity is crucial in maintaining optimal conditions for various chemical reactions and processes.

- Swimming pool maintenance: In swimming pool maintenance, muriatic acid is highly effective for balancing water chemistry. It is used to lower pH and total alkalinity levels, preventing scale formation and ensuring proper sanitizer effectiveness. The acid's quick action and affordability make it a popular choice for pool owners and maintenance professionals.

- Metal treatment and processing: Muriatic acid plays a crucial role in metal treatment and processing industries. It is effective in pickling and descaling metals, particularly steel and iron. The acid removes oxides and impurities from metal surfaces, preparing them for further processing, coating, or welding. Its effectiveness in dissolving metal oxides makes it valuable in metallurgical applications.

- Waste treatment and environmental applications: Muriatic acid is effective in various waste treatment and environmental applications. It is used in the treatment of industrial wastewater, neutralization of alkaline waste, and removal of heavy metals from contaminated soils. The acid's strong reactivity makes it useful in breaking down complex organic compounds and in the remediation of contaminated sites.

02 pH adjustment in industrial processes

Muriatic acid is widely used for pH adjustment in various industrial processes. Its effectiveness in lowering pH levels makes it valuable in water treatment, chemical manufacturing, and food processing industries. The acid's ability to neutralize alkaline solutions and control acidity is crucial in maintaining optimal conditions for many industrial applications.Expand Specific Solutions03 Swimming pool maintenance

Muriatic acid is highly effective in maintaining proper pH levels in swimming pools. It is used to lower the pH and total alkalinity of pool water, preventing scale formation and ensuring optimal chlorine effectiveness. The acid's quick action and affordability make it a popular choice for pool owners and maintenance professionals.Expand Specific Solutions04 Metal treatment and processing

In the metal industry, muriatic acid is effective for various treatment processes. It is used for pickling steel and other metals to remove surface oxides and impurities. The acid's ability to dissolve metal oxides makes it valuable in metal surface preparation, electroplating, and metal recovery processes.Expand Specific Solutions05 Pharmaceutical and chemical synthesis

Muriatic acid plays a crucial role in pharmaceutical and chemical synthesis processes. Its effectiveness as a reagent and catalyst in various chemical reactions makes it indispensable in the production of drugs, dyes, and other organic compounds. The acid's ability to facilitate hydrolysis and dehydration reactions contributes to its wide use in these industries.Expand Specific Solutions

Key Players in Aerospace Cleaning Solutions

The aerospace component cleaning industry is in a mature stage, with a stable market size driven by regular maintenance needs of aircraft fleets worldwide. The global market for aerospace cleaning chemicals is estimated to be in the billions of dollars annually. Technologically, muriatic acid's effectiveness in cleaning aerospace components is well-established, but ongoing research focuses on improving safety, environmental impact, and efficiency. Key players like Lufthansa Technik AG, Ecolab USA, Inc., and Beijing Yadi Lite Aviation New Materials Co., Ltd. are at the forefront of developing and implementing advanced cleaning solutions. These companies, along with others such as AECC Aero Science & Technology Co., Ltd. and STELIA Aerospace, are continuously refining their products and processes to meet the stringent requirements of the aerospace industry.

Lufthansa Technik AG

Technical Solution: Lufthansa Technik AG has developed an advanced cleaning process for aerospace components using muriatic acid (hydrochloric acid). Their method involves a carefully controlled application of diluted muriatic acid, typically in concentrations of 10-15%, to effectively remove corrosion, oxidation, and contaminants from various aircraft parts[1]. The process includes pre-cleaning, acid application, neutralization, and post-treatment steps. Lufthansa Technik has also implemented a closed-loop system for acid recovery and recycling, reducing environmental impact and operational costs[3]. Their technique is particularly effective for cleaning heat exchangers, engine components, and landing gear parts, where traditional cleaning methods may be less effective[2].

Strengths: Highly effective in removing stubborn contaminants and corrosion; environmentally responsible due to acid recycling; cost-effective for large-scale operations. Weaknesses: Requires careful handling and safety protocols; potential for material damage if not properly controlled; limited applicability to certain sensitive materials.

Ecolab USA, Inc.

Technical Solution: Ecolab USA, Inc. has developed a specialized muriatic acid-based cleaning solution for aerospace components, focusing on environmental safety and efficiency. Their proprietary formula, known as "EcoClean Aero", combines muriatic acid with corrosion inhibitors and surfactants to enhance cleaning power while minimizing potential damage to sensitive aerospace materials[1]. The solution is designed to be used in both immersion and spray applications, allowing for versatility in cleaning various component sizes and shapes. Ecolab's process includes a unique pH-controlled neutralization step that ensures complete acid removal and surface passivation[2]. Additionally, they have implemented an advanced wastewater treatment system that allows for on-site processing and recycling of used cleaning solutions, significantly reducing environmental impact and disposal costs[3].

Strengths: Environmentally friendly formulation; versatile application methods; effective neutralization process. Weaknesses: May require specialized equipment for optimal use; potentially higher initial costs compared to traditional cleaning methods.

Innovations in Muriatic Acid Formulations

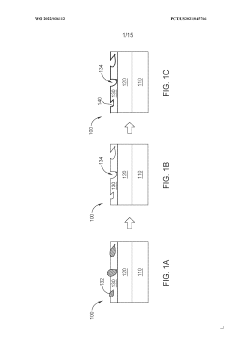

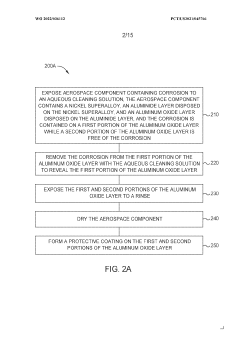

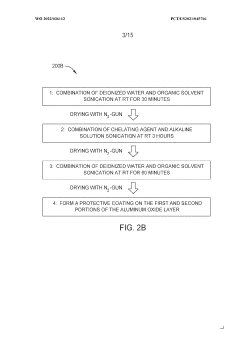

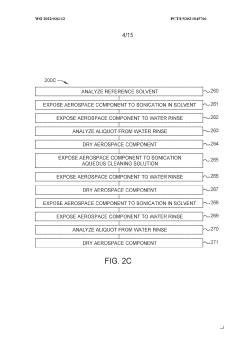

Methods for detecting end-points for cleaning processes of aerospace components

PatentWO2022036112A1

Innovation

- The method involves exposing aerospace components with corrosion to aqueous or acidic cleaning solutions, using UV-vis spectroscopy for end-point detection, and forming protective coatings on nickel superalloys with aluminide and aluminum oxide layers to remove corrosion and prevent further damage.

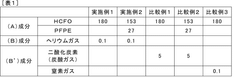

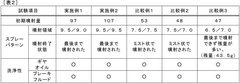

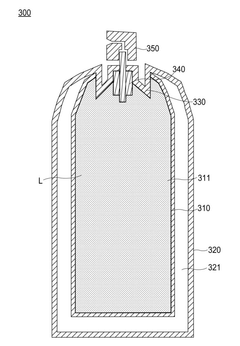

Aerosol composition and aerosol can including same

PatentWO2022176793A1

Innovation

- An aerosol composition using a fluorinated solvent as the cleaning agent and helium gas as the propellant, which maintains high jetting force and a narrow spray pattern by minimizing the solubility of helium in the solvent and ensuring consistent internal pressure, thereby allowing precise and efficient cleaning.

Environmental Impact and Regulations

The use of muriatic acid in cleaning aerospace components raises significant environmental concerns and is subject to stringent regulations. This powerful cleaning agent, while effective, poses potential risks to ecosystems and human health if not properly managed.

Environmental impacts of muriatic acid primarily stem from its corrosive nature and potential for contamination. When released into water bodies, it can drastically alter pH levels, leading to adverse effects on aquatic life. Soil contamination is another concern, as acid runoff can damage vegetation and disrupt soil chemistry. Furthermore, the production and transportation of muriatic acid contribute to carbon emissions and energy consumption.

Regulatory frameworks governing the use of muriatic acid in aerospace applications are comprehensive and multifaceted. In the United States, the Environmental Protection Agency (EPA) regulates its use under the Toxic Substances Control Act (TSCA) and the Clean Water Act. The Occupational Safety and Health Administration (OSHA) sets strict guidelines for workplace handling and exposure limits.

Internationally, the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation imposes stringent controls on the use and disposal of muriatic acid. Many countries have adopted similar regulations, emphasizing proper storage, handling, and disposal practices to minimize environmental impact.

Compliance with these regulations necessitates robust waste management protocols in aerospace facilities. This includes neutralization of acid waste before disposal, implementation of spill prevention and response plans, and proper training of personnel in handling procedures. Many facilities are required to obtain permits for acid use and must regularly report on their chemical management practices.

The aerospace industry has been proactively seeking alternatives to muriatic acid, driven by both regulatory pressure and corporate sustainability goals. Research into environmentally friendly cleaning agents, such as bio-based solvents and supercritical CO2 cleaning, is ongoing. These alternatives aim to maintain cleaning efficacy while reducing environmental footprint and regulatory burden.

Despite regulatory challenges, muriatic acid remains in use due to its effectiveness and cost-efficiency. However, the industry trend is moving towards more sustainable practices. This includes optimizing acid use through precision application techniques, implementing closed-loop recycling systems, and investing in advanced wastewater treatment technologies to mitigate environmental impacts.

Environmental impacts of muriatic acid primarily stem from its corrosive nature and potential for contamination. When released into water bodies, it can drastically alter pH levels, leading to adverse effects on aquatic life. Soil contamination is another concern, as acid runoff can damage vegetation and disrupt soil chemistry. Furthermore, the production and transportation of muriatic acid contribute to carbon emissions and energy consumption.

Regulatory frameworks governing the use of muriatic acid in aerospace applications are comprehensive and multifaceted. In the United States, the Environmental Protection Agency (EPA) regulates its use under the Toxic Substances Control Act (TSCA) and the Clean Water Act. The Occupational Safety and Health Administration (OSHA) sets strict guidelines for workplace handling and exposure limits.

Internationally, the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation imposes stringent controls on the use and disposal of muriatic acid. Many countries have adopted similar regulations, emphasizing proper storage, handling, and disposal practices to minimize environmental impact.

Compliance with these regulations necessitates robust waste management protocols in aerospace facilities. This includes neutralization of acid waste before disposal, implementation of spill prevention and response plans, and proper training of personnel in handling procedures. Many facilities are required to obtain permits for acid use and must regularly report on their chemical management practices.

The aerospace industry has been proactively seeking alternatives to muriatic acid, driven by both regulatory pressure and corporate sustainability goals. Research into environmentally friendly cleaning agents, such as bio-based solvents and supercritical CO2 cleaning, is ongoing. These alternatives aim to maintain cleaning efficacy while reducing environmental footprint and regulatory burden.

Despite regulatory challenges, muriatic acid remains in use due to its effectiveness and cost-efficiency. However, the industry trend is moving towards more sustainable practices. This includes optimizing acid use through precision application techniques, implementing closed-loop recycling systems, and investing in advanced wastewater treatment technologies to mitigate environmental impacts.

Safety Considerations and Handling Procedures

When working with muriatic acid for cleaning aerospace components, safety considerations and proper handling procedures are paramount. The corrosive nature of this acid necessitates strict adherence to safety protocols to protect personnel and equipment.

Personal protective equipment (PPE) is essential when handling muriatic acid. This includes chemical-resistant gloves, goggles or a face shield, and protective clothing such as a lab coat or acid-resistant apron. Respiratory protection may also be necessary, especially in poorly ventilated areas or when there is a risk of acid mist formation.

Proper ventilation is crucial in any workspace where muriatic acid is used. Fume hoods or local exhaust ventilation systems should be employed to remove acid vapors and prevent inhalation. It is advisable to conduct acid cleaning operations in well-ventilated areas or outdoors when possible.

Storage and transportation of muriatic acid require special attention. The acid should be stored in properly labeled, acid-resistant containers in a cool, dry area away from incompatible materials. Secondary containment measures should be implemented to prevent spills from spreading. When transporting the acid, use appropriate carriers and secure the containers to prevent tipping or damage.

Emergency response procedures must be established and communicated to all personnel working with or near muriatic acid. This includes the location and proper use of eyewash stations and safety showers, as well as spill containment and neutralization protocols. A readily accessible supply of neutralizing agents, such as sodium bicarbonate or lime, should be maintained in the work area.

Dilution of muriatic acid should always be performed by adding acid to water, never the reverse, to prevent dangerous splashing and heat generation. This process should be conducted slowly and with constant stirring to ensure uniform mixing and temperature control.

Proper disposal of waste acid and neutralized solutions is essential to comply with environmental regulations and prevent harm to ecosystems. Facilities should have established procedures for the collection, treatment, and disposal of acid waste in accordance with local and national guidelines.

Training is a critical component of safe muriatic acid handling. All personnel involved in its use should receive comprehensive instruction on proper handling techniques, PPE usage, emergency procedures, and the specific hazards associated with the acid. Regular refresher training and safety audits should be conducted to ensure ongoing compliance with safety protocols.

By implementing these safety considerations and handling procedures, aerospace facilities can minimize the risks associated with using muriatic acid for component cleaning while maximizing its effectiveness in removing contaminants and preparing surfaces for further processing or assembly.

Personal protective equipment (PPE) is essential when handling muriatic acid. This includes chemical-resistant gloves, goggles or a face shield, and protective clothing such as a lab coat or acid-resistant apron. Respiratory protection may also be necessary, especially in poorly ventilated areas or when there is a risk of acid mist formation.

Proper ventilation is crucial in any workspace where muriatic acid is used. Fume hoods or local exhaust ventilation systems should be employed to remove acid vapors and prevent inhalation. It is advisable to conduct acid cleaning operations in well-ventilated areas or outdoors when possible.

Storage and transportation of muriatic acid require special attention. The acid should be stored in properly labeled, acid-resistant containers in a cool, dry area away from incompatible materials. Secondary containment measures should be implemented to prevent spills from spreading. When transporting the acid, use appropriate carriers and secure the containers to prevent tipping or damage.

Emergency response procedures must be established and communicated to all personnel working with or near muriatic acid. This includes the location and proper use of eyewash stations and safety showers, as well as spill containment and neutralization protocols. A readily accessible supply of neutralizing agents, such as sodium bicarbonate or lime, should be maintained in the work area.

Dilution of muriatic acid should always be performed by adding acid to water, never the reverse, to prevent dangerous splashing and heat generation. This process should be conducted slowly and with constant stirring to ensure uniform mixing and temperature control.

Proper disposal of waste acid and neutralized solutions is essential to comply with environmental regulations and prevent harm to ecosystems. Facilities should have established procedures for the collection, treatment, and disposal of acid waste in accordance with local and national guidelines.

Training is a critical component of safe muriatic acid handling. All personnel involved in its use should receive comprehensive instruction on proper handling techniques, PPE usage, emergency procedures, and the specific hazards associated with the acid. Regular refresher training and safety audits should be conducted to ensure ongoing compliance with safety protocols.

By implementing these safety considerations and handling procedures, aerospace facilities can minimize the risks associated with using muriatic acid for component cleaning while maximizing its effectiveness in removing contaminants and preparing surfaces for further processing or assembly.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!