Analyzing Muriatic Acid's Effectiveness in Cleaning Power Plant Equipment

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Muriatic Acid Background and Objectives

Muriatic acid, also known as hydrochloric acid, has been a staple in industrial cleaning processes for decades. Its effectiveness in removing scale, rust, and other mineral deposits has made it particularly valuable in the maintenance of power plant equipment. The history of muriatic acid usage in industrial applications dates back to the early 20th century, with its role in power plant maintenance becoming increasingly prominent in the 1950s and 1960s as energy demands grew and plant efficiency became paramount.

The primary objective of analyzing muriatic acid's effectiveness in cleaning power plant equipment is to optimize maintenance procedures, extend equipment lifespan, and ultimately improve overall plant efficiency. This analysis aims to quantify the acid's cleaning power, assess its impact on various materials commonly found in power plant components, and evaluate its cost-effectiveness compared to alternative cleaning methods.

As power plants face increasing pressure to reduce downtime and maximize output, the importance of efficient cleaning processes cannot be overstated. Muriatic acid's ability to quickly dissolve mineral deposits and corrosion products makes it an attractive option for maintaining critical equipment such as boilers, condensers, and cooling towers. However, its corrosive nature also presents challenges that must be carefully considered.

Recent technological advancements have led to the development of inhibited muriatic acid formulations, which aim to reduce the acid's corrosive effects on metal surfaces while maintaining its cleaning efficacy. These innovations have sparked renewed interest in the use of muriatic acid for power plant maintenance, prompting a need for comprehensive analysis of its performance under various conditions.

The evolving regulatory landscape surrounding industrial chemical usage and environmental protection has also influenced the trajectory of muriatic acid application in power plants. Stricter regulations on emissions and waste disposal have necessitated a reevaluation of cleaning processes, with a focus on minimizing environmental impact while maintaining operational efficiency.

As the power generation industry continues to evolve, with increasing integration of renewable energy sources and the modernization of existing facilities, the role of effective cleaning agents like muriatic acid becomes even more critical. This analysis seeks to provide a foundation for informed decision-making regarding the use of muriatic acid in power plant maintenance, taking into account factors such as cleaning effectiveness, material compatibility, safety considerations, and environmental impact.

The primary objective of analyzing muriatic acid's effectiveness in cleaning power plant equipment is to optimize maintenance procedures, extend equipment lifespan, and ultimately improve overall plant efficiency. This analysis aims to quantify the acid's cleaning power, assess its impact on various materials commonly found in power plant components, and evaluate its cost-effectiveness compared to alternative cleaning methods.

As power plants face increasing pressure to reduce downtime and maximize output, the importance of efficient cleaning processes cannot be overstated. Muriatic acid's ability to quickly dissolve mineral deposits and corrosion products makes it an attractive option for maintaining critical equipment such as boilers, condensers, and cooling towers. However, its corrosive nature also presents challenges that must be carefully considered.

Recent technological advancements have led to the development of inhibited muriatic acid formulations, which aim to reduce the acid's corrosive effects on metal surfaces while maintaining its cleaning efficacy. These innovations have sparked renewed interest in the use of muriatic acid for power plant maintenance, prompting a need for comprehensive analysis of its performance under various conditions.

The evolving regulatory landscape surrounding industrial chemical usage and environmental protection has also influenced the trajectory of muriatic acid application in power plants. Stricter regulations on emissions and waste disposal have necessitated a reevaluation of cleaning processes, with a focus on minimizing environmental impact while maintaining operational efficiency.

As the power generation industry continues to evolve, with increasing integration of renewable energy sources and the modernization of existing facilities, the role of effective cleaning agents like muriatic acid becomes even more critical. This analysis seeks to provide a foundation for informed decision-making regarding the use of muriatic acid in power plant maintenance, taking into account factors such as cleaning effectiveness, material compatibility, safety considerations, and environmental impact.

Industrial Demand Analysis

The industrial demand for effective cleaning solutions in power plant equipment maintenance has been steadily increasing over the past decade. Power plants, being critical infrastructure for energy production, require regular and thorough cleaning to maintain optimal performance and extend the lifespan of their equipment. Muriatic acid, also known as hydrochloric acid, has emerged as a potential solution for addressing the persistent issue of scale buildup and corrosion in power plant machinery.

The power generation industry faces significant challenges in maintaining the cleanliness and efficiency of its equipment, particularly in boilers, heat exchangers, and cooling systems. These components are prone to accumulating mineral deposits, rust, and other contaminants that can severely impact their performance and energy efficiency. As a result, there is a growing demand for cleaning agents that can effectively remove these deposits without causing damage to the underlying metal surfaces.

Muriatic acid has gained attention in this context due to its strong acidic properties and ability to dissolve various types of mineral deposits. The industrial demand for muriatic acid in power plant cleaning applications is driven by several factors. Firstly, the increasing global energy demand has led to the expansion of power generation capacity, resulting in a larger installed base of equipment requiring maintenance. Secondly, stricter environmental regulations and efficiency standards have pushed power plant operators to seek more effective cleaning solutions to optimize their operations and reduce emissions.

The market for industrial cleaning chemicals in the power generation sector is expected to grow significantly in the coming years. This growth is fueled by the need for more frequent and thorough cleaning cycles to maintain equipment efficiency and comply with regulatory requirements. Additionally, the trend towards preventive maintenance strategies in the industry has increased the demand for reliable and efficient cleaning solutions.

However, the use of muriatic acid in power plant cleaning applications also presents challenges and concerns. Safety considerations, environmental impact, and potential equipment damage are key factors that influence its adoption. As a result, there is a growing interest in developing optimized formulations and application methods that can maximize the cleaning effectiveness of muriatic acid while minimizing its associated risks.

The industrial demand analysis also reveals a shift towards more sustainable and environmentally friendly cleaning solutions. This trend has led to research and development efforts focused on finding alternatives or modifications to traditional acid-based cleaning methods. Some power plant operators are exploring the use of biodegradable additives or less corrosive acid formulations to achieve a balance between cleaning efficacy and environmental responsibility.

In conclusion, the industrial demand for effective cleaning solutions in power plant equipment maintenance, particularly those involving muriatic acid, is driven by the need for improved operational efficiency, regulatory compliance, and asset longevity. As the power generation industry continues to evolve, the demand for innovative and sustainable cleaning technologies is expected to grow, presenting opportunities for further research and development in this field.

The power generation industry faces significant challenges in maintaining the cleanliness and efficiency of its equipment, particularly in boilers, heat exchangers, and cooling systems. These components are prone to accumulating mineral deposits, rust, and other contaminants that can severely impact their performance and energy efficiency. As a result, there is a growing demand for cleaning agents that can effectively remove these deposits without causing damage to the underlying metal surfaces.

Muriatic acid has gained attention in this context due to its strong acidic properties and ability to dissolve various types of mineral deposits. The industrial demand for muriatic acid in power plant cleaning applications is driven by several factors. Firstly, the increasing global energy demand has led to the expansion of power generation capacity, resulting in a larger installed base of equipment requiring maintenance. Secondly, stricter environmental regulations and efficiency standards have pushed power plant operators to seek more effective cleaning solutions to optimize their operations and reduce emissions.

The market for industrial cleaning chemicals in the power generation sector is expected to grow significantly in the coming years. This growth is fueled by the need for more frequent and thorough cleaning cycles to maintain equipment efficiency and comply with regulatory requirements. Additionally, the trend towards preventive maintenance strategies in the industry has increased the demand for reliable and efficient cleaning solutions.

However, the use of muriatic acid in power plant cleaning applications also presents challenges and concerns. Safety considerations, environmental impact, and potential equipment damage are key factors that influence its adoption. As a result, there is a growing interest in developing optimized formulations and application methods that can maximize the cleaning effectiveness of muriatic acid while minimizing its associated risks.

The industrial demand analysis also reveals a shift towards more sustainable and environmentally friendly cleaning solutions. This trend has led to research and development efforts focused on finding alternatives or modifications to traditional acid-based cleaning methods. Some power plant operators are exploring the use of biodegradable additives or less corrosive acid formulations to achieve a balance between cleaning efficacy and environmental responsibility.

In conclusion, the industrial demand for effective cleaning solutions in power plant equipment maintenance, particularly those involving muriatic acid, is driven by the need for improved operational efficiency, regulatory compliance, and asset longevity. As the power generation industry continues to evolve, the demand for innovative and sustainable cleaning technologies is expected to grow, presenting opportunities for further research and development in this field.

Current Challenges in Power Plant Cleaning

Power plant equipment cleaning faces several significant challenges in today's industrial landscape. One of the primary issues is the accumulation of scale, corrosion, and mineral deposits on critical components such as boilers, heat exchangers, and cooling towers. These deposits can severely impact the efficiency and performance of power generation systems, leading to increased operational costs and reduced output.

The selection of appropriate cleaning agents presents another major challenge. Traditional cleaning methods often involve harsh chemicals that can be harmful to both equipment and personnel. Balancing the effectiveness of cleaning solutions with environmental and safety concerns is a delicate task that requires careful consideration and expertise.

Accessibility to equipment surfaces is a persistent problem in power plant cleaning. Many components are located in confined spaces or have complex geometries, making it difficult to apply cleaning agents uniformly and effectively. This challenge is compounded by the need to minimize downtime during cleaning operations, as extended shutdowns can result in significant financial losses for power plants.

The disposal of cleaning waste is another critical issue. Cleaning processes generate large volumes of contaminated wastewater that must be treated and disposed of in compliance with increasingly stringent environmental regulations. This not only adds to the overall cost of cleaning operations but also poses potential environmental risks if not managed properly.

Temperature management during cleaning is a significant technical challenge. Many power plant components operate at high temperatures, and rapid cooling for cleaning purposes can lead to thermal stress and potential damage. Developing cleaning methods that can be applied at elevated temperatures or finding ways to safely cool equipment without causing harm is an ongoing area of research and development.

The frequency and timing of cleaning operations also present challenges. Determining the optimal cleaning schedule to maximize efficiency while minimizing disruptions to power generation is a complex task that requires careful analysis of operational data and predictive maintenance strategies.

Lastly, the diversity of materials used in power plant equipment complicates the cleaning process. Different materials may require specific cleaning agents and techniques to avoid damage or degradation. Developing universal cleaning solutions that are effective across a wide range of materials without causing adverse effects is an ongoing challenge in the industry.

The selection of appropriate cleaning agents presents another major challenge. Traditional cleaning methods often involve harsh chemicals that can be harmful to both equipment and personnel. Balancing the effectiveness of cleaning solutions with environmental and safety concerns is a delicate task that requires careful consideration and expertise.

Accessibility to equipment surfaces is a persistent problem in power plant cleaning. Many components are located in confined spaces or have complex geometries, making it difficult to apply cleaning agents uniformly and effectively. This challenge is compounded by the need to minimize downtime during cleaning operations, as extended shutdowns can result in significant financial losses for power plants.

The disposal of cleaning waste is another critical issue. Cleaning processes generate large volumes of contaminated wastewater that must be treated and disposed of in compliance with increasingly stringent environmental regulations. This not only adds to the overall cost of cleaning operations but also poses potential environmental risks if not managed properly.

Temperature management during cleaning is a significant technical challenge. Many power plant components operate at high temperatures, and rapid cooling for cleaning purposes can lead to thermal stress and potential damage. Developing cleaning methods that can be applied at elevated temperatures or finding ways to safely cool equipment without causing harm is an ongoing area of research and development.

The frequency and timing of cleaning operations also present challenges. Determining the optimal cleaning schedule to maximize efficiency while minimizing disruptions to power generation is a complex task that requires careful analysis of operational data and predictive maintenance strategies.

Lastly, the diversity of materials used in power plant equipment complicates the cleaning process. Different materials may require specific cleaning agents and techniques to avoid damage or degradation. Developing universal cleaning solutions that are effective across a wide range of materials without causing adverse effects is an ongoing challenge in the industry.

Muriatic Acid Cleaning Techniques

01 Cleaning and etching applications

Muriatic acid, also known as hydrochloric acid, is highly effective in cleaning and etching various surfaces. It is commonly used for removing rust, scale, and mineral deposits from metal surfaces, concrete, and masonry. Its strong acidic properties make it suitable for preparing surfaces for painting or further treatment.- Cleaning and etching applications: Muriatic acid, also known as hydrochloric acid, is highly effective in cleaning and etching various surfaces. It is commonly used for removing rust, scale, and mineral deposits from metal surfaces, concrete, and masonry. The acid's strong corrosive properties make it suitable for preparing surfaces for painting or further treatment.

- pH adjustment in industrial processes: Muriatic acid is widely used for pH adjustment in various industrial processes. Its effectiveness in lowering pH levels makes it valuable in water treatment, chemical manufacturing, and food processing industries. The acid's ability to neutralize alkaline solutions and control acidity is crucial in maintaining optimal conditions for many chemical reactions and processes.

- Swimming pool maintenance: Muriatic acid is highly effective in maintaining swimming pool water quality. It is used to lower the pH and total alkalinity of pool water, preventing scale formation and ensuring proper chlorine effectiveness. The acid also helps in cleaning pool tiles and removing calcium deposits, contributing to overall pool hygiene and appearance.

- Metal treatment and processing: In metal treatment and processing, muriatic acid demonstrates high effectiveness. It is used for pickling steel and other metals to remove surface oxides and impurities before further processing or coating. The acid's ability to dissolve metal oxides makes it valuable in metal extraction processes and in the production of various metal compounds.

- Pharmaceutical and chemical synthesis: Muriatic acid plays a crucial role in pharmaceutical and chemical synthesis processes. Its effectiveness as a strong acid makes it useful in the production of various organic compounds, active pharmaceutical ingredients, and chemical intermediates. The acid's ability to catalyze reactions and facilitate molecular transformations contributes to its importance in these industries.

02 pH adjustment in industrial processes

Muriatic acid is widely used for pH adjustment in various industrial processes. Its effectiveness in lowering pH levels makes it valuable in water treatment, chemical manufacturing, and food processing industries. The acid's ability to neutralize alkaline solutions quickly and efficiently contributes to its widespread use in these applications.Expand Specific Solutions03 Swimming pool maintenance

Muriatic acid is highly effective in maintaining proper pH levels in swimming pools. It is used to lower the pH and total alkalinity of pool water, preventing scale formation and ensuring optimal chlorine effectiveness. The acid's strong properties allow for quick adjustments to water chemistry, making it a popular choice among pool owners and maintenance professionals.Expand Specific Solutions04 Metal treatment and processing

In the metal industry, muriatic acid is effective for various treatment processes. It is used for pickling steel and other metals to remove surface oxides and impurities before further processing or coating. The acid's ability to dissolve metal oxides makes it valuable in metal surface preparation and finishing applications.Expand Specific Solutions05 Pharmaceutical and chemical synthesis

Muriatic acid plays a crucial role in pharmaceutical and chemical synthesis processes. Its effectiveness as a strong acid makes it useful in the production of various chemicals and pharmaceutical compounds. The acid is often used as a reagent or catalyst in organic synthesis reactions, contributing to the manufacturing of numerous products in these industries.Expand Specific Solutions

Key Players in Industrial Cleaning Solutions

The competitive landscape for analyzing muriatic acid's effectiveness in cleaning power plant equipment is in a mature stage, with a well-established market and proven technologies. The global market size for industrial cleaning chemicals is substantial, estimated to be in the billions of dollars. Major players like Ecolab USA, Inc., Siemens Energy Global GmbH & Co. KG, and Evoqua Water Technologies LLC dominate the sector, offering comprehensive solutions for power plant maintenance. These companies have developed advanced formulations and application methods, leveraging their extensive research and development capabilities. The technology's maturity is evident in the specialized products offered by chemical manufacturers such as Chemetall GmbH and Kanto Chemical Co., Inc., which cater specifically to the power generation industry's cleaning needs.

Siemens Corp.

Technical Solution: Siemens has developed a sophisticated approach to using muriatic acid for cleaning power plant equipment, integrating it into their broader power plant maintenance solutions. Their method involves a multi-stage cleaning process that begins with a detailed analysis of equipment condition using advanced imaging and sensor technologies. This allows for targeted application of muriatic acid solutions, optimized for specific types of fouling and scale. Siemens employs computer-controlled dosing systems that adjust acid concentration and flow rates in real-time based on continuous monitoring of key parameters such as pH, temperature, and conductivity[6]. The company has also developed specialized nozzles and circulation systems that ensure even distribution of the acid solution across complex equipment geometries. To enhance safety and environmental compliance, Siemens has implemented a closed-loop acid recovery and neutralization system, minimizing waste and reducing the risk of chemical exposure[8].

Strengths: Highly automated and integrated approach with advanced monitoring and control systems. Weaknesses: May be more suitable for large-scale power plants due to complexity and cost.

Westinghouse Electric Co. LLC

Technical Solution: Westinghouse Electric has developed a comprehensive muriatic acid cleaning program specifically tailored for nuclear power plant equipment. Their approach focuses on the unique challenges of cleaning radioactive components while maintaining strict safety and regulatory compliance. Westinghouse's method involves a carefully controlled application of muriatic acid solutions, with concentrations and exposure times optimized through extensive laboratory testing and field experience. The company utilizes specialized robotic systems for acid application in high-radiation areas, minimizing human exposure. Westinghouse has also developed proprietary additives that enhance the acid's cleaning effectiveness while reducing its corrosive impact on sensitive materials commonly found in nuclear plant components[7]. Their process includes advanced filtration and ion exchange systems to manage radioactive contaminants released during cleaning, ensuring safe disposal or recycling of spent acid solutions[9].

Strengths: Specialized expertise in nuclear plant applications with advanced safety features. Weaknesses: Highly specialized approach may have limited applicability outside the nuclear industry.

Innovative Approaches in Acid Cleaning

Method for cleaning a container

PatentWO1999061179A1

Innovation

- A simplified method using an alkaline cleaning solution with a pH of 8.5 or greater, comprising ammonium EDTA salt, hydrazine, and surfactants, which allows for degreasing and pickling in a single process step at low temperatures, eliminating the need for hydrofluoric acid and rinsing steps.

Method for determining whether acidic aqueous solution is usable

PatentWO2014129324A1

Innovation

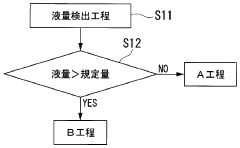

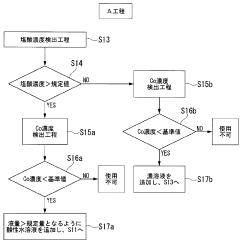

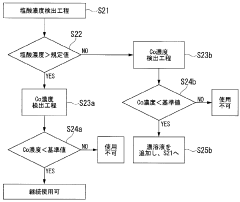

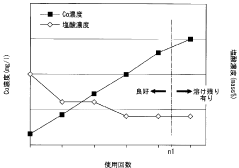

- A method to determine the usability of an acidic aqueous solution by monitoring its concentration and specific metal content, adding a concentrated solution when necessary to maintain effective cleaning levels, and ensuring adequate solution volume, thereby maintaining the cleaning ability of the acidic aqueous solution.

Environmental Impact Assessment

The use of muriatic acid for cleaning power plant equipment raises significant environmental concerns that require careful assessment. The primary environmental impact stems from the potential release of acidic wastewater into surrounding ecosystems. If not properly neutralized and treated, this wastewater can alter the pH balance of water bodies, leading to detrimental effects on aquatic life and vegetation. The acidic runoff may also leach heavy metals from soil and sediments, further contaminating water sources and potentially entering the food chain.

Air quality is another critical consideration. During the cleaning process, muriatic acid can release harmful vapors, including hydrogen chloride gas. These emissions can contribute to air pollution, potentially affecting both workers and nearby communities. The corrosive nature of these vapors may also damage surrounding infrastructure and vegetation if not adequately contained.

Soil contamination is a risk if acid spills occur during transportation, storage, or application. This can lead to soil acidification, reducing fertility and impacting local flora and fauna. The potential for groundwater contamination through soil leaching is also a significant concern, particularly in areas with high water tables or porous geological formations.

The production and transportation of muriatic acid also contribute to the overall environmental footprint. Manufacturing processes often involve energy-intensive methods and may result in greenhouse gas emissions. Transportation risks include accidental spills during transit, which could have severe localized environmental impacts.

Waste management is a crucial aspect of the environmental impact assessment. Proper disposal of spent acid solutions and neutralization byproducts is essential to prevent environmental contamination. This may require specialized treatment facilities and careful monitoring of disposal practices.

Biodiversity impacts must be considered, especially if the power plant is located near sensitive ecosystems. Changes in water chemistry or air quality could disrupt local habitats and affect species composition and population dynamics.

To mitigate these environmental risks, comprehensive safety protocols and containment measures are necessary. This includes proper training for personnel, use of protective equipment, and implementation of spill response plans. Additionally, exploring alternative cleaning methods or less hazardous substances could significantly reduce the environmental impact of power plant maintenance activities.

Air quality is another critical consideration. During the cleaning process, muriatic acid can release harmful vapors, including hydrogen chloride gas. These emissions can contribute to air pollution, potentially affecting both workers and nearby communities. The corrosive nature of these vapors may also damage surrounding infrastructure and vegetation if not adequately contained.

Soil contamination is a risk if acid spills occur during transportation, storage, or application. This can lead to soil acidification, reducing fertility and impacting local flora and fauna. The potential for groundwater contamination through soil leaching is also a significant concern, particularly in areas with high water tables or porous geological formations.

The production and transportation of muriatic acid also contribute to the overall environmental footprint. Manufacturing processes often involve energy-intensive methods and may result in greenhouse gas emissions. Transportation risks include accidental spills during transit, which could have severe localized environmental impacts.

Waste management is a crucial aspect of the environmental impact assessment. Proper disposal of spent acid solutions and neutralization byproducts is essential to prevent environmental contamination. This may require specialized treatment facilities and careful monitoring of disposal practices.

Biodiversity impacts must be considered, especially if the power plant is located near sensitive ecosystems. Changes in water chemistry or air quality could disrupt local habitats and affect species composition and population dynamics.

To mitigate these environmental risks, comprehensive safety protocols and containment measures are necessary. This includes proper training for personnel, use of protective equipment, and implementation of spill response plans. Additionally, exploring alternative cleaning methods or less hazardous substances could significantly reduce the environmental impact of power plant maintenance activities.

Safety Protocols and Regulations

The use of muriatic acid in cleaning power plant equipment necessitates strict adherence to comprehensive safety protocols and regulations. These guidelines are crucial for protecting workers, preventing environmental contamination, and ensuring the overall integrity of the cleaning process.

Personal protective equipment (PPE) is a fundamental requirement for all personnel involved in handling muriatic acid. This includes chemical-resistant gloves, goggles, face shields, and protective clothing. Respiratory protection may also be necessary, depending on the concentration of acid and the ventilation conditions in the work area.

Proper storage and handling procedures must be implemented to minimize the risk of spills or accidental exposure. Muriatic acid should be stored in corrosion-resistant containers in well-ventilated areas, away from incompatible materials. Clear labeling and regular inspections of storage areas are essential to maintain safety standards.

Emergency response plans must be in place and regularly updated. These plans should outline procedures for addressing spills, chemical exposure, and other potential hazards. Eyewash stations and safety showers must be readily accessible in areas where muriatic acid is used or stored.

Training programs are critical to ensure that all employees understand the hazards associated with muriatic acid and are proficient in safe handling techniques. Regular refresher courses should be conducted to reinforce safety practices and update workers on any changes in regulations or procedures.

Environmental regulations play a significant role in the use of muriatic acid in power plant cleaning. Proper disposal methods must be employed to prevent contamination of water sources or soil. Neutralization of waste acid and compliance with local and national environmental standards are essential aspects of the cleaning process.

Ventilation systems in areas where muriatic acid is used must be designed to effectively remove acid vapors and maintain safe air quality. Regular monitoring of air quality and the functionality of ventilation systems is necessary to ensure a safe working environment.

Documentation and record-keeping are crucial components of safety protocols. This includes maintaining safety data sheets (SDS), documenting training sessions, recording incidents or near-misses, and keeping logs of equipment maintenance and inspections.

Regular safety audits and inspections should be conducted to identify potential hazards and ensure compliance with established protocols. These audits can help in continuously improving safety measures and addressing any gaps in the existing procedures.

Collaboration with regulatory bodies and industry experts is essential for staying updated on the latest safety standards and best practices. This may involve participating in industry forums, consulting with safety specialists, and engaging in continuous improvement initiatives to enhance the overall safety culture within the power plant cleaning operations.

Personal protective equipment (PPE) is a fundamental requirement for all personnel involved in handling muriatic acid. This includes chemical-resistant gloves, goggles, face shields, and protective clothing. Respiratory protection may also be necessary, depending on the concentration of acid and the ventilation conditions in the work area.

Proper storage and handling procedures must be implemented to minimize the risk of spills or accidental exposure. Muriatic acid should be stored in corrosion-resistant containers in well-ventilated areas, away from incompatible materials. Clear labeling and regular inspections of storage areas are essential to maintain safety standards.

Emergency response plans must be in place and regularly updated. These plans should outline procedures for addressing spills, chemical exposure, and other potential hazards. Eyewash stations and safety showers must be readily accessible in areas where muriatic acid is used or stored.

Training programs are critical to ensure that all employees understand the hazards associated with muriatic acid and are proficient in safe handling techniques. Regular refresher courses should be conducted to reinforce safety practices and update workers on any changes in regulations or procedures.

Environmental regulations play a significant role in the use of muriatic acid in power plant cleaning. Proper disposal methods must be employed to prevent contamination of water sources or soil. Neutralization of waste acid and compliance with local and national environmental standards are essential aspects of the cleaning process.

Ventilation systems in areas where muriatic acid is used must be designed to effectively remove acid vapors and maintain safe air quality. Regular monitoring of air quality and the functionality of ventilation systems is necessary to ensure a safe working environment.

Documentation and record-keeping are crucial components of safety protocols. This includes maintaining safety data sheets (SDS), documenting training sessions, recording incidents or near-misses, and keeping logs of equipment maintenance and inspections.

Regular safety audits and inspections should be conducted to identify potential hazards and ensure compliance with established protocols. These audits can help in continuously improving safety measures and addressing any gaps in the existing procedures.

Collaboration with regulatory bodies and industry experts is essential for staying updated on the latest safety standards and best practices. This may involve participating in industry forums, consulting with safety specialists, and engaging in continuous improvement initiatives to enhance the overall safety culture within the power plant cleaning operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!