Analyzing the Impact of Magnesium Nitride in Corrosion Resistance

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitride Corrosion Resistance Background

Magnesium nitride has emerged as a promising material in the field of corrosion resistance, attracting significant attention from researchers and industry professionals alike. The exploration of this compound's potential in enhancing corrosion resistance stems from the growing need for more effective and sustainable solutions to combat material degradation in various applications.

The journey of magnesium nitride in corrosion resistance research can be traced back to the early 2000s when scientists began investigating alternative materials to traditional corrosion-resistant coatings. Initial studies focused on understanding the fundamental properties of magnesium nitride, including its chemical stability, mechanical strength, and interaction with different environments.

As research progressed, the unique characteristics of magnesium nitride became increasingly apparent. Its ability to form stable protective layers on metal surfaces, coupled with its excellent adhesion properties, positioned it as a promising candidate for corrosion protection. This led to a surge in experimental studies aimed at optimizing magnesium nitride coatings for various substrates and environmental conditions.

The evolution of magnesium nitride research in corrosion resistance has been marked by several key milestones. Early breakthroughs included the development of novel synthesis methods to produce high-quality magnesium nitride coatings with controlled composition and microstructure. Subsequent advancements focused on enhancing the material's performance through doping, nanostructuring, and composite formation.

In recent years, the scope of magnesium nitride research has expanded to encompass a wide range of applications, from automotive and aerospace industries to marine environments and biomedical implants. This diversification has driven the need for more comprehensive studies on the material's behavior under different corrosive conditions and its long-term stability.

The current technological landscape surrounding magnesium nitride in corrosion resistance is characterized by a multidisciplinary approach. Researchers are combining insights from materials science, electrochemistry, and surface engineering to develop innovative solutions. Advanced characterization techniques, such as in-situ electron microscopy and spectroscopy, have played a crucial role in unraveling the mechanisms underlying magnesium nitride's corrosion resistance properties.

As we look towards the future, the field of magnesium nitride corrosion resistance continues to evolve. Emerging trends include the integration of smart coating technologies, the development of self-healing magnesium nitride-based materials, and the exploration of environmentally friendly production methods. These advancements aim to address the growing demand for more efficient, durable, and sustainable corrosion protection solutions across various industries.

The journey of magnesium nitride in corrosion resistance research can be traced back to the early 2000s when scientists began investigating alternative materials to traditional corrosion-resistant coatings. Initial studies focused on understanding the fundamental properties of magnesium nitride, including its chemical stability, mechanical strength, and interaction with different environments.

As research progressed, the unique characteristics of magnesium nitride became increasingly apparent. Its ability to form stable protective layers on metal surfaces, coupled with its excellent adhesion properties, positioned it as a promising candidate for corrosion protection. This led to a surge in experimental studies aimed at optimizing magnesium nitride coatings for various substrates and environmental conditions.

The evolution of magnesium nitride research in corrosion resistance has been marked by several key milestones. Early breakthroughs included the development of novel synthesis methods to produce high-quality magnesium nitride coatings with controlled composition and microstructure. Subsequent advancements focused on enhancing the material's performance through doping, nanostructuring, and composite formation.

In recent years, the scope of magnesium nitride research has expanded to encompass a wide range of applications, from automotive and aerospace industries to marine environments and biomedical implants. This diversification has driven the need for more comprehensive studies on the material's behavior under different corrosive conditions and its long-term stability.

The current technological landscape surrounding magnesium nitride in corrosion resistance is characterized by a multidisciplinary approach. Researchers are combining insights from materials science, electrochemistry, and surface engineering to develop innovative solutions. Advanced characterization techniques, such as in-situ electron microscopy and spectroscopy, have played a crucial role in unraveling the mechanisms underlying magnesium nitride's corrosion resistance properties.

As we look towards the future, the field of magnesium nitride corrosion resistance continues to evolve. Emerging trends include the integration of smart coating technologies, the development of self-healing magnesium nitride-based materials, and the exploration of environmentally friendly production methods. These advancements aim to address the growing demand for more efficient, durable, and sustainable corrosion protection solutions across various industries.

Market Demand Analysis

The market demand for corrosion-resistant materials has been steadily increasing across various industries, with magnesium nitride emerging as a promising candidate. The global corrosion inhibitors market, which includes materials like magnesium nitride, is projected to grow significantly in the coming years. This growth is driven by the rising need for protection against corrosion in industries such as oil and gas, power generation, water treatment, and manufacturing.

In the oil and gas sector, the demand for corrosion-resistant materials is particularly high due to the harsh operating environments and the critical nature of equipment. Magnesium nitride's potential to enhance corrosion resistance in this sector could lead to substantial cost savings and improved safety measures. The power generation industry, especially in areas with high humidity or coastal regions, also presents a significant market opportunity for magnesium nitride-based corrosion protection solutions.

The water treatment industry is another key market for corrosion-resistant materials. As global water scarcity issues intensify, the need for efficient water treatment and distribution systems becomes more critical. Magnesium nitride's potential application in protecting water infrastructure from corrosion could contribute to reducing water loss and improving system longevity.

In the manufacturing sector, particularly in automotive and aerospace industries, the demand for lightweight yet corrosion-resistant materials is on the rise. Magnesium nitride's potential to improve the corrosion resistance of magnesium alloys could open up new possibilities for these industries, allowing for the development of lighter, more fuel-efficient vehicles and aircraft.

The construction industry also presents a significant market opportunity for magnesium nitride-based corrosion protection solutions. With the increasing focus on sustainable and durable infrastructure, materials that can extend the lifespan of buildings and structures while reducing maintenance costs are in high demand.

Market trends indicate a growing preference for environmentally friendly corrosion protection solutions. If magnesium nitride can be developed and applied in an eco-friendly manner, it could gain a competitive edge in the market. Additionally, the increasing adoption of advanced manufacturing techniques, such as 3D printing, could create new opportunities for the application of magnesium nitride in corrosion-resistant coatings and materials.

As research and development in magnesium nitride's corrosion resistance properties progress, it is likely to attract attention from both established players in the corrosion protection market and innovative startups. This could lead to increased investment in the technology and accelerate its commercialization.

In the oil and gas sector, the demand for corrosion-resistant materials is particularly high due to the harsh operating environments and the critical nature of equipment. Magnesium nitride's potential to enhance corrosion resistance in this sector could lead to substantial cost savings and improved safety measures. The power generation industry, especially in areas with high humidity or coastal regions, also presents a significant market opportunity for magnesium nitride-based corrosion protection solutions.

The water treatment industry is another key market for corrosion-resistant materials. As global water scarcity issues intensify, the need for efficient water treatment and distribution systems becomes more critical. Magnesium nitride's potential application in protecting water infrastructure from corrosion could contribute to reducing water loss and improving system longevity.

In the manufacturing sector, particularly in automotive and aerospace industries, the demand for lightweight yet corrosion-resistant materials is on the rise. Magnesium nitride's potential to improve the corrosion resistance of magnesium alloys could open up new possibilities for these industries, allowing for the development of lighter, more fuel-efficient vehicles and aircraft.

The construction industry also presents a significant market opportunity for magnesium nitride-based corrosion protection solutions. With the increasing focus on sustainable and durable infrastructure, materials that can extend the lifespan of buildings and structures while reducing maintenance costs are in high demand.

Market trends indicate a growing preference for environmentally friendly corrosion protection solutions. If magnesium nitride can be developed and applied in an eco-friendly manner, it could gain a competitive edge in the market. Additionally, the increasing adoption of advanced manufacturing techniques, such as 3D printing, could create new opportunities for the application of magnesium nitride in corrosion-resistant coatings and materials.

As research and development in magnesium nitride's corrosion resistance properties progress, it is likely to attract attention from both established players in the corrosion protection market and innovative startups. This could lead to increased investment in the technology and accelerate its commercialization.

Current Challenges in Corrosion Resistance

Corrosion resistance remains a critical challenge in various industries, with significant economic and safety implications. Despite advancements in materials science and protective coatings, several obstacles persist in achieving optimal corrosion resistance, particularly in harsh environments.

One of the primary challenges is the development of cost-effective, long-lasting protective coatings. While high-performance coatings exist, their widespread adoption is hindered by high costs and complex application processes. Balancing durability with affordability continues to be a major focus for researchers and manufacturers alike.

The unpredictable nature of corrosive environments poses another significant challenge. Corrosion mechanisms can vary greatly depending on factors such as temperature, humidity, pH levels, and the presence of specific chemical agents. This variability makes it difficult to design universal corrosion-resistant solutions, necessitating tailored approaches for different applications.

Nanoscale corrosion phenomena present a unique set of challenges. As materials are engineered at increasingly smaller scales, traditional corrosion models may not accurately predict behavior at the nanoscale. Understanding and controlling corrosion at this level is crucial for developing next-generation materials and coatings.

The interface between different materials in composite structures is particularly vulnerable to corrosion. Galvanic corrosion at these interfaces can lead to premature failure of otherwise robust systems. Developing effective strategies to mitigate interfacial corrosion without compromising the benefits of composite materials remains a significant challenge.

Environmental regulations and sustainability concerns add another layer of complexity to corrosion resistance efforts. Many traditional corrosion inhibitors and surface treatments are being phased out due to their environmental impact, necessitating the development of eco-friendly alternatives that maintain or improve upon existing performance standards.

In the context of magnesium nitride's potential impact on corrosion resistance, several specific challenges emerge. The reactivity of magnesium nitride with water and oxygen in ambient conditions can lead to the formation of magnesium hydroxide and ammonia, potentially altering the surface properties and corrosion resistance characteristics over time. Controlling this reactivity while harnessing the beneficial properties of magnesium nitride is a key challenge.

Furthermore, integrating magnesium nitride into existing corrosion protection systems presents technical hurdles. Ensuring compatibility with common substrate materials, developing appropriate application methods, and maintaining the stability of magnesium nitride in various environmental conditions are all areas requiring further research and development.

One of the primary challenges is the development of cost-effective, long-lasting protective coatings. While high-performance coatings exist, their widespread adoption is hindered by high costs and complex application processes. Balancing durability with affordability continues to be a major focus for researchers and manufacturers alike.

The unpredictable nature of corrosive environments poses another significant challenge. Corrosion mechanisms can vary greatly depending on factors such as temperature, humidity, pH levels, and the presence of specific chemical agents. This variability makes it difficult to design universal corrosion-resistant solutions, necessitating tailored approaches for different applications.

Nanoscale corrosion phenomena present a unique set of challenges. As materials are engineered at increasingly smaller scales, traditional corrosion models may not accurately predict behavior at the nanoscale. Understanding and controlling corrosion at this level is crucial for developing next-generation materials and coatings.

The interface between different materials in composite structures is particularly vulnerable to corrosion. Galvanic corrosion at these interfaces can lead to premature failure of otherwise robust systems. Developing effective strategies to mitigate interfacial corrosion without compromising the benefits of composite materials remains a significant challenge.

Environmental regulations and sustainability concerns add another layer of complexity to corrosion resistance efforts. Many traditional corrosion inhibitors and surface treatments are being phased out due to their environmental impact, necessitating the development of eco-friendly alternatives that maintain or improve upon existing performance standards.

In the context of magnesium nitride's potential impact on corrosion resistance, several specific challenges emerge. The reactivity of magnesium nitride with water and oxygen in ambient conditions can lead to the formation of magnesium hydroxide and ammonia, potentially altering the surface properties and corrosion resistance characteristics over time. Controlling this reactivity while harnessing the beneficial properties of magnesium nitride is a key challenge.

Furthermore, integrating magnesium nitride into existing corrosion protection systems presents technical hurdles. Ensuring compatibility with common substrate materials, developing appropriate application methods, and maintaining the stability of magnesium nitride in various environmental conditions are all areas requiring further research and development.

Existing Magnesium Nitride Solutions

01 Magnesium nitride coatings for corrosion resistance

Magnesium nitride coatings can be applied to various substrates to enhance their corrosion resistance. These coatings form a protective layer that prevents the underlying material from coming into contact with corrosive agents. The coatings can be deposited using various methods such as physical vapor deposition or chemical vapor deposition.- Magnesium nitride coatings for corrosion resistance: Magnesium nitride coatings can be applied to various substrates to enhance their corrosion resistance. These coatings form a protective layer that prevents the underlying material from coming into contact with corrosive agents. The coatings can be deposited using various methods such as physical vapor deposition or chemical vapor deposition.

- Magnesium nitride as a component in corrosion-resistant alloys: Magnesium nitride can be incorporated into alloy compositions to improve their corrosion resistance. These alloys may contain other elements such as aluminum, zinc, or rare earth metals. The presence of magnesium nitride in the alloy structure can help to form a protective layer on the surface, enhancing the overall corrosion resistance of the material.

- Surface treatment processes involving magnesium nitride: Various surface treatment processes can be employed to improve the corrosion resistance of materials using magnesium nitride. These processes may include nitriding, ion implantation, or plasma treatment. The surface treatment creates a magnesium nitride-rich layer on the material surface, which acts as a barrier against corrosive agents.

- Magnesium nitride in composite materials for corrosion protection: Composite materials incorporating magnesium nitride can be developed for enhanced corrosion resistance. These composites may combine magnesium nitride with other materials such as ceramics, polymers, or metals. The resulting composite material can offer improved corrosion resistance while maintaining other desirable properties such as strength or lightweight characteristics.

- Magnesium nitride-based inhibitors for corrosion protection: Magnesium nitride can be used as a component in corrosion inhibitors. These inhibitors can be added to coatings, paints, or other protective systems to enhance their corrosion resistance properties. The magnesium nitride-based inhibitors work by forming a protective layer on the material surface or by neutralizing corrosive agents in the environment.

02 Magnesium nitride-based composite materials

Composite materials incorporating magnesium nitride can exhibit improved corrosion resistance. These composites may include other elements or compounds that synergistically enhance the overall corrosion resistance. The composition and structure of these composites can be tailored to suit specific applications and environmental conditions.Expand Specific Solutions03 Surface treatment methods for magnesium nitride

Various surface treatment methods can be applied to magnesium nitride to improve its corrosion resistance. These may include chemical passivation, heat treatments, or the application of additional protective layers. Such treatments can modify the surface properties of magnesium nitride, making it more resistant to corrosive environments.Expand Specific Solutions04 Magnesium nitride in anti-corrosion alloys

Magnesium nitride can be incorporated into alloy systems to enhance their corrosion resistance. These alloys may combine the beneficial properties of magnesium nitride with those of other elements to create materials with superior corrosion resistance. The precise composition and processing of these alloys can be optimized for specific applications.Expand Specific Solutions05 Nanostructured magnesium nitride for corrosion protection

Nanostructured forms of magnesium nitride, such as nanoparticles or nanocoatings, can offer enhanced corrosion resistance. The increased surface area and unique properties of nanoscale materials can provide improved barrier properties and reactivity, leading to better protection against corrosive agents. These nanostructured materials can be incorporated into various protective systems or applied directly to surfaces.Expand Specific Solutions

Key Players in Corrosion Resistance Industry

The competitive landscape for analyzing the impact of magnesium nitride in corrosion resistance is in its early development stage, with a growing market potential as industries seek advanced corrosion protection solutions. The technology's maturity is still evolving, with research institutions like Okayama University, Jilin University, and National Chiao Tung University leading academic investigations. Companies such as A.L.M.T. Corp., PRC-DeSoto International, and NGK Insulators are exploring industrial applications, while major players like ExxonMobil Chemical Patents and Norsk Hydro ASA are likely investing in R&D. The involvement of diverse entities, from specialized materials firms to large conglomerates, indicates a competitive field with significant growth prospects in various sectors, including automotive, aerospace, and energy.

Helmholtz-Zentrum hereon GmbH

Technical Solution: Helmholtz-Zentrum hereon GmbH has developed advanced magnesium nitride-based coatings for enhanced corrosion resistance. Their approach involves the deposition of Mg3N2 layers on various metal substrates using plasma-enhanced chemical vapor deposition (PECVD) techniques[1]. The resulting coatings exhibit excellent adhesion and form a protective barrier against corrosive environments. The company has also explored the incorporation of magnesium nitride nanoparticles into polymer matrices to create composite coatings with improved corrosion resistance properties[3]. These coatings have shown promising results in marine and industrial applications, where they effectively protect underlying metals from degradation in harsh environments.

Strengths: Expertise in advanced coating technologies, strong research capabilities in materials science. Weaknesses: Limited commercial scale production, potential high costs associated with specialized deposition techniques.

Norsk Hydro ASA

Technical Solution: Norsk Hydro ASA has developed a novel approach to incorporating magnesium nitride into aluminum alloys to enhance their corrosion resistance. Their process involves the controlled nitridation of magnesium-rich regions within the aluminum matrix, resulting in the formation of fine Mg3N2 precipitates[2]. These precipitates act as sacrificial anodes, preferentially corroding and protecting the surrounding aluminum. The company has also explored the use of magnesium nitride as a surface treatment for aluminum products, creating a protective layer that significantly improves corrosion resistance in marine and industrial environments[4]. Norsk Hydro's technology has been successfully applied to various aluminum products, including automotive components and marine structures.

Strengths: Extensive experience in aluminum production and processing, established market presence. Weaknesses: Technology primarily focused on aluminum applications, may have limited applicability to other metals.

Core Innovations in Magnesium Nitride Application

Corrosion resistant Mg based alloy containing Al, Si, Mn and RE metals

PatentInactiveUS6793877B1

Innovation

- Novel composition of Mg-based alloy with specific ranges of Al, Si, Mn, and RE metals for improved corrosion resistance.

- Addition of small amounts of rare earth metals to reduce both Mn and Fe levels, enhancing corrosion resistance.

- Controlled addition of Mn to reduce Fe impurities, contributing to improved corrosion resistance.

Magnesium alloy having excellent mechanical properties and corrosion resistance, and method for manufacturing same

PatentWO2017116020A1

Innovation

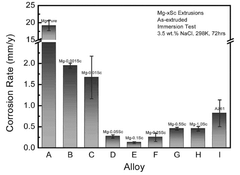

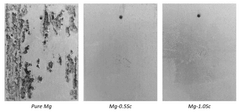

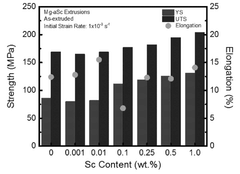

- Incorporating scandium into magnesium alloys, which suppresses microgalvanic corrosion and enhances the passivation properties of the surface film without deteriorating mechanical properties, thereby improving corrosion resistance.

Environmental Impact Assessment

The environmental impact assessment of magnesium nitride in corrosion resistance applications is a critical aspect of its implementation. This compound, while offering significant benefits in protecting materials from corrosion, also presents potential environmental concerns that must be carefully evaluated.

Magnesium nitride's production process involves the reaction of magnesium with nitrogen at high temperatures. This energy-intensive process contributes to greenhouse gas emissions, particularly if the energy source is not renewable. The manufacturing facilities may also release particulate matter and other air pollutants, necessitating stringent emission control measures.

Water usage and potential contamination are additional environmental considerations. The synthesis and application of magnesium nitride may require substantial water resources, and improper handling or disposal could lead to water pollution. Nitride compounds can potentially contribute to eutrophication if released into aquatic ecosystems, disrupting the natural balance of these environments.

The long-term environmental fate of magnesium nitride coatings is another area of concern. As these coatings wear off or degrade over time, they may release magnesium and nitrogen compounds into the environment. While magnesium is generally considered non-toxic and is an essential nutrient for many organisms, excessive amounts can alter soil and water chemistry.

On the positive side, the use of magnesium nitride in corrosion resistance can indirectly benefit the environment by extending the lifespan of materials and reducing the need for frequent replacements. This can lead to decreased resource consumption and waste generation over time. Additionally, by preventing corrosion, it reduces the release of potentially harmful corrosion byproducts into the environment.

The recyclability and end-of-life management of materials treated with magnesium nitride coatings are important considerations. Research into efficient recycling methods and safe disposal practices is crucial to minimize the environmental footprint of this technology.

Regulatory compliance is a key aspect of environmental impact assessment. The use of magnesium nitride must adhere to local, national, and international environmental regulations, including those governing air and water quality, waste management, and chemical safety.

In conclusion, while magnesium nitride offers promising benefits for corrosion resistance, its environmental impact must be carefully managed. Ongoing research and development should focus on optimizing production processes, improving coating durability, and developing eco-friendly application methods to mitigate potential environmental risks.

Magnesium nitride's production process involves the reaction of magnesium with nitrogen at high temperatures. This energy-intensive process contributes to greenhouse gas emissions, particularly if the energy source is not renewable. The manufacturing facilities may also release particulate matter and other air pollutants, necessitating stringent emission control measures.

Water usage and potential contamination are additional environmental considerations. The synthesis and application of magnesium nitride may require substantial water resources, and improper handling or disposal could lead to water pollution. Nitride compounds can potentially contribute to eutrophication if released into aquatic ecosystems, disrupting the natural balance of these environments.

The long-term environmental fate of magnesium nitride coatings is another area of concern. As these coatings wear off or degrade over time, they may release magnesium and nitrogen compounds into the environment. While magnesium is generally considered non-toxic and is an essential nutrient for many organisms, excessive amounts can alter soil and water chemistry.

On the positive side, the use of magnesium nitride in corrosion resistance can indirectly benefit the environment by extending the lifespan of materials and reducing the need for frequent replacements. This can lead to decreased resource consumption and waste generation over time. Additionally, by preventing corrosion, it reduces the release of potentially harmful corrosion byproducts into the environment.

The recyclability and end-of-life management of materials treated with magnesium nitride coatings are important considerations. Research into efficient recycling methods and safe disposal practices is crucial to minimize the environmental footprint of this technology.

Regulatory compliance is a key aspect of environmental impact assessment. The use of magnesium nitride must adhere to local, national, and international environmental regulations, including those governing air and water quality, waste management, and chemical safety.

In conclusion, while magnesium nitride offers promising benefits for corrosion resistance, its environmental impact must be carefully managed. Ongoing research and development should focus on optimizing production processes, improving coating durability, and developing eco-friendly application methods to mitigate potential environmental risks.

Cost-Benefit Analysis of Magnesium Nitride Use

The implementation of magnesium nitride in corrosion resistance applications presents a complex cost-benefit scenario that requires careful analysis. On the cost side, the production of magnesium nitride involves significant initial investments in manufacturing facilities and equipment. The synthesis process, typically involving the direct nitridation of magnesium metal or the reaction of magnesium compounds with ammonia at high temperatures, demands specialized reactors and controlled environments, contributing to higher production costs.

Raw material costs for magnesium nitride production are generally moderate, with magnesium being relatively abundant. However, the energy-intensive nature of the synthesis process adds to the overall expenses. Additionally, the handling and storage of magnesium nitride require specific conditions due to its reactivity with moisture, potentially increasing logistical costs.

On the benefit side, magnesium nitride offers superior corrosion resistance properties, particularly in high-temperature and aggressive chemical environments. This can lead to substantial long-term savings in maintenance and replacement costs for industrial equipment and infrastructure. The extended lifespan of treated surfaces and components can offset the initial higher costs of magnesium nitride application.

In specific industries such as aerospace, automotive, and chemical processing, where corrosion-related failures can result in significant economic losses and safety risks, the use of magnesium nitride coatings or additives can provide a compelling value proposition. The potential reduction in downtime, improved safety, and enhanced product reliability contribute to the overall economic benefits.

Furthermore, the unique properties of magnesium nitride open up possibilities for new product developments and applications, potentially creating new market opportunities and revenue streams. This aspect should be considered in the long-term cost-benefit analysis, as it may lead to competitive advantages and market differentiation.

Environmental considerations also play a role in the cost-benefit analysis. While the production of magnesium nitride may have some environmental impacts, its use in corrosion prevention can lead to reduced material waste and energy consumption associated with frequent replacements of corroded components. This aligns with sustainability goals and may provide additional economic benefits through compliance with environmental regulations and improved corporate image.

In conclusion, while the upfront costs of implementing magnesium nitride in corrosion resistance applications can be significant, the long-term benefits in terms of durability, performance, and potential new market opportunities present a compelling case for its adoption in various industries. A thorough assessment of specific application requirements, market conditions, and long-term strategic goals is essential to determine the overall economic viability of magnesium nitride use in corrosion resistance solutions.

Raw material costs for magnesium nitride production are generally moderate, with magnesium being relatively abundant. However, the energy-intensive nature of the synthesis process adds to the overall expenses. Additionally, the handling and storage of magnesium nitride require specific conditions due to its reactivity with moisture, potentially increasing logistical costs.

On the benefit side, magnesium nitride offers superior corrosion resistance properties, particularly in high-temperature and aggressive chemical environments. This can lead to substantial long-term savings in maintenance and replacement costs for industrial equipment and infrastructure. The extended lifespan of treated surfaces and components can offset the initial higher costs of magnesium nitride application.

In specific industries such as aerospace, automotive, and chemical processing, where corrosion-related failures can result in significant economic losses and safety risks, the use of magnesium nitride coatings or additives can provide a compelling value proposition. The potential reduction in downtime, improved safety, and enhanced product reliability contribute to the overall economic benefits.

Furthermore, the unique properties of magnesium nitride open up possibilities for new product developments and applications, potentially creating new market opportunities and revenue streams. This aspect should be considered in the long-term cost-benefit analysis, as it may lead to competitive advantages and market differentiation.

Environmental considerations also play a role in the cost-benefit analysis. While the production of magnesium nitride may have some environmental impacts, its use in corrosion prevention can lead to reduced material waste and energy consumption associated with frequent replacements of corroded components. This aligns with sustainability goals and may provide additional economic benefits through compliance with environmental regulations and improved corporate image.

In conclusion, while the upfront costs of implementing magnesium nitride in corrosion resistance applications can be significant, the long-term benefits in terms of durability, performance, and potential new market opportunities present a compelling case for its adoption in various industries. A thorough assessment of specific application requirements, market conditions, and long-term strategic goals is essential to determine the overall economic viability of magnesium nitride use in corrosion resistance solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!