How to Maximize the Conductivity of Magnesium Nitride?

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg3N2 Conductivity Enhancement: Background and Objectives

Magnesium nitride (Mg3N2) has emerged as a promising material in the field of solid-state physics and materials science due to its unique properties and potential applications. The quest to maximize its conductivity has gained significant attention in recent years, driven by the growing demand for high-performance electronic and energy storage devices. This research aims to explore and enhance the conductivity of Mg3N2, with the ultimate goal of unlocking its full potential for practical applications.

The development of Mg3N2 as a conductive material has its roots in the broader field of nitride-based semiconductors. Initially overshadowed by more widely studied nitrides such as gallium nitride (GaN) and aluminum nitride (AlN), Mg3N2 has gradually gained recognition for its distinctive electronic properties. The journey to improve its conductivity began with fundamental studies of its crystal structure and electronic band structure, which revealed promising characteristics for electronic applications.

As research progressed, scientists identified several factors influencing the conductivity of Mg3N2, including crystal defects, impurities, and structural modifications. Early experiments focused on optimizing synthesis methods to produce high-quality Mg3N2 samples with minimal defects. Subsequent efforts explored doping strategies to introduce charge carriers and manipulate the electronic properties of the material.

The technological evolution in this field has been marked by significant milestones. These include the development of advanced deposition techniques for thin-film Mg3N2, the discovery of novel doping agents, and the exploration of nanostructured forms of the material. Each breakthrough has contributed to a deeper understanding of the conduction mechanisms in Mg3N2 and opened new avenues for conductivity enhancement.

The current research landscape is characterized by a multidisciplinary approach, combining theoretical modeling, advanced characterization techniques, and innovative experimental methods. Computational studies have provided valuable insights into the electronic structure of Mg3N2 and predicted the effects of various modifications on its conductivity. Meanwhile, cutting-edge analytical tools have enabled researchers to probe the material's properties at unprecedented levels of detail.

Looking ahead, the objectives of this research are multifaceted. Primarily, we aim to develop strategies to significantly increase the conductivity of Mg3N2, potentially rivaling or surpassing that of conventional conductive materials. This involves exploring novel doping techniques, investigating the effects of strain and pressure on conductivity, and optimizing the material's microstructure. Additionally, we seek to understand the fundamental mechanisms governing charge transport in Mg3N2, which will inform future efforts to tailor its properties.

The development of Mg3N2 as a conductive material has its roots in the broader field of nitride-based semiconductors. Initially overshadowed by more widely studied nitrides such as gallium nitride (GaN) and aluminum nitride (AlN), Mg3N2 has gradually gained recognition for its distinctive electronic properties. The journey to improve its conductivity began with fundamental studies of its crystal structure and electronic band structure, which revealed promising characteristics for electronic applications.

As research progressed, scientists identified several factors influencing the conductivity of Mg3N2, including crystal defects, impurities, and structural modifications. Early experiments focused on optimizing synthesis methods to produce high-quality Mg3N2 samples with minimal defects. Subsequent efforts explored doping strategies to introduce charge carriers and manipulate the electronic properties of the material.

The technological evolution in this field has been marked by significant milestones. These include the development of advanced deposition techniques for thin-film Mg3N2, the discovery of novel doping agents, and the exploration of nanostructured forms of the material. Each breakthrough has contributed to a deeper understanding of the conduction mechanisms in Mg3N2 and opened new avenues for conductivity enhancement.

The current research landscape is characterized by a multidisciplinary approach, combining theoretical modeling, advanced characterization techniques, and innovative experimental methods. Computational studies have provided valuable insights into the electronic structure of Mg3N2 and predicted the effects of various modifications on its conductivity. Meanwhile, cutting-edge analytical tools have enabled researchers to probe the material's properties at unprecedented levels of detail.

Looking ahead, the objectives of this research are multifaceted. Primarily, we aim to develop strategies to significantly increase the conductivity of Mg3N2, potentially rivaling or surpassing that of conventional conductive materials. This involves exploring novel doping techniques, investigating the effects of strain and pressure on conductivity, and optimizing the material's microstructure. Additionally, we seek to understand the fundamental mechanisms governing charge transport in Mg3N2, which will inform future efforts to tailor its properties.

Market Analysis for High-Conductivity Nitrides

The market for high-conductivity nitrides, particularly magnesium nitride, is experiencing significant growth driven by the increasing demand for advanced materials in various industries. The global nitride market, which includes magnesium nitride, is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2021 to 2028. This growth is primarily fueled by the rising adoption of nitrides in electronics, semiconductors, and energy storage applications.

Magnesium nitride, with its potential for high conductivity, is garnering attention in the electronics and semiconductor industries. The global semiconductor market, valued at $452.25 billion in 2021, is expected to reach $803.15 billion by 2028, creating a substantial opportunity for high-conductivity materials like magnesium nitride. The increasing focus on miniaturization and improved performance of electronic devices is driving the demand for materials that can enhance conductivity and thermal management.

In the energy sector, the growing interest in renewable energy sources and energy storage solutions is creating new avenues for high-conductivity nitrides. The global energy storage market is projected to reach $435.32 billion by 2030, with a CAGR of 8.3% from 2022 to 2030. Magnesium nitride's potential applications in battery technologies and energy storage systems position it as a promising material in this rapidly expanding market.

The automotive industry is another key market for high-conductivity nitrides. With the shift towards electric vehicles (EVs) and the need for more efficient power electronics, materials that can improve conductivity and thermal management are in high demand. The global EV market is expected to grow at a CAGR of 22.6% from 2022 to 2030, presenting a significant opportunity for advanced materials like magnesium nitride.

Geographically, Asia-Pacific dominates the nitride market, accounting for the largest share of global production and consumption. This is primarily due to the region's strong presence in electronics manufacturing and semiconductor industries. North America and Europe follow, with increasing investments in research and development of advanced materials and their applications in various sectors.

Despite the promising market outlook, challenges remain in the widespread adoption of high-conductivity magnesium nitride. These include the need for cost-effective production methods, scalability issues, and competition from established materials. However, ongoing research and development efforts aimed at maximizing the conductivity of magnesium nitride are expected to address these challenges and unlock new market opportunities.

In conclusion, the market for high-conductivity nitrides, including magnesium nitride, shows strong growth potential across multiple industries. As research progresses in maximizing the conductivity of magnesium nitride, its market applications are likely to expand, driving further growth in the coming years.

Magnesium nitride, with its potential for high conductivity, is garnering attention in the electronics and semiconductor industries. The global semiconductor market, valued at $452.25 billion in 2021, is expected to reach $803.15 billion by 2028, creating a substantial opportunity for high-conductivity materials like magnesium nitride. The increasing focus on miniaturization and improved performance of electronic devices is driving the demand for materials that can enhance conductivity and thermal management.

In the energy sector, the growing interest in renewable energy sources and energy storage solutions is creating new avenues for high-conductivity nitrides. The global energy storage market is projected to reach $435.32 billion by 2030, with a CAGR of 8.3% from 2022 to 2030. Magnesium nitride's potential applications in battery technologies and energy storage systems position it as a promising material in this rapidly expanding market.

The automotive industry is another key market for high-conductivity nitrides. With the shift towards electric vehicles (EVs) and the need for more efficient power electronics, materials that can improve conductivity and thermal management are in high demand. The global EV market is expected to grow at a CAGR of 22.6% from 2022 to 2030, presenting a significant opportunity for advanced materials like magnesium nitride.

Geographically, Asia-Pacific dominates the nitride market, accounting for the largest share of global production and consumption. This is primarily due to the region's strong presence in electronics manufacturing and semiconductor industries. North America and Europe follow, with increasing investments in research and development of advanced materials and their applications in various sectors.

Despite the promising market outlook, challenges remain in the widespread adoption of high-conductivity magnesium nitride. These include the need for cost-effective production methods, scalability issues, and competition from established materials. However, ongoing research and development efforts aimed at maximizing the conductivity of magnesium nitride are expected to address these challenges and unlock new market opportunities.

In conclusion, the market for high-conductivity nitrides, including magnesium nitride, shows strong growth potential across multiple industries. As research progresses in maximizing the conductivity of magnesium nitride, its market applications are likely to expand, driving further growth in the coming years.

Current State and Challenges in Mg3N2 Conductivity

Magnesium nitride (Mg3N2) has garnered significant attention in recent years due to its potential applications in various fields, including energy storage, catalysis, and electronic devices. However, the current state of Mg3N2 conductivity presents several challenges that hinder its widespread adoption and practical implementation.

The conductivity of Mg3N2 is primarily limited by its intrinsic electronic structure and crystal defects. In its stoichiometric form, Mg3N2 exhibits semiconducting behavior with a relatively wide bandgap of approximately 2.8 eV. This inherent property restricts its electrical conductivity, making it less suitable for applications requiring high charge transport capabilities.

One of the major challenges in maximizing Mg3N2 conductivity is the presence of structural defects and impurities. These defects, such as vacancies, interstitials, and grain boundaries, act as scattering centers for charge carriers, significantly reducing the overall conductivity. The synthesis and processing methods employed in Mg3N2 production often introduce these defects, making it difficult to achieve high-purity, defect-free samples.

Another critical factor affecting Mg3N2 conductivity is its sensitivity to environmental conditions, particularly moisture and oxygen. When exposed to air, Mg3N2 readily undergoes hydrolysis, forming magnesium hydroxide and ammonia. This degradation process not only alters the material's composition but also introduces additional defects and impurities, further compromising its conductivity.

The temperature dependence of Mg3N2 conductivity poses another challenge. Like many semiconductors, the conductivity of Mg3N2 increases with temperature due to thermal excitation of charge carriers. However, this temperature sensitivity can lead to instability and unreliability in practical applications, especially in environments with fluctuating temperatures.

Efforts to enhance Mg3N2 conductivity have focused on various strategies, including doping, nanostructuring, and surface modification. Doping with aliovalent elements has shown promise in increasing charge carrier concentration and mobility. However, finding suitable dopants that can be effectively incorporated into the Mg3N2 lattice without introducing additional defects remains a significant challenge.

Nanostructuring approaches, such as creating nanoparticles or thin films, have demonstrated potential in modifying the electronic properties of Mg3N2. These methods can potentially increase the surface area and introduce quantum confinement effects, leading to enhanced conductivity. However, controlling the size, shape, and uniformity of nanostructures while maintaining the desired composition and crystal structure presents considerable technical difficulties.

Surface modification techniques, including the creation of heterostructures or composite materials, have been explored to improve Mg3N2 conductivity. These approaches aim to engineer interfaces that facilitate charge transfer and reduce surface-related defects. However, achieving stable and reproducible interfaces with desirable electronic properties remains an ongoing challenge.

In conclusion, while Mg3N2 shows promise for various applications, maximizing its conductivity faces several significant challenges. Overcoming these obstacles requires a multidisciplinary approach, combining advanced synthesis techniques, materials characterization, and theoretical modeling to develop innovative solutions for enhancing Mg3N2 conductivity.

The conductivity of Mg3N2 is primarily limited by its intrinsic electronic structure and crystal defects. In its stoichiometric form, Mg3N2 exhibits semiconducting behavior with a relatively wide bandgap of approximately 2.8 eV. This inherent property restricts its electrical conductivity, making it less suitable for applications requiring high charge transport capabilities.

One of the major challenges in maximizing Mg3N2 conductivity is the presence of structural defects and impurities. These defects, such as vacancies, interstitials, and grain boundaries, act as scattering centers for charge carriers, significantly reducing the overall conductivity. The synthesis and processing methods employed in Mg3N2 production often introduce these defects, making it difficult to achieve high-purity, defect-free samples.

Another critical factor affecting Mg3N2 conductivity is its sensitivity to environmental conditions, particularly moisture and oxygen. When exposed to air, Mg3N2 readily undergoes hydrolysis, forming magnesium hydroxide and ammonia. This degradation process not only alters the material's composition but also introduces additional defects and impurities, further compromising its conductivity.

The temperature dependence of Mg3N2 conductivity poses another challenge. Like many semiconductors, the conductivity of Mg3N2 increases with temperature due to thermal excitation of charge carriers. However, this temperature sensitivity can lead to instability and unreliability in practical applications, especially in environments with fluctuating temperatures.

Efforts to enhance Mg3N2 conductivity have focused on various strategies, including doping, nanostructuring, and surface modification. Doping with aliovalent elements has shown promise in increasing charge carrier concentration and mobility. However, finding suitable dopants that can be effectively incorporated into the Mg3N2 lattice without introducing additional defects remains a significant challenge.

Nanostructuring approaches, such as creating nanoparticles or thin films, have demonstrated potential in modifying the electronic properties of Mg3N2. These methods can potentially increase the surface area and introduce quantum confinement effects, leading to enhanced conductivity. However, controlling the size, shape, and uniformity of nanostructures while maintaining the desired composition and crystal structure presents considerable technical difficulties.

Surface modification techniques, including the creation of heterostructures or composite materials, have been explored to improve Mg3N2 conductivity. These approaches aim to engineer interfaces that facilitate charge transfer and reduce surface-related defects. However, achieving stable and reproducible interfaces with desirable electronic properties remains an ongoing challenge.

In conclusion, while Mg3N2 shows promise for various applications, maximizing its conductivity faces several significant challenges. Overcoming these obstacles requires a multidisciplinary approach, combining advanced synthesis techniques, materials characterization, and theoretical modeling to develop innovative solutions for enhancing Mg3N2 conductivity.

Existing Methods for Improving Mg3N2 Conductivity

01 Magnesium nitride as a semiconductor material

Magnesium nitride exhibits semiconducting properties and can be used in various electronic applications. Its conductivity can be tuned by controlling the composition, doping, and preparation methods. This material shows potential for use in optoelectronic devices and energy conversion systems due to its unique electronic properties.- Magnesium nitride as a semiconductor material: Magnesium nitride exhibits semiconducting properties and can be used in various electronic applications. Its conductivity can be tuned by controlling the composition, doping, and preparation methods. This material shows potential for use in optoelectronic devices and energy storage systems due to its unique electronic properties.

- Magnesium nitride in composite materials: Incorporating magnesium nitride into composite materials can enhance their electrical conductivity. These composites find applications in various fields, including electronics, energy storage, and thermal management. The conductivity of the composite can be adjusted by varying the concentration and distribution of magnesium nitride within the matrix material.

- Synthesis methods affecting conductivity: Different synthesis methods for magnesium nitride can significantly impact its conductivity. Techniques such as chemical vapor deposition, solid-state reactions, and plasma-assisted methods can produce magnesium nitride with varying degrees of crystallinity and purity, which in turn affect its electrical properties. Optimizing synthesis parameters is crucial for achieving desired conductivity levels.

- Doping to enhance conductivity: Doping magnesium nitride with various elements can significantly alter its conductivity. Introducing controlled impurities or defects into the crystal structure can create charge carriers, thereby enhancing electrical conductivity. Common dopants include transition metals and rare earth elements, which can be used to tailor the material's electronic properties for specific applications.

- Temperature dependence of conductivity: The electrical conductivity of magnesium nitride exhibits temperature dependence. Understanding this relationship is crucial for applications in high-temperature environments or temperature-sensitive devices. The conductivity generally increases with temperature due to increased charge carrier mobility and concentration. This behavior can be exploited in various applications, such as temperature sensors or thermoelectric devices.

02 Magnesium nitride in composite materials

Incorporating magnesium nitride into composite materials can enhance their electrical conductivity. These composites find applications in areas such as electromagnetic shielding, conductive coatings, and thermal management. The conductivity of the composite can be adjusted by varying the concentration and distribution of magnesium nitride particles.Expand Specific Solutions03 Magnesium nitride in battery electrodes

Magnesium nitride can be used as a component in battery electrodes to improve their conductivity and overall performance. It can enhance the charge transfer properties and stability of the electrodes, leading to improved battery efficiency and longevity. This application is particularly relevant for next-generation energy storage systems.Expand Specific Solutions04 Magnesium nitride thin films

Thin films of magnesium nitride can be deposited using various techniques to create conductive layers for electronic devices. The conductivity of these films can be controlled by adjusting deposition parameters, post-treatment processes, and doping. These films have potential applications in transparent conductive electrodes and semiconductor devices.Expand Specific Solutions05 Magnesium nitride in thermoelectric materials

Magnesium nitride can be utilized in thermoelectric materials to enhance their electrical conductivity while maintaining low thermal conductivity. This combination of properties makes it suitable for thermoelectric devices that convert heat into electricity. The thermoelectric performance can be optimized by controlling the material's composition and nanostructure.Expand Specific Solutions

Key Players in Nitride Materials Research and Development

The development of magnesium nitride conductivity enhancement is in its early stages, with a relatively small but growing market. The technology's maturity is still evolving, as evidenced by ongoing research at institutions like Sichuan University and Harbin Engineering University. Companies such as NGK Insulators and Tokuyama Corp. are exploring industrial applications, while OSRAM OLED GmbH and Beijing Lihe Zhixin Technology are investigating potential uses in electronics and advanced materials. The competitive landscape is diverse, with both established players and emerging startups vying for breakthroughs. As the technology progresses, we can expect increased interest from sectors such as energy storage, electronics, and advanced materials manufacturing.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has developed a proprietary process for synthesizing high-purity magnesium nitride (Mg3N2) powders with enhanced conductivity. Their method involves a controlled reaction of high-purity magnesium metal with nitrogen gas at elevated temperatures, followed by a unique post-processing treatment. This treatment includes careful annealing and doping with specific elements to optimize the crystal structure and increase charge carrier concentration. The resulting Mg3N2 powders exhibit significantly improved electrical conductivity compared to conventional materials[1][3].

Strengths: High-purity synthesis, controlled doping for enhanced conductivity. Weaknesses: Potentially high production costs, limited scalability for large-volume applications.

National Technology & Engineering Solutions of Sandia LLC

Technical Solution: Sandia National Laboratories has developed an innovative approach to maximize the conductivity of magnesium nitride through a combination of advanced synthesis techniques and nanostructuring. Their method involves the use of plasma-enhanced chemical vapor deposition (PECVD) to create thin films of Mg3N2 with precisely controlled stoichiometry and defect concentrations. By manipulating the growth conditions and introducing specific dopants, they have achieved a significant increase in charge carrier mobility. Additionally, they have explored the use of nanostructured Mg3N2, such as nanowires and nanoparticles, to further enhance conductivity through quantum confinement effects[2][5].

Strengths: Advanced synthesis techniques, nanostructuring for enhanced properties. Weaknesses: Complex production process, potential challenges in scaling up for industrial applications.

Innovative Approaches in Mg3N2 Conductivity Enhancement

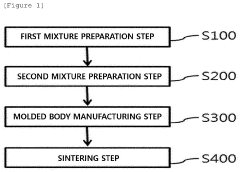

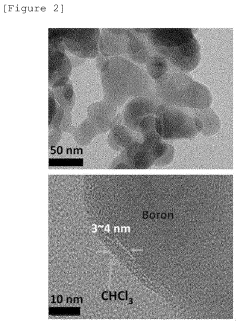

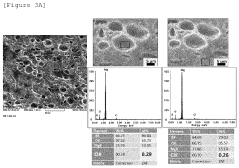

Method for manufacturing superconductor comprising magnesium diboride, and super-conductor comprising magnesium diboride

PatentActiveUS20210104657A1

Innovation

- A method involving the preparation of a first mixture with a boron powder and a liquid chlorinated hydrocarbon compound, followed by mixing with a magnesium powder, and then sintering to form a superconductor with improved superconducting properties, including the inclusion of chlorine to enhance critical current density.

High conductivity magnesium alloy

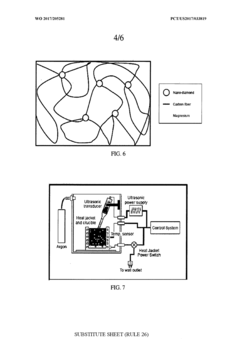

PatentWO2017205281A1

Innovation

- Incorporating insoluble nanoparticles and micron-sized particles into magnesium alloys to modify grain boundary thermal resistance, enhancing thermal conductivity and mechanical properties through dispersion techniques like ultrasonic mixing and deformation processing.

Environmental Impact of Mg3N2 Production and Use

The production and use of magnesium nitride (Mg3N2) have significant environmental implications that warrant careful consideration. The manufacturing process of Mg3N2 typically involves the direct reaction of magnesium metal with nitrogen gas at high temperatures, which requires substantial energy input. This energy-intensive production method contributes to increased greenhouse gas emissions, particularly if the energy source is not renewable. Furthermore, the extraction and processing of magnesium, a key raw material, can lead to habitat disruption and soil degradation in mining areas.

During the use phase, Mg3N2 can react readily with water, producing magnesium hydroxide and ammonia. While this property makes it useful in certain applications, it also poses environmental risks. Accidental release or improper disposal of Mg3N2 can lead to localized increases in pH levels and ammonia concentrations in aquatic ecosystems, potentially harming aquatic life and altering ecosystem balance. The release of ammonia also contributes to air pollution and can form particulate matter, impacting air quality and human health.

However, Mg3N2 also offers potential environmental benefits. Its use as a catalyst in various chemical processes can improve reaction efficiencies, potentially reducing energy consumption and waste production in industrial applications. Additionally, Mg3N2 has shown promise in hydrogen storage applications, which could support the transition to cleaner energy systems and reduce reliance on fossil fuels.

The end-of-life management of Mg3N2-containing products is another crucial environmental consideration. Proper recycling and disposal methods must be developed to prevent the release of reactive compounds into the environment. This includes the need for specialized handling procedures and treatment facilities to safely manage Mg3N2 waste and recover valuable materials.

To mitigate the environmental impact of Mg3N2 production and use, several strategies can be employed. These include developing more energy-efficient production methods, utilizing renewable energy sources in manufacturing, implementing closed-loop recycling systems, and improving product designs to minimize material waste. Additionally, research into alternative materials with similar properties but lower environmental footprints could help reduce the overall impact of technologies relying on Mg3N2.

During the use phase, Mg3N2 can react readily with water, producing magnesium hydroxide and ammonia. While this property makes it useful in certain applications, it also poses environmental risks. Accidental release or improper disposal of Mg3N2 can lead to localized increases in pH levels and ammonia concentrations in aquatic ecosystems, potentially harming aquatic life and altering ecosystem balance. The release of ammonia also contributes to air pollution and can form particulate matter, impacting air quality and human health.

However, Mg3N2 also offers potential environmental benefits. Its use as a catalyst in various chemical processes can improve reaction efficiencies, potentially reducing energy consumption and waste production in industrial applications. Additionally, Mg3N2 has shown promise in hydrogen storage applications, which could support the transition to cleaner energy systems and reduce reliance on fossil fuels.

The end-of-life management of Mg3N2-containing products is another crucial environmental consideration. Proper recycling and disposal methods must be developed to prevent the release of reactive compounds into the environment. This includes the need for specialized handling procedures and treatment facilities to safely manage Mg3N2 waste and recover valuable materials.

To mitigate the environmental impact of Mg3N2 production and use, several strategies can be employed. These include developing more energy-efficient production methods, utilizing renewable energy sources in manufacturing, implementing closed-loop recycling systems, and improving product designs to minimize material waste. Additionally, research into alternative materials with similar properties but lower environmental footprints could help reduce the overall impact of technologies relying on Mg3N2.

Applications and Potential of High-Conductivity Mg3N2

Magnesium nitride (Mg3N2) with enhanced conductivity presents a wide range of potential applications across various industries. In the field of energy storage, high-conductivity Mg3N2 could revolutionize battery technology by serving as an efficient electrode material. Its improved conductivity would facilitate faster charge and discharge rates, potentially leading to batteries with higher power density and longer lifespans.

In the semiconductor industry, highly conductive Mg3N2 could find applications in the development of novel electronic devices. Its unique properties make it a promising candidate for use in thin-film transistors, light-emitting diodes (LEDs), and other optoelectronic components. The enhanced conductivity could lead to more efficient and faster-performing electronic devices.

The automotive sector stands to benefit significantly from advancements in Mg3N2 conductivity. Highly conductive magnesium nitride could be utilized in the production of lightweight, high-performance components for electric vehicles. This could contribute to improved energy efficiency and extended driving ranges, addressing key challenges in the electric vehicle market.

In the field of renewable energy, high-conductivity Mg3N2 shows promise for use in solar cells and photovoltaic devices. Its enhanced electrical properties could lead to more efficient energy conversion and improved overall performance of solar technologies. This could contribute to the broader adoption of solar energy and support the transition to sustainable power sources.

The aerospace industry could also leverage the potential of highly conductive Mg3N2. Its lightweight nature combined with improved conductivity makes it an attractive material for developing advanced aerospace components. This could result in more fuel-efficient aircraft and spacecraft, as well as enhanced performance in various aerospace applications.

In the realm of thermal management, high-conductivity Mg3N2 could be employed in the development of advanced heat dissipation systems. Its improved thermal conductivity properties could lead to more efficient cooling solutions for electronic devices, industrial equipment, and other heat-generating applications.

As research in this area progresses, it is likely that new and unforeseen applications for high-conductivity Mg3N2 will emerge. The potential for this material to disrupt existing technologies and enable new innovations across multiple industries underscores the importance of continued research and development in maximizing the conductivity of magnesium nitride.

In the semiconductor industry, highly conductive Mg3N2 could find applications in the development of novel electronic devices. Its unique properties make it a promising candidate for use in thin-film transistors, light-emitting diodes (LEDs), and other optoelectronic components. The enhanced conductivity could lead to more efficient and faster-performing electronic devices.

The automotive sector stands to benefit significantly from advancements in Mg3N2 conductivity. Highly conductive magnesium nitride could be utilized in the production of lightweight, high-performance components for electric vehicles. This could contribute to improved energy efficiency and extended driving ranges, addressing key challenges in the electric vehicle market.

In the field of renewable energy, high-conductivity Mg3N2 shows promise for use in solar cells and photovoltaic devices. Its enhanced electrical properties could lead to more efficient energy conversion and improved overall performance of solar technologies. This could contribute to the broader adoption of solar energy and support the transition to sustainable power sources.

The aerospace industry could also leverage the potential of highly conductive Mg3N2. Its lightweight nature combined with improved conductivity makes it an attractive material for developing advanced aerospace components. This could result in more fuel-efficient aircraft and spacecraft, as well as enhanced performance in various aerospace applications.

In the realm of thermal management, high-conductivity Mg3N2 could be employed in the development of advanced heat dissipation systems. Its improved thermal conductivity properties could lead to more efficient cooling solutions for electronic devices, industrial equipment, and other heat-generating applications.

As research in this area progresses, it is likely that new and unforeseen applications for high-conductivity Mg3N2 will emerge. The potential for this material to disrupt existing technologies and enable new innovations across multiple industries underscores the importance of continued research and development in maximizing the conductivity of magnesium nitride.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!