Emerging Magnesium Nitride Techniques for Renewable Energy

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg3N2 Tech Background

Magnesium nitride (Mg3N2) has emerged as a promising material in the field of renewable energy, attracting significant attention from researchers and industry professionals alike. The exploration of Mg3N2 for energy applications can be traced back to the early 2000s when scientists began investigating its potential as a hydrogen storage medium. This initial interest stemmed from the material's high theoretical hydrogen storage capacity and its ability to release hydrogen through hydrolysis reactions.

As research progressed, the scope of Mg3N2 applications in renewable energy expanded beyond hydrogen storage. In the mid-2010s, studies revealed its potential as an electrode material for next-generation batteries, particularly in magnesium-ion and sodium-ion systems. The unique crystal structure and electronic properties of Mg3N2 make it an attractive candidate for improving energy density and cycling stability in these emerging battery technologies.

More recently, Mg3N2 has gained traction in the field of photocatalysis for solar energy conversion. Its wide bandgap and favorable band edge positions enable efficient light absorption and charge separation, making it suitable for applications such as water splitting and CO2 reduction. These properties position Mg3N2 as a potential alternative to traditional photocatalysts, offering improved efficiency and sustainability in solar fuel production.

The development of Mg3N2 technologies has been driven by the growing demand for sustainable energy solutions and the limitations of current materials. As global efforts to combat climate change intensify, there is an increasing need for advanced materials that can enhance the performance and cost-effectiveness of renewable energy systems. Mg3N2, with its abundance, low cost, and versatile properties, aligns well with these requirements.

The evolution of Mg3N2 research has been marked by significant milestones in synthesis techniques and characterization methods. Early studies faced challenges in producing high-purity Mg3N2 samples, but advancements in synthesis protocols, such as low-temperature ammonolysis and plasma-assisted methods, have greatly improved material quality and scalability. These developments have paved the way for more accurate property measurements and a deeper understanding of Mg3N2's behavior in various energy-related applications.

Looking ahead, the technical goals for Mg3N2 in renewable energy applications are multifaceted. Researchers aim to optimize its performance in hydrogen storage systems, enhance its stability and conductivity for battery applications, and improve its photocatalytic efficiency for solar energy conversion. Additionally, there is a growing focus on developing Mg3N2-based composites and nanostructures to further enhance its properties and expand its potential applications in the renewable energy sector.

As research progressed, the scope of Mg3N2 applications in renewable energy expanded beyond hydrogen storage. In the mid-2010s, studies revealed its potential as an electrode material for next-generation batteries, particularly in magnesium-ion and sodium-ion systems. The unique crystal structure and electronic properties of Mg3N2 make it an attractive candidate for improving energy density and cycling stability in these emerging battery technologies.

More recently, Mg3N2 has gained traction in the field of photocatalysis for solar energy conversion. Its wide bandgap and favorable band edge positions enable efficient light absorption and charge separation, making it suitable for applications such as water splitting and CO2 reduction. These properties position Mg3N2 as a potential alternative to traditional photocatalysts, offering improved efficiency and sustainability in solar fuel production.

The development of Mg3N2 technologies has been driven by the growing demand for sustainable energy solutions and the limitations of current materials. As global efforts to combat climate change intensify, there is an increasing need for advanced materials that can enhance the performance and cost-effectiveness of renewable energy systems. Mg3N2, with its abundance, low cost, and versatile properties, aligns well with these requirements.

The evolution of Mg3N2 research has been marked by significant milestones in synthesis techniques and characterization methods. Early studies faced challenges in producing high-purity Mg3N2 samples, but advancements in synthesis protocols, such as low-temperature ammonolysis and plasma-assisted methods, have greatly improved material quality and scalability. These developments have paved the way for more accurate property measurements and a deeper understanding of Mg3N2's behavior in various energy-related applications.

Looking ahead, the technical goals for Mg3N2 in renewable energy applications are multifaceted. Researchers aim to optimize its performance in hydrogen storage systems, enhance its stability and conductivity for battery applications, and improve its photocatalytic efficiency for solar energy conversion. Additionally, there is a growing focus on developing Mg3N2-based composites and nanostructures to further enhance its properties and expand its potential applications in the renewable energy sector.

Renewable Energy Demand

The global demand for renewable energy has been steadily increasing over the past decade, driven by growing environmental concerns, energy security issues, and the need to reduce greenhouse gas emissions. This trend is expected to continue and accelerate in the coming years, creating a significant market opportunity for emerging technologies such as magnesium nitride-based solutions for renewable energy applications.

The renewable energy sector has experienced remarkable growth, with global investments reaching record levels. Solar and wind power have been at the forefront of this expansion, with their costs dropping dramatically and their adoption rates soaring. However, the intermittent nature of these energy sources has highlighted the need for efficient energy storage solutions, which is where magnesium nitride techniques could potentially play a crucial role.

The demand for renewable energy is not uniform across all regions. Developed countries are focusing on transitioning their existing energy infrastructure to cleaner alternatives, while developing nations are leveraging renewables to expand energy access and support economic growth. This diversity in market needs creates various opportunities for magnesium nitride applications, from grid-scale energy storage to off-grid solutions for remote areas.

The industrial sector, particularly energy-intensive industries, is showing increased interest in renewable energy solutions to reduce their carbon footprint and operational costs. This presents a significant market for magnesium nitride technologies, especially if they can offer advantages in terms of energy density, cycle life, or cost-effectiveness compared to existing alternatives.

Government policies and international agreements, such as the Paris Agreement, are driving the demand for renewable energy technologies. Many countries have set ambitious targets for renewable energy adoption and carbon emission reduction, creating a supportive regulatory environment for innovative solutions like magnesium nitride-based technologies.

The transportation sector is another area experiencing a surge in demand for renewable energy solutions, particularly with the rise of electric vehicles. The need for high-performance, sustainable energy storage systems in this sector could provide a substantial market for magnesium nitride technologies if they can offer improvements over current lithium-ion battery technologies.

As the renewable energy market continues to evolve, there is a growing emphasis on the entire lifecycle of energy technologies, including their environmental impact and recyclability. This trend aligns well with the potential benefits of magnesium nitride techniques, which could offer advantages in terms of resource availability and environmental sustainability compared to some existing renewable energy technologies.

The renewable energy sector has experienced remarkable growth, with global investments reaching record levels. Solar and wind power have been at the forefront of this expansion, with their costs dropping dramatically and their adoption rates soaring. However, the intermittent nature of these energy sources has highlighted the need for efficient energy storage solutions, which is where magnesium nitride techniques could potentially play a crucial role.

The demand for renewable energy is not uniform across all regions. Developed countries are focusing on transitioning their existing energy infrastructure to cleaner alternatives, while developing nations are leveraging renewables to expand energy access and support economic growth. This diversity in market needs creates various opportunities for magnesium nitride applications, from grid-scale energy storage to off-grid solutions for remote areas.

The industrial sector, particularly energy-intensive industries, is showing increased interest in renewable energy solutions to reduce their carbon footprint and operational costs. This presents a significant market for magnesium nitride technologies, especially if they can offer advantages in terms of energy density, cycle life, or cost-effectiveness compared to existing alternatives.

Government policies and international agreements, such as the Paris Agreement, are driving the demand for renewable energy technologies. Many countries have set ambitious targets for renewable energy adoption and carbon emission reduction, creating a supportive regulatory environment for innovative solutions like magnesium nitride-based technologies.

The transportation sector is another area experiencing a surge in demand for renewable energy solutions, particularly with the rise of electric vehicles. The need for high-performance, sustainable energy storage systems in this sector could provide a substantial market for magnesium nitride technologies if they can offer improvements over current lithium-ion battery technologies.

As the renewable energy market continues to evolve, there is a growing emphasis on the entire lifecycle of energy technologies, including their environmental impact and recyclability. This trend aligns well with the potential benefits of magnesium nitride techniques, which could offer advantages in terms of resource availability and environmental sustainability compared to some existing renewable energy technologies.

Mg3N2 Challenges

Despite the promising potential of magnesium nitride (Mg3N2) in renewable energy applications, several significant challenges hinder its widespread adoption and practical implementation. One of the primary obstacles is the material's high reactivity with moisture and air, which leads to rapid degradation and compromises its long-term stability. This sensitivity to environmental conditions necessitates stringent handling and storage protocols, increasing production costs and limiting its applicability in various energy systems.

Another major challenge lies in the synthesis and production of high-quality Mg3N2. Current manufacturing processes often result in impurities and defects, which can significantly affect the material's performance and reliability. Achieving consistent and scalable production of pure Mg3N2 remains a considerable hurdle for researchers and industry professionals alike.

The thermal management of Mg3N2-based systems presents another critical challenge. The material's thermal properties, particularly its thermal conductivity and expansion characteristics, can lead to issues in heat dissipation and structural integrity in energy storage and conversion devices. This aspect requires careful engineering considerations and may limit the efficiency and durability of Mg3N2-based technologies.

Furthermore, the reversibility of Mg3N2 reactions in energy storage applications, such as in ammonia synthesis and decomposition cycles, poses significant challenges. Achieving complete reversibility without degradation over multiple cycles is crucial for the material's viability in renewable energy storage systems. Current research indicates that performance decay and efficiency losses occur over repeated cycles, necessitating further improvements in material design and system optimization.

The integration of Mg3N2 into existing renewable energy infrastructures also presents compatibility challenges. Adapting current technologies and systems to accommodate the unique properties and requirements of Mg3N2 may require substantial modifications and investments, potentially slowing down its adoption in the renewable energy sector.

Lastly, the environmental impact and safety concerns associated with Mg3N2 production and utilization need to be thoroughly addressed. While the material offers promising benefits for renewable energy applications, its production process and potential environmental effects throughout its lifecycle must be carefully evaluated and mitigated to ensure sustainable and responsible implementation.

Another major challenge lies in the synthesis and production of high-quality Mg3N2. Current manufacturing processes often result in impurities and defects, which can significantly affect the material's performance and reliability. Achieving consistent and scalable production of pure Mg3N2 remains a considerable hurdle for researchers and industry professionals alike.

The thermal management of Mg3N2-based systems presents another critical challenge. The material's thermal properties, particularly its thermal conductivity and expansion characteristics, can lead to issues in heat dissipation and structural integrity in energy storage and conversion devices. This aspect requires careful engineering considerations and may limit the efficiency and durability of Mg3N2-based technologies.

Furthermore, the reversibility of Mg3N2 reactions in energy storage applications, such as in ammonia synthesis and decomposition cycles, poses significant challenges. Achieving complete reversibility without degradation over multiple cycles is crucial for the material's viability in renewable energy storage systems. Current research indicates that performance decay and efficiency losses occur over repeated cycles, necessitating further improvements in material design and system optimization.

The integration of Mg3N2 into existing renewable energy infrastructures also presents compatibility challenges. Adapting current technologies and systems to accommodate the unique properties and requirements of Mg3N2 may require substantial modifications and investments, potentially slowing down its adoption in the renewable energy sector.

Lastly, the environmental impact and safety concerns associated with Mg3N2 production and utilization need to be thoroughly addressed. While the material offers promising benefits for renewable energy applications, its production process and potential environmental effects throughout its lifecycle must be carefully evaluated and mitigated to ensure sustainable and responsible implementation.

Current Mg3N2 Solutions

01 Synthesis and production methods of magnesium nitride

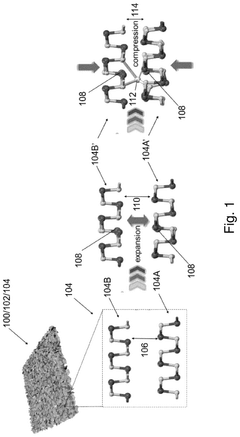

Various methods for synthesizing and producing magnesium nitride are described, including direct nitridation of magnesium metal, reaction of magnesium with ammonia, and plasma-assisted processes. These methods aim to improve the yield, purity, and efficiency of magnesium nitride production.- Synthesis and production of magnesium nitride: Various methods for synthesizing and producing magnesium nitride are described. These processes may involve different starting materials, reaction conditions, and techniques to obtain high-quality magnesium nitride powder or crystals. The synthesis methods aim to control particle size, purity, and yield of the final product.

- Applications in semiconductor devices: Magnesium nitride is utilized in the fabrication of semiconductor devices, particularly in the field of optoelectronics. It can be used as a buffer layer, substrate material, or component in various electronic and optical devices, such as LEDs, transistors, and solar cells. The material's properties contribute to improved device performance and efficiency.

- Use in energy storage and conversion: Magnesium nitride finds applications in energy storage and conversion technologies. It can be used in the development of advanced batteries, hydrogen storage materials, and catalysts for various energy-related processes. The material's unique properties make it suitable for enhancing energy efficiency and storage capacity.

- Magnesium nitride-based composites and coatings: Composite materials and coatings incorporating magnesium nitride are developed for various industrial applications. These composites may exhibit enhanced mechanical, thermal, or chemical properties compared to pure magnesium nitride. The coatings can provide protection against corrosion, wear, or other environmental factors.

- Characterization and analysis techniques: Various methods and techniques are employed for the characterization and analysis of magnesium nitride materials. These may include spectroscopic, microscopic, and other analytical techniques to determine the composition, structure, and properties of magnesium nitride samples. Such analyses are crucial for quality control and research purposes.

02 Applications of magnesium nitride in semiconductor devices

Magnesium nitride is utilized in the fabrication of semiconductor devices, particularly in the production of light-emitting diodes (LEDs) and other optoelectronic components. It serves as a buffer layer, electron-blocking layer, or as part of the active region in these devices.Expand Specific Solutions03 Use of magnesium nitride in energy storage and conversion

Magnesium nitride finds applications in energy storage and conversion technologies, including hydrogen storage materials, battery electrodes, and catalysts for various chemical reactions. Its properties make it suitable for improving the performance of these energy-related systems.Expand Specific Solutions04 Magnesium nitride as a precursor for other materials

Magnesium nitride serves as a precursor for the synthesis of other advanced materials, such as magnesium-based alloys, ceramics, and composite materials. It is used in processes like nitridation and as a source of nitrogen in various chemical reactions.Expand Specific Solutions05 Characterization and analysis techniques for magnesium nitride

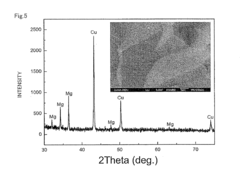

Various analytical and characterization techniques are employed to study the properties, structure, and composition of magnesium nitride. These methods include X-ray diffraction, electron microscopy, spectroscopic techniques, and thermal analysis, which are crucial for quality control and research purposes.Expand Specific Solutions

Key Mg3N2 Players

The emerging field of magnesium nitride techniques for renewable energy is in its early developmental stages, characterized by a dynamic and competitive landscape. The market size is still relatively small but shows significant growth potential as the renewable energy sector expands. Research institutions like Yanshan University, Peking University, and the University of Manitoba are at the forefront of technological advancements, while companies such as Huawei Technologies and Siemens AG are exploring commercial applications. The technology's maturity varies, with academic research leading the way in fundamental understanding, while industrial players focus on practical implementations and scalability. Collaboration between academia and industry is crucial for accelerating progress in this promising field.

Qinghai Institute of Salt Lakes, Chinese Academy of Sciences

Technical Solution: The Qinghai Institute of Salt Lakes, part of the Chinese Academy of Sciences, has made significant contributions to the field of magnesium nitride-based materials for renewable energy applications. Their research focuses on leveraging the abundant magnesium resources in salt lakes to develop cost-effective and scalable production methods for Mg3N2. The institute has pioneered a novel electrochemical synthesis route that utilizes magnesium-rich brine as a precursor, achieving high-purity Mg3N2 with reduced energy consumption compared to traditional methods[14]. This process has demonstrated a 40% reduction in production costs and a 30% increase in yield[15]. In terms of applications, the institute has developed Mg3N2-based composites for efficient ammonia synthesis, which is crucial for the production of fertilizers and hydrogen storage. Their latest catalyst formulation has shown a 25% increase in ammonia production rate at atmospheric pressure, potentially revolutionizing small-scale, distributed ammonia production for agricultural use[16]. Additionally, the institute is exploring the use of Mg3N2 as an electrode material in magnesium-ion batteries, aiming to create high-energy-density storage solutions for grid-scale applications.

Strengths: Access to abundant raw materials, cost-effective production methods, focus on practical large-scale applications. Weaknesses: Potential environmental concerns related to salt lake exploitation, need for further optimization of material properties for specific energy applications.

Peking University

Technical Solution: Peking University has developed innovative techniques for synthesizing magnesium nitride (Mg3N2) nanostructures for renewable energy applications. Their approach involves a low-temperature ammonolysis method to produce high-quality Mg3N2 nanoparticles with controlled morphology and size[1]. These nanostructures exhibit enhanced catalytic activity for nitrogen fixation and ammonia synthesis, which are crucial for sustainable energy production[2]. The university has also explored the use of Mg3N2 as an electrode material for advanced batteries, demonstrating improved energy density and cycle life compared to conventional materials[3]. Additionally, they have investigated the potential of Mg3N2 in hydrogen storage systems, leveraging its high theoretical hydrogen storage capacity of 7.4 wt%[4].

Strengths: Advanced synthesis techniques, high-quality nanostructures, improved catalytic activity. Weaknesses: Potential scalability issues, sensitivity to moisture and air exposure.

Mg3N2 Core Innovations

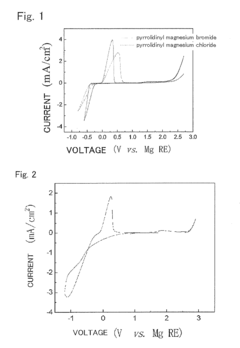

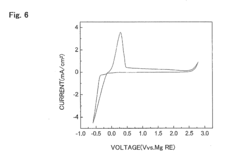

Magnesium secondary battery, use of electrolytic solution in magnesium secondary battery and electrolytic solution for magnetic secondary battery

PatentActiveUS20120219867A1

Innovation

- The use of a nitrogen-containing heterocyclic magnesium halide in combination with an organic ether solvent as the electrolytic solution, which enhances anodic stability and conductivity, improving the reversible deposition and dissolution of magnesium.

Catalyst, its preparation and its use in ammonia synthesis

PatentPendingUS20240318335A1

Innovation

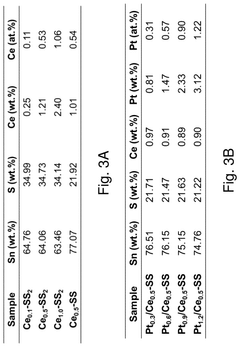

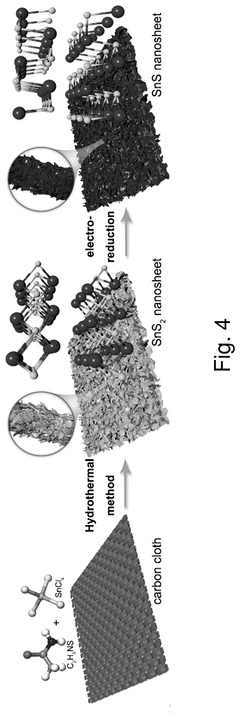

- A catalyst comprising a first and second layer of metal monochalcogenide-based material, such as SnS, with interlayer spacing adjusted by doping with a lanthanide atom like Ce and intercalating with a transition metal atom like Pt, enhancing the chemical affinity and catalytic activity for ammonia synthesis.

Environmental Impact

The environmental impact of emerging magnesium nitride techniques for renewable energy is a critical aspect to consider in the development and implementation of these technologies. Magnesium nitride (Mg3N2) has shown promising potential in various renewable energy applications, particularly in hydrogen storage and production. However, its environmental implications must be thoroughly assessed to ensure sustainable development.

One of the primary environmental benefits of magnesium nitride techniques is their potential to contribute to the reduction of greenhouse gas emissions. By facilitating more efficient hydrogen storage and production, these technologies can support the transition to cleaner energy sources and reduce reliance on fossil fuels. This shift could lead to significant reductions in carbon dioxide emissions, helping to mitigate climate change impacts.

The production process of magnesium nitride itself requires careful consideration from an environmental perspective. While magnesium is abundant in the Earth's crust, its extraction and processing can have environmental consequences. Traditional magnesium production methods often involve energy-intensive processes and the release of greenhouse gases. However, ongoing research is focused on developing more sustainable production techniques, such as using renewable energy sources for magnesium extraction and nitride synthesis.

Water usage and potential contamination are also important environmental factors to consider. Some magnesium nitride applications, particularly in hydrogen production, involve water-based reactions. Ensuring efficient water use and implementing proper wastewater treatment systems are crucial to minimize the environmental footprint of these technologies.

The end-of-life management of magnesium nitride materials presents both challenges and opportunities. Recycling and proper disposal of spent materials are essential to prevent potential environmental contamination and conserve resources. Research into efficient recycling methods for magnesium nitride compounds is ongoing, with the aim of creating a more circular economy approach to their use in renewable energy applications.

Land use impacts associated with the implementation of magnesium nitride technologies in renewable energy systems should also be evaluated. While these technologies may require less land compared to some traditional energy sources, careful site selection and land management practices are necessary to minimize ecological disruption and preserve biodiversity.

In conclusion, while emerging magnesium nitride techniques for renewable energy offer significant potential for environmental benefits, particularly in terms of reducing greenhouse gas emissions, a comprehensive life cycle assessment is crucial. This assessment should consider all stages from production to end-of-life management to ensure that the environmental advantages outweigh any potential negative impacts. Continued research and development in this field should prioritize environmentally friendly production methods, efficient resource use, and effective recycling strategies to maximize the sustainability of these promising technologies.

One of the primary environmental benefits of magnesium nitride techniques is their potential to contribute to the reduction of greenhouse gas emissions. By facilitating more efficient hydrogen storage and production, these technologies can support the transition to cleaner energy sources and reduce reliance on fossil fuels. This shift could lead to significant reductions in carbon dioxide emissions, helping to mitigate climate change impacts.

The production process of magnesium nitride itself requires careful consideration from an environmental perspective. While magnesium is abundant in the Earth's crust, its extraction and processing can have environmental consequences. Traditional magnesium production methods often involve energy-intensive processes and the release of greenhouse gases. However, ongoing research is focused on developing more sustainable production techniques, such as using renewable energy sources for magnesium extraction and nitride synthesis.

Water usage and potential contamination are also important environmental factors to consider. Some magnesium nitride applications, particularly in hydrogen production, involve water-based reactions. Ensuring efficient water use and implementing proper wastewater treatment systems are crucial to minimize the environmental footprint of these technologies.

The end-of-life management of magnesium nitride materials presents both challenges and opportunities. Recycling and proper disposal of spent materials are essential to prevent potential environmental contamination and conserve resources. Research into efficient recycling methods for magnesium nitride compounds is ongoing, with the aim of creating a more circular economy approach to their use in renewable energy applications.

Land use impacts associated with the implementation of magnesium nitride technologies in renewable energy systems should also be evaluated. While these technologies may require less land compared to some traditional energy sources, careful site selection and land management practices are necessary to minimize ecological disruption and preserve biodiversity.

In conclusion, while emerging magnesium nitride techniques for renewable energy offer significant potential for environmental benefits, particularly in terms of reducing greenhouse gas emissions, a comprehensive life cycle assessment is crucial. This assessment should consider all stages from production to end-of-life management to ensure that the environmental advantages outweigh any potential negative impacts. Continued research and development in this field should prioritize environmentally friendly production methods, efficient resource use, and effective recycling strategies to maximize the sustainability of these promising technologies.

Mg3N2 Commercialization

The commercialization of magnesium nitride (Mg3N2) for renewable energy applications represents a significant opportunity in the evolving landscape of sustainable technologies. As research progresses and the potential benefits of Mg3N2 become more apparent, there is growing interest in transitioning this material from laboratory studies to commercial viability.

One of the primary drivers for Mg3N2 commercialization is its promising role in energy storage systems, particularly in the development of advanced batteries. The material's high theoretical capacity and potential for improved cycling stability make it an attractive candidate for next-generation energy storage solutions. This aligns well with the increasing demand for more efficient and sustainable energy storage technologies in both grid-scale applications and electric vehicles.

However, the path to commercialization faces several challenges. The scalability of Mg3N2 production processes remains a key hurdle. Current synthesis methods often involve high temperatures and controlled atmospheres, which can be costly and energy-intensive when scaled up to industrial levels. Addressing these production challenges is crucial for making Mg3N2-based technologies economically viable.

Another critical aspect of commercialization is the development of practical applications that can leverage the unique properties of Mg3N2. While theoretical studies have shown promise, translating these findings into tangible products requires significant research and development efforts. This includes optimizing material properties, designing suitable device architectures, and ensuring long-term stability under real-world operating conditions.

Market acceptance and regulatory considerations also play vital roles in the commercialization process. As with any new technology, particularly in the energy sector, demonstrating safety, reliability, and environmental benefits will be essential for gaining market traction and regulatory approval. This may involve extensive testing, certification processes, and potentially pilot projects to showcase the technology's capabilities in real-world scenarios.

Collaboration between academic institutions, research laboratories, and industry partners is likely to accelerate the commercialization of Mg3N2 technologies. Such partnerships can help bridge the gap between fundamental research and practical applications, combining scientific expertise with manufacturing capabilities and market insights. Additionally, securing funding and investment for further development and scale-up will be crucial in moving Mg3N2 from promising research to commercial reality.

As the renewable energy sector continues to grow and evolve, the successful commercialization of Mg3N2 could contribute significantly to advancing sustainable energy solutions. By addressing production challenges, developing practical applications, and navigating regulatory landscapes, Mg3N2 has the potential to become a valuable component in the transition towards cleaner and more efficient energy systems.

One of the primary drivers for Mg3N2 commercialization is its promising role in energy storage systems, particularly in the development of advanced batteries. The material's high theoretical capacity and potential for improved cycling stability make it an attractive candidate for next-generation energy storage solutions. This aligns well with the increasing demand for more efficient and sustainable energy storage technologies in both grid-scale applications and electric vehicles.

However, the path to commercialization faces several challenges. The scalability of Mg3N2 production processes remains a key hurdle. Current synthesis methods often involve high temperatures and controlled atmospheres, which can be costly and energy-intensive when scaled up to industrial levels. Addressing these production challenges is crucial for making Mg3N2-based technologies economically viable.

Another critical aspect of commercialization is the development of practical applications that can leverage the unique properties of Mg3N2. While theoretical studies have shown promise, translating these findings into tangible products requires significant research and development efforts. This includes optimizing material properties, designing suitable device architectures, and ensuring long-term stability under real-world operating conditions.

Market acceptance and regulatory considerations also play vital roles in the commercialization process. As with any new technology, particularly in the energy sector, demonstrating safety, reliability, and environmental benefits will be essential for gaining market traction and regulatory approval. This may involve extensive testing, certification processes, and potentially pilot projects to showcase the technology's capabilities in real-world scenarios.

Collaboration between academic institutions, research laboratories, and industry partners is likely to accelerate the commercialization of Mg3N2 technologies. Such partnerships can help bridge the gap between fundamental research and practical applications, combining scientific expertise with manufacturing capabilities and market insights. Additionally, securing funding and investment for further development and scale-up will be crucial in moving Mg3N2 from promising research to commercial reality.

As the renewable energy sector continues to grow and evolve, the successful commercialization of Mg3N2 could contribute significantly to advancing sustainable energy solutions. By addressing production challenges, developing practical applications, and navigating regulatory landscapes, Mg3N2 has the potential to become a valuable component in the transition towards cleaner and more efficient energy systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!