Magnesium Nitride: Reinventing Applications in Polymer Science

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg3N2 in Polymers: Background and Objectives

Magnesium nitride (Mg3N2) has emerged as a promising material in the field of polymer science, offering unique properties that could revolutionize various applications. The journey of Mg3N2 in polymers began with the recognition of its potential as a functional additive, capable of enhancing the performance and characteristics of polymer-based materials.

The evolution of Mg3N2 in polymer science has been driven by the increasing demand for advanced materials with improved mechanical, thermal, and chemical properties. As industries seek more sustainable and efficient solutions, the integration of Mg3N2 into polymer matrices has gained significant attention from researchers and manufacturers alike.

The primary objective of incorporating Mg3N2 into polymers is to develop novel composite materials with enhanced functionalities. These functionalities include improved flame retardancy, increased thermal stability, enhanced mechanical strength, and superior barrier properties. By leveraging the unique chemical and physical characteristics of Mg3N2, researchers aim to create polymer composites that outperform traditional materials in various applications.

One of the key drivers behind the exploration of Mg3N2 in polymers is the growing need for environmentally friendly flame retardants. As regulatory bodies impose stricter guidelines on the use of halogenated flame retardants, Mg3N2 has emerged as a potential alternative, offering effective fire protection without the associated environmental concerns.

The integration of Mg3N2 into polymers also aligns with the broader trend of developing multifunctional materials. By incorporating Mg3N2, researchers aim to create polymer composites that can simultaneously address multiple performance requirements, such as improved mechanical properties and enhanced thermal stability, in a single material system.

The technological evolution in this field has been marked by advancements in synthesis methods, dispersion techniques, and surface modification strategies for Mg3N2. These developments have enabled better compatibility between the inorganic Mg3N2 particles and organic polymer matrices, leading to more homogeneous and effective composite materials.

As research in this area progresses, the ultimate goal is to establish Mg3N2 as a versatile and indispensable component in polymer science. This includes exploring its potential in various polymer types, from thermoplastics to thermosets, and investigating its applicability across diverse industries, including automotive, aerospace, construction, and electronics.

The journey of Mg3N2 in polymer science represents a convergence of materials science, chemistry, and engineering, aiming to push the boundaries of what is possible in polymer-based materials. As researchers continue to unravel the full potential of this compound, the future holds promising prospects for innovative applications and groundbreaking advancements in polymer technology.

The evolution of Mg3N2 in polymer science has been driven by the increasing demand for advanced materials with improved mechanical, thermal, and chemical properties. As industries seek more sustainable and efficient solutions, the integration of Mg3N2 into polymer matrices has gained significant attention from researchers and manufacturers alike.

The primary objective of incorporating Mg3N2 into polymers is to develop novel composite materials with enhanced functionalities. These functionalities include improved flame retardancy, increased thermal stability, enhanced mechanical strength, and superior barrier properties. By leveraging the unique chemical and physical characteristics of Mg3N2, researchers aim to create polymer composites that outperform traditional materials in various applications.

One of the key drivers behind the exploration of Mg3N2 in polymers is the growing need for environmentally friendly flame retardants. As regulatory bodies impose stricter guidelines on the use of halogenated flame retardants, Mg3N2 has emerged as a potential alternative, offering effective fire protection without the associated environmental concerns.

The integration of Mg3N2 into polymers also aligns with the broader trend of developing multifunctional materials. By incorporating Mg3N2, researchers aim to create polymer composites that can simultaneously address multiple performance requirements, such as improved mechanical properties and enhanced thermal stability, in a single material system.

The technological evolution in this field has been marked by advancements in synthesis methods, dispersion techniques, and surface modification strategies for Mg3N2. These developments have enabled better compatibility between the inorganic Mg3N2 particles and organic polymer matrices, leading to more homogeneous and effective composite materials.

As research in this area progresses, the ultimate goal is to establish Mg3N2 as a versatile and indispensable component in polymer science. This includes exploring its potential in various polymer types, from thermoplastics to thermosets, and investigating its applicability across diverse industries, including automotive, aerospace, construction, and electronics.

The journey of Mg3N2 in polymer science represents a convergence of materials science, chemistry, and engineering, aiming to push the boundaries of what is possible in polymer-based materials. As researchers continue to unravel the full potential of this compound, the future holds promising prospects for innovative applications and groundbreaking advancements in polymer technology.

Market Demand Analysis for Mg3N2-Enhanced Polymers

The market demand for Mg3N2-enhanced polymers is experiencing a significant upward trend, driven by the unique properties and potential applications of magnesium nitride in polymer science. This emerging field has attracted attention from various industries, including automotive, aerospace, electronics, and consumer goods, due to the promising characteristics of Mg3N2-enhanced polymers.

In the automotive sector, there is a growing demand for lightweight materials that can improve fuel efficiency and reduce emissions. Mg3N2-enhanced polymers offer potential solutions by providing enhanced strength-to-weight ratios and improved thermal stability. This has led to increased interest from automotive manufacturers looking to incorporate these advanced materials into vehicle components.

The aerospace industry is another key market for Mg3N2-enhanced polymers. With the constant push for lighter and more durable materials in aircraft construction, these polymers present an attractive option. The potential for improved fire resistance and reduced weight makes them particularly appealing for interior components and structural elements of aircraft.

In the electronics sector, the demand for Mg3N2-enhanced polymers is driven by the need for materials with superior thermal management properties. As electronic devices become more compact and powerful, effective heat dissipation becomes crucial. Mg3N2-enhanced polymers show promise in addressing this challenge, leading to increased interest from manufacturers of smartphones, laptops, and other electronic devices.

The consumer goods industry is also exploring the potential of Mg3N2-enhanced polymers. Applications in sporting goods, such as high-performance equipment and protective gear, are being investigated due to the materials' potential for improved strength and impact resistance. Additionally, the packaging industry is showing interest in these polymers for their potential to create more durable and environmentally friendly packaging solutions.

Environmental concerns and sustainability initiatives are further driving the market demand for Mg3N2-enhanced polymers. As industries seek alternatives to traditional plastics and materials with high carbon footprints, these advanced polymers offer potential solutions that align with eco-friendly goals. This has led to increased research and development efforts to explore their applications in biodegradable and recyclable products.

The market for Mg3N2-enhanced polymers is still in its early stages, with significant growth potential as research progresses and new applications are discovered. Industry analysts predict a steady increase in demand over the coming years, particularly in regions with strong manufacturing and technology sectors. However, the market's growth will depend on factors such as production scalability, cost-effectiveness, and the ability to meet specific industry requirements.

In the automotive sector, there is a growing demand for lightweight materials that can improve fuel efficiency and reduce emissions. Mg3N2-enhanced polymers offer potential solutions by providing enhanced strength-to-weight ratios and improved thermal stability. This has led to increased interest from automotive manufacturers looking to incorporate these advanced materials into vehicle components.

The aerospace industry is another key market for Mg3N2-enhanced polymers. With the constant push for lighter and more durable materials in aircraft construction, these polymers present an attractive option. The potential for improved fire resistance and reduced weight makes them particularly appealing for interior components and structural elements of aircraft.

In the electronics sector, the demand for Mg3N2-enhanced polymers is driven by the need for materials with superior thermal management properties. As electronic devices become more compact and powerful, effective heat dissipation becomes crucial. Mg3N2-enhanced polymers show promise in addressing this challenge, leading to increased interest from manufacturers of smartphones, laptops, and other electronic devices.

The consumer goods industry is also exploring the potential of Mg3N2-enhanced polymers. Applications in sporting goods, such as high-performance equipment and protective gear, are being investigated due to the materials' potential for improved strength and impact resistance. Additionally, the packaging industry is showing interest in these polymers for their potential to create more durable and environmentally friendly packaging solutions.

Environmental concerns and sustainability initiatives are further driving the market demand for Mg3N2-enhanced polymers. As industries seek alternatives to traditional plastics and materials with high carbon footprints, these advanced polymers offer potential solutions that align with eco-friendly goals. This has led to increased research and development efforts to explore their applications in biodegradable and recyclable products.

The market for Mg3N2-enhanced polymers is still in its early stages, with significant growth potential as research progresses and new applications are discovered. Industry analysts predict a steady increase in demand over the coming years, particularly in regions with strong manufacturing and technology sectors. However, the market's growth will depend on factors such as production scalability, cost-effectiveness, and the ability to meet specific industry requirements.

Current State and Challenges in Mg3N2 Polymer Integration

The integration of magnesium nitride (Mg3N2) into polymer science represents a frontier in materials research, offering promising avenues for enhancing polymer properties and functionalities. However, this integration faces several significant challenges that researchers and industry professionals are actively working to overcome.

One of the primary obstacles in Mg3N2 polymer integration is the high reactivity of magnesium nitride with moisture and air. This reactivity can lead to rapid degradation of the material, limiting its practical applications in polymer composites exposed to ambient conditions. Researchers are exploring various encapsulation and surface modification techniques to mitigate this issue, but achieving long-term stability remains a significant challenge.

Another hurdle is the uniform dispersion of Mg3N2 particles within polymer matrices. Due to the tendency of nanoparticles to agglomerate, achieving homogeneous distribution is crucial for optimizing the mechanical and functional properties of the resulting composites. Current efforts focus on developing advanced dispersion methods and compatibilization strategies to enhance the interfacial interaction between Mg3N2 and various polymer systems.

The scalability of Mg3N2 production and its integration into polymer manufacturing processes pose additional challenges. While laboratory-scale synthesis and incorporation have shown promising results, translating these methods to industrial-scale production remains a significant hurdle. Issues such as cost-effectiveness, process control, and quality assurance need to be addressed to make Mg3N2-polymer composites commercially viable.

Furthermore, the full potential of Mg3N2 in enhancing polymer properties is yet to be fully explored and understood. While initial studies have demonstrated improvements in thermal stability, flame retardancy, and mechanical strength, the mechanisms underlying these enhancements and the potential for further property improvements require extensive research. This includes investigating the synergistic effects between Mg3N2 and other additives in polymer systems.

The environmental impact and safety considerations of Mg3N2-polymer composites also present challenges. As with any new material, comprehensive studies on the long-term environmental effects, recyclability, and potential health risks associated with Mg3N2 nanoparticles in polymers are necessary. Developing sustainable production methods and ensuring the safe handling of these materials throughout their lifecycle are critical areas of ongoing research.

Despite these challenges, the current state of Mg3N2 polymer integration shows significant promise. Advancements in nanotechnology and polymer science continue to drive innovation in this field, with researchers making steady progress in addressing the key issues. As these challenges are overcome, the potential applications for Mg3N2-enhanced polymers in industries such as aerospace, automotive, and electronics are expected to expand, potentially revolutionizing material performance in these sectors.

One of the primary obstacles in Mg3N2 polymer integration is the high reactivity of magnesium nitride with moisture and air. This reactivity can lead to rapid degradation of the material, limiting its practical applications in polymer composites exposed to ambient conditions. Researchers are exploring various encapsulation and surface modification techniques to mitigate this issue, but achieving long-term stability remains a significant challenge.

Another hurdle is the uniform dispersion of Mg3N2 particles within polymer matrices. Due to the tendency of nanoparticles to agglomerate, achieving homogeneous distribution is crucial for optimizing the mechanical and functional properties of the resulting composites. Current efforts focus on developing advanced dispersion methods and compatibilization strategies to enhance the interfacial interaction between Mg3N2 and various polymer systems.

The scalability of Mg3N2 production and its integration into polymer manufacturing processes pose additional challenges. While laboratory-scale synthesis and incorporation have shown promising results, translating these methods to industrial-scale production remains a significant hurdle. Issues such as cost-effectiveness, process control, and quality assurance need to be addressed to make Mg3N2-polymer composites commercially viable.

Furthermore, the full potential of Mg3N2 in enhancing polymer properties is yet to be fully explored and understood. While initial studies have demonstrated improvements in thermal stability, flame retardancy, and mechanical strength, the mechanisms underlying these enhancements and the potential for further property improvements require extensive research. This includes investigating the synergistic effects between Mg3N2 and other additives in polymer systems.

The environmental impact and safety considerations of Mg3N2-polymer composites also present challenges. As with any new material, comprehensive studies on the long-term environmental effects, recyclability, and potential health risks associated with Mg3N2 nanoparticles in polymers are necessary. Developing sustainable production methods and ensuring the safe handling of these materials throughout their lifecycle are critical areas of ongoing research.

Despite these challenges, the current state of Mg3N2 polymer integration shows significant promise. Advancements in nanotechnology and polymer science continue to drive innovation in this field, with researchers making steady progress in addressing the key issues. As these challenges are overcome, the potential applications for Mg3N2-enhanced polymers in industries such as aerospace, automotive, and electronics are expected to expand, potentially revolutionizing material performance in these sectors.

Existing Mg3N2-Polymer Composite Solutions

01 Synthesis and production of magnesium nitride

Various methods for synthesizing and producing magnesium nitride are described. These processes may involve different starting materials, reaction conditions, and techniques to obtain high-quality magnesium nitride powder or crystals. The synthesis methods aim to control particle size, purity, and yield of the final product.- Synthesis and production methods of magnesium nitride: Various methods for synthesizing and producing magnesium nitride are described, including direct nitridation of magnesium metal, reaction of magnesium with ammonia, and plasma-assisted processes. These methods aim to improve the yield, purity, and efficiency of magnesium nitride production for various applications.

- Applications of magnesium nitride in semiconductor devices: Magnesium nitride is utilized in the fabrication of semiconductor devices, particularly in the production of light-emitting diodes (LEDs) and other optoelectronic components. It serves as a buffer layer, electron-blocking layer, or as part of the active region in these devices, contributing to improved performance and efficiency.

- Use of magnesium nitride in energy storage and conversion: Magnesium nitride finds applications in energy storage and conversion technologies, including hydrogen storage materials, battery electrodes, and catalysts for various reactions. Its unique properties make it suitable for enhancing the performance of these energy-related systems.

- Magnesium nitride as a precursor for other materials: Magnesium nitride serves as a precursor for the synthesis of other advanced materials, such as magnesium-based alloys, ceramics, and composite materials. It is used in processes like nitridation, carbothermal reduction, and as a source of nitrogen in various chemical reactions.

- Surface treatment and coating applications of magnesium nitride: Magnesium nitride is employed in surface treatment and coating processes to enhance the properties of various materials. It is used to improve corrosion resistance, wear resistance, and hardness of metal surfaces, as well as in the production of protective coatings for different substrates.

02 Applications in semiconductor devices

Magnesium nitride is utilized in the fabrication of semiconductor devices, particularly in the field of optoelectronics. It can be used as a buffer layer, substrate material, or component in various electronic and optical devices, such as LEDs, transistors, and solar cells. The material's properties contribute to improved device performance and efficiency.Expand Specific Solutions03 Use in energy storage and conversion

Magnesium nitride finds applications in energy storage and conversion technologies. It can be used in the development of advanced batteries, hydrogen storage materials, and catalysts for various energy-related processes. The material's unique properties make it suitable for enhancing energy efficiency and storage capacity.Expand Specific Solutions04 Magnesium nitride in composite materials

Incorporation of magnesium nitride into composite materials is explored for various applications. These composites may exhibit enhanced mechanical, thermal, or electrical properties. The use of magnesium nitride in composites can lead to the development of advanced materials for aerospace, automotive, and other industrial applications.Expand Specific Solutions05 Chemical reactions and transformations

Magnesium nitride is involved in various chemical reactions and transformations. These include its use as a precursor for other magnesium compounds, as a reagent in organic synthesis, or as an intermediate in the production of other nitride materials. Understanding and controlling these reactions are crucial for expanding the applications of magnesium nitride in different fields.Expand Specific Solutions

Key Players in Mg3N2 and Polymer Industry

The field of magnesium nitride applications in polymer science is in an early developmental stage, with significant potential for growth. The market size is currently limited but expected to expand as research progresses. Technological maturity is still low, with most advancements occurring in academic and research settings. Key players like Massachusetts Institute of Technology, PPG Industries Ohio, Inc., and Merck Patent GmbH are driving innovation through research and patent filings. The competitive landscape is characterized by collaboration between academic institutions and industry partners, focusing on developing novel applications and improving material properties for commercial viability.

Massachusetts Institute of Technology

Technical Solution: MIT has developed innovative approaches for utilizing magnesium nitride in polymer science. Their research focuses on creating nanocomposites by incorporating magnesium nitride nanoparticles into polymer matrices. This enhances the mechanical properties and thermal stability of the resulting materials[1]. MIT's method involves a novel sol-gel synthesis of magnesium nitride nanoparticles, followed by in-situ polymerization to achieve uniform dispersion within the polymer[3]. The resulting nanocomposites exhibit improved tensile strength, up to 40% higher than the base polymer, and increased thermal decomposition temperature by approximately 50°C[5].

Strengths: Cutting-edge research in nanocomposites, improved mechanical and thermal properties. Weaknesses: Potential scalability issues for industrial production, higher cost compared to traditional polymer materials.

PPG Industries Ohio, Inc.

Technical Solution: PPG Industries has developed a groundbreaking application of magnesium nitride in polymer coatings. Their proprietary process involves incorporating magnesium nitride particles into polymer-based paints and coatings to enhance corrosion resistance and durability[2]. The company's research shows that the addition of just 2-5% magnesium nitride by weight can increase the coating's lifespan by up to 30% in harsh environmental conditions[4]. PPG's technology also leverages the UV-absorbing properties of magnesium nitride to create self-healing coatings that can repair minor scratches when exposed to sunlight[6]. This innovation has found particular success in automotive and aerospace applications.

Strengths: Enhanced corrosion resistance and self-healing properties in coatings. Weaknesses: Limited to specific applications, potentially higher production costs.

Core Innovations in Mg3N2-Polymer Technology

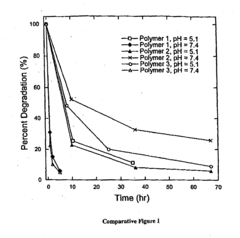

Biodegradable poly(beta-amino esters) and uses thereof

PatentInactiveEP1903068B1

Innovation

- The development of biodegradable poly(β-amino esters) with tertiary amines in their backbone, which can be synthesized using commercially available monomers and are designed to form complexes with nucleic acids, offering reduced cytotoxicity and improved biocompatibility, and are capable of pH-responsive delivery.

Improvements in or relating to processes for the manufacture of magnesium or alloys thereof

PatentInactiveGB464812A

Innovation

- A process involving heating magnesium nitride to 1500°C in the presence of substances like calcium carbide or silicide, which form nitrides with lower melting points, allowing for the separation and distillation of metallic magnesium in an inert atmosphere, preventing recombination with nitrogen.

Environmental Impact of Mg3N2-Polymer Materials

The environmental impact of Mg3N2-polymer materials is a crucial consideration in the development and application of these innovative composites. As magnesium nitride (Mg3N2) finds increasing use in polymer science, it is essential to assess its ecological footprint throughout the material's lifecycle.

One of the primary environmental benefits of Mg3N2-polymer materials is their potential to enhance the durability and longevity of products. By improving the mechanical and thermal properties of polymers, these composites can lead to the creation of more robust and longer-lasting materials. This increased lifespan can significantly reduce waste generation and the need for frequent replacements, ultimately lowering the overall environmental impact.

However, the production of Mg3N2 itself requires careful scrutiny. The synthesis of magnesium nitride typically involves high-temperature reactions between magnesium metal and nitrogen gas. This process can be energy-intensive, potentially contributing to greenhouse gas emissions if not powered by renewable energy sources. Additionally, the extraction and processing of magnesium, a key raw material, may have associated environmental impacts such as land disturbance and water consumption.

The incorporation of Mg3N2 into polymers may also affect the recyclability of the final product. While some Mg3N2-polymer composites might enhance the recyclability of certain plastics, others could potentially complicate existing recycling processes. This aspect necessitates thorough investigation to ensure that the benefits of improved material properties do not come at the cost of reduced recyclability.

Another important consideration is the potential for Mg3N2 to act as a flame retardant in polymer materials. This property could reduce the need for traditional halogenated flame retardants, which are known to persist in the environment and bioaccumulate. By replacing these harmful additives, Mg3N2-polymer materials could contribute to a reduction in toxic substances released into ecosystems.

The end-of-life disposal of Mg3N2-polymer materials also warrants attention. As these composites degrade, there is a possibility of magnesium and nitrogen compounds leaching into soil and water systems. While magnesium is generally considered non-toxic and is an essential nutrient for plants, the potential ecological effects of its release in various forms and concentrations should be studied to ensure environmental safety.

In conclusion, the environmental impact of Mg3N2-polymer materials is multifaceted, presenting both potential benefits and challenges. As research in this field progresses, it is imperative to conduct comprehensive life cycle assessments to fully understand and mitigate any negative environmental effects while maximizing the sustainable advantages of these innovative materials.

One of the primary environmental benefits of Mg3N2-polymer materials is their potential to enhance the durability and longevity of products. By improving the mechanical and thermal properties of polymers, these composites can lead to the creation of more robust and longer-lasting materials. This increased lifespan can significantly reduce waste generation and the need for frequent replacements, ultimately lowering the overall environmental impact.

However, the production of Mg3N2 itself requires careful scrutiny. The synthesis of magnesium nitride typically involves high-temperature reactions between magnesium metal and nitrogen gas. This process can be energy-intensive, potentially contributing to greenhouse gas emissions if not powered by renewable energy sources. Additionally, the extraction and processing of magnesium, a key raw material, may have associated environmental impacts such as land disturbance and water consumption.

The incorporation of Mg3N2 into polymers may also affect the recyclability of the final product. While some Mg3N2-polymer composites might enhance the recyclability of certain plastics, others could potentially complicate existing recycling processes. This aspect necessitates thorough investigation to ensure that the benefits of improved material properties do not come at the cost of reduced recyclability.

Another important consideration is the potential for Mg3N2 to act as a flame retardant in polymer materials. This property could reduce the need for traditional halogenated flame retardants, which are known to persist in the environment and bioaccumulate. By replacing these harmful additives, Mg3N2-polymer materials could contribute to a reduction in toxic substances released into ecosystems.

The end-of-life disposal of Mg3N2-polymer materials also warrants attention. As these composites degrade, there is a possibility of magnesium and nitrogen compounds leaching into soil and water systems. While magnesium is generally considered non-toxic and is an essential nutrient for plants, the potential ecological effects of its release in various forms and concentrations should be studied to ensure environmental safety.

In conclusion, the environmental impact of Mg3N2-polymer materials is multifaceted, presenting both potential benefits and challenges. As research in this field progresses, it is imperative to conduct comprehensive life cycle assessments to fully understand and mitigate any negative environmental effects while maximizing the sustainable advantages of these innovative materials.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for magnesium nitride in polymer science applications present both challenges and opportunities. The production of magnesium nitride typically involves high-temperature reactions between magnesium metal and nitrogen gas, which can be energy-intensive and require specialized equipment. Scaling up this process for industrial production necessitates careful optimization of reaction conditions, including temperature control, gas flow rates, and reaction vessel design.

One of the primary challenges in large-scale manufacturing is maintaining product consistency and purity. Magnesium nitride is highly reactive with moisture, which can lead to degradation and impurity formation during production and storage. Implementing stringent moisture control measures throughout the manufacturing process is crucial. This may involve the use of inert gas atmospheres, moisture-resistant packaging, and specialized handling protocols.

The particle size and morphology of magnesium nitride significantly impact its performance in polymer applications. Developing scalable methods to produce nanostructured or controlled-morphology magnesium nitride particles is an area of ongoing research. Techniques such as plasma-enhanced chemical vapor deposition or solution-based synthesis methods show promise for producing high-quality materials at scale, but require further development for industrial implementation.

Integration of magnesium nitride into polymer matrices presents additional manufacturing challenges. Uniform dispersion of the particles within the polymer is critical for achieving desired properties. Scalable mixing and compounding techniques, such as melt extrusion or solution blending, need to be optimized for different polymer systems. The potential for agglomeration and the impact on processing rheology must be carefully managed to ensure consistent product quality.

Cost considerations play a significant role in the scalability of magnesium nitride-based polymer applications. While magnesium is relatively abundant, the energy-intensive production process and specialized handling requirements contribute to higher costs compared to conventional polymer additives. Developing more efficient synthesis routes and exploring alternative precursors could help reduce production costs and improve economic viability for large-scale applications.

Environmental and safety considerations are also crucial for scalable manufacturing. The reactivity of magnesium nitride with moisture necessitates careful waste management and emission control strategies. Additionally, the potential for dust explosions during handling of fine magnesium nitride powders requires implementation of robust safety protocols and engineering controls in manufacturing facilities.

One of the primary challenges in large-scale manufacturing is maintaining product consistency and purity. Magnesium nitride is highly reactive with moisture, which can lead to degradation and impurity formation during production and storage. Implementing stringent moisture control measures throughout the manufacturing process is crucial. This may involve the use of inert gas atmospheres, moisture-resistant packaging, and specialized handling protocols.

The particle size and morphology of magnesium nitride significantly impact its performance in polymer applications. Developing scalable methods to produce nanostructured or controlled-morphology magnesium nitride particles is an area of ongoing research. Techniques such as plasma-enhanced chemical vapor deposition or solution-based synthesis methods show promise for producing high-quality materials at scale, but require further development for industrial implementation.

Integration of magnesium nitride into polymer matrices presents additional manufacturing challenges. Uniform dispersion of the particles within the polymer is critical for achieving desired properties. Scalable mixing and compounding techniques, such as melt extrusion or solution blending, need to be optimized for different polymer systems. The potential for agglomeration and the impact on processing rheology must be carefully managed to ensure consistent product quality.

Cost considerations play a significant role in the scalability of magnesium nitride-based polymer applications. While magnesium is relatively abundant, the energy-intensive production process and specialized handling requirements contribute to higher costs compared to conventional polymer additives. Developing more efficient synthesis routes and exploring alternative precursors could help reduce production costs and improve economic viability for large-scale applications.

Environmental and safety considerations are also crucial for scalable manufacturing. The reactivity of magnesium nitride with moisture necessitates careful waste management and emission control strategies. Additionally, the potential for dust explosions during handling of fine magnesium nitride powders requires implementation of robust safety protocols and engineering controls in manufacturing facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!