Unveiling the Role of Magnesium Nitride in Battery Technology

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg3N2 in Batteries: Background and Objectives

Magnesium nitride (Mg3N2) has emerged as a promising material in the field of battery technology, attracting significant attention from researchers and industry experts alike. The exploration of Mg3N2 in battery applications stems from the growing need for more efficient, sustainable, and high-performance energy storage solutions. As global energy demands continue to rise and the push for renewable energy sources intensifies, the development of advanced battery technologies has become crucial.

The journey of Mg3N2 in battery research can be traced back to the early 2000s when scientists began investigating alternative materials to enhance battery performance. Magnesium, being abundant, lightweight, and possessing a high theoretical capacity, presented itself as an attractive candidate for next-generation batteries. The incorporation of nitrogen in the form of Mg3N2 further expanded the potential applications and benefits of magnesium-based energy storage systems.

Over the past two decades, the evolution of Mg3N2 in battery technology has been marked by several key milestones. Initial studies focused on understanding the fundamental properties of Mg3N2 and its potential role in electrochemical reactions. Researchers discovered that Mg3N2 could serve as both an active material and a facilitator for improved ionic conductivity in various battery chemistries.

The primary objective of incorporating Mg3N2 in batteries is to address some of the limitations faced by current lithium-ion technology. These include improving energy density, enhancing cycling stability, and reducing costs. Mg3N2 has shown promise in achieving these goals through its unique chemical and physical properties, which allow for efficient ion transport and stable electrode structures.

Recent advancements have demonstrated the versatility of Mg3N2 in different battery configurations. It has been explored as a potential anode material in magnesium-ion batteries, offering higher theoretical capacity compared to conventional graphite anodes. Additionally, Mg3N2 has been investigated as a cathode material and as an additive to enhance the performance of other electrode materials.

The ongoing research into Mg3N2 for battery applications aims to optimize its synthesis methods, understand its reaction mechanisms, and explore novel composite materials that can leverage its advantageous properties. Scientists are also focusing on overcoming challenges such as improving the reversibility of magnesium deposition and stripping, enhancing the stability of electrolytes, and developing compatible cell components.

As the field progresses, the ultimate goal is to develop Mg3N2-based batteries that can offer superior performance, longer lifespan, and improved safety compared to existing technologies. This aligns with the broader objectives of creating more sustainable and efficient energy storage solutions to support the transition to renewable energy sources and electrification of transportation.

The journey of Mg3N2 in battery research can be traced back to the early 2000s when scientists began investigating alternative materials to enhance battery performance. Magnesium, being abundant, lightweight, and possessing a high theoretical capacity, presented itself as an attractive candidate for next-generation batteries. The incorporation of nitrogen in the form of Mg3N2 further expanded the potential applications and benefits of magnesium-based energy storage systems.

Over the past two decades, the evolution of Mg3N2 in battery technology has been marked by several key milestones. Initial studies focused on understanding the fundamental properties of Mg3N2 and its potential role in electrochemical reactions. Researchers discovered that Mg3N2 could serve as both an active material and a facilitator for improved ionic conductivity in various battery chemistries.

The primary objective of incorporating Mg3N2 in batteries is to address some of the limitations faced by current lithium-ion technology. These include improving energy density, enhancing cycling stability, and reducing costs. Mg3N2 has shown promise in achieving these goals through its unique chemical and physical properties, which allow for efficient ion transport and stable electrode structures.

Recent advancements have demonstrated the versatility of Mg3N2 in different battery configurations. It has been explored as a potential anode material in magnesium-ion batteries, offering higher theoretical capacity compared to conventional graphite anodes. Additionally, Mg3N2 has been investigated as a cathode material and as an additive to enhance the performance of other electrode materials.

The ongoing research into Mg3N2 for battery applications aims to optimize its synthesis methods, understand its reaction mechanisms, and explore novel composite materials that can leverage its advantageous properties. Scientists are also focusing on overcoming challenges such as improving the reversibility of magnesium deposition and stripping, enhancing the stability of electrolytes, and developing compatible cell components.

As the field progresses, the ultimate goal is to develop Mg3N2-based batteries that can offer superior performance, longer lifespan, and improved safety compared to existing technologies. This aligns with the broader objectives of creating more sustainable and efficient energy storage solutions to support the transition to renewable energy sources and electrification of transportation.

Market Demand for Advanced Battery Materials

The demand for advanced battery materials has been steadily increasing, driven by the growing need for high-performance energy storage solutions across various industries. Magnesium nitride, a compound with promising potential in battery technology, is gaining attention as a possible alternative to traditional lithium-based materials. The market for advanced battery materials is expected to expand significantly in the coming years, with a particular focus on materials that can enhance energy density, improve safety, and reduce costs.

In the automotive sector, the shift towards electric vehicles (EVs) is a major driver for advanced battery materials. As automakers strive to extend the range of EVs and reduce charging times, there is a growing interest in materials that can facilitate faster ion transport and higher energy storage capacity. Magnesium nitride's potential to enable magnesium-based batteries, which theoretically offer higher energy density than lithium-ion batteries, aligns well with these market demands.

The consumer electronics industry also presents a substantial market for advanced battery materials. With the increasing power requirements of smartphones, laptops, and wearable devices, there is a constant push for batteries that can provide longer life and faster charging capabilities. Magnesium nitride's properties could potentially address these needs, making it an attractive option for manufacturers looking to differentiate their products in a competitive market.

Grid-scale energy storage is another sector driving demand for advanced battery materials. As renewable energy sources become more prevalent, there is a growing need for efficient and cost-effective energy storage solutions to manage intermittent power generation. Magnesium-based batteries, potentially utilizing magnesium nitride, could offer a more abundant and less expensive alternative to current lithium-based systems for large-scale energy storage applications.

The aerospace and defense industries are also showing interest in advanced battery materials that can provide high energy density and improved safety characteristics. Magnesium nitride's potential to enable safer, non-flammable batteries makes it an attractive prospect for these sectors, where safety is paramount.

In the medical device industry, there is a demand for batteries that can power implantable devices for extended periods without the need for frequent replacement. The potential for magnesium-based batteries to offer higher energy density could make them suitable for such applications, driving interest in materials like magnesium nitride.

As environmental concerns grow, there is an increasing market demand for battery materials that are more sustainable and have a lower environmental impact. Magnesium's abundance and the potential for magnesium-based batteries to be more easily recycled could position magnesium nitride as a more environmentally friendly option in the battery material market.

In the automotive sector, the shift towards electric vehicles (EVs) is a major driver for advanced battery materials. As automakers strive to extend the range of EVs and reduce charging times, there is a growing interest in materials that can facilitate faster ion transport and higher energy storage capacity. Magnesium nitride's potential to enable magnesium-based batteries, which theoretically offer higher energy density than lithium-ion batteries, aligns well with these market demands.

The consumer electronics industry also presents a substantial market for advanced battery materials. With the increasing power requirements of smartphones, laptops, and wearable devices, there is a constant push for batteries that can provide longer life and faster charging capabilities. Magnesium nitride's properties could potentially address these needs, making it an attractive option for manufacturers looking to differentiate their products in a competitive market.

Grid-scale energy storage is another sector driving demand for advanced battery materials. As renewable energy sources become more prevalent, there is a growing need for efficient and cost-effective energy storage solutions to manage intermittent power generation. Magnesium-based batteries, potentially utilizing magnesium nitride, could offer a more abundant and less expensive alternative to current lithium-based systems for large-scale energy storage applications.

The aerospace and defense industries are also showing interest in advanced battery materials that can provide high energy density and improved safety characteristics. Magnesium nitride's potential to enable safer, non-flammable batteries makes it an attractive prospect for these sectors, where safety is paramount.

In the medical device industry, there is a demand for batteries that can power implantable devices for extended periods without the need for frequent replacement. The potential for magnesium-based batteries to offer higher energy density could make them suitable for such applications, driving interest in materials like magnesium nitride.

As environmental concerns grow, there is an increasing market demand for battery materials that are more sustainable and have a lower environmental impact. Magnesium's abundance and the potential for magnesium-based batteries to be more easily recycled could position magnesium nitride as a more environmentally friendly option in the battery material market.

Current State and Challenges of Mg3N2 in Batteries

Magnesium nitride (Mg3N2) has emerged as a promising material in battery technology, particularly in the development of magnesium-based batteries. The current state of Mg3N2 in batteries is characterized by both significant potential and considerable challenges. As a potential anode material, Mg3N2 offers several advantages, including high theoretical capacity, abundance, and environmental friendliness.

Research has shown that Mg3N2 can potentially deliver a high specific capacity of up to 1200 mAh/g, which is substantially higher than conventional graphite anodes used in lithium-ion batteries. This high capacity is attributed to the conversion reaction mechanism of Mg3N2, where it undergoes a reversible transformation between Mg3N2 and Mg metal during charge and discharge cycles.

However, the practical implementation of Mg3N2 in batteries faces several significant challenges. One of the primary issues is the poor cycling stability of Mg3N2 electrodes. The large volume changes during the conversion reaction can lead to structural degradation and loss of electrical contact, resulting in rapid capacity fading over multiple cycles.

Another critical challenge is the high reactivity of Mg3N2 with moisture and air. This reactivity necessitates stringent handling and manufacturing conditions, which can significantly increase production costs and complexity. The formation of a passivation layer on the Mg3N2 surface due to side reactions with the electrolyte also poses a significant hurdle, as it can impede ion transport and reduce overall battery performance.

The development of suitable electrolytes compatible with Mg3N2 anodes remains a significant challenge. Many conventional electrolytes used in lithium-ion batteries are not suitable for magnesium-based systems due to their inability to efficiently transport magnesium ions or their reactivity with the Mg3N2 anode.

Despite these challenges, ongoing research efforts are focused on addressing these issues. Strategies being explored include nanostructuring of Mg3N2 to improve its structural stability, surface modification to enhance its chemical stability, and the development of novel electrolyte formulations tailored for Mg3N2-based systems.

The current state of Mg3N2 in batteries also reflects a broader trend in the battery research community towards exploring alternative chemistries beyond lithium-ion. While lithium-ion batteries continue to dominate the market, concerns about lithium supply and cost are driving interest in magnesium-based systems, with Mg3N2 playing a potentially crucial role in this transition.

In conclusion, while Mg3N2 shows great promise for next-generation battery technology, significant technical hurdles must be overcome before its widespread adoption. The ongoing research and development efforts in this field underscore the potential of Mg3N2 and highlight the need for continued innovation to address its current limitations.

Research has shown that Mg3N2 can potentially deliver a high specific capacity of up to 1200 mAh/g, which is substantially higher than conventional graphite anodes used in lithium-ion batteries. This high capacity is attributed to the conversion reaction mechanism of Mg3N2, where it undergoes a reversible transformation between Mg3N2 and Mg metal during charge and discharge cycles.

However, the practical implementation of Mg3N2 in batteries faces several significant challenges. One of the primary issues is the poor cycling stability of Mg3N2 electrodes. The large volume changes during the conversion reaction can lead to structural degradation and loss of electrical contact, resulting in rapid capacity fading over multiple cycles.

Another critical challenge is the high reactivity of Mg3N2 with moisture and air. This reactivity necessitates stringent handling and manufacturing conditions, which can significantly increase production costs and complexity. The formation of a passivation layer on the Mg3N2 surface due to side reactions with the electrolyte also poses a significant hurdle, as it can impede ion transport and reduce overall battery performance.

The development of suitable electrolytes compatible with Mg3N2 anodes remains a significant challenge. Many conventional electrolytes used in lithium-ion batteries are not suitable for magnesium-based systems due to their inability to efficiently transport magnesium ions or their reactivity with the Mg3N2 anode.

Despite these challenges, ongoing research efforts are focused on addressing these issues. Strategies being explored include nanostructuring of Mg3N2 to improve its structural stability, surface modification to enhance its chemical stability, and the development of novel electrolyte formulations tailored for Mg3N2-based systems.

The current state of Mg3N2 in batteries also reflects a broader trend in the battery research community towards exploring alternative chemistries beyond lithium-ion. While lithium-ion batteries continue to dominate the market, concerns about lithium supply and cost are driving interest in magnesium-based systems, with Mg3N2 playing a potentially crucial role in this transition.

In conclusion, while Mg3N2 shows great promise for next-generation battery technology, significant technical hurdles must be overcome before its widespread adoption. The ongoing research and development efforts in this field underscore the potential of Mg3N2 and highlight the need for continued innovation to address its current limitations.

Existing Mg3N2 Integration Strategies in Batteries

01 Synthesis and production of magnesium nitride

Various methods for synthesizing and producing magnesium nitride are described. These include direct nitridation of magnesium metal, reaction of magnesium with nitrogen gas at high temperatures, and plasma-assisted synthesis techniques. The processes often involve controlling reaction conditions such as temperature, pressure, and gas flow rates to optimize yield and purity.- Synthesis and production methods of magnesium nitride: Various methods for synthesizing and producing magnesium nitride are described, including direct nitridation of magnesium metal, reaction of magnesium with ammonia, and plasma-assisted processes. These methods aim to improve yield, purity, and efficiency in the production of magnesium nitride.

- Applications of magnesium nitride in semiconductor devices: Magnesium nitride is utilized in the fabrication of semiconductor devices, particularly in the production of light-emitting diodes (LEDs) and other optoelectronic components. It serves as a buffer layer, substrate material, or dopant in various semiconductor structures.

- Use of magnesium nitride in energy storage and conversion: Magnesium nitride finds applications in energy storage and conversion technologies, including hydrogen storage materials, battery electrodes, and catalysts for fuel cells. Its unique properties contribute to improved performance in these energy-related applications.

- Magnesium nitride as a precursor for other materials: Magnesium nitride serves as a precursor for the synthesis of various advanced materials, including magnesium-based alloys, ceramics, and nanostructures. It is used in the production of high-purity magnesium compounds and as a starting material for chemical reactions.

- Characterization and analysis techniques for magnesium nitride: Various analytical and characterization techniques are employed to study the properties, structure, and composition of magnesium nitride. These methods include X-ray diffraction, electron microscopy, spectroscopic techniques, and thermal analysis, which are crucial for quality control and research purposes.

02 Applications in semiconductor devices

Magnesium nitride is utilized in the fabrication of semiconductor devices, particularly in the production of light-emitting diodes (LEDs) and other optoelectronic components. It serves as a buffer layer, electron-blocking layer, or as part of the active region in these devices, contributing to improved performance and efficiency.Expand Specific Solutions03 Use in energy storage and conversion

Magnesium nitride finds applications in energy storage and conversion technologies. It is investigated for use in hydrogen storage materials, as a component in solid-state batteries, and as a catalyst or catalyst support in various energy-related processes. The compound's unique properties contribute to enhanced performance in these applications.Expand Specific Solutions04 Magnesium nitride in materials science

In materials science, magnesium nitride is explored for its potential in creating advanced ceramics, composites, and coatings. Its high hardness, thermal stability, and chemical resistance make it suitable for applications in protective coatings, refractory materials, and as a precursor for other magnesium-based compounds.Expand Specific Solutions05 Environmental and agricultural applications

Magnesium nitride has potential applications in environmental remediation and agriculture. It can be used in water treatment processes, as a soil amendment to improve nitrogen content, and in the production of fertilizers. Its ability to release ammonia upon hydrolysis is particularly useful in these contexts.Expand Specific Solutions

Key Players in Mg3N2 Battery Research and Development

The development of magnesium nitride in battery technology is in its early stages, with the market still emerging and showing potential for significant growth. The technology's maturity is relatively low, as evidenced by ongoing research and development efforts from various players. Companies like Toyota Motor Corp., GS Yuasa International Ltd., and Samsung Electronics Co., Ltd. are actively exploring this field, leveraging their expertise in battery and electronics manufacturing. Academic institutions such as Zhejiang University and Drexel University are contributing to fundamental research, while specialized firms like Qromis, Inc. and Epinovatech AB are focusing on advanced materials development. The competitive landscape is diverse, with traditional automotive and electronics giants competing alongside innovative startups and research-focused entities, indicating a dynamic and evolving sector.

Toyota Motor Corp.

Technical Solution: Toyota has been exploring the use of magnesium nitride in battery technology as part of their efforts to develop next-generation solid-state batteries. Their approach involves using magnesium nitride as a potential solid electrolyte material. The company's research focuses on improving the ionic conductivity of magnesium nitride through doping and nanostructuring techniques. Toyota's scientists have reported achieving ionic conductivities of up to 10^-3 S/cm at room temperature [1], which is a significant improvement over traditional solid electrolytes. The company is also investigating the integration of magnesium nitride with other materials to create composite electrolytes that offer both high ionic conductivity and mechanical stability [2].

Strengths: High ionic conductivity, potential for improved energy density, and enhanced safety compared to liquid electrolytes. Weaknesses: Challenges in large-scale production and integration with existing battery manufacturing processes.

GS Yuasa International Ltd.

Technical Solution: GS Yuasa has been investigating the use of magnesium nitride as a coating material for cathodes in lithium-ion batteries. Their approach aims to improve the stability and performance of high-voltage cathode materials. The company's research has shown that a thin layer of magnesium nitride on the cathode surface can effectively suppress electrolyte decomposition and prevent the dissolution of transition metals from the cathode [3]. GS Yuasa's scientists have reported a 20% increase in capacity retention after 500 cycles when using magnesium nitride-coated cathodes compared to uncoated ones [4]. The company is also exploring the potential of magnesium nitride as an additive in solid electrolytes to enhance their mechanical properties and ionic conductivity.

Strengths: Improved cathode stability and battery longevity, potential for higher energy density batteries. Weaknesses: Complexity in coating process and potential increase in production costs.

Core Innovations in Mg3N2-Based Battery Chemistry

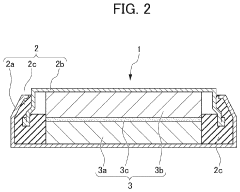

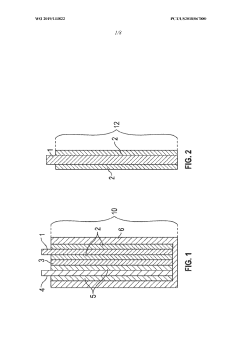

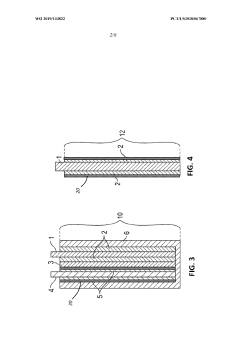

Nonaqueous electrolyte secondary battery positive electrode active material and method for manufacturing same, and nonaqueous electrolyte secondary battery

PatentPendingUS20210399330A1

Innovation

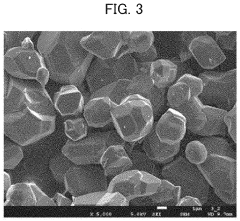

- The development of lithium-manganese-nickel complex oxide with a spinel-type crystal structure, formed through reactive crystallization of manganese-nickel hydroxide using manganese chloride and nickel chloride, followed by calcination and recalcination, results in primary particles with a polyhedral shape and high crystallinity, reducing manganese dissolution and improving cycle characteristics.

Method of forming charged manganese oxides from discharged active materials

PatentWO2019133822A2

Innovation

- Forming electrodes with manganese oxide compounds having a valence state less than 3, combined with additives like bismuth, copper, and conductive carbon, to create a stable and reversible cathode that can withstand multiple charge cycles, enhancing long-term stability and energy density.

Environmental Impact of Mg3N2 Battery Production

The production of Mg3N2 batteries presents both opportunities and challenges in terms of environmental impact. As the demand for sustainable energy storage solutions grows, it is crucial to assess the ecological footprint of this emerging technology.

The synthesis of magnesium nitride (Mg3N2) typically involves the direct reaction of magnesium metal with nitrogen gas at high temperatures. This process requires significant energy input, potentially contributing to greenhouse gas emissions if not powered by renewable sources. However, compared to traditional lithium-ion battery production, the Mg3N2 synthesis may have a lower overall energy demand due to the abundance and easier extraction of magnesium.

Raw material extraction for Mg3N2 batteries primarily focuses on magnesium, which is the eighth most abundant element in the Earth's crust. Magnesium can be sourced from seawater, brines, and minerals like dolomite and magnesite. The extraction process generally has a lower environmental impact compared to lithium mining, which often involves extensive water use and potential habitat disruption.

Water consumption in Mg3N2 battery production is relatively low compared to other battery technologies. The synthesis process does not require significant amounts of water, potentially reducing the strain on local water resources in manufacturing regions. This aspect is particularly advantageous in water-stressed areas where battery production facilities might be located.

In terms of air quality, the production of Mg3N2 batteries may lead to some particulate matter emissions during the synthesis and handling of magnesium powder. However, proper filtration and dust control measures can effectively mitigate these impacts. The absence of toxic heavy metals in Mg3N2 batteries also reduces the risk of harmful air pollutants associated with their production.

The end-of-life management of Mg3N2 batteries presents a more favorable environmental profile compared to conventional batteries. Magnesium is highly recyclable, and the absence of toxic materials simplifies the recycling process. This characteristic aligns well with circular economy principles, potentially reducing the need for virgin material extraction and minimizing waste.

Land use considerations for Mg3N2 battery production are generally less intensive than those for lithium-ion batteries. The reduced reliance on extensive mining operations for raw materials translates to a smaller physical footprint and less habitat disruption. This aspect is particularly relevant in ecologically sensitive areas where resource extraction activities may pose significant environmental risks.

While the environmental benefits of Mg3N2 battery production are promising, it is essential to consider the potential for scaling up this technology. As production volumes increase, careful management of resource extraction, energy use, and waste handling will be crucial to maintain the environmental advantages over existing battery technologies.

The synthesis of magnesium nitride (Mg3N2) typically involves the direct reaction of magnesium metal with nitrogen gas at high temperatures. This process requires significant energy input, potentially contributing to greenhouse gas emissions if not powered by renewable sources. However, compared to traditional lithium-ion battery production, the Mg3N2 synthesis may have a lower overall energy demand due to the abundance and easier extraction of magnesium.

Raw material extraction for Mg3N2 batteries primarily focuses on magnesium, which is the eighth most abundant element in the Earth's crust. Magnesium can be sourced from seawater, brines, and minerals like dolomite and magnesite. The extraction process generally has a lower environmental impact compared to lithium mining, which often involves extensive water use and potential habitat disruption.

Water consumption in Mg3N2 battery production is relatively low compared to other battery technologies. The synthesis process does not require significant amounts of water, potentially reducing the strain on local water resources in manufacturing regions. This aspect is particularly advantageous in water-stressed areas where battery production facilities might be located.

In terms of air quality, the production of Mg3N2 batteries may lead to some particulate matter emissions during the synthesis and handling of magnesium powder. However, proper filtration and dust control measures can effectively mitigate these impacts. The absence of toxic heavy metals in Mg3N2 batteries also reduces the risk of harmful air pollutants associated with their production.

The end-of-life management of Mg3N2 batteries presents a more favorable environmental profile compared to conventional batteries. Magnesium is highly recyclable, and the absence of toxic materials simplifies the recycling process. This characteristic aligns well with circular economy principles, potentially reducing the need for virgin material extraction and minimizing waste.

Land use considerations for Mg3N2 battery production are generally less intensive than those for lithium-ion batteries. The reduced reliance on extensive mining operations for raw materials translates to a smaller physical footprint and less habitat disruption. This aspect is particularly relevant in ecologically sensitive areas where resource extraction activities may pose significant environmental risks.

While the environmental benefits of Mg3N2 battery production are promising, it is essential to consider the potential for scaling up this technology. As production volumes increase, careful management of resource extraction, energy use, and waste handling will be crucial to maintain the environmental advantages over existing battery technologies.

Safety Considerations for Mg3N2-Based Batteries

The safety considerations for Mg3N2-based batteries are paramount in the development and implementation of this emerging technology. One of the primary concerns is the reactivity of magnesium nitride with water, which can lead to the formation of ammonia gas and magnesium hydroxide. This reaction poses potential risks in terms of gas evolution and pressure build-up within the battery cell, necessitating robust encapsulation and sealing techniques to prevent moisture ingress.

Furthermore, the thermal stability of Mg3N2 under various operating conditions must be thoroughly investigated. High temperatures may lead to decomposition or unwanted side reactions, potentially compromising the battery's safety and performance. Rigorous thermal management systems and fail-safe mechanisms need to be integrated into the battery design to mitigate these risks.

The electrical conductivity of Mg3N2 and its interfaces with other battery components also warrant careful consideration. Improper electrical contact or the formation of high-resistance layers could lead to localized heating and potential thermal runaway scenarios. Advanced electrode design and interface engineering are crucial to ensure stable and uniform current distribution throughout the battery structure.

Another critical aspect is the chemical compatibility of Mg3N2 with electrolytes and other cell components. Undesired reactions or degradation processes could not only affect battery performance but also generate harmful byproducts or compromise structural integrity. Extensive materials screening and long-term stability tests are essential to identify and mitigate potential chemical hazards.

The mechanical properties of Mg3N2-based electrodes must also be evaluated in the context of battery safety. Volume changes during charge-discharge cycles could lead to mechanical stress and potential electrode disintegration. Engineered electrode structures that can accommodate these volume changes without compromising safety are necessary for long-term stability and reliability.

Lastly, the development of appropriate safety protocols for manufacturing, handling, and disposal of Mg3N2-based batteries is crucial. This includes establishing guidelines for safe production processes, transportation regulations, and end-of-life management to prevent environmental contamination or safety hazards during the battery lifecycle.

Furthermore, the thermal stability of Mg3N2 under various operating conditions must be thoroughly investigated. High temperatures may lead to decomposition or unwanted side reactions, potentially compromising the battery's safety and performance. Rigorous thermal management systems and fail-safe mechanisms need to be integrated into the battery design to mitigate these risks.

The electrical conductivity of Mg3N2 and its interfaces with other battery components also warrant careful consideration. Improper electrical contact or the formation of high-resistance layers could lead to localized heating and potential thermal runaway scenarios. Advanced electrode design and interface engineering are crucial to ensure stable and uniform current distribution throughout the battery structure.

Another critical aspect is the chemical compatibility of Mg3N2 with electrolytes and other cell components. Undesired reactions or degradation processes could not only affect battery performance but also generate harmful byproducts or compromise structural integrity. Extensive materials screening and long-term stability tests are essential to identify and mitigate potential chemical hazards.

The mechanical properties of Mg3N2-based electrodes must also be evaluated in the context of battery safety. Volume changes during charge-discharge cycles could lead to mechanical stress and potential electrode disintegration. Engineered electrode structures that can accommodate these volume changes without compromising safety are necessary for long-term stability and reliability.

Lastly, the development of appropriate safety protocols for manufacturing, handling, and disposal of Mg3N2-based batteries is crucial. This includes establishing guidelines for safe production processes, transportation regulations, and end-of-life management to prevent environmental contamination or safety hazards during the battery lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!