How to Apply Magnesium Nitride in Plasma Applications?

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg3N2 in Plasma Tech: Background and Objectives

Magnesium nitride (Mg3N2) has emerged as a promising material in the field of plasma applications, attracting significant attention from researchers and industry professionals alike. The evolution of plasma technology has created a demand for novel materials that can enhance performance and efficiency across various applications. Mg3N2, with its unique properties, stands at the forefront of this technological advancement.

The journey of Mg3N2 in plasma technology began with the recognition of its potential as a source of reactive nitrogen species. As plasma applications expanded in areas such as surface modification, thin film deposition, and chemical synthesis, the need for materials that could provide controlled nitrogen release became apparent. Mg3N2, with its ability to decompose and release nitrogen under specific conditions, presented itself as a viable candidate for these applications.

The primary objective in applying Mg3N2 in plasma applications is to harness its nitrogen-releasing capabilities to create more efficient and controllable plasma processes. Researchers aim to develop methods for incorporating Mg3N2 into plasma systems in ways that optimize nitrogen delivery while maintaining stable plasma conditions. This involves understanding the decomposition kinetics of Mg3N2 under various plasma parameters and developing techniques to integrate it effectively into existing plasma technologies.

Another crucial goal is to explore the potential of Mg3N2 in enhancing the performance of plasma-based surface treatments. The controlled release of nitrogen from Mg3N2 could lead to improved nitriding processes, resulting in superior surface hardness and wear resistance in treated materials. Additionally, researchers are investigating the use of Mg3N2 in plasma-enhanced chemical vapor deposition (PECVD) processes, where it could serve as a precursor for nitrogen-doped thin films with unique properties.

The application of Mg3N2 in plasma technology also aims to address environmental concerns associated with traditional nitrogen sources. By utilizing a solid-state nitrogen source like Mg3N2, researchers hope to reduce the reliance on gaseous nitrogen precursors, potentially leading to safer and more environmentally friendly plasma processes. This aligns with the broader trend towards sustainable and green technologies in industrial applications.

As research in this field progresses, the objectives extend to understanding the fundamental interactions between Mg3N2 and plasma environments. This includes studying the plasma-induced decomposition mechanisms of Mg3N2, the formation of reactive nitrogen species, and their subsequent reactions in the plasma phase. Such knowledge is crucial for optimizing the use of Mg3N2 in plasma applications and for developing new plasma-based processes that leverage its unique properties.

The journey of Mg3N2 in plasma technology began with the recognition of its potential as a source of reactive nitrogen species. As plasma applications expanded in areas such as surface modification, thin film deposition, and chemical synthesis, the need for materials that could provide controlled nitrogen release became apparent. Mg3N2, with its ability to decompose and release nitrogen under specific conditions, presented itself as a viable candidate for these applications.

The primary objective in applying Mg3N2 in plasma applications is to harness its nitrogen-releasing capabilities to create more efficient and controllable plasma processes. Researchers aim to develop methods for incorporating Mg3N2 into plasma systems in ways that optimize nitrogen delivery while maintaining stable plasma conditions. This involves understanding the decomposition kinetics of Mg3N2 under various plasma parameters and developing techniques to integrate it effectively into existing plasma technologies.

Another crucial goal is to explore the potential of Mg3N2 in enhancing the performance of plasma-based surface treatments. The controlled release of nitrogen from Mg3N2 could lead to improved nitriding processes, resulting in superior surface hardness and wear resistance in treated materials. Additionally, researchers are investigating the use of Mg3N2 in plasma-enhanced chemical vapor deposition (PECVD) processes, where it could serve as a precursor for nitrogen-doped thin films with unique properties.

The application of Mg3N2 in plasma technology also aims to address environmental concerns associated with traditional nitrogen sources. By utilizing a solid-state nitrogen source like Mg3N2, researchers hope to reduce the reliance on gaseous nitrogen precursors, potentially leading to safer and more environmentally friendly plasma processes. This aligns with the broader trend towards sustainable and green technologies in industrial applications.

As research in this field progresses, the objectives extend to understanding the fundamental interactions between Mg3N2 and plasma environments. This includes studying the plasma-induced decomposition mechanisms of Mg3N2, the formation of reactive nitrogen species, and their subsequent reactions in the plasma phase. Such knowledge is crucial for optimizing the use of Mg3N2 in plasma applications and for developing new plasma-based processes that leverage its unique properties.

Market Demand for Mg3N2 in Plasma Applications

The market demand for magnesium nitride (Mg3N2) in plasma applications is experiencing a significant upward trend, driven by the growing interest in advanced materials for various industrial and technological sectors. Plasma applications, which involve the use of ionized gases for material processing, surface modification, and other high-tech manufacturing processes, are increasingly exploring the potential of Mg3N2 as a novel and effective material.

In the semiconductor industry, there is a rising demand for Mg3N2 in plasma-enhanced chemical vapor deposition (PECVD) processes. The unique properties of Mg3N2, including its high thermal stability and ability to form nitride layers, make it an attractive option for creating thin films and coatings on electronic components. This application is particularly relevant in the production of advanced integrated circuits and optoelectronic devices, where precise control of material properties is crucial.

The aerospace and automotive sectors are also showing increased interest in Mg3N2 for plasma-based surface treatments. The material's potential to enhance the hardness, wear resistance, and corrosion protection of metal components is driving its adoption in these industries. As manufacturers seek to improve the performance and longevity of critical parts, the demand for Mg3N2 in plasma nitriding and other surface modification techniques is expected to grow.

In the field of energy storage and conversion, Mg3N2 is gaining attention for its potential applications in plasma-assisted synthesis of advanced materials for batteries and fuel cells. The ability of Mg3N2 to serve as a precursor for the formation of complex nitrides and oxynitrides is opening new avenues for the development of high-performance electrode materials and electrolytes.

The environmental technology sector is another area where the demand for Mg3N2 in plasma applications is on the rise. Plasma-based waste treatment and air purification systems are exploring the use of Mg3N2 as a catalyst or reactive material to enhance the efficiency of pollutant removal processes. This application aligns with the growing global focus on sustainable technologies and environmental protection.

Despite the promising market outlook, the widespread adoption of Mg3N2 in plasma applications faces some challenges. The relatively high cost of production and the need for specialized handling due to its reactivity with moisture are factors that may limit its immediate large-scale use. However, ongoing research and development efforts are focused on addressing these issues, which is expected to further boost market demand in the coming years.

As industries continue to seek innovative materials for advanced manufacturing processes, the market for Mg3N2 in plasma applications is projected to expand. The material's unique properties and versatility across multiple high-tech sectors suggest a strong potential for growth, particularly as new applications and improved production methods are developed.

In the semiconductor industry, there is a rising demand for Mg3N2 in plasma-enhanced chemical vapor deposition (PECVD) processes. The unique properties of Mg3N2, including its high thermal stability and ability to form nitride layers, make it an attractive option for creating thin films and coatings on electronic components. This application is particularly relevant in the production of advanced integrated circuits and optoelectronic devices, where precise control of material properties is crucial.

The aerospace and automotive sectors are also showing increased interest in Mg3N2 for plasma-based surface treatments. The material's potential to enhance the hardness, wear resistance, and corrosion protection of metal components is driving its adoption in these industries. As manufacturers seek to improve the performance and longevity of critical parts, the demand for Mg3N2 in plasma nitriding and other surface modification techniques is expected to grow.

In the field of energy storage and conversion, Mg3N2 is gaining attention for its potential applications in plasma-assisted synthesis of advanced materials for batteries and fuel cells. The ability of Mg3N2 to serve as a precursor for the formation of complex nitrides and oxynitrides is opening new avenues for the development of high-performance electrode materials and electrolytes.

The environmental technology sector is another area where the demand for Mg3N2 in plasma applications is on the rise. Plasma-based waste treatment and air purification systems are exploring the use of Mg3N2 as a catalyst or reactive material to enhance the efficiency of pollutant removal processes. This application aligns with the growing global focus on sustainable technologies and environmental protection.

Despite the promising market outlook, the widespread adoption of Mg3N2 in plasma applications faces some challenges. The relatively high cost of production and the need for specialized handling due to its reactivity with moisture are factors that may limit its immediate large-scale use. However, ongoing research and development efforts are focused on addressing these issues, which is expected to further boost market demand in the coming years.

As industries continue to seek innovative materials for advanced manufacturing processes, the market for Mg3N2 in plasma applications is projected to expand. The material's unique properties and versatility across multiple high-tech sectors suggest a strong potential for growth, particularly as new applications and improved production methods are developed.

Current State and Challenges of Mg3N2 in Plasma

Magnesium nitride (Mg3N2) has gained increasing attention in plasma applications due to its unique properties and potential benefits. However, the current state of Mg3N2 in plasma technology presents both promising advancements and significant challenges.

In terms of progress, researchers have successfully demonstrated the use of Mg3N2 in various plasma-based processes. One notable application is in plasma-enhanced chemical vapor deposition (PECVD), where Mg3N2 has shown potential as a precursor for the growth of high-quality magnesium nitride thin films. These films exhibit excellent optical and electrical properties, making them suitable for optoelectronic devices and semiconductor applications.

Another area of advancement is the use of Mg3N2 in plasma nitriding processes. The incorporation of Mg3N2 into the plasma has been found to enhance the surface hardness and wear resistance of treated materials, particularly in the case of magnesium alloys. This has opened up new possibilities for improving the mechanical properties of lightweight materials in industries such as automotive and aerospace.

Despite these promising developments, several challenges hinder the widespread adoption of Mg3N2 in plasma applications. One major obstacle is the high reactivity of Mg3N2 with moisture and oxygen, which can lead to rapid degradation and reduced effectiveness in plasma environments. This necessitates careful handling and storage procedures, as well as the development of protective coatings or encapsulation techniques to maintain the stability of Mg3N2 during plasma processing.

Another significant challenge is the limited understanding of the complex interactions between Mg3N2 and plasma species. The behavior of Mg3N2 in different plasma conditions, including various gas compositions, pressures, and temperatures, requires further investigation to optimize its performance and expand its range of applications.

The scalability of Mg3N2-based plasma processes also presents a hurdle. While promising results have been achieved in laboratory settings, translating these findings to industrial-scale production remains challenging. Issues such as uniformity, reproducibility, and cost-effectiveness need to be addressed to make Mg3N2 plasma applications commercially viable.

Furthermore, the environmental and safety concerns associated with Mg3N2 usage in plasma processes require careful consideration. The potential release of nitrogen-containing compounds and magnesium particles during plasma treatment necessitates the development of appropriate containment and filtration systems to ensure worker safety and environmental protection.

In conclusion, while Mg3N2 shows great potential in plasma applications, overcoming these challenges will be crucial for its widespread adoption. Continued research and development efforts are needed to address the stability, scalability, and safety aspects of Mg3N2 in plasma technology, paving the way for innovative applications across various industries.

In terms of progress, researchers have successfully demonstrated the use of Mg3N2 in various plasma-based processes. One notable application is in plasma-enhanced chemical vapor deposition (PECVD), where Mg3N2 has shown potential as a precursor for the growth of high-quality magnesium nitride thin films. These films exhibit excellent optical and electrical properties, making them suitable for optoelectronic devices and semiconductor applications.

Another area of advancement is the use of Mg3N2 in plasma nitriding processes. The incorporation of Mg3N2 into the plasma has been found to enhance the surface hardness and wear resistance of treated materials, particularly in the case of magnesium alloys. This has opened up new possibilities for improving the mechanical properties of lightweight materials in industries such as automotive and aerospace.

Despite these promising developments, several challenges hinder the widespread adoption of Mg3N2 in plasma applications. One major obstacle is the high reactivity of Mg3N2 with moisture and oxygen, which can lead to rapid degradation and reduced effectiveness in plasma environments. This necessitates careful handling and storage procedures, as well as the development of protective coatings or encapsulation techniques to maintain the stability of Mg3N2 during plasma processing.

Another significant challenge is the limited understanding of the complex interactions between Mg3N2 and plasma species. The behavior of Mg3N2 in different plasma conditions, including various gas compositions, pressures, and temperatures, requires further investigation to optimize its performance and expand its range of applications.

The scalability of Mg3N2-based plasma processes also presents a hurdle. While promising results have been achieved in laboratory settings, translating these findings to industrial-scale production remains challenging. Issues such as uniformity, reproducibility, and cost-effectiveness need to be addressed to make Mg3N2 plasma applications commercially viable.

Furthermore, the environmental and safety concerns associated with Mg3N2 usage in plasma processes require careful consideration. The potential release of nitrogen-containing compounds and magnesium particles during plasma treatment necessitates the development of appropriate containment and filtration systems to ensure worker safety and environmental protection.

In conclusion, while Mg3N2 shows great potential in plasma applications, overcoming these challenges will be crucial for its widespread adoption. Continued research and development efforts are needed to address the stability, scalability, and safety aspects of Mg3N2 in plasma technology, paving the way for innovative applications across various industries.

Existing Mg3N2 Applications in Plasma Technology

01 Synthesis and production of magnesium nitride

Various methods for synthesizing and producing magnesium nitride are described. These include direct nitridation of magnesium metal, reaction of magnesium with ammonia, and plasma-assisted processes. The synthesis conditions, such as temperature, pressure, and reaction time, are optimized to improve yield and purity.- Synthesis and production methods of magnesium nitride: Various methods for synthesizing and producing magnesium nitride are described, including direct nitridation of magnesium metal, reaction of magnesium with ammonia, and plasma-assisted processes. These methods aim to improve yield, purity, and efficiency in the production of magnesium nitride.

- Applications of magnesium nitride in semiconductor devices: Magnesium nitride is utilized in the fabrication of semiconductor devices, particularly in the production of light-emitting diodes (LEDs) and other optoelectronic components. It serves as a buffer layer, electron-blocking layer, or as part of the active region in these devices.

- Use of magnesium nitride in energy storage and conversion: Magnesium nitride finds applications in energy storage and conversion technologies, including as a component in hydrogen storage materials, electrodes for batteries, and catalysts for various chemical reactions. Its properties contribute to improved performance in these energy-related applications.

- Magnesium nitride as a precursor for other materials: Magnesium nitride serves as a precursor for the synthesis of other advanced materials, such as magnesium-based alloys, ceramics, and composite materials. It is used in processes like nitridation and as a source of nitrogen in various chemical reactions.

- Properties and characterization of magnesium nitride: Research focuses on studying and characterizing the physical, chemical, and electronic properties of magnesium nitride. This includes investigations into its crystal structure, thermal stability, electrical conductivity, and optical properties, which are crucial for optimizing its use in various applications.

02 Applications in semiconductor devices

Magnesium nitride is utilized in the fabrication of semiconductor devices, particularly in the production of light-emitting diodes (LEDs) and other optoelectronic components. It serves as a buffer layer, electron-blocking layer, or dopant in various semiconductor structures to enhance device performance.Expand Specific Solutions03 Use in energy storage and conversion

Magnesium nitride finds applications in energy storage and conversion technologies. It is investigated as a potential material for hydrogen storage, as an electrode material in batteries, and as a catalyst in various energy-related reactions. Its properties are exploited to improve the efficiency and performance of these systems.Expand Specific Solutions04 Magnesium nitride-based composites and coatings

Composite materials and coatings incorporating magnesium nitride are developed for various applications. These composites exhibit enhanced mechanical, thermal, or electrical properties compared to pure magnesium nitride. The coatings provide protection against corrosion, wear, or other environmental factors.Expand Specific Solutions05 Purification and characterization techniques

Methods for purifying and characterizing magnesium nitride are described. These include techniques for removing impurities, analyzing composition and structure, and determining physical and chemical properties. Advanced analytical tools and procedures are employed to ensure high-quality magnesium nitride for various applications.Expand Specific Solutions

Key Players in Mg3N2 and Plasma Industry

The application of magnesium nitride in plasma technologies is an emerging field, currently in its early development stages. The market size is relatively small but growing, driven by increasing demand for advanced materials in semiconductor and electronics industries. The technology's maturity is still evolving, with research institutions like Tohoku University and Centre National de la Recherche Scientifique leading fundamental studies. Companies such as Tokyo Electron Ltd. and Applied Materials, Inc. are exploring potential industrial applications, while specialized firms like SPTS Technologies Ltd. are developing plasma-based processes that could incorporate magnesium nitride. The competitive landscape is characterized by a mix of academic research, established semiconductor equipment manufacturers, and innovative materials companies, indicating a dynamic and collaborative environment for technological advancement.

Tokyo Electron Ltd.

Technical Solution: Tokyo Electron (TEL) has developed plasma processing equipment that can be adapted for magnesium nitride applications. Their TACTRAS™ platform utilizes a unique radial line slot antenna (RLSA) to generate high-density plasma, which can be used for depositing magnesium nitride films with excellent uniformity and low damage[4]. TEL has also explored the use of pulsed plasma techniques in their systems, which could potentially enhance the deposition of magnesium nitride by providing better control over ion energy and reducing plasma-induced damage[5]. Additionally, the company's ALD systems, such as the NT333™, could be modified to deposit ultra-thin magnesium nitride films for advanced semiconductor applications[6].

Strengths: Innovative plasma generation technology, expertise in pulsed plasma techniques, and potential for precise atomic layer deposition. Weaknesses: May require further optimization for specific magnesium nitride applications and integration with existing semiconductor processes.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced plasma-enhanced chemical vapor deposition (PECVD) systems that can potentially utilize magnesium nitride in plasma applications. Their Endura® platform incorporates a high-density plasma source capable of depositing various nitride films, including magnesium nitride, with precise control over film composition and thickness[1]. The company's proprietary hollow cathode magnetron technology enables the creation of high-density plasma, which is crucial for the efficient deposition of magnesium nitride films[2]. Applied Materials has also explored the use of magnesium nitride as a potential buffer layer in GaN-based devices, leveraging its plasma expertise to optimize the deposition process and improve device performance[3].

Strengths: Advanced PECVD technology, precise control over film properties, and extensive experience in plasma processing. Weaknesses: Potential challenges in scaling up magnesium nitride deposition for large-area applications and optimizing process parameters for specific device requirements.

Core Innovations in Mg3N2 for Plasma Use

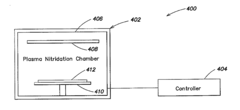

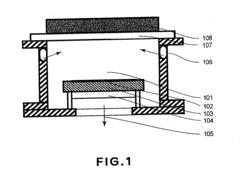

Methods and apparatus for incorporating nitrogen in oxide films

PatentActiveUS20110168093A1

Innovation

- Preconditioning a process chamber with an aggressive plasma at least 150% higher than the plasma power used during nitridation, followed by plasma nitridation, to enhance nitrogen incorporation consistency and reduce device-to-device variations.

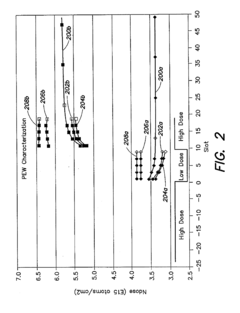

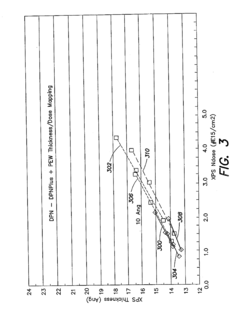

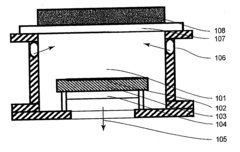

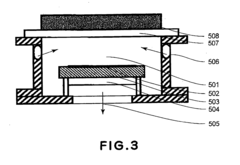

Plasma nitriding method

PatentInactiveUS20050196973A1

Innovation

- A plasma nitriding method involving a gas containing nitrogen and hydrogen atoms, with a predetermined pressure of at least 2 Torr and a spacing between the substrate and the densest plasma portion of 75 mm or more, which results in NH4+ ion dominant nitriding, reducing electron temperature and injected ion energy, allowing for the production of ultra-thin oxide-nitride films with a half-value depth of 0.8 nm or less.

Safety and Environmental Considerations

The application of magnesium nitride in plasma technologies necessitates careful consideration of safety and environmental factors. Magnesium nitride, while offering promising potential in plasma applications, presents unique challenges that must be addressed to ensure safe and sustainable use.

From a safety perspective, magnesium nitride can be reactive when exposed to moisture or air, potentially leading to the formation of ammonia and magnesium hydroxide. This reactivity requires stringent handling protocols and storage conditions to prevent unintended reactions. Workers involved in the production, handling, or application of magnesium nitride must be equipped with appropriate personal protective equipment (PPE) and trained in proper safety procedures.

The potential for dust formation during the handling of magnesium nitride powder also poses respiratory risks. Implementing effective dust control measures, such as enclosed systems and proper ventilation, is crucial to minimize exposure. Regular air quality monitoring in work areas where magnesium nitride is used or processed should be conducted to ensure compliance with occupational exposure limits.

Environmental considerations are equally important when applying magnesium nitride in plasma applications. The production process of magnesium nitride may involve energy-intensive steps, contributing to carbon emissions. Efforts to optimize production efficiency and explore cleaner energy sources can help mitigate this environmental impact. Additionally, the potential release of nitrogen compounds during plasma processes involving magnesium nitride must be carefully managed to prevent air and water pollution.

Waste management is another critical aspect of environmental stewardship. Proper disposal or recycling of magnesium nitride-containing materials and by-products is essential to prevent soil and water contamination. Developing closed-loop systems that allow for the recovery and reuse of magnesium nitride can significantly reduce waste generation and resource consumption.

The long-term environmental effects of magnesium nitride in plasma applications are not yet fully understood. Ongoing research is needed to assess its potential impacts on ecosystems and human health. This includes studying the fate and behavior of magnesium nitride and its derivatives in the environment, as well as evaluating any potential bioaccumulation or ecotoxicological effects.

Regulatory compliance is a key consideration in the application of magnesium nitride in plasma technologies. Adhering to relevant environmental regulations, such as those governing air emissions, water discharges, and hazardous waste management, is crucial. Companies working with magnesium nitride should stay informed about evolving regulatory requirements and proactively implement best practices to ensure compliance and minimize environmental risks.

From a safety perspective, magnesium nitride can be reactive when exposed to moisture or air, potentially leading to the formation of ammonia and magnesium hydroxide. This reactivity requires stringent handling protocols and storage conditions to prevent unintended reactions. Workers involved in the production, handling, or application of magnesium nitride must be equipped with appropriate personal protective equipment (PPE) and trained in proper safety procedures.

The potential for dust formation during the handling of magnesium nitride powder also poses respiratory risks. Implementing effective dust control measures, such as enclosed systems and proper ventilation, is crucial to minimize exposure. Regular air quality monitoring in work areas where magnesium nitride is used or processed should be conducted to ensure compliance with occupational exposure limits.

Environmental considerations are equally important when applying magnesium nitride in plasma applications. The production process of magnesium nitride may involve energy-intensive steps, contributing to carbon emissions. Efforts to optimize production efficiency and explore cleaner energy sources can help mitigate this environmental impact. Additionally, the potential release of nitrogen compounds during plasma processes involving magnesium nitride must be carefully managed to prevent air and water pollution.

Waste management is another critical aspect of environmental stewardship. Proper disposal or recycling of magnesium nitride-containing materials and by-products is essential to prevent soil and water contamination. Developing closed-loop systems that allow for the recovery and reuse of magnesium nitride can significantly reduce waste generation and resource consumption.

The long-term environmental effects of magnesium nitride in plasma applications are not yet fully understood. Ongoing research is needed to assess its potential impacts on ecosystems and human health. This includes studying the fate and behavior of magnesium nitride and its derivatives in the environment, as well as evaluating any potential bioaccumulation or ecotoxicological effects.

Regulatory compliance is a key consideration in the application of magnesium nitride in plasma technologies. Adhering to relevant environmental regulations, such as those governing air emissions, water discharges, and hazardous waste management, is crucial. Companies working with magnesium nitride should stay informed about evolving regulatory requirements and proactively implement best practices to ensure compliance and minimize environmental risks.

Economic Viability of Mg3N2 in Plasma Applications

The economic viability of magnesium nitride (Mg3N2) in plasma applications is a critical factor in determining its potential for widespread adoption. The cost-effectiveness of Mg3N2 must be evaluated against alternative materials and technologies currently used in plasma processes.

One of the primary advantages of Mg3N2 is its relatively low cost compared to other nitrogen-rich compounds. The raw materials for producing Mg3N2, primarily magnesium and nitrogen, are abundant and readily available. This abundance contributes to the potential for cost-effective large-scale production, which is crucial for industrial plasma applications.

However, the economic viability of Mg3N2 in plasma applications also depends on its performance characteristics. While Mg3N2 shows promise in enhancing plasma properties, such as increased electron density and improved energy efficiency, these benefits must translate into tangible economic advantages. For instance, if the use of Mg3N2 results in significantly reduced energy consumption or increased process efficiency, it could justify higher initial material costs.

The durability and lifespan of Mg3N2 in plasma environments are also crucial factors in its economic viability. If Mg3N2 demonstrates superior resistance to degradation under plasma conditions compared to current materials, it could lead to reduced maintenance costs and longer operational periods between replacements. This longevity would contribute positively to its overall economic value proposition.

Another aspect to consider is the potential for Mg3N2 to enable new or improved plasma applications. If its unique properties allow for the development of novel plasma-based processes or products, the economic benefits could extend beyond mere cost savings to include new revenue streams and market opportunities.

The scalability of Mg3N2 production and integration into existing plasma systems is also a key economic consideration. If significant modifications to current plasma equipment or manufacturing processes are required to incorporate Mg3N2, it could impact its economic viability. Conversely, if Mg3N2 can be easily integrated into existing systems with minimal modifications, it would enhance its economic attractiveness.

Lastly, regulatory factors and environmental considerations play a role in the economic viability of Mg3N2 in plasma applications. If the use of Mg3N2 leads to reduced environmental impact or helps meet stricter regulatory standards, it could provide additional economic incentives for its adoption, particularly in industries facing increasing environmental scrutiny.

One of the primary advantages of Mg3N2 is its relatively low cost compared to other nitrogen-rich compounds. The raw materials for producing Mg3N2, primarily magnesium and nitrogen, are abundant and readily available. This abundance contributes to the potential for cost-effective large-scale production, which is crucial for industrial plasma applications.

However, the economic viability of Mg3N2 in plasma applications also depends on its performance characteristics. While Mg3N2 shows promise in enhancing plasma properties, such as increased electron density and improved energy efficiency, these benefits must translate into tangible economic advantages. For instance, if the use of Mg3N2 results in significantly reduced energy consumption or increased process efficiency, it could justify higher initial material costs.

The durability and lifespan of Mg3N2 in plasma environments are also crucial factors in its economic viability. If Mg3N2 demonstrates superior resistance to degradation under plasma conditions compared to current materials, it could lead to reduced maintenance costs and longer operational periods between replacements. This longevity would contribute positively to its overall economic value proposition.

Another aspect to consider is the potential for Mg3N2 to enable new or improved plasma applications. If its unique properties allow for the development of novel plasma-based processes or products, the economic benefits could extend beyond mere cost savings to include new revenue streams and market opportunities.

The scalability of Mg3N2 production and integration into existing plasma systems is also a key economic consideration. If significant modifications to current plasma equipment or manufacturing processes are required to incorporate Mg3N2, it could impact its economic viability. Conversely, if Mg3N2 can be easily integrated into existing systems with minimal modifications, it would enhance its economic attractiveness.

Lastly, regulatory factors and environmental considerations play a role in the economic viability of Mg3N2 in plasma applications. If the use of Mg3N2 leads to reduced environmental impact or helps meet stricter regulatory standards, it could provide additional economic incentives for its adoption, particularly in industries facing increasing environmental scrutiny.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!