How to Enhance Chemical Vapor Deposition with Magnesium Nitride?

AUG 1, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CVD with MgN Background

Chemical Vapor Deposition (CVD) has been a cornerstone technique in materials science and semiconductor manufacturing for decades. The process involves the deposition of thin films on various substrates through chemical reactions of vapor-phase precursors. In recent years, there has been growing interest in enhancing CVD processes using novel materials, with magnesium nitride (Mg3N2) emerging as a promising candidate.

The exploration of magnesium nitride in CVD processes stems from its unique properties and potential applications. Mg3N2 is a wide-bandgap semiconductor with a high melting point and excellent thermal stability. These characteristics make it an attractive material for use in optoelectronic devices, protective coatings, and as a precursor for other nitride-based compounds.

The integration of magnesium nitride into CVD processes aims to address several challenges in thin film deposition. Traditional CVD methods often struggle with achieving uniform film thickness, controlling film composition, and depositing at lower temperatures. By incorporating Mg3N2, researchers hope to overcome these limitations and expand the capabilities of CVD technology.

One of the primary goals in enhancing CVD with magnesium nitride is to improve the quality and properties of deposited films. Mg3N2 has shown potential in facilitating the growth of smoother, more uniform films with enhanced electrical and optical properties. This is particularly valuable in the production of advanced electronic and photonic devices, where film quality directly impacts device performance.

Furthermore, the use of magnesium nitride in CVD processes opens up new possibilities for the synthesis of complex nitride materials. By combining Mg3N2 with other precursors, it becomes possible to create novel ternary and quaternary nitride compounds with tailored properties. This versatility is crucial for developing next-generation materials for various applications, including energy storage, catalysis, and quantum computing.

The evolution of CVD technology with magnesium nitride also aligns with the broader trend towards more sustainable and environmentally friendly manufacturing processes. Mg3N2-enhanced CVD has the potential to reduce process temperatures and precursor consumption, leading to more energy-efficient and cost-effective production methods. This aspect is particularly relevant in the context of increasing environmental regulations and the push for greener technologies across industries.

The exploration of magnesium nitride in CVD processes stems from its unique properties and potential applications. Mg3N2 is a wide-bandgap semiconductor with a high melting point and excellent thermal stability. These characteristics make it an attractive material for use in optoelectronic devices, protective coatings, and as a precursor for other nitride-based compounds.

The integration of magnesium nitride into CVD processes aims to address several challenges in thin film deposition. Traditional CVD methods often struggle with achieving uniform film thickness, controlling film composition, and depositing at lower temperatures. By incorporating Mg3N2, researchers hope to overcome these limitations and expand the capabilities of CVD technology.

One of the primary goals in enhancing CVD with magnesium nitride is to improve the quality and properties of deposited films. Mg3N2 has shown potential in facilitating the growth of smoother, more uniform films with enhanced electrical and optical properties. This is particularly valuable in the production of advanced electronic and photonic devices, where film quality directly impacts device performance.

Furthermore, the use of magnesium nitride in CVD processes opens up new possibilities for the synthesis of complex nitride materials. By combining Mg3N2 with other precursors, it becomes possible to create novel ternary and quaternary nitride compounds with tailored properties. This versatility is crucial for developing next-generation materials for various applications, including energy storage, catalysis, and quantum computing.

The evolution of CVD technology with magnesium nitride also aligns with the broader trend towards more sustainable and environmentally friendly manufacturing processes. Mg3N2-enhanced CVD has the potential to reduce process temperatures and precursor consumption, leading to more energy-efficient and cost-effective production methods. This aspect is particularly relevant in the context of increasing environmental regulations and the push for greener technologies across industries.

Market Analysis for MgN CVD

The market for Chemical Vapor Deposition (CVD) with Magnesium Nitride (MgN) is experiencing significant growth, driven by the increasing demand for advanced semiconductor devices and optoelectronic components. The global CVD market, which encompasses MgN CVD, is projected to expand at a steady rate over the next five years, with a particular focus on applications in the electronics and photonics industries.

The demand for MgN CVD is primarily fueled by its potential to enhance the performance of various electronic devices, including high-power transistors, light-emitting diodes (LEDs), and solar cells. The unique properties of magnesium nitride, such as its wide bandgap and high thermal conductivity, make it an attractive material for these applications. As the electronics industry continues to push for miniaturization and improved efficiency, the market for MgN CVD is expected to grow in tandem.

In the semiconductor sector, MgN CVD is gaining traction as a potential alternative to traditional materials like gallium nitride (GaN) for power electronics applications. The ability of MgN to operate at higher temperatures and voltages compared to GaN is driving research and development efforts in this area. This trend is likely to create new opportunities for MgN CVD in the power electronics market, particularly in electric vehicles and renewable energy systems.

The optoelectronics industry is another key driver for MgN CVD market growth. The material's wide bandgap properties make it suitable for use in UV-emitting devices and high-efficiency LEDs. As the demand for energy-efficient lighting solutions and advanced display technologies continues to rise, the market for MgN CVD in this sector is expected to expand significantly.

Geographically, Asia-Pacific is anticipated to be the largest and fastest-growing market for MgN CVD, owing to the region's dominant position in semiconductor manufacturing and electronics production. Countries like China, South Korea, and Taiwan are investing heavily in advanced semiconductor technologies, which is likely to boost the adoption of MgN CVD in the region.

However, the market for MgN CVD also faces certain challenges. The high cost of equipment and materials associated with the CVD process remains a significant barrier to widespread adoption. Additionally, the complexity of the MgN CVD process and the need for precise control over deposition parameters present technical challenges that need to be addressed to expand market penetration.

Despite these challenges, the overall outlook for the MgN CVD market remains positive. The growing emphasis on renewable energy and the increasing adoption of electric vehicles are expected to create new opportunities for MgN-based power electronics. Furthermore, ongoing research into novel applications of MgN in quantum computing and advanced photonics could potentially open up new market segments in the future.

The demand for MgN CVD is primarily fueled by its potential to enhance the performance of various electronic devices, including high-power transistors, light-emitting diodes (LEDs), and solar cells. The unique properties of magnesium nitride, such as its wide bandgap and high thermal conductivity, make it an attractive material for these applications. As the electronics industry continues to push for miniaturization and improved efficiency, the market for MgN CVD is expected to grow in tandem.

In the semiconductor sector, MgN CVD is gaining traction as a potential alternative to traditional materials like gallium nitride (GaN) for power electronics applications. The ability of MgN to operate at higher temperatures and voltages compared to GaN is driving research and development efforts in this area. This trend is likely to create new opportunities for MgN CVD in the power electronics market, particularly in electric vehicles and renewable energy systems.

The optoelectronics industry is another key driver for MgN CVD market growth. The material's wide bandgap properties make it suitable for use in UV-emitting devices and high-efficiency LEDs. As the demand for energy-efficient lighting solutions and advanced display technologies continues to rise, the market for MgN CVD in this sector is expected to expand significantly.

Geographically, Asia-Pacific is anticipated to be the largest and fastest-growing market for MgN CVD, owing to the region's dominant position in semiconductor manufacturing and electronics production. Countries like China, South Korea, and Taiwan are investing heavily in advanced semiconductor technologies, which is likely to boost the adoption of MgN CVD in the region.

However, the market for MgN CVD also faces certain challenges. The high cost of equipment and materials associated with the CVD process remains a significant barrier to widespread adoption. Additionally, the complexity of the MgN CVD process and the need for precise control over deposition parameters present technical challenges that need to be addressed to expand market penetration.

Despite these challenges, the overall outlook for the MgN CVD market remains positive. The growing emphasis on renewable energy and the increasing adoption of electric vehicles are expected to create new opportunities for MgN-based power electronics. Furthermore, ongoing research into novel applications of MgN in quantum computing and advanced photonics could potentially open up new market segments in the future.

MgN CVD Challenges

Chemical Vapor Deposition (CVD) with Magnesium Nitride (MgN) faces several significant challenges that hinder its widespread adoption and efficiency. One of the primary obstacles is the high reactivity of magnesium with oxygen and moisture, which necessitates stringent control of the deposition environment. This reactivity often leads to the formation of undesired magnesium oxide or hydroxide compounds, compromising the quality and purity of the MgN films.

Another major challenge lies in the precise control of stoichiometry during the deposition process. Achieving the correct ratio of magnesium to nitrogen in the deposited film is crucial for obtaining the desired properties of MgN. However, the volatility of magnesium and the tendency of nitrogen to form molecular N2 make it difficult to maintain the optimal balance throughout the deposition process.

Temperature control presents another significant hurdle in MgN CVD. The process typically requires high temperatures to achieve sufficient vapor pressure of magnesium precursors and to promote the desired chemical reactions. However, these elevated temperatures can lead to thermal stress in the substrate and deposited film, potentially causing defects, cracking, or delamination.

The choice of suitable precursors for MgN CVD is also a critical challenge. Many conventional magnesium precursors are either too reactive or have low vapor pressures, limiting their effectiveness in CVD processes. Developing new precursors that offer a balance between reactivity and stability, while maintaining high vapor pressure at reasonable temperatures, remains an ongoing area of research.

Uniformity and conformality of the deposited MgN films pose additional challenges, especially for complex substrate geometries. Achieving uniform thickness and composition across large areas or within high-aspect-ratio structures requires careful optimization of process parameters, including gas flow dynamics, precursor distribution, and substrate temperature uniformity.

The integration of MgN films with other materials and device structures presents further complications. Issues such as interfacial reactions, thermal expansion mismatches, and adhesion problems need to be addressed to ensure the compatibility and reliability of MgN layers in various applications.

Lastly, the scalability of MgN CVD processes for industrial applications remains a significant challenge. Translating laboratory-scale successes to large-area deposition systems while maintaining film quality, uniformity, and process efficiency is crucial for the commercial viability of MgN-based technologies.

Another major challenge lies in the precise control of stoichiometry during the deposition process. Achieving the correct ratio of magnesium to nitrogen in the deposited film is crucial for obtaining the desired properties of MgN. However, the volatility of magnesium and the tendency of nitrogen to form molecular N2 make it difficult to maintain the optimal balance throughout the deposition process.

Temperature control presents another significant hurdle in MgN CVD. The process typically requires high temperatures to achieve sufficient vapor pressure of magnesium precursors and to promote the desired chemical reactions. However, these elevated temperatures can lead to thermal stress in the substrate and deposited film, potentially causing defects, cracking, or delamination.

The choice of suitable precursors for MgN CVD is also a critical challenge. Many conventional magnesium precursors are either too reactive or have low vapor pressures, limiting their effectiveness in CVD processes. Developing new precursors that offer a balance between reactivity and stability, while maintaining high vapor pressure at reasonable temperatures, remains an ongoing area of research.

Uniformity and conformality of the deposited MgN films pose additional challenges, especially for complex substrate geometries. Achieving uniform thickness and composition across large areas or within high-aspect-ratio structures requires careful optimization of process parameters, including gas flow dynamics, precursor distribution, and substrate temperature uniformity.

The integration of MgN films with other materials and device structures presents further complications. Issues such as interfacial reactions, thermal expansion mismatches, and adhesion problems need to be addressed to ensure the compatibility and reliability of MgN layers in various applications.

Lastly, the scalability of MgN CVD processes for industrial applications remains a significant challenge. Translating laboratory-scale successes to large-area deposition systems while maintaining film quality, uniformity, and process efficiency is crucial for the commercial viability of MgN-based technologies.

Current MgN CVD Methods

01 Precursor and gas flow optimization

Enhancing chemical vapor deposition (CVD) processes by optimizing precursor and gas flow rates. This includes controlling the introduction of reactants, carrier gases, and dopants to improve deposition uniformity, film quality, and growth rate. Advanced gas delivery systems and flow controllers are utilized to achieve precise control over the deposition environment.- Precursor and gas flow optimization: Enhancing chemical vapor deposition (CVD) processes by optimizing precursor and gas flow rates. This involves controlling the introduction of reactant gases, adjusting flow patterns, and managing gas ratios to improve deposition uniformity and efficiency.

- Temperature and pressure control: Improving CVD processes through precise temperature and pressure management. This includes developing advanced heating systems, implementing temperature gradients, and controlling chamber pressure to enhance deposition rates and film quality.

- Plasma-enhanced CVD techniques: Utilizing plasma to enhance CVD processes, allowing for lower deposition temperatures and improved film properties. This involves optimizing plasma power, frequency, and gas composition to achieve desired film characteristics and deposition rates.

- Substrate surface modification: Enhancing CVD processes by modifying substrate surfaces prior to deposition. This includes cleaning techniques, surface activation methods, and the application of seed layers to improve film adhesion and growth.

- In-situ monitoring and process control: Implementing real-time monitoring and feedback systems to enhance CVD processes. This involves using sensors, spectroscopic techniques, and advanced control algorithms to optimize deposition parameters and ensure consistent film quality.

02 Temperature and pressure control

Improving CVD processes through precise temperature and pressure management within the deposition chamber. This involves using advanced heating systems, temperature sensors, and pressure regulators to maintain optimal conditions for film growth. Techniques such as rapid thermal processing and pulsed pressure variations are employed to enhance deposition characteristics and film properties.Expand Specific Solutions03 Plasma-enhanced CVD techniques

Utilizing plasma to enhance the CVD process, allowing for lower deposition temperatures and improved film properties. This technique involves the generation of reactive species through plasma excitation, which can lead to better film adhesion, density, and conformality. Various plasma sources and power delivery methods are employed to optimize the deposition process.Expand Specific Solutions04 Substrate surface preparation and modification

Enhancing CVD processes through proper substrate preparation and surface modification techniques. This includes cleaning procedures, surface activation methods, and the use of seed layers or nucleation sites to promote uniform film growth. Advanced surface treatments are employed to improve film adhesion and control the initial stages of deposition.Expand Specific Solutions05 In-situ monitoring and process control

Implementing real-time monitoring and feedback control systems to enhance CVD processes. This involves the use of various analytical techniques such as spectroscopy, interferometry, and mass spectrometry to monitor film growth, composition, and properties during deposition. Advanced control algorithms are employed to adjust process parameters dynamically, ensuring optimal deposition conditions throughout the process.Expand Specific Solutions

MgN CVD Industry Players

The chemical vapor deposition (CVD) enhancement with magnesium nitride is in an early development stage, with a growing market potential due to increasing demand for advanced semiconductor materials. The technology's maturity is still evolving, as evidenced by ongoing research at institutions like Nanchang University and Central South University. Industry leaders such as Applied Materials, Inc., ASM International NV, and GLOBALFOUNDRIES, Inc. are actively exploring this field, indicating its strategic importance. The competitive landscape is diverse, with both established semiconductor companies and specialized materials firms like Air Products & Chemicals, Inc. vying for market share. As the technology progresses, we can expect increased collaboration between academia and industry to drive innovation and commercialization.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed an advanced Chemical Vapor Deposition (CVD) process incorporating magnesium nitride to enhance thin film deposition. Their technique utilizes a specialized precursor delivery system that precisely controls the introduction of magnesium and nitrogen sources into the reaction chamber[1]. This process allows for the formation of high-quality magnesium nitride layers with improved uniformity and reduced defects. The company has also implemented in-situ plasma treatment to activate the surface and promote better adhesion of the magnesium nitride film[3]. Additionally, they have integrated real-time monitoring systems to optimize deposition parameters, resulting in enhanced film properties and increased throughput[5].

Strengths: Precise control over film composition and thickness, improved film quality, and increased production efficiency. Weaknesses: Potentially higher equipment costs and complexity in process control.

ASM International NV

Technical Solution: ASM International has innovated in enhancing CVD with magnesium nitride through their Atomic Layer Deposition (ALD) technology. Their approach involves alternating pulses of magnesium and nitrogen precursors, allowing for atomic-level control of film growth[2]. This method enables the deposition of ultra-thin, conformal magnesium nitride layers with excellent step coverage, even on complex 3D structures. ASM has also developed a unique precursor chemistry that enhances the reactivity of magnesium with nitrogen, leading to improved film density and reduced impurities[4]. Furthermore, they have implemented advanced plasma-enhanced ALD techniques to lower deposition temperatures, making the process compatible with a wider range of substrates[6].

Strengths: Exceptional control over film thickness and composition, superior conformality on complex structures. Weaknesses: Slower deposition rates compared to traditional CVD, potentially limiting throughput for thicker films.

Key MgN CVD Innovations

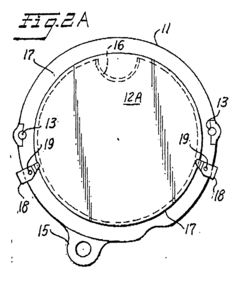

Plasma enhanced chemical vapor deposition/etching improved uniformity by electrode modifications

PatentInactiveEP0416982A3

Innovation

- A new electrode design featuring a reduced thickness circumferential region with notched or mesa-like structures to enhance electric field density and triangular-shaped support pins to minimize shadow effects, ensuring uniform coating or etching across the wafer surface.

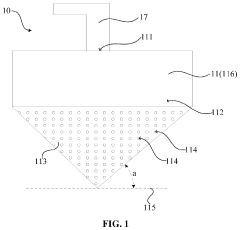

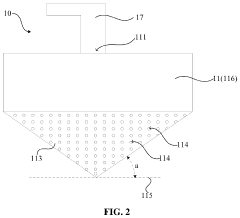

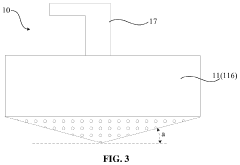

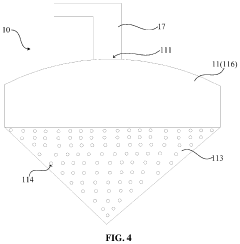

Spray head, chemical vapor deposition device, and working method of chemical vapor deposition device

PatentInactiveUS20220049355A1

Innovation

- A spray head with a specially designed air outlet panel having a conical surface where the middle portion is farther away from the first end than the edge portion, improving film uniformity by adjusting the thickness distribution during the deposition process.

MgN CVD Safety Protocols

Chemical Vapor Deposition (CVD) with Magnesium Nitride (MgN) is a powerful technique for creating thin films and coatings, but it requires stringent safety protocols to ensure the well-being of operators and the integrity of the process. The primary safety concerns stem from the reactivity of magnesium and the potential for nitrogen gas release.

Proper personal protective equipment (PPE) is essential for all personnel involved in MgN CVD processes. This includes flame-resistant lab coats, safety goggles, and chemical-resistant gloves. Respiratory protection may also be necessary, depending on the specific process parameters and potential for gas release.

The CVD chamber must be equipped with robust safety features, including emergency shut-off systems, pressure relief valves, and gas detection sensors. Regular maintenance and calibration of these safety systems are crucial to ensure their reliability. The chamber should also be housed in a well-ventilated area with appropriate fume extraction systems to manage any potential gas leaks.

Handling and storage of magnesium precursors require special attention. These materials should be kept in sealed containers in a cool, dry environment, away from sources of ignition. Proper labeling and segregation from incompatible materials are essential to prevent accidental reactions.

Training is a critical component of MgN CVD safety protocols. All personnel involved in the process should receive comprehensive training on the hazards associated with the materials and equipment, as well as proper operating procedures and emergency response protocols. Regular refresher courses and safety drills should be conducted to maintain a high level of preparedness.

Waste management is another crucial aspect of MgN CVD safety. Proper disposal procedures for spent precursors, byproducts, and contaminated materials must be established and strictly followed. This may involve neutralization, containment, or specialized disposal services, depending on the nature of the waste.

Emergency response plans should be developed and regularly reviewed. These plans should cover scenarios such as fires, gas leaks, and equipment malfunctions. Clear evacuation routes and assembly points must be established and communicated to all personnel.

Monitoring and documentation play a vital role in maintaining safety standards. Regular safety audits, equipment inspections, and process reviews should be conducted and documented. Any incidents or near-misses should be thoroughly investigated, with lessons learned incorporated into updated safety protocols.

By implementing and adhering to these comprehensive safety protocols, the risks associated with MgN CVD can be effectively managed, allowing for the safe and efficient enhancement of this valuable deposition technique.

Proper personal protective equipment (PPE) is essential for all personnel involved in MgN CVD processes. This includes flame-resistant lab coats, safety goggles, and chemical-resistant gloves. Respiratory protection may also be necessary, depending on the specific process parameters and potential for gas release.

The CVD chamber must be equipped with robust safety features, including emergency shut-off systems, pressure relief valves, and gas detection sensors. Regular maintenance and calibration of these safety systems are crucial to ensure their reliability. The chamber should also be housed in a well-ventilated area with appropriate fume extraction systems to manage any potential gas leaks.

Handling and storage of magnesium precursors require special attention. These materials should be kept in sealed containers in a cool, dry environment, away from sources of ignition. Proper labeling and segregation from incompatible materials are essential to prevent accidental reactions.

Training is a critical component of MgN CVD safety protocols. All personnel involved in the process should receive comprehensive training on the hazards associated with the materials and equipment, as well as proper operating procedures and emergency response protocols. Regular refresher courses and safety drills should be conducted to maintain a high level of preparedness.

Waste management is another crucial aspect of MgN CVD safety. Proper disposal procedures for spent precursors, byproducts, and contaminated materials must be established and strictly followed. This may involve neutralization, containment, or specialized disposal services, depending on the nature of the waste.

Emergency response plans should be developed and regularly reviewed. These plans should cover scenarios such as fires, gas leaks, and equipment malfunctions. Clear evacuation routes and assembly points must be established and communicated to all personnel.

Monitoring and documentation play a vital role in maintaining safety standards. Regular safety audits, equipment inspections, and process reviews should be conducted and documented. Any incidents or near-misses should be thoroughly investigated, with lessons learned incorporated into updated safety protocols.

By implementing and adhering to these comprehensive safety protocols, the risks associated with MgN CVD can be effectively managed, allowing for the safe and efficient enhancement of this valuable deposition technique.

MgN CVD Scalability

The scalability of Chemical Vapor Deposition (CVD) with Magnesium Nitride (MgN) is a critical factor in its potential industrial applications. As the demand for high-quality MgN thin films grows, the ability to scale up the CVD process becomes increasingly important. Current research indicates that MgN CVD can be scaled up to produce larger area films, but several challenges need to be addressed.

One of the primary considerations in scaling up MgN CVD is the uniformity of film deposition across larger substrates. As the substrate size increases, maintaining consistent film thickness and composition becomes more challenging. This is partly due to the difficulty in achieving uniform gas flow and temperature distribution across larger deposition chambers. Advanced gas flow modeling and chamber design optimization are being explored to mitigate these issues.

Another key aspect of scalability is the deposition rate. While MgN CVD can produce high-quality films, the deposition rate is often slower compared to other CVD processes. Increasing the deposition rate without compromising film quality is crucial for industrial-scale production. Researchers are investigating various approaches, including the use of plasma-enhanced CVD and the optimization of precursor chemistry to achieve higher growth rates.

The choice of precursors also plays a significant role in the scalability of MgN CVD. Traditional precursors may not be suitable for large-scale production due to cost, safety, or handling issues. Development of new, more efficient precursors that are easier to handle and less expensive is an active area of research. These efforts aim to make the process more economically viable for industrial applications.

Temperature control is another critical factor in scaling up MgN CVD. Maintaining uniform temperature across larger substrates is challenging but essential for consistent film properties. Advanced heating systems and temperature monitoring techniques are being developed to address this issue. Some researchers are exploring the potential of low-temperature CVD processes for MgN, which could simplify temperature control in large-scale systems.

Lastly, the integration of in-situ monitoring and control systems is becoming increasingly important for scalable MgN CVD processes. Real-time monitoring of film growth and composition allows for better process control and consistency in large-scale production. Techniques such as spectroscopic ellipsometry and mass spectrometry are being adapted for use in industrial-scale CVD systems.

One of the primary considerations in scaling up MgN CVD is the uniformity of film deposition across larger substrates. As the substrate size increases, maintaining consistent film thickness and composition becomes more challenging. This is partly due to the difficulty in achieving uniform gas flow and temperature distribution across larger deposition chambers. Advanced gas flow modeling and chamber design optimization are being explored to mitigate these issues.

Another key aspect of scalability is the deposition rate. While MgN CVD can produce high-quality films, the deposition rate is often slower compared to other CVD processes. Increasing the deposition rate without compromising film quality is crucial for industrial-scale production. Researchers are investigating various approaches, including the use of plasma-enhanced CVD and the optimization of precursor chemistry to achieve higher growth rates.

The choice of precursors also plays a significant role in the scalability of MgN CVD. Traditional precursors may not be suitable for large-scale production due to cost, safety, or handling issues. Development of new, more efficient precursors that are easier to handle and less expensive is an active area of research. These efforts aim to make the process more economically viable for industrial applications.

Temperature control is another critical factor in scaling up MgN CVD. Maintaining uniform temperature across larger substrates is challenging but essential for consistent film properties. Advanced heating systems and temperature monitoring techniques are being developed to address this issue. Some researchers are exploring the potential of low-temperature CVD processes for MgN, which could simplify temperature control in large-scale systems.

Lastly, the integration of in-situ monitoring and control systems is becoming increasingly important for scalable MgN CVD processes. Real-time monitoring of film growth and composition allows for better process control and consistency in large-scale production. Techniques such as spectroscopic ellipsometry and mass spectrometry are being adapted for use in industrial-scale CVD systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!