How Magnesium Nitride Reinforces Structural Integrity in Manufacturing?

AUG 1, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg3N2 in Manufacturing

Magnesium nitride (Mg3N2) has emerged as a promising material in manufacturing due to its unique properties and potential to enhance structural integrity. This compound, formed by the reaction of magnesium with nitrogen, exhibits a high melting point, excellent thermal stability, and remarkable mechanical strength. These characteristics make it particularly suitable for applications in high-temperature environments and structural reinforcement.

In the manufacturing sector, Mg3N2 is increasingly being utilized as a reinforcing agent in composite materials. When incorporated into metal matrix composites, it significantly improves the overall strength-to-weight ratio, a critical factor in industries such as aerospace and automotive manufacturing. The addition of Mg3N2 particles to aluminum or magnesium alloys, for instance, results in enhanced mechanical properties, including increased tensile strength and improved wear resistance.

One of the key mechanisms by which Mg3N2 reinforces structural integrity is through its role in grain refinement. When introduced into molten metals during the casting process, Mg3N2 particles act as nucleation sites for crystal formation. This leads to a finer grain structure in the solidified material, which in turn contributes to improved strength and ductility. The refined microstructure also enhances the material's resistance to crack propagation, thereby increasing its overall durability and lifespan.

Furthermore, Mg3N2 has shown promise in the field of ceramic matrix composites. Its high thermal stability makes it an excellent candidate for reinforcing ceramics used in high-temperature applications. The incorporation of Mg3N2 into ceramic matrices can lead to improved fracture toughness and thermal shock resistance, critical properties for components used in extreme environments such as gas turbines or rocket engines.

In powder metallurgy, Mg3N2 is being explored as an additive to enhance the sintering process. Its presence can facilitate better bonding between metal particles during sintering, resulting in denser and stronger final products. This application is particularly relevant in the production of complex-shaped components where traditional manufacturing methods may be challenging or cost-prohibitive.

The use of Mg3N2 in manufacturing also extends to surface treatments and coatings. When applied as a thin film or coating, it can provide enhanced wear resistance and corrosion protection to underlying materials. This is especially valuable in industries where components are subjected to harsh operating conditions, such as in chemical processing or marine environments.

In the manufacturing sector, Mg3N2 is increasingly being utilized as a reinforcing agent in composite materials. When incorporated into metal matrix composites, it significantly improves the overall strength-to-weight ratio, a critical factor in industries such as aerospace and automotive manufacturing. The addition of Mg3N2 particles to aluminum or magnesium alloys, for instance, results in enhanced mechanical properties, including increased tensile strength and improved wear resistance.

One of the key mechanisms by which Mg3N2 reinforces structural integrity is through its role in grain refinement. When introduced into molten metals during the casting process, Mg3N2 particles act as nucleation sites for crystal formation. This leads to a finer grain structure in the solidified material, which in turn contributes to improved strength and ductility. The refined microstructure also enhances the material's resistance to crack propagation, thereby increasing its overall durability and lifespan.

Furthermore, Mg3N2 has shown promise in the field of ceramic matrix composites. Its high thermal stability makes it an excellent candidate for reinforcing ceramics used in high-temperature applications. The incorporation of Mg3N2 into ceramic matrices can lead to improved fracture toughness and thermal shock resistance, critical properties for components used in extreme environments such as gas turbines or rocket engines.

In powder metallurgy, Mg3N2 is being explored as an additive to enhance the sintering process. Its presence can facilitate better bonding between metal particles during sintering, resulting in denser and stronger final products. This application is particularly relevant in the production of complex-shaped components where traditional manufacturing methods may be challenging or cost-prohibitive.

The use of Mg3N2 in manufacturing also extends to surface treatments and coatings. When applied as a thin film or coating, it can provide enhanced wear resistance and corrosion protection to underlying materials. This is especially valuable in industries where components are subjected to harsh operating conditions, such as in chemical processing or marine environments.

Market Demand Analysis

The market demand for magnesium nitride in manufacturing has been steadily increasing due to its unique properties that enhance structural integrity. This compound has gained significant attention in various industrial sectors, particularly in aerospace, automotive, and construction industries, where high-strength and lightweight materials are crucial.

In the aerospace sector, the demand for magnesium nitride-reinforced composites has surged as manufacturers seek to reduce aircraft weight while maintaining or improving structural strength. This trend aligns with the industry's push towards more fuel-efficient and environmentally friendly aircraft designs. The automotive industry has also shown growing interest in magnesium nitride-based materials, driven by the need to meet stringent fuel efficiency standards and reduce vehicle emissions.

The construction industry has begun exploring the potential of magnesium nitride in reinforcing concrete and other building materials. This application aims to improve the durability and longevity of structures, especially in harsh environmental conditions. The material's resistance to corrosion and high temperature makes it particularly attractive for infrastructure projects in coastal areas or regions prone to extreme weather.

Market analysts project a compound annual growth rate (CAGR) for magnesium nitride-based products in the manufacturing sector to exceed the average growth rate of traditional reinforcement materials. This growth is attributed to the increasing awareness of the material's benefits and the ongoing research and development efforts to optimize its production and application processes.

The electronics industry has also emerged as a potential growth market for magnesium nitride. Its use in semiconductor manufacturing and as a component in advanced electronic packaging solutions has opened new avenues for market expansion. The material's thermal management properties make it valuable in high-performance computing and power electronics applications.

Despite the positive market outlook, challenges remain in scaling up production and reducing costs associated with magnesium nitride synthesis. These factors currently limit its widespread adoption across all potential application areas. However, ongoing technological advancements and increasing investment in research and development are expected to address these challenges in the coming years.

The global push towards sustainable and eco-friendly manufacturing processes has further bolstered the market demand for magnesium nitride. Its potential to replace more energy-intensive or environmentally harmful materials in certain applications aligns well with corporate sustainability goals and regulatory requirements aimed at reducing industrial carbon footprints.

In the aerospace sector, the demand for magnesium nitride-reinforced composites has surged as manufacturers seek to reduce aircraft weight while maintaining or improving structural strength. This trend aligns with the industry's push towards more fuel-efficient and environmentally friendly aircraft designs. The automotive industry has also shown growing interest in magnesium nitride-based materials, driven by the need to meet stringent fuel efficiency standards and reduce vehicle emissions.

The construction industry has begun exploring the potential of magnesium nitride in reinforcing concrete and other building materials. This application aims to improve the durability and longevity of structures, especially in harsh environmental conditions. The material's resistance to corrosion and high temperature makes it particularly attractive for infrastructure projects in coastal areas or regions prone to extreme weather.

Market analysts project a compound annual growth rate (CAGR) for magnesium nitride-based products in the manufacturing sector to exceed the average growth rate of traditional reinforcement materials. This growth is attributed to the increasing awareness of the material's benefits and the ongoing research and development efforts to optimize its production and application processes.

The electronics industry has also emerged as a potential growth market for magnesium nitride. Its use in semiconductor manufacturing and as a component in advanced electronic packaging solutions has opened new avenues for market expansion. The material's thermal management properties make it valuable in high-performance computing and power electronics applications.

Despite the positive market outlook, challenges remain in scaling up production and reducing costs associated with magnesium nitride synthesis. These factors currently limit its widespread adoption across all potential application areas. However, ongoing technological advancements and increasing investment in research and development are expected to address these challenges in the coming years.

The global push towards sustainable and eco-friendly manufacturing processes has further bolstered the market demand for magnesium nitride. Its potential to replace more energy-intensive or environmentally harmful materials in certain applications aligns well with corporate sustainability goals and regulatory requirements aimed at reducing industrial carbon footprints.

Technical Challenges

The integration of magnesium nitride in manufacturing processes to enhance structural integrity faces several significant technical challenges. One of the primary obstacles is the material's high reactivity with moisture and oxygen, which can lead to rapid degradation and loss of its reinforcing properties. This sensitivity to environmental factors necessitates the development of advanced protective coatings or encapsulation techniques to maintain the material's stability during processing and in final applications.

Another major challenge lies in the uniform dispersion of magnesium nitride within the matrix material. Achieving homogeneous distribution is crucial for optimal reinforcement, but the tendency of nanoparticles to agglomerate can result in inconsistent mechanical properties throughout the manufactured component. This issue requires innovative mixing and processing methods to ensure even distribution without compromising the material's integrity.

The high processing temperatures often required in manufacturing can pose additional difficulties when working with magnesium nitride. The material may undergo phase transformations or decomposition at elevated temperatures, potentially altering its reinforcing capabilities. Developing temperature-controlled processing techniques that maintain the desired crystal structure and properties of magnesium nitride throughout the manufacturing process is essential.

Compatibility between magnesium nitride and the matrix material presents another technical hurdle. Ensuring strong interfacial bonding between the reinforcement and the matrix is critical for effective load transfer and overall structural enhancement. However, differences in thermal expansion coefficients and chemical compatibility can lead to weak interfaces or even delamination, compromising the integrity of the final product.

Scale-up and cost-effectiveness in manufacturing processes incorporating magnesium nitride reinforcement also pose significant challenges. Transitioning from laboratory-scale production to industrial-scale manufacturing while maintaining consistent quality and performance is a complex task. Additionally, the high cost of magnesium nitride production and the specialized equipment required for its safe handling and processing can impact the economic viability of its widespread adoption in manufacturing.

Lastly, the long-term stability and performance of magnesium nitride-reinforced materials under various environmental conditions and stress scenarios remain areas of concern. Developing accelerated testing methods and predictive models to assess the durability and reliability of these materials over extended periods is crucial for their successful implementation in critical structural applications.

Another major challenge lies in the uniform dispersion of magnesium nitride within the matrix material. Achieving homogeneous distribution is crucial for optimal reinforcement, but the tendency of nanoparticles to agglomerate can result in inconsistent mechanical properties throughout the manufactured component. This issue requires innovative mixing and processing methods to ensure even distribution without compromising the material's integrity.

The high processing temperatures often required in manufacturing can pose additional difficulties when working with magnesium nitride. The material may undergo phase transformations or decomposition at elevated temperatures, potentially altering its reinforcing capabilities. Developing temperature-controlled processing techniques that maintain the desired crystal structure and properties of magnesium nitride throughout the manufacturing process is essential.

Compatibility between magnesium nitride and the matrix material presents another technical hurdle. Ensuring strong interfacial bonding between the reinforcement and the matrix is critical for effective load transfer and overall structural enhancement. However, differences in thermal expansion coefficients and chemical compatibility can lead to weak interfaces or even delamination, compromising the integrity of the final product.

Scale-up and cost-effectiveness in manufacturing processes incorporating magnesium nitride reinforcement also pose significant challenges. Transitioning from laboratory-scale production to industrial-scale manufacturing while maintaining consistent quality and performance is a complex task. Additionally, the high cost of magnesium nitride production and the specialized equipment required for its safe handling and processing can impact the economic viability of its widespread adoption in manufacturing.

Lastly, the long-term stability and performance of magnesium nitride-reinforced materials under various environmental conditions and stress scenarios remain areas of concern. Developing accelerated testing methods and predictive models to assess the durability and reliability of these materials over extended periods is crucial for their successful implementation in critical structural applications.

Current Mg3N2 Solutions

01 Structural integrity analysis of magnesium nitride components

Advanced techniques for analyzing the structural integrity of magnesium nitride components in various applications. This includes methods for assessing material properties, stress distribution, and potential failure modes to ensure the reliability and durability of structures containing magnesium nitride.- Structural integrity analysis of magnesium nitride components: Advanced techniques for analyzing and evaluating the structural integrity of magnesium nitride components in various applications. This includes methods for assessing material properties, stress distribution, and potential failure modes to ensure the reliability and durability of structures containing magnesium nitride.

- Magnesium nitride composite materials for improved structural performance: Development of composite materials incorporating magnesium nitride to enhance structural integrity. These composites combine the unique properties of magnesium nitride with other materials to create structures with improved strength, stiffness, and resistance to environmental factors.

- Non-destructive testing methods for magnesium nitride structures: Innovative non-destructive testing techniques specifically designed for evaluating the structural integrity of magnesium nitride components. These methods allow for the detection of defects, cracks, or other structural issues without compromising the integrity of the material or structure.

- Environmental effects on magnesium nitride structural integrity: Studies and methodologies for assessing the impact of various environmental factors on the structural integrity of magnesium nitride. This includes evaluating the effects of temperature, humidity, corrosive agents, and other environmental conditions on the long-term performance and durability of magnesium nitride structures.

- Magnesium nitride coatings for structural reinforcement: Development of magnesium nitride-based coatings and surface treatments to enhance the structural integrity of various materials and components. These coatings can provide improved wear resistance, corrosion protection, and overall structural reinforcement to extend the lifespan and performance of treated structures.

02 Magnesium nitride in high-temperature applications

Exploration of magnesium nitride's potential in high-temperature environments, focusing on its thermal stability and structural integrity under extreme conditions. This includes research on its use in refractory materials, thermal barriers, and other high-temperature industrial applications.Expand Specific Solutions03 Composite materials incorporating magnesium nitride

Development of composite materials that incorporate magnesium nitride to enhance structural integrity and performance. This includes studies on the interaction between magnesium nitride and other materials, as well as the optimization of composite formulations for specific applications.Expand Specific Solutions04 Non-destructive testing methods for magnesium nitride structures

Innovative non-destructive testing techniques specifically designed for evaluating the structural integrity of magnesium nitride components. These methods aim to detect defects, assess material properties, and monitor the condition of magnesium nitride structures without causing damage.Expand Specific Solutions05 Surface treatment and coating technologies for magnesium nitride

Advanced surface treatment and coating technologies developed to enhance the structural integrity and performance of magnesium nitride components. These techniques focus on improving corrosion resistance, wear resistance, and overall durability of magnesium nitride surfaces in various applications.Expand Specific Solutions

Key Industry Players

The magnesium nitride reinforcement technology in manufacturing is in its early development stage, with a growing market potential due to increasing demand for lightweight, high-strength materials. The technology's maturity varies across different applications, with companies like Proterial Ltd., Kobe Steel, Ltd., and CeramTec GmbH leading in research and development. Academic institutions such as Lanzhou University of Technology and Chongqing University are contributing to fundamental research. The competitive landscape is diverse, including established materials companies and emerging specialized firms, indicating a dynamic and evolving market with opportunities for innovation and collaboration.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has pioneered a novel approach to reinforcing structural integrity using magnesium nitride in steel manufacturing. Their method involves introducing magnesium nitride particles during the steelmaking process, which act as nucleation sites for fine-grained microstructures. This results in a more uniform grain distribution and enhanced mechanical properties. The company has reported a 15-20% increase in tensile strength and improved ductility in their high-strength steel products[3]. Additionally, Kobe Steel has developed a magnesium nitride-based coating technology for steel components, which provides excellent wear resistance and thermal stability in high-temperature applications[4].

Strengths: Applicable to a wide range of steel products. Improves both strength and ductility. Weaknesses: May require modifications to existing steel production processes. Potential for increased production costs.

CeramTec GmbH

Technical Solution: CeramTec GmbH has developed an innovative approach to incorporating magnesium nitride in advanced ceramic materials to enhance structural integrity. Their process involves the synthesis of magnesium nitride nanoparticles, which are then uniformly dispersed within ceramic matrices. This results in a significant improvement in fracture toughness, with increases of up to 40% reported in some ceramic compositions[5]. The company has also developed a unique sintering process that allows for the retention of the magnesium nitride phase at high temperatures, enabling the production of ceramic components with improved thermal shock resistance and mechanical stability at elevated temperatures[6].

Strengths: Significant improvements in fracture toughness and thermal properties. Applicable to a wide range of ceramic materials. Weaknesses: Complex synthesis and processing techniques may increase production costs. Limited to ceramic-based materials.

Core Mg3N2 Innovations

Composite structural material compositions resistant to biodegradation

PatentInactiveUS20210061712A1

Innovation

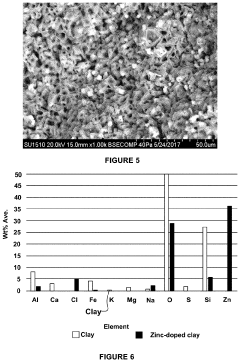

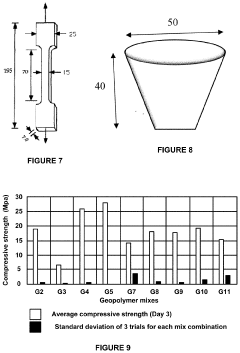

- Development of a geopolymer-based structural material composition that encapsulates antibacterial agents like zinc oxide within a geopolymer matrix, using carriers such as bentonite clay, to create a long-lasting, environmentally friendly coating that reduces bio-corrosion without leaching harmful substances.

Environmental Impact

The incorporation of magnesium nitride in manufacturing processes has significant environmental implications that warrant careful consideration. While this compound offers substantial benefits in terms of structural reinforcement, its production and use can impact the environment in various ways.

Magnesium nitride production typically involves high-temperature reactions between magnesium and nitrogen gas. This energy-intensive process contributes to greenhouse gas emissions, particularly when fossil fuels are used as the energy source. However, the potential for using renewable energy in production could mitigate these environmental concerns.

The use of magnesium nitride in manufacturing can lead to improved product durability and longevity. This enhanced lifespan of manufactured goods may result in reduced waste generation and decreased demand for raw materials over time. Consequently, this could contribute to resource conservation and a reduction in the overall environmental footprint of industrial production.

Water pollution is another environmental aspect to consider. Magnesium nitride can react with water to form magnesium hydroxide and ammonia. If not properly managed, these byproducts could potentially contaminate water sources. Implementing robust waste management protocols and closed-loop systems in manufacturing facilities is crucial to mitigate this risk.

On the positive side, the reinforcing properties of magnesium nitride may allow for the use of less material in certain applications, potentially reducing the overall material consumption in manufacturing processes. This could lead to a decrease in resource extraction and associated environmental impacts.

The end-of-life disposal of products containing magnesium nitride presents both challenges and opportunities. While the compound itself is not considered highly toxic, proper recycling and disposal methods need to be developed to prevent potential environmental contamination. Developing efficient recycling processes for magnesium nitride-containing materials could contribute to a more circular economy approach in manufacturing.

In terms of air quality, the production and handling of magnesium nitride powder may generate particulate matter. Implementing appropriate dust control measures and personal protective equipment in manufacturing facilities is essential to minimize potential air pollution and protect worker health.

As research into magnesium nitride applications continues, there is potential for developing more environmentally friendly production methods and applications. This could include exploring bio-based precursors for magnesium nitride synthesis or investigating its use in environmental remediation technologies.

Magnesium nitride production typically involves high-temperature reactions between magnesium and nitrogen gas. This energy-intensive process contributes to greenhouse gas emissions, particularly when fossil fuels are used as the energy source. However, the potential for using renewable energy in production could mitigate these environmental concerns.

The use of magnesium nitride in manufacturing can lead to improved product durability and longevity. This enhanced lifespan of manufactured goods may result in reduced waste generation and decreased demand for raw materials over time. Consequently, this could contribute to resource conservation and a reduction in the overall environmental footprint of industrial production.

Water pollution is another environmental aspect to consider. Magnesium nitride can react with water to form magnesium hydroxide and ammonia. If not properly managed, these byproducts could potentially contaminate water sources. Implementing robust waste management protocols and closed-loop systems in manufacturing facilities is crucial to mitigate this risk.

On the positive side, the reinforcing properties of magnesium nitride may allow for the use of less material in certain applications, potentially reducing the overall material consumption in manufacturing processes. This could lead to a decrease in resource extraction and associated environmental impacts.

The end-of-life disposal of products containing magnesium nitride presents both challenges and opportunities. While the compound itself is not considered highly toxic, proper recycling and disposal methods need to be developed to prevent potential environmental contamination. Developing efficient recycling processes for magnesium nitride-containing materials could contribute to a more circular economy approach in manufacturing.

In terms of air quality, the production and handling of magnesium nitride powder may generate particulate matter. Implementing appropriate dust control measures and personal protective equipment in manufacturing facilities is essential to minimize potential air pollution and protect worker health.

As research into magnesium nitride applications continues, there is potential for developing more environmentally friendly production methods and applications. This could include exploring bio-based precursors for magnesium nitride synthesis or investigating its use in environmental remediation technologies.

Cost-Benefit Analysis

The implementation of magnesium nitride in manufacturing processes presents a complex cost-benefit scenario that requires careful analysis. On the cost side, the production and integration of magnesium nitride into existing manufacturing systems can be initially expensive. This includes the costs associated with raw materials, specialized equipment for synthesis and application, and potential modifications to existing production lines.

However, these upfront investments must be weighed against the long-term benefits that magnesium nitride reinforcement can provide. One of the primary advantages is the potential for significant improvements in product durability and lifespan. By enhancing structural integrity, magnesium nitride can reduce the frequency of product failures and the need for replacements, leading to decreased warranty claims and improved customer satisfaction.

From a manufacturing perspective, the use of magnesium nitride can lead to process efficiencies. Its ability to reinforce materials may allow for the use of thinner or lighter components without compromising strength, potentially reducing material costs and energy consumption during production. This can translate into substantial savings over time, especially in high-volume manufacturing scenarios.

The environmental impact should also be considered in the cost-benefit analysis. While the production of magnesium nitride may have its own environmental footprint, the overall lifecycle impact of products reinforced with this material could be lower due to increased durability and reduced need for replacements. This aligns with growing consumer demand for sustainable products and could provide a competitive edge in environmentally conscious markets.

In terms of market positioning, the use of magnesium nitride as a reinforcing agent can enable manufacturers to differentiate their products based on superior quality and performance. This may justify premium pricing strategies, potentially offsetting the higher initial production costs and leading to improved profit margins.

It's important to note that the cost-benefit ratio may vary significantly depending on the specific application and industry. For high-stress applications in aerospace or automotive industries, the benefits of magnesium nitride reinforcement may far outweigh the costs. In contrast, for low-stress consumer goods, the cost-benefit analysis might be less favorable.

However, these upfront investments must be weighed against the long-term benefits that magnesium nitride reinforcement can provide. One of the primary advantages is the potential for significant improvements in product durability and lifespan. By enhancing structural integrity, magnesium nitride can reduce the frequency of product failures and the need for replacements, leading to decreased warranty claims and improved customer satisfaction.

From a manufacturing perspective, the use of magnesium nitride can lead to process efficiencies. Its ability to reinforce materials may allow for the use of thinner or lighter components without compromising strength, potentially reducing material costs and energy consumption during production. This can translate into substantial savings over time, especially in high-volume manufacturing scenarios.

The environmental impact should also be considered in the cost-benefit analysis. While the production of magnesium nitride may have its own environmental footprint, the overall lifecycle impact of products reinforced with this material could be lower due to increased durability and reduced need for replacements. This aligns with growing consumer demand for sustainable products and could provide a competitive edge in environmentally conscious markets.

In terms of market positioning, the use of magnesium nitride as a reinforcing agent can enable manufacturers to differentiate their products based on superior quality and performance. This may justify premium pricing strategies, potentially offsetting the higher initial production costs and leading to improved profit margins.

It's important to note that the cost-benefit ratio may vary significantly depending on the specific application and industry. For high-stress applications in aerospace or automotive industries, the benefits of magnesium nitride reinforcement may far outweigh the costs. In contrast, for low-stress consumer goods, the cost-benefit analysis might be less favorable.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!