Applications of Microcrystalline Cellulose in Flexible Conductive Materials

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MCC in Flexible Conductors: Background and Objectives

Microcrystalline cellulose (MCC) has emerged as a promising material in the development of flexible conductive materials, marking a significant advancement in the field of sustainable electronics. This technology combines the eco-friendly attributes of cellulose with the demands of modern electronic applications, addressing the growing need for environmentally responsible and versatile conductive materials.

The evolution of MCC in flexible conductors can be traced back to the increasing focus on renewable resources in material science. As traditional electronic materials faced challenges related to environmental impact and resource scarcity, researchers began exploring alternatives derived from abundant natural polymers. Cellulose, being the most abundant biopolymer on Earth, naturally became a focal point of these investigations.

The journey of MCC in this field has been characterized by continuous improvements in processing techniques and composite formulations. Initial efforts focused on overcoming the inherent non-conductive nature of cellulose, leading to the development of various strategies for incorporating conductive elements while maintaining flexibility and biocompatibility.

The primary objective in this technological domain is to create flexible conductive materials that can rival or surpass the performance of conventional options while offering additional benefits such as biodegradability, low cost, and ease of manufacturing. This goal aligns with broader industry trends towards sustainable and wearable electronics, smart textiles, and flexible displays.

Key milestones in the development of MCC-based flexible conductors include the successful integration of conductive nanoparticles, the development of cellulose nanofiber composites, and the exploration of surface modification techniques to enhance conductivity. These advancements have opened up new possibilities for applications in areas such as flexible sensors, energy storage devices, and interactive packaging.

The technology's progression is driven by several factors, including the push for circular economy principles in electronics, the demand for flexible and conformable electronic components, and the need for materials that can withstand mechanical stress without losing functionality. As research continues, the focus is increasingly on optimizing the balance between conductivity, flexibility, and sustainability.

Looking ahead, the field of MCC in flexible conductive materials is poised for further innovation. Emerging trends include the exploration of hybrid materials combining MCC with other bio-based polymers, the development of self-healing conductive composites, and the integration of MCC-based conductors into 3D-printable formulations for customized electronic components.

The evolution of MCC in flexible conductors can be traced back to the increasing focus on renewable resources in material science. As traditional electronic materials faced challenges related to environmental impact and resource scarcity, researchers began exploring alternatives derived from abundant natural polymers. Cellulose, being the most abundant biopolymer on Earth, naturally became a focal point of these investigations.

The journey of MCC in this field has been characterized by continuous improvements in processing techniques and composite formulations. Initial efforts focused on overcoming the inherent non-conductive nature of cellulose, leading to the development of various strategies for incorporating conductive elements while maintaining flexibility and biocompatibility.

The primary objective in this technological domain is to create flexible conductive materials that can rival or surpass the performance of conventional options while offering additional benefits such as biodegradability, low cost, and ease of manufacturing. This goal aligns with broader industry trends towards sustainable and wearable electronics, smart textiles, and flexible displays.

Key milestones in the development of MCC-based flexible conductors include the successful integration of conductive nanoparticles, the development of cellulose nanofiber composites, and the exploration of surface modification techniques to enhance conductivity. These advancements have opened up new possibilities for applications in areas such as flexible sensors, energy storage devices, and interactive packaging.

The technology's progression is driven by several factors, including the push for circular economy principles in electronics, the demand for flexible and conformable electronic components, and the need for materials that can withstand mechanical stress without losing functionality. As research continues, the focus is increasingly on optimizing the balance between conductivity, flexibility, and sustainability.

Looking ahead, the field of MCC in flexible conductive materials is poised for further innovation. Emerging trends include the exploration of hybrid materials combining MCC with other bio-based polymers, the development of self-healing conductive composites, and the integration of MCC-based conductors into 3D-printable formulations for customized electronic components.

Market Analysis for MCC-based Conductive Materials

The market for microcrystalline cellulose (MCC)-based conductive materials is experiencing significant growth, driven by the increasing demand for flexible and sustainable electronics. This market segment is positioned at the intersection of advanced materials science and the burgeoning field of flexible electronics, offering substantial opportunities for innovation and commercial application.

The global flexible electronics market, which encompasses MCC-based conductive materials, is projected to expand rapidly in the coming years. This growth is fueled by the rising adoption of wearable devices, smart packaging, and flexible displays across various industries including consumer electronics, healthcare, and automotive sectors.

MCC-based conductive materials offer several advantages over traditional conductive materials, including biodegradability, flexibility, and cost-effectiveness. These properties make them particularly attractive for applications in disposable electronics, smart textiles, and environmentally friendly sensors. The increasing focus on sustainability and circular economy principles in manufacturing is expected to further boost the demand for MCC-based conductive materials.

In the consumer electronics sector, there is a growing trend towards flexible and foldable devices, creating a substantial market opportunity for MCC-based conductive materials. These materials can be used in flexible touchscreens, bendable batteries, and stretchable circuits, enabling the development of innovative form factors in smartphones, tablets, and wearable devices.

The healthcare industry represents another significant market for MCC-based conductive materials. The demand for disposable medical devices, smart bandages, and wearable health monitors is rising, driven by the need for remote patient monitoring and personalized healthcare solutions. MCC-based materials offer biocompatibility and flexibility, making them ideal for these applications.

The automotive sector is also showing interest in MCC-based conductive materials for use in smart textiles for car interiors, flexible sensors for advanced driver assistance systems, and lightweight components for electric vehicles. As the automotive industry continues to evolve towards more connected and electrified vehicles, the demand for flexible and sustainable conductive materials is expected to increase.

Despite the promising market outlook, challenges remain in scaling up production and improving the performance of MCC-based conductive materials to match that of traditional conductive materials in certain high-performance applications. Ongoing research and development efforts are focused on enhancing the conductivity, durability, and processing methods of these materials to expand their potential applications and market penetration.

The global flexible electronics market, which encompasses MCC-based conductive materials, is projected to expand rapidly in the coming years. This growth is fueled by the rising adoption of wearable devices, smart packaging, and flexible displays across various industries including consumer electronics, healthcare, and automotive sectors.

MCC-based conductive materials offer several advantages over traditional conductive materials, including biodegradability, flexibility, and cost-effectiveness. These properties make them particularly attractive for applications in disposable electronics, smart textiles, and environmentally friendly sensors. The increasing focus on sustainability and circular economy principles in manufacturing is expected to further boost the demand for MCC-based conductive materials.

In the consumer electronics sector, there is a growing trend towards flexible and foldable devices, creating a substantial market opportunity for MCC-based conductive materials. These materials can be used in flexible touchscreens, bendable batteries, and stretchable circuits, enabling the development of innovative form factors in smartphones, tablets, and wearable devices.

The healthcare industry represents another significant market for MCC-based conductive materials. The demand for disposable medical devices, smart bandages, and wearable health monitors is rising, driven by the need for remote patient monitoring and personalized healthcare solutions. MCC-based materials offer biocompatibility and flexibility, making them ideal for these applications.

The automotive sector is also showing interest in MCC-based conductive materials for use in smart textiles for car interiors, flexible sensors for advanced driver assistance systems, and lightweight components for electric vehicles. As the automotive industry continues to evolve towards more connected and electrified vehicles, the demand for flexible and sustainable conductive materials is expected to increase.

Despite the promising market outlook, challenges remain in scaling up production and improving the performance of MCC-based conductive materials to match that of traditional conductive materials in certain high-performance applications. Ongoing research and development efforts are focused on enhancing the conductivity, durability, and processing methods of these materials to expand their potential applications and market penetration.

Current Challenges in MCC Conductive Applications

Despite the promising potential of microcrystalline cellulose (MCC) in flexible conductive materials, several significant challenges currently hinder its widespread application and commercialization. These obstacles span across various aspects of material science, engineering, and manufacturing processes.

One of the primary challenges is achieving consistent and high electrical conductivity in MCC-based materials. While MCC itself is not conductive, it serves as a substrate or matrix for conductive elements. The integration of conductive materials, such as carbon nanotubes or metallic nanoparticles, into the MCC structure in a uniform and stable manner remains a complex task. Ensuring homogeneous dispersion of these conductive elements throughout the MCC matrix is crucial for maintaining consistent electrical properties across the material.

Another significant hurdle is balancing the trade-off between flexibility and conductivity. As the concentration of conductive elements increases to improve conductivity, the flexibility of the material often decreases. This inverse relationship poses a challenge in developing materials that maintain high conductivity while retaining the desired flexibility for various applications.

The durability and long-term stability of MCC-based conductive materials present another set of challenges. These materials must withstand repeated bending, stretching, and environmental stresses without significant degradation of their conductive properties. Developing robust interfaces between the MCC matrix and conductive elements to prevent delamination or loss of conductivity over time is a critical area of ongoing research.

Scalability and cost-effectiveness in manufacturing processes also pose significant challenges. While laboratory-scale production of MCC-based conductive materials has shown promise, scaling up to industrial production levels while maintaining quality and performance consistency remains a hurdle. Additionally, the cost of incorporating specialized conductive materials into MCC can be prohibitive for mass-market applications, necessitating the development of more economical production methods and material combinations.

Environmental stability is another concern, particularly for applications in wearable electronics or outdoor use. MCC-based materials must resist degradation from moisture, UV radiation, and temperature fluctuations. Developing effective encapsulation techniques or inherently resistant formulations without compromising flexibility or conductivity is an ongoing challenge.

Lastly, the standardization of testing and characterization methods for MCC-based conductive materials is lacking. This absence of standardized protocols makes it difficult to compare different materials and assess their suitability for specific applications, hindering broader adoption and commercialization efforts.

Addressing these challenges requires interdisciplinary collaboration and innovative approaches in materials science, nanotechnology, and manufacturing processes. Overcoming these hurdles will be crucial for realizing the full potential of MCC in flexible conductive materials and enabling their widespread application in next-generation electronics and smart textiles.

One of the primary challenges is achieving consistent and high electrical conductivity in MCC-based materials. While MCC itself is not conductive, it serves as a substrate or matrix for conductive elements. The integration of conductive materials, such as carbon nanotubes or metallic nanoparticles, into the MCC structure in a uniform and stable manner remains a complex task. Ensuring homogeneous dispersion of these conductive elements throughout the MCC matrix is crucial for maintaining consistent electrical properties across the material.

Another significant hurdle is balancing the trade-off between flexibility and conductivity. As the concentration of conductive elements increases to improve conductivity, the flexibility of the material often decreases. This inverse relationship poses a challenge in developing materials that maintain high conductivity while retaining the desired flexibility for various applications.

The durability and long-term stability of MCC-based conductive materials present another set of challenges. These materials must withstand repeated bending, stretching, and environmental stresses without significant degradation of their conductive properties. Developing robust interfaces between the MCC matrix and conductive elements to prevent delamination or loss of conductivity over time is a critical area of ongoing research.

Scalability and cost-effectiveness in manufacturing processes also pose significant challenges. While laboratory-scale production of MCC-based conductive materials has shown promise, scaling up to industrial production levels while maintaining quality and performance consistency remains a hurdle. Additionally, the cost of incorporating specialized conductive materials into MCC can be prohibitive for mass-market applications, necessitating the development of more economical production methods and material combinations.

Environmental stability is another concern, particularly for applications in wearable electronics or outdoor use. MCC-based materials must resist degradation from moisture, UV radiation, and temperature fluctuations. Developing effective encapsulation techniques or inherently resistant formulations without compromising flexibility or conductivity is an ongoing challenge.

Lastly, the standardization of testing and characterization methods for MCC-based conductive materials is lacking. This absence of standardized protocols makes it difficult to compare different materials and assess their suitability for specific applications, hindering broader adoption and commercialization efforts.

Addressing these challenges requires interdisciplinary collaboration and innovative approaches in materials science, nanotechnology, and manufacturing processes. Overcoming these hurdles will be crucial for realizing the full potential of MCC in flexible conductive materials and enabling their widespread application in next-generation electronics and smart textiles.

Existing MCC-based Conductive Material Solutions

01 Electrical conductivity enhancement of microcrystalline cellulose

Methods to improve the electrical conductivity of microcrystalline cellulose (MCC) through various treatments or modifications. This can include the incorporation of conductive materials or chemical modifications to enhance the inherent conductivity of MCC, making it suitable for applications requiring electrical properties.- Electrical conductivity of microcrystalline cellulose composites: Microcrystalline cellulose can be combined with conductive materials to create composites with enhanced electrical conductivity. These composites can be used in various applications, including electronics and energy storage devices. The conductivity can be adjusted by varying the ratio of microcrystalline cellulose to conductive additives.

- Ionic conductivity in microcrystalline cellulose-based electrolytes: Microcrystalline cellulose can be used as a matrix for ionic conductors in solid-state electrolytes. By incorporating ionic salts or other conductive species into the microcrystalline cellulose structure, materials with improved ionic conductivity can be developed for applications in batteries and other electrochemical devices.

- Thermal conductivity of microcrystalline cellulose materials: The thermal conductivity of microcrystalline cellulose can be modified through various treatments and processing methods. This property is important for applications in insulation materials and thermal management systems. The thermal conductivity can be enhanced or reduced depending on the specific requirements of the application.

- Surface modification of microcrystalline cellulose for conductivity control: The surface of microcrystalline cellulose can be modified to alter its conductivity properties. This can involve chemical treatments, coating with conductive materials, or grafting of conductive polymers onto the cellulose surface. Such modifications can enhance the overall conductivity of the material or create selective conductive pathways.

- Microcrystalline cellulose in conductive paper and film applications: Microcrystalline cellulose can be used in the production of conductive papers and films. By incorporating conductive additives or through specific processing techniques, these cellulose-based materials can exhibit controlled conductivity, making them suitable for applications in flexible electronics, smart packaging, and electromagnetic shielding.

02 Use of microcrystalline cellulose in conductive composites

Incorporation of microcrystalline cellulose into composite materials to create conductive or semi-conductive products. This can involve combining MCC with other conductive materials or polymers to develop materials with specific electrical properties for various applications.Expand Specific Solutions03 Microcrystalline cellulose in energy storage devices

Application of microcrystalline cellulose in the development of energy storage devices such as batteries or supercapacitors. MCC can be used as a component in electrodes or separators, potentially enhancing the conductivity or performance of these devices.Expand Specific Solutions04 Surface modification of microcrystalline cellulose for conductivity

Techniques for modifying the surface of microcrystalline cellulose particles to improve their electrical conductivity. This can include chemical treatments, coating processes, or grafting of conductive materials onto the MCC surface.Expand Specific Solutions05 Microcrystalline cellulose in conductive paper or films

Utilization of microcrystalline cellulose in the production of conductive paper or thin films. This involves incorporating MCC into paper-making processes or film formation techniques to create materials with enhanced electrical properties for specialized applications.Expand Specific Solutions

Key Players in MCC Conductive Materials Industry

The market for microcrystalline cellulose in flexible conductive materials is in an early growth stage, with increasing research and development efforts. The global market size is expanding, driven by demand for sustainable and high-performance materials in electronics and energy storage applications. Technologically, the field is rapidly evolving, with companies like Borregaard AS, Lenzing AG, and FPInnovations leading in cellulose-based innovations. Academic institutions such as Nanjing Forestry University and South China University of Technology are contributing significant research. While the technology shows promise, further advancements are needed to improve conductivity, flexibility, and scalability for widespread commercial adoption.

Borregaard AS

Technical Solution: Borregaard AS has developed a novel approach to creating flexible conductive materials using microcrystalline cellulose (MCC). Their method involves combining MCC with conductive nanoparticles, such as silver or carbon nanotubes, to create a composite material. This composite is then processed into thin, flexible sheets or films. The MCC acts as a biodegradable and renewable matrix, while the nanoparticles provide electrical conductivity. The company has optimized the dispersion of nanoparticles within the MCC matrix to achieve uniform conductivity across the material[1]. Additionally, they have developed a proprietary surface modification technique for the MCC, which enhances its compatibility with the conductive nanoparticles and improves the overall mechanical properties of the composite[3].

Strengths: Utilizes renewable resources, biodegradable, highly flexible, and customizable conductivity. Weaknesses: May have lower conductivity compared to traditional metal-based conductors, potential for higher production costs.

Lenzing AG

Technical Solution: Lenzing AG has pioneered a technique for incorporating microcrystalline cellulose into flexible conductive materials through a process called "cellulose welding." This innovative approach involves partially dissolving MCC fibers and then reforming them into a continuous network. During this process, conductive nanoparticles or graphene sheets are introduced and become entangled within the cellulose network[2]. The resulting material exhibits excellent flexibility and stretchability while maintaining electrical conductivity. Lenzing has also developed a method to control the porosity of the final material, allowing for tunable properties such as breathability and moisture management[4]. Their technology has shown particular promise in wearable electronics and smart textiles applications, where comfort and durability are crucial factors[5].

Strengths: High flexibility and stretchability, tunable properties, suitable for wearable applications. Weaknesses: Complex manufacturing process, potential limitations in high-conductivity applications.

Innovations in MCC Conductive Composites

Microcrystalline cellulose and method for making

PatentInactiveEP1707577A3

Innovation

- A method involving the use of high hemicellulose pulps with a treating agent, such as inorganic acids, to produce microcrystalline cellulose with specific properties like LODP, X-ray crystallinity index, and brightness levels, suitable for conversion from sawdust and low-specific-gravity wood, reducing processing costs and waste utilization.

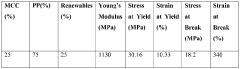

Food packaging comprising composite of thermoplastics and microcrystalline cellulose

PatentWO2021048470A1

Innovation

- A composite material comprising 10 wt% or more of microcrystalline cellulose (MCC) with thermoplastics, which increases stiffness and tensile strength, allowing for the production of rigid, biodegradable, and industrially compostable packaging suitable for various applications, including cups, containers, and lids, while reducing the need for fossil-based polymers.

Environmental Impact of MCC-based Conductive Materials

The environmental impact of microcrystalline cellulose (MCC)-based conductive materials is a crucial consideration in their development and application. These materials offer potential advantages in terms of sustainability and biodegradability compared to traditional conductive materials, but their environmental footprint must be carefully evaluated across their entire lifecycle.

MCC is derived from natural cellulose sources, primarily wood pulp or cotton linters. The production process typically involves acid hydrolysis, which can have environmental implications if not properly managed. However, the use of renewable raw materials and the potential for closed-loop manufacturing processes can significantly reduce the overall environmental impact compared to synthetic alternatives.

One of the key environmental benefits of MCC-based conductive materials is their biodegradability. Unlike many conventional conductive materials that persist in the environment for extended periods, MCC-based materials can decompose naturally under appropriate conditions. This characteristic is particularly valuable in addressing the growing concern of electronic waste and disposable flexible electronics.

The energy consumption associated with the production of MCC-based conductive materials is generally lower than that required for traditional metal-based conductors. This reduced energy footprint contributes to lower greenhouse gas emissions throughout the material's lifecycle. Additionally, the lightweight nature of these materials can lead to reduced transportation-related emissions when used in final products.

Water usage and potential water pollution are important factors to consider in the environmental assessment of MCC-based conductive materials. While the production process may require significant water inputs, advancements in water recycling and treatment technologies can mitigate these impacts. Proper wastewater management is essential to prevent the release of chemicals used in the MCC modification process into aquatic ecosystems.

The end-of-life phase of MCC-based conductive materials presents both challenges and opportunities from an environmental perspective. Their biodegradability can reduce the burden on landfills and minimize soil and water contamination. However, the presence of conductive additives and other modifications may affect the material's decomposition rate and environmental fate. Research into optimizing the balance between conductivity and biodegradability is ongoing.

The potential for recycling and upcycling MCC-based conductive materials is an area of growing interest. While the recycling of these composite materials may be more complex than that of pure MCC, developing effective recycling strategies could further enhance their environmental credentials and contribute to a circular economy approach in electronics manufacturing.

MCC is derived from natural cellulose sources, primarily wood pulp or cotton linters. The production process typically involves acid hydrolysis, which can have environmental implications if not properly managed. However, the use of renewable raw materials and the potential for closed-loop manufacturing processes can significantly reduce the overall environmental impact compared to synthetic alternatives.

One of the key environmental benefits of MCC-based conductive materials is their biodegradability. Unlike many conventional conductive materials that persist in the environment for extended periods, MCC-based materials can decompose naturally under appropriate conditions. This characteristic is particularly valuable in addressing the growing concern of electronic waste and disposable flexible electronics.

The energy consumption associated with the production of MCC-based conductive materials is generally lower than that required for traditional metal-based conductors. This reduced energy footprint contributes to lower greenhouse gas emissions throughout the material's lifecycle. Additionally, the lightweight nature of these materials can lead to reduced transportation-related emissions when used in final products.

Water usage and potential water pollution are important factors to consider in the environmental assessment of MCC-based conductive materials. While the production process may require significant water inputs, advancements in water recycling and treatment technologies can mitigate these impacts. Proper wastewater management is essential to prevent the release of chemicals used in the MCC modification process into aquatic ecosystems.

The end-of-life phase of MCC-based conductive materials presents both challenges and opportunities from an environmental perspective. Their biodegradability can reduce the burden on landfills and minimize soil and water contamination. However, the presence of conductive additives and other modifications may affect the material's decomposition rate and environmental fate. Research into optimizing the balance between conductivity and biodegradability is ongoing.

The potential for recycling and upcycling MCC-based conductive materials is an area of growing interest. While the recycling of these composite materials may be more complex than that of pure MCC, developing effective recycling strategies could further enhance their environmental credentials and contribute to a circular economy approach in electronics manufacturing.

Scalability and Manufacturing Processes

The scalability and manufacturing processes for incorporating microcrystalline cellulose (MCC) into flexible conductive materials present both opportunities and challenges. As the demand for sustainable and high-performance electronic components grows, the ability to scale up production becomes crucial for commercial viability.

Current manufacturing processes for MCC-based flexible conductive materials typically involve solution-based methods. These include techniques such as solution casting, layer-by-layer assembly, and in-situ polymerization. While these methods are effective for small-scale production and research purposes, they often face limitations when it comes to large-scale manufacturing.

One promising approach for scalable production is the use of continuous roll-to-roll (R2R) processing. This technique allows for the deposition of MCC and conductive materials onto flexible substrates in a continuous manner, significantly increasing production throughput. R2R processing can be adapted to various deposition methods, including spray coating, slot-die coating, and gravure printing, offering versatility in material application.

Another scalable manufacturing process is extrusion, which can be used to produce MCC-based conductive composites in the form of fibers or films. This method allows for the continuous production of materials with consistent properties and can be easily integrated into existing manufacturing lines for textiles or packaging materials.

Challenges in scaling up production include maintaining uniform dispersion of MCC and conductive materials throughout the substrate, ensuring consistent electrical and mechanical properties across large areas, and optimizing drying and curing processes for high-speed production. Additionally, the hygroscopic nature of MCC can pose challenges in maintaining material stability during manufacturing and storage.

To address these challenges, innovations in material formulation and processing techniques are necessary. For instance, the development of pre-functionalized MCC or the use of compatibilizers can improve dispersion and interfacial adhesion with conductive materials. Advanced drying technologies, such as infrared or microwave drying, can be implemented to reduce processing time and energy consumption.

Quality control and in-line monitoring systems are crucial for ensuring consistent product quality in large-scale manufacturing. Techniques such as optical inspection, electrical resistance measurement, and mechanical testing can be integrated into the production line to provide real-time feedback and process optimization.

As the technology matures, it is expected that economies of scale will drive down production costs, making MCC-based flexible conductive materials more competitive in the market. This will likely lead to increased adoption in various applications, from wearable electronics to smart packaging and beyond.

Current manufacturing processes for MCC-based flexible conductive materials typically involve solution-based methods. These include techniques such as solution casting, layer-by-layer assembly, and in-situ polymerization. While these methods are effective for small-scale production and research purposes, they often face limitations when it comes to large-scale manufacturing.

One promising approach for scalable production is the use of continuous roll-to-roll (R2R) processing. This technique allows for the deposition of MCC and conductive materials onto flexible substrates in a continuous manner, significantly increasing production throughput. R2R processing can be adapted to various deposition methods, including spray coating, slot-die coating, and gravure printing, offering versatility in material application.

Another scalable manufacturing process is extrusion, which can be used to produce MCC-based conductive composites in the form of fibers or films. This method allows for the continuous production of materials with consistent properties and can be easily integrated into existing manufacturing lines for textiles or packaging materials.

Challenges in scaling up production include maintaining uniform dispersion of MCC and conductive materials throughout the substrate, ensuring consistent electrical and mechanical properties across large areas, and optimizing drying and curing processes for high-speed production. Additionally, the hygroscopic nature of MCC can pose challenges in maintaining material stability during manufacturing and storage.

To address these challenges, innovations in material formulation and processing techniques are necessary. For instance, the development of pre-functionalized MCC or the use of compatibilizers can improve dispersion and interfacial adhesion with conductive materials. Advanced drying technologies, such as infrared or microwave drying, can be implemented to reduce processing time and energy consumption.

Quality control and in-line monitoring systems are crucial for ensuring consistent product quality in large-scale manufacturing. Techniques such as optical inspection, electrical resistance measurement, and mechanical testing can be integrated into the production line to provide real-time feedback and process optimization.

As the technology matures, it is expected that economies of scale will drive down production costs, making MCC-based flexible conductive materials more competitive in the market. This will likely lead to increased adoption in various applications, from wearable electronics to smart packaging and beyond.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!