Applications of Microcrystalline Cellulose in Thin Film Solar Cells

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MCC in Solar Cells: Background and Objectives

Microcrystalline cellulose (MCC) has emerged as a promising material in the field of thin film solar cells, offering a unique combination of properties that address several challenges in photovoltaic technology. The development of MCC applications in solar cells stems from the broader trend of incorporating sustainable and biodegradable materials into renewable energy technologies.

The evolution of thin film solar cells has been driven by the need for more efficient, cost-effective, and environmentally friendly alternatives to traditional silicon-based photovoltaics. MCC, derived from abundant cellulose sources, aligns perfectly with these objectives, presenting an opportunity to enhance solar cell performance while reducing environmental impact.

Historically, the use of cellulose in electronics has been limited due to its inherent properties. However, advancements in materials science and nanotechnology have unlocked new possibilities for cellulose-based materials, particularly in the form of MCC. The unique crystalline structure of MCC, combined with its optical and mechanical properties, has sparked interest in its potential applications in solar cell technology.

The primary technical objectives for incorporating MCC in thin film solar cells include improving light management, enhancing charge transport, and increasing overall cell efficiency. Researchers aim to leverage MCC's high transparency, tunable refractive index, and ability to form nanostructured films to optimize light absorption and reduce reflection losses in solar cells.

Another key goal is to utilize MCC as a sustainable alternative to synthetic polymers commonly used in solar cell fabrication. This aligns with the growing emphasis on developing eco-friendly and recyclable photovoltaic technologies. By integrating MCC into various components of thin film solar cells, such as substrate materials, electron transport layers, or encapsulants, researchers seek to reduce the carbon footprint of solar energy production.

The development of MCC applications in solar cells also aims to address stability and durability issues often associated with organic and perovskite-based thin film technologies. The inherent stability of cellulose structures offers potential improvements in cell longevity and resistance to environmental degradation.

As research in this field progresses, the overarching objective is to demonstrate the feasibility of MCC-enhanced solar cells at a commercial scale. This involves optimizing manufacturing processes, ensuring compatibility with existing production techniques, and achieving cost-effectiveness to compete with conventional solar technologies.

The evolution of thin film solar cells has been driven by the need for more efficient, cost-effective, and environmentally friendly alternatives to traditional silicon-based photovoltaics. MCC, derived from abundant cellulose sources, aligns perfectly with these objectives, presenting an opportunity to enhance solar cell performance while reducing environmental impact.

Historically, the use of cellulose in electronics has been limited due to its inherent properties. However, advancements in materials science and nanotechnology have unlocked new possibilities for cellulose-based materials, particularly in the form of MCC. The unique crystalline structure of MCC, combined with its optical and mechanical properties, has sparked interest in its potential applications in solar cell technology.

The primary technical objectives for incorporating MCC in thin film solar cells include improving light management, enhancing charge transport, and increasing overall cell efficiency. Researchers aim to leverage MCC's high transparency, tunable refractive index, and ability to form nanostructured films to optimize light absorption and reduce reflection losses in solar cells.

Another key goal is to utilize MCC as a sustainable alternative to synthetic polymers commonly used in solar cell fabrication. This aligns with the growing emphasis on developing eco-friendly and recyclable photovoltaic technologies. By integrating MCC into various components of thin film solar cells, such as substrate materials, electron transport layers, or encapsulants, researchers seek to reduce the carbon footprint of solar energy production.

The development of MCC applications in solar cells also aims to address stability and durability issues often associated with organic and perovskite-based thin film technologies. The inherent stability of cellulose structures offers potential improvements in cell longevity and resistance to environmental degradation.

As research in this field progresses, the overarching objective is to demonstrate the feasibility of MCC-enhanced solar cells at a commercial scale. This involves optimizing manufacturing processes, ensuring compatibility with existing production techniques, and achieving cost-effectiveness to compete with conventional solar technologies.

Market Analysis for MCC-Enhanced Solar Cells

The market for microcrystalline cellulose (MCC) enhanced solar cells is experiencing significant growth, driven by the increasing demand for sustainable and efficient energy solutions. As the global push for renewable energy intensifies, thin film solar cells have gained traction due to their flexibility, lightweight nature, and potential for cost-effective production.

The integration of MCC into thin film solar cells represents a promising development in the photovoltaic industry. MCC, derived from abundant and renewable cellulose sources, offers unique properties that can enhance the performance and durability of solar cells. Its incorporation addresses several key market needs, including improved efficiency, reduced manufacturing costs, and enhanced environmental sustainability.

Current market trends indicate a growing interest in MCC-enhanced solar cells across various sectors. The residential solar market, in particular, shows strong potential for adoption due to the aesthetic advantages and versatility of thin film technology. Commercial and industrial applications are also expanding, with MCC-enhanced solar cells being integrated into building materials and portable electronic devices.

The market size for MCC-enhanced solar cells is projected to grow substantially over the next decade. This growth is fueled by increasing investments in renewable energy infrastructure, government incentives for clean energy adoption, and the declining costs of solar technology. The Asia-Pacific region, led by China and India, is expected to dominate the market, followed by North America and Europe.

Key market drivers include the rising awareness of environmental issues, the need for energy security, and the continuous improvements in solar cell efficiency. The incorporation of MCC addresses these drivers by offering a more sustainable and potentially more efficient alternative to traditional solar cell materials.

However, the market also faces challenges. Competition from established silicon-based solar technologies remains strong, and there are concerns about the long-term stability and scalability of MCC-enhanced solar cells. Overcoming these challenges will be crucial for widespread market adoption.

Despite these obstacles, the market outlook for MCC-enhanced solar cells remains positive. The technology's potential to reduce the environmental impact of solar cell production while improving performance aligns well with global sustainability goals. As research and development efforts continue to advance, the market is expected to see the emergence of new applications and improved products, further driving growth in this innovative sector of the solar industry.

The integration of MCC into thin film solar cells represents a promising development in the photovoltaic industry. MCC, derived from abundant and renewable cellulose sources, offers unique properties that can enhance the performance and durability of solar cells. Its incorporation addresses several key market needs, including improved efficiency, reduced manufacturing costs, and enhanced environmental sustainability.

Current market trends indicate a growing interest in MCC-enhanced solar cells across various sectors. The residential solar market, in particular, shows strong potential for adoption due to the aesthetic advantages and versatility of thin film technology. Commercial and industrial applications are also expanding, with MCC-enhanced solar cells being integrated into building materials and portable electronic devices.

The market size for MCC-enhanced solar cells is projected to grow substantially over the next decade. This growth is fueled by increasing investments in renewable energy infrastructure, government incentives for clean energy adoption, and the declining costs of solar technology. The Asia-Pacific region, led by China and India, is expected to dominate the market, followed by North America and Europe.

Key market drivers include the rising awareness of environmental issues, the need for energy security, and the continuous improvements in solar cell efficiency. The incorporation of MCC addresses these drivers by offering a more sustainable and potentially more efficient alternative to traditional solar cell materials.

However, the market also faces challenges. Competition from established silicon-based solar technologies remains strong, and there are concerns about the long-term stability and scalability of MCC-enhanced solar cells. Overcoming these challenges will be crucial for widespread market adoption.

Despite these obstacles, the market outlook for MCC-enhanced solar cells remains positive. The technology's potential to reduce the environmental impact of solar cell production while improving performance aligns well with global sustainability goals. As research and development efforts continue to advance, the market is expected to see the emergence of new applications and improved products, further driving growth in this innovative sector of the solar industry.

Current Challenges in MCC Integration

The integration of microcrystalline cellulose (MCC) into thin film solar cells presents several significant challenges that researchers and manufacturers must overcome. One of the primary obstacles is achieving uniform dispersion of MCC within the solar cell matrix. The tendency of MCC particles to agglomerate due to strong hydrogen bonding can lead to inhomogeneous distribution, potentially compromising the overall performance and efficiency of the solar cell.

Another critical challenge lies in maintaining the optical transparency of the thin film while incorporating MCC. The introduction of MCC particles can potentially increase light scattering and absorption, which may reduce the amount of light reaching the active layers of the solar cell. Striking the right balance between MCC concentration and optical clarity is crucial for optimizing device performance.

The interface between MCC and other components of the solar cell structure poses additional difficulties. Ensuring strong adhesion and compatibility between MCC and the surrounding materials is essential for maintaining structural integrity and preventing delamination or degradation over time. This challenge is particularly pronounced when integrating MCC with inorganic semiconductors or conductive polymers commonly used in thin film solar cells.

Moisture sensitivity is another significant concern in MCC integration. The hydrophilic nature of cellulose makes MCC susceptible to water absorption, which can lead to swelling, dimensional instability, and potential degradation of the solar cell structure. Developing effective moisture barrier strategies or modifying MCC to reduce its hygroscopicity is crucial for ensuring long-term stability and performance of MCC-integrated solar cells.

The processing and manufacturing of MCC-enhanced thin film solar cells also present technical hurdles. Incorporating MCC into existing production processes without significantly altering established manufacturing techniques or increasing costs remains a challenge. Adapting current deposition methods, such as solution processing or vapor deposition, to accommodate MCC integration while maintaining scalability and cost-effectiveness is an ongoing area of research and development.

Furthermore, the impact of MCC on the electrical properties of the solar cell must be carefully managed. While MCC can potentially enhance certain aspects of solar cell performance, such as mechanical strength or thermal stability, its inherent electrical insulating properties may interfere with charge transport mechanisms within the device. Optimizing the MCC content and distribution to minimize any negative effects on electrical conductivity is essential for maintaining or improving overall solar cell efficiency.

Lastly, the long-term stability and durability of MCC-integrated thin film solar cells under various environmental conditions remain areas of concern. Understanding and mitigating potential degradation mechanisms, such as UV-induced breakdown of cellulose or thermal expansion mismatches between MCC and other cell components, are critical for ensuring the reliability and longevity of these advanced solar cell designs.

Another critical challenge lies in maintaining the optical transparency of the thin film while incorporating MCC. The introduction of MCC particles can potentially increase light scattering and absorption, which may reduce the amount of light reaching the active layers of the solar cell. Striking the right balance between MCC concentration and optical clarity is crucial for optimizing device performance.

The interface between MCC and other components of the solar cell structure poses additional difficulties. Ensuring strong adhesion and compatibility between MCC and the surrounding materials is essential for maintaining structural integrity and preventing delamination or degradation over time. This challenge is particularly pronounced when integrating MCC with inorganic semiconductors or conductive polymers commonly used in thin film solar cells.

Moisture sensitivity is another significant concern in MCC integration. The hydrophilic nature of cellulose makes MCC susceptible to water absorption, which can lead to swelling, dimensional instability, and potential degradation of the solar cell structure. Developing effective moisture barrier strategies or modifying MCC to reduce its hygroscopicity is crucial for ensuring long-term stability and performance of MCC-integrated solar cells.

The processing and manufacturing of MCC-enhanced thin film solar cells also present technical hurdles. Incorporating MCC into existing production processes without significantly altering established manufacturing techniques or increasing costs remains a challenge. Adapting current deposition methods, such as solution processing or vapor deposition, to accommodate MCC integration while maintaining scalability and cost-effectiveness is an ongoing area of research and development.

Furthermore, the impact of MCC on the electrical properties of the solar cell must be carefully managed. While MCC can potentially enhance certain aspects of solar cell performance, such as mechanical strength or thermal stability, its inherent electrical insulating properties may interfere with charge transport mechanisms within the device. Optimizing the MCC content and distribution to minimize any negative effects on electrical conductivity is essential for maintaining or improving overall solar cell efficiency.

Lastly, the long-term stability and durability of MCC-integrated thin film solar cells under various environmental conditions remain areas of concern. Understanding and mitigating potential degradation mechanisms, such as UV-induced breakdown of cellulose or thermal expansion mismatches between MCC and other cell components, are critical for ensuring the reliability and longevity of these advanced solar cell designs.

Existing MCC Incorporation Techniques

01 Production methods of microcrystalline cellulose

Various methods are employed to produce microcrystalline cellulose, including acid hydrolysis of cellulose fibers, mechanical processing, and enzymatic treatments. These processes aim to break down cellulose into smaller crystalline particles while maintaining their structural integrity. The production methods can be optimized to control particle size, crystallinity, and other physical properties of the resulting microcrystalline cellulose.- Production and modification of microcrystalline cellulose: Various methods are employed to produce and modify microcrystalline cellulose, including acid hydrolysis, enzymatic treatment, and mechanical processing. These techniques aim to improve the properties of microcrystalline cellulose for specific applications, such as enhancing its stability, particle size distribution, or functionality.

- Applications in pharmaceutical formulations: Microcrystalline cellulose is widely used in pharmaceutical formulations as an excipient. It serves various functions, including as a binder, disintegrant, and filler in tablet and capsule formulations. Its properties contribute to improved drug release, stability, and overall performance of pharmaceutical products.

- Use in food and cosmetic industries: Microcrystalline cellulose finds applications in food and cosmetic products as a stabilizer, thickener, and texturizing agent. It is used to improve the consistency, mouthfeel, and shelf-life of various food items and personal care products.

- Composite materials and reinforcement: Microcrystalline cellulose is utilized in the development of composite materials, where it acts as a reinforcing agent. It can enhance the mechanical properties, thermal stability, and biodegradability of various materials, including plastics, paper, and construction materials.

- Environmental and sustainability applications: Microcrystalline cellulose is explored for its potential in environmental and sustainability applications. This includes its use in biodegradable packaging materials, water treatment processes, and as a renewable resource for various industrial applications, aligning with eco-friendly initiatives.

02 Applications in pharmaceutical formulations

Microcrystalline cellulose is widely used in pharmaceutical formulations as an excipient. It serves as a binder, disintegrant, and filler in tablet and capsule formulations. Its unique properties, such as compressibility and flow characteristics, make it an ideal ingredient for direct compression tableting. It can also be used in controlled release formulations and as a stabilizer for suspensions.Expand Specific Solutions03 Use in food and cosmetic industries

Microcrystalline cellulose finds applications in food and cosmetic products as a texturizing agent, emulsion stabilizer, and fat replacer. In food products, it can improve mouthfeel, control moisture, and enhance stability. In cosmetics, it is used in creams, lotions, and powders to modify texture and improve product performance. Its natural origin and safety profile make it a popular choice in these industries.Expand Specific Solutions04 Modifications and composite materials

Microcrystalline cellulose can be modified or combined with other materials to create composite materials with enhanced properties. Surface modifications can alter its hydrophobicity or introduce functional groups. Composites with polymers or inorganic materials can result in materials with improved mechanical strength, barrier properties, or specific functionalities. These modified forms expand the range of applications for microcrystalline cellulose in various industries.Expand Specific Solutions05 Characterization and quality control

Various analytical techniques are used to characterize microcrystalline cellulose and ensure its quality. These include particle size analysis, X-ray diffraction for crystallinity determination, spectroscopic methods for chemical composition, and rheological measurements for flow properties. Quality control measures are essential to maintain consistent performance in different applications and to meet regulatory requirements in pharmaceutical and food industries.Expand Specific Solutions

Key Players in MCC-Solar Cell Research

The market for microcrystalline cellulose applications in thin film solar cells is in an early development stage, characterized by ongoing research and limited commercial deployment. While the global thin film solar market is projected to grow significantly, microcrystalline cellulose's role remains niche. Companies like Applied Materials, Samsung SDI, and Shin-Etsu Chemical are exploring this technology, leveraging their expertise in materials science and semiconductor manufacturing. Research institutions such as Industrial Technology Research Institute and universities like Zhejiang University are also contributing to advancing the technology. However, the maturity level is still low, with most developments at the laboratory or pilot scale, indicating a need for further research and development before widespread commercial adoption.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced thin film solar cell technologies incorporating microcrystalline cellulose (MCC) as a sustainable and eco-friendly material. Their approach involves using MCC as a templating agent to create nanostructured surfaces on the solar cell, enhancing light trapping and increasing overall efficiency. The company has also explored MCC as a biodegradable substrate material for flexible solar cells, potentially reducing manufacturing costs and environmental impact[1][3]. Their process integrates MCC into the cell structure through a proprietary deposition technique, which allows for precise control of the cellulose nanocrystal orientation, resulting in improved charge carrier transport and reduced recombination losses[5].

Strengths: Expertise in thin film deposition, established manufacturing infrastructure, and strong R&D capabilities. Weaknesses: Potential higher initial costs for integrating new materials, and competition from traditional silicon-based solar technologies.

Industrial Technology Research Institute

Technical Solution: The Industrial Technology Research Institute (ITRI) has pioneered the use of microcrystalline cellulose in thin film solar cells through their innovative "Green Solar Cell" project. ITRI's approach involves utilizing MCC as a bio-based, transparent substrate for flexible solar cells, replacing traditional petroleum-derived plastics. Their process incorporates a unique surface treatment of the MCC to enhance adhesion with the subsequent layers of the solar cell structure. ITRI has also developed a method to use MCC as a dispersing agent for carbon nanotubes in the conductive layers of the cell, improving electrical conductivity while maintaining transparency[2][4]. Additionally, they have explored the use of cellulose nanofibrils derived from MCC to create a nanostructured antireflective coating, significantly reducing surface reflectance and increasing light absorption[6].

Strengths: Strong focus on green technologies, extensive experience in material science, and collaboration with industry partners. Weaknesses: Potential challenges in scaling up production and competing with established solar cell manufacturers.

Innovations in MCC-Based Solar Cell Design

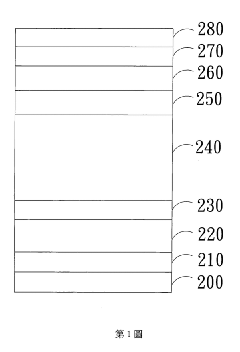

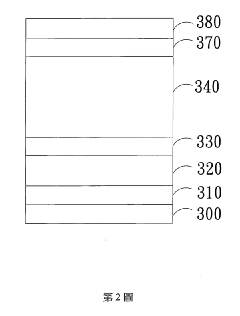

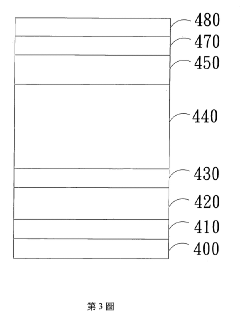

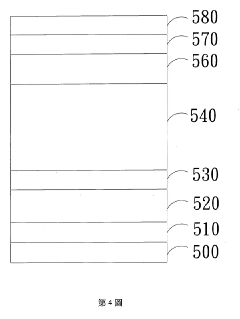

Thin-film solar cell and manufacturing method thereof

PatentInactiveTW201312773A

Innovation

- Introduction of an I-type microcrystalline silicon layer between the I-type microcrystalline silicon germanium layer and the I-type amorphous silicon layer to reduce the energy barrier.

- Use of a multi-layer structure incorporating microcrystalline and amorphous silicon layers to improve overall cell efficiency.

- Combination of microcrystalline silicon germanium and microcrystalline silicon layers to enhance light absorption and carrier transport.

Microcrystalline silicon deposition for thin film solar applications

PatentInactiveEP2206156A1

Innovation

- A method involving a gas mixture of a silicon-containing compound and hydrogen gas is used to form intrinsic type microcrystalline silicon layers at varying deposition rates, allowing for the formation of thin film multi-junction solar cells with reduced deposition time without damaging underlying layers.

Environmental Impact of MCC-Based Solar Cells

The integration of microcrystalline cellulose (MCC) in thin film solar cells represents a significant step towards more sustainable and environmentally friendly photovoltaic technologies. As the world increasingly shifts towards renewable energy sources, the environmental impact of solar cell production and disposal becomes a critical consideration. MCC-based solar cells offer several environmental advantages over traditional silicon-based cells.

Firstly, the production of MCC-based solar cells generally requires less energy and generates fewer greenhouse gas emissions compared to conventional silicon solar cells. The raw material, cellulose, is abundant and renewable, often sourced from waste products of the paper and textile industries. This reduces the environmental burden associated with material extraction and processing.

The manufacturing process for MCC-based solar cells typically involves less toxic chemicals and lower processing temperatures than those used in silicon cell production. This not only reduces the environmental footprint of the manufacturing process but also enhances workplace safety. Additionally, the lower energy requirements for production contribute to a shorter energy payback time for these solar cells.

MCC-based solar cells also offer advantages in terms of end-of-life management. Unlike traditional solar panels that contain heavy metals and other potentially harmful materials, MCC-based cells are largely biodegradable. This characteristic significantly reduces the environmental impact of disposal and simplifies recycling processes.

Furthermore, the flexibility and lightweight nature of MCC-based thin film solar cells allow for diverse applications, including integration into building materials and portable devices. This versatility can lead to reduced transportation emissions and energy consumption in the deployment of solar energy systems.

However, it is important to note that the environmental benefits of MCC-based solar cells must be balanced against their current limitations in efficiency and durability compared to silicon-based cells. Ongoing research aims to improve these aspects while maintaining the environmental advantages.

In conclusion, while further studies are needed to fully quantify their life-cycle environmental impact, MCC-based solar cells show promising potential for reducing the ecological footprint of solar energy technology. Their development aligns with global efforts to create more sustainable and circular energy solutions, potentially playing a crucial role in the transition to a greener energy landscape.

Firstly, the production of MCC-based solar cells generally requires less energy and generates fewer greenhouse gas emissions compared to conventional silicon solar cells. The raw material, cellulose, is abundant and renewable, often sourced from waste products of the paper and textile industries. This reduces the environmental burden associated with material extraction and processing.

The manufacturing process for MCC-based solar cells typically involves less toxic chemicals and lower processing temperatures than those used in silicon cell production. This not only reduces the environmental footprint of the manufacturing process but also enhances workplace safety. Additionally, the lower energy requirements for production contribute to a shorter energy payback time for these solar cells.

MCC-based solar cells also offer advantages in terms of end-of-life management. Unlike traditional solar panels that contain heavy metals and other potentially harmful materials, MCC-based cells are largely biodegradable. This characteristic significantly reduces the environmental impact of disposal and simplifies recycling processes.

Furthermore, the flexibility and lightweight nature of MCC-based thin film solar cells allow for diverse applications, including integration into building materials and portable devices. This versatility can lead to reduced transportation emissions and energy consumption in the deployment of solar energy systems.

However, it is important to note that the environmental benefits of MCC-based solar cells must be balanced against their current limitations in efficiency and durability compared to silicon-based cells. Ongoing research aims to improve these aspects while maintaining the environmental advantages.

In conclusion, while further studies are needed to fully quantify their life-cycle environmental impact, MCC-based solar cells show promising potential for reducing the ecological footprint of solar energy technology. Their development aligns with global efforts to create more sustainable and circular energy solutions, potentially playing a crucial role in the transition to a greener energy landscape.

Cost-Benefit Analysis of MCC Integration

The integration of microcrystalline cellulose (MCC) in thin film solar cells presents a complex cost-benefit scenario that requires careful analysis. On the cost side, incorporating MCC into the manufacturing process may initially increase production expenses due to the need for specialized equipment and potential modifications to existing production lines. The sourcing and processing of high-quality MCC suitable for solar cell applications could also contribute to higher material costs compared to traditional components.

However, these upfront investments may be offset by several potential benefits. MCC's unique properties, such as its high mechanical strength and optical transparency, could lead to improved solar cell efficiency and durability. This enhancement in performance may result in longer-lasting solar panels, reducing the frequency of replacements and associated costs over the lifetime of the installation. Additionally, the use of MCC as a renewable and biodegradable material aligns with growing environmental concerns, potentially opening up new market segments and increasing consumer appeal.

From a manufacturing perspective, MCC's ability to form stable suspensions and its compatibility with various solvents could simplify certain production processes. This might lead to reduced processing times and lower energy consumption during manufacturing, contributing to overall cost savings. The lightweight nature of MCC could also decrease transportation costs and simplify installation procedures, particularly for large-scale solar projects.

In terms of market positioning, the incorporation of MCC into thin film solar cells could provide a unique selling point, potentially commanding premium pricing for eco-friendly and high-performance solar products. This differentiation strategy may lead to increased market share and higher profit margins, helping to recoup the initial investment in MCC integration more rapidly.

It is crucial to consider the scalability of MCC production to meet the demands of large-scale solar cell manufacturing. As production volumes increase, economies of scale may further reduce the cost of MCC integration, improving the overall cost-benefit ratio. Additionally, potential government incentives or subsidies for using renewable materials in solar technology could provide financial benefits that offset initial implementation costs.

The long-term environmental benefits of using MCC, such as reduced carbon footprint and easier end-of-life recycling of solar panels, should also be factored into the cost-benefit analysis. While these benefits may not have an immediate financial impact, they contribute to the overall sustainability profile of the product and may become increasingly valuable as environmental regulations tighten globally.

However, these upfront investments may be offset by several potential benefits. MCC's unique properties, such as its high mechanical strength and optical transparency, could lead to improved solar cell efficiency and durability. This enhancement in performance may result in longer-lasting solar panels, reducing the frequency of replacements and associated costs over the lifetime of the installation. Additionally, the use of MCC as a renewable and biodegradable material aligns with growing environmental concerns, potentially opening up new market segments and increasing consumer appeal.

From a manufacturing perspective, MCC's ability to form stable suspensions and its compatibility with various solvents could simplify certain production processes. This might lead to reduced processing times and lower energy consumption during manufacturing, contributing to overall cost savings. The lightweight nature of MCC could also decrease transportation costs and simplify installation procedures, particularly for large-scale solar projects.

In terms of market positioning, the incorporation of MCC into thin film solar cells could provide a unique selling point, potentially commanding premium pricing for eco-friendly and high-performance solar products. This differentiation strategy may lead to increased market share and higher profit margins, helping to recoup the initial investment in MCC integration more rapidly.

It is crucial to consider the scalability of MCC production to meet the demands of large-scale solar cell manufacturing. As production volumes increase, economies of scale may further reduce the cost of MCC integration, improving the overall cost-benefit ratio. Additionally, potential government incentives or subsidies for using renewable materials in solar technology could provide financial benefits that offset initial implementation costs.

The long-term environmental benefits of using MCC, such as reduced carbon footprint and easier end-of-life recycling of solar panels, should also be factored into the cost-benefit analysis. While these benefits may not have an immediate financial impact, they contribute to the overall sustainability profile of the product and may become increasingly valuable as environmental regulations tighten globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!