Applications of Perchloric Acid in Chemical Vapor Deposition Processes

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CVD Perchloric Acid Background and Objectives

Chemical Vapor Deposition (CVD) has been a cornerstone in the fabrication of advanced materials and thin films for decades. Within this realm, perchloric acid has emerged as a significant player, offering unique properties that enhance various CVD processes. The evolution of perchloric acid applications in CVD can be traced back to the mid-20th century, with its use becoming more prevalent in the 1980s and 1990s as semiconductor manufacturing techniques advanced.

Perchloric acid's role in CVD stems from its powerful oxidizing properties and ability to form volatile perchlorates with many elements. These characteristics make it particularly useful in the deposition of metal oxides and complex oxide materials, which are crucial in the production of electronic components, optical coatings, and advanced ceramics. The acid's high oxidation potential allows for the creation of high-purity oxide films at relatively low temperatures, a key advantage in many industrial applications.

The technological trajectory of perchloric acid in CVD has been driven by the increasing demands for miniaturization and performance enhancement in electronics and other high-tech industries. As device architectures become more complex and feature sizes shrink, the need for precise control over film composition and thickness has intensified. Perchloric acid-based CVD processes have evolved to meet these challenges, offering improved uniformity, conformality, and stoichiometric control in deposited layers.

Recent trends in CVD technology involving perchloric acid include its integration into atomic layer deposition (ALD) processes, where ultra-thin films are deposited with atomic-level precision. This convergence of CVD and ALD techniques has opened new avenues for material engineering at the nanoscale, particularly in the development of advanced semiconductor devices and energy storage materials.

The primary objectives of current research and development efforts in perchloric acid CVD applications are multifaceted. These include expanding the range of materials that can be deposited using perchloric acid precursors, enhancing process safety and environmental sustainability, and developing novel reactor designs that optimize the use of perchloric acid in CVD systems. Additionally, there is a growing focus on understanding the fundamental reaction mechanisms and kinetics of perchloric acid in vapor deposition processes to enable more precise control over film properties and growth rates.

As we look to the future, the continued exploration of perchloric acid in CVD processes aims to unlock new possibilities in materials science and nanotechnology. The goal is to leverage its unique chemical properties to enable the fabrication of next-generation devices and materials with unprecedented performance characteristics, while simultaneously addressing the challenges of scalability, cost-effectiveness, and environmental impact.

Perchloric acid's role in CVD stems from its powerful oxidizing properties and ability to form volatile perchlorates with many elements. These characteristics make it particularly useful in the deposition of metal oxides and complex oxide materials, which are crucial in the production of electronic components, optical coatings, and advanced ceramics. The acid's high oxidation potential allows for the creation of high-purity oxide films at relatively low temperatures, a key advantage in many industrial applications.

The technological trajectory of perchloric acid in CVD has been driven by the increasing demands for miniaturization and performance enhancement in electronics and other high-tech industries. As device architectures become more complex and feature sizes shrink, the need for precise control over film composition and thickness has intensified. Perchloric acid-based CVD processes have evolved to meet these challenges, offering improved uniformity, conformality, and stoichiometric control in deposited layers.

Recent trends in CVD technology involving perchloric acid include its integration into atomic layer deposition (ALD) processes, where ultra-thin films are deposited with atomic-level precision. This convergence of CVD and ALD techniques has opened new avenues for material engineering at the nanoscale, particularly in the development of advanced semiconductor devices and energy storage materials.

The primary objectives of current research and development efforts in perchloric acid CVD applications are multifaceted. These include expanding the range of materials that can be deposited using perchloric acid precursors, enhancing process safety and environmental sustainability, and developing novel reactor designs that optimize the use of perchloric acid in CVD systems. Additionally, there is a growing focus on understanding the fundamental reaction mechanisms and kinetics of perchloric acid in vapor deposition processes to enable more precise control over film properties and growth rates.

As we look to the future, the continued exploration of perchloric acid in CVD processes aims to unlock new possibilities in materials science and nanotechnology. The goal is to leverage its unique chemical properties to enable the fabrication of next-generation devices and materials with unprecedented performance characteristics, while simultaneously addressing the challenges of scalability, cost-effectiveness, and environmental impact.

Market Analysis for CVD Processes Using Perchloric Acid

The Chemical Vapor Deposition (CVD) market utilizing perchloric acid has shown significant growth potential in recent years. This growth is primarily driven by the increasing demand for high-quality thin films in various industries, including semiconductors, optoelectronics, and advanced materials. The global CVD market is expected to expand at a compound annual growth rate (CAGR) of 8.5% from 2021 to 2026, with the perchloric acid segment playing a crucial role in this growth.

Perchloric acid's unique properties make it an attractive option for CVD processes, particularly in applications requiring high-purity, uniform thin films. Its strong oxidizing capabilities and ability to form volatile metal perchlorates contribute to its effectiveness in CVD reactions. This has led to increased adoption in the production of advanced electronic components, such as high-k dielectrics and metal oxide films for next-generation devices.

The semiconductor industry remains the largest consumer of CVD processes using perchloric acid. With the ongoing miniaturization of electronic devices and the push for more efficient and powerful chips, the demand for precise and high-quality thin film deposition continues to rise. This trend is expected to drive the market for perchloric acid-based CVD processes in the coming years.

Emerging applications in the field of nanotechnology and advanced materials are also contributing to market growth. Perchloric acid-based CVD processes are being explored for the synthesis of novel nanomaterials, including graphene and carbon nanotubes, which have potential applications in energy storage, flexible electronics, and sensors.

Geographically, Asia-Pacific dominates the market for CVD processes using perchloric acid, primarily due to the strong presence of semiconductor and electronics manufacturing in countries like China, South Korea, and Taiwan. North America and Europe follow, with significant research and development activities in advanced materials and emerging technologies.

However, the market faces challenges related to safety concerns and environmental regulations surrounding the use of perchloric acid. This has led to increased research into alternative precursors and process optimizations to mitigate these issues. Despite these challenges, the unique advantages offered by perchloric acid in CVD processes continue to drive its adoption in high-value applications.

As the demand for advanced electronic devices and novel materials grows, the market for CVD processes using perchloric acid is expected to expand further. Innovations in process control, safety measures, and new applications are likely to shape the future of this market segment.

Perchloric acid's unique properties make it an attractive option for CVD processes, particularly in applications requiring high-purity, uniform thin films. Its strong oxidizing capabilities and ability to form volatile metal perchlorates contribute to its effectiveness in CVD reactions. This has led to increased adoption in the production of advanced electronic components, such as high-k dielectrics and metal oxide films for next-generation devices.

The semiconductor industry remains the largest consumer of CVD processes using perchloric acid. With the ongoing miniaturization of electronic devices and the push for more efficient and powerful chips, the demand for precise and high-quality thin film deposition continues to rise. This trend is expected to drive the market for perchloric acid-based CVD processes in the coming years.

Emerging applications in the field of nanotechnology and advanced materials are also contributing to market growth. Perchloric acid-based CVD processes are being explored for the synthesis of novel nanomaterials, including graphene and carbon nanotubes, which have potential applications in energy storage, flexible electronics, and sensors.

Geographically, Asia-Pacific dominates the market for CVD processes using perchloric acid, primarily due to the strong presence of semiconductor and electronics manufacturing in countries like China, South Korea, and Taiwan. North America and Europe follow, with significant research and development activities in advanced materials and emerging technologies.

However, the market faces challenges related to safety concerns and environmental regulations surrounding the use of perchloric acid. This has led to increased research into alternative precursors and process optimizations to mitigate these issues. Despite these challenges, the unique advantages offered by perchloric acid in CVD processes continue to drive its adoption in high-value applications.

As the demand for advanced electronic devices and novel materials grows, the market for CVD processes using perchloric acid is expected to expand further. Innovations in process control, safety measures, and new applications are likely to shape the future of this market segment.

Current Challenges in Perchloric Acid CVD Applications

Despite the significant advancements in Chemical Vapor Deposition (CVD) processes utilizing perchloric acid, several challenges persist in its application. One of the primary concerns is the inherent safety risks associated with handling perchloric acid. Its strong oxidizing properties and potential for explosive reactions necessitate stringent safety protocols, which can complicate process implementation and increase operational costs.

The corrosive nature of perchloric acid poses another significant challenge, as it can lead to accelerated degradation of equipment and infrastructure. This not only results in increased maintenance expenses but also raises concerns about the long-term reliability and consistency of CVD processes employing this acid. Consequently, materials selection for reactors, piping, and other components becomes critical, often requiring expensive corrosion-resistant alloys or specialized coatings.

Environmental considerations present yet another hurdle in perchloric acid CVD applications. The disposal of waste products and the potential for atmospheric emissions require sophisticated treatment systems and rigorous monitoring protocols. Compliance with increasingly stringent environmental regulations adds complexity and cost to CVD operations using perchloric acid.

The precise control of reaction conditions in perchloric acid CVD processes remains challenging. Fluctuations in temperature, pressure, or reactant concentrations can significantly impact the quality and uniformity of deposited films. Achieving consistent results across large substrate areas or in high-volume production settings demands advanced process control systems and expertise.

Furthermore, the scalability of perchloric acid CVD processes for industrial applications presents ongoing difficulties. While effective at laboratory scales, translating these processes to commercial production levels often encounters issues related to uniformity, throughput, and cost-effectiveness. The need for specialized equipment and safety measures can make scaling up prohibitively expensive for some applications.

Lastly, the limited understanding of the exact reaction mechanisms in perchloric acid CVD processes hinders optimization efforts. The complex interplay between the acid, precursors, and substrate surfaces under various conditions is not fully elucidated, making it challenging to predict and control film properties precisely. This knowledge gap impedes the development of new applications and the refinement of existing processes.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, process engineering, and safety technologies. Ongoing research efforts focus on developing alternative precursors, improving reactor designs, and enhancing process control strategies to overcome the current limitations of perchloric acid in CVD applications.

The corrosive nature of perchloric acid poses another significant challenge, as it can lead to accelerated degradation of equipment and infrastructure. This not only results in increased maintenance expenses but also raises concerns about the long-term reliability and consistency of CVD processes employing this acid. Consequently, materials selection for reactors, piping, and other components becomes critical, often requiring expensive corrosion-resistant alloys or specialized coatings.

Environmental considerations present yet another hurdle in perchloric acid CVD applications. The disposal of waste products and the potential for atmospheric emissions require sophisticated treatment systems and rigorous monitoring protocols. Compliance with increasingly stringent environmental regulations adds complexity and cost to CVD operations using perchloric acid.

The precise control of reaction conditions in perchloric acid CVD processes remains challenging. Fluctuations in temperature, pressure, or reactant concentrations can significantly impact the quality and uniformity of deposited films. Achieving consistent results across large substrate areas or in high-volume production settings demands advanced process control systems and expertise.

Furthermore, the scalability of perchloric acid CVD processes for industrial applications presents ongoing difficulties. While effective at laboratory scales, translating these processes to commercial production levels often encounters issues related to uniformity, throughput, and cost-effectiveness. The need for specialized equipment and safety measures can make scaling up prohibitively expensive for some applications.

Lastly, the limited understanding of the exact reaction mechanisms in perchloric acid CVD processes hinders optimization efforts. The complex interplay between the acid, precursors, and substrate surfaces under various conditions is not fully elucidated, making it challenging to predict and control film properties precisely. This knowledge gap impedes the development of new applications and the refinement of existing processes.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, process engineering, and safety technologies. Ongoing research efforts focus on developing alternative precursors, improving reactor designs, and enhancing process control strategies to overcome the current limitations of perchloric acid in CVD applications.

Existing Perchloric Acid CVD Methodologies

01 Synthesis and production of perchloric acid

Methods for synthesizing and producing perchloric acid, including various chemical reactions and industrial processes. This may involve the use of specific catalysts, reactants, and equipment to ensure efficient and safe production of perchloric acid.- Synthesis and production of perchloric acid: Methods for synthesizing and producing perchloric acid, including various chemical reactions and industrial processes. This may involve the use of specific catalysts, reactants, and equipment to ensure efficient and safe production of perchloric acid.

- Applications of perchloric acid in chemical analysis: Utilization of perchloric acid in various analytical techniques and procedures. This includes its use as a strong oxidizing agent in chemical reactions, as well as its role in sample preparation and digestion for analytical chemistry applications.

- Safety measures and handling of perchloric acid: Protocols and equipment designed for the safe handling, storage, and disposal of perchloric acid. This includes specialized containment systems, personal protective equipment, and emergency response procedures to mitigate the risks associated with this highly corrosive and potentially explosive substance.

- Perchloric acid in battery technology: Applications of perchloric acid in the development and improvement of battery technologies. This may involve its use as an electrolyte component or in the preparation of electrode materials for various types of batteries, potentially enhancing their performance and efficiency.

- Purification and quality control of perchloric acid: Techniques and methods for purifying perchloric acid and ensuring its quality for various applications. This includes processes for removing impurities, concentration adjustments, and analytical methods for verifying the purity and concentration of perchloric acid samples.

02 Applications of perchloric acid in chemical analysis

Utilization of perchloric acid in various analytical techniques and procedures. This includes its use as a strong oxidizing agent in chemical analysis, sample preparation, and as a component in analytical reagents for detecting and quantifying specific substances.Expand Specific Solutions03 Safety measures and handling of perchloric acid

Protocols and equipment designed for the safe handling, storage, and disposal of perchloric acid. This includes specialized containment systems, personal protective equipment, and emergency response procedures to mitigate the risks associated with this highly corrosive and potentially explosive substance.Expand Specific Solutions04 Perchloric acid in battery technology

Applications of perchloric acid in the development and improvement of battery technologies. This may include its use as an electrolyte component or in the preparation of electrode materials, potentially enhancing battery performance, capacity, or longevity.Expand Specific Solutions05 Purification and concentration of perchloric acid

Techniques and processes for purifying and concentrating perchloric acid to meet specific industrial or laboratory requirements. This may involve distillation, membrane separation, or other advanced purification methods to achieve high-purity perchloric acid solutions.Expand Specific Solutions

Key Industry Players in Perchloric Acid CVD

The applications of perchloric acid in chemical vapor deposition (CVD) processes represent a niche but growing segment within the semiconductor industry. The market is in its early growth stage, with increasing demand driven by the need for high-purity materials in advanced semiconductor manufacturing. Key players like DuPont, Micron Technology, and Applied Materials are investing in research and development to optimize perchloric acid-based CVD processes. The technology is still evolving, with companies like SMIC and UMC focusing on improving process efficiency and yield. As the semiconductor industry continues to advance, the market for perchloric acid in CVD applications is expected to expand, albeit with careful consideration of safety and environmental concerns.

Micron Technology, Inc.

Technical Solution: Micron Technology has implemented perchloric acid-based CVD processes in their memory device fabrication. Their approach focuses on using perchloric acid as an oxidizing agent in the deposition of high-quality dielectric layers for DRAM capacitors. The company has developed a unique two-step deposition process where perchloric acid is first used to create a thin, highly conformal seed layer, followed by a bulk deposition step[3]. This method allows for the creation of ultra-thin, high-density dielectric films with excellent electrical properties. Micron has also incorporated in-situ plasma treatment using perchloric acid to improve the interface quality between the dielectric and electrode materials, resulting in enhanced device reliability and performance[4].

Strengths: Ability to create ultra-thin, high-density dielectric films with excellent electrical properties. Weaknesses: Complexity of the two-step process may impact throughput in high-volume manufacturing.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced Chemical Vapor Deposition (CVD) processes utilizing perchloric acid as a precursor. Their technology focuses on enhancing the deposition of high-k dielectric materials for semiconductor devices. The company's approach involves using perchloric acid to create a highly oxidizing environment, which facilitates the formation of uniform and dense metal oxide films[1]. This method allows for precise control over film thickness and composition, crucial for manufacturing advanced integrated circuits. Applied Materials has also integrated this technology into their cluster tools, enabling in-situ surface cleaning and film deposition without breaking vacuum, thereby reducing contamination risks and improving overall device performance[2].

Strengths: Precise control over film properties, reduced contamination, and improved device performance. Weaknesses: Potential safety concerns due to the reactive nature of perchloric acid, requiring stringent handling protocols.

Innovative Perchloric Acid CVD Technologies

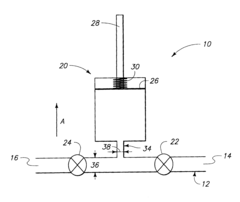

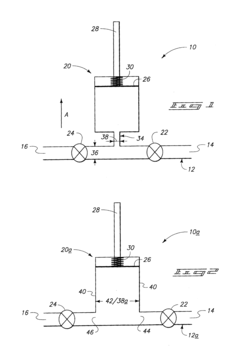

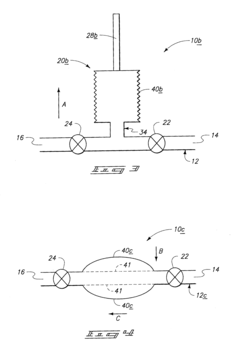

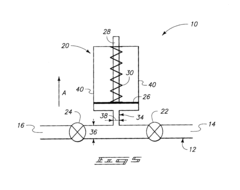

Chemical vapor deposition methods, and atomic layer deposition method

PatentInactiveUS6787463B2

Innovation

- A reactive gaseous deposition precursor feed apparatus featuring a variable volume accumulator reservoir with a moveable piston or bellows, which maintains constant pressure and adjusts volume to expel precursors into a deposition chamber, ensuring uniform deposition by controlling the flow of precursors through inlet and outlet valves.

Chemical vapour infiltration or deposition process

PatentInactiveUS20220041513A1

Innovation

- Incorporating carbon dioxide into the gas phase alongside a pyrocarbon precursor compound, such as a hydrocarbon, to produce molecular hydrogen, thereby reducing PAH formation, with carbon dioxide content optimized between 2% and 15% volume to control its oxidizing character and enhance hydrogen formation kinetics.

Safety Protocols for Perchloric Acid in CVD Processes

The use of perchloric acid in Chemical Vapor Deposition (CVD) processes necessitates stringent safety protocols due to its highly reactive and potentially explosive nature. Proper handling and storage of perchloric acid are paramount to ensure the safety of personnel and facilities involved in CVD operations.

Firstly, all personnel working with perchloric acid must undergo comprehensive safety training. This training should cover the properties of perchloric acid, potential hazards, proper handling techniques, and emergency response procedures. Regular refresher courses should be mandatory to maintain awareness and reinforce safety practices.

Personal protective equipment (PPE) is crucial when working with perchloric acid. Workers must wear chemical-resistant gloves, goggles, face shields, and acid-resistant aprons or suits. Respiratory protection may also be necessary, depending on the specific application and potential for vapor exposure.

The storage of perchloric acid requires special considerations. It should be kept in a cool, well-ventilated area, away from combustible materials and other chemicals. Dedicated storage cabinets with secondary containment should be used to prevent accidental spills or leaks from spreading.

In CVD processes, the use of perchloric acid should be confined to specially designed fume hoods or enclosed systems. These systems must be equipped with wash-down facilities to prevent the accumulation of explosive perchlorates. Regular cleaning and maintenance of these systems are essential to prevent the buildup of potentially hazardous residues.

Emergency response plans must be in place and regularly updated. This includes the availability of appropriate fire extinguishing agents, as water-based extinguishers can be ineffective or even dangerous when used on perchloric acid fires. Spill kits specifically designed for strong oxidizers should be readily accessible in all areas where perchloric acid is used or stored.

Proper waste management is another critical aspect of safety protocols. Perchloric acid waste must be segregated from other chemical waste streams and disposed of according to local regulations. Neutralization and dilution procedures should be clearly defined and followed meticulously.

Regular safety audits and inspections should be conducted to ensure compliance with established protocols. These audits should include checks on storage conditions, PPE usage, equipment integrity, and adherence to handling procedures. Any deviations or potential hazards identified during these audits must be addressed promptly.

Implementing a robust incident reporting and investigation system is essential for continuous improvement of safety measures. All incidents, near-misses, and potential hazards related to perchloric acid use in CVD processes should be thoroughly documented and analyzed to prevent future occurrences.

Firstly, all personnel working with perchloric acid must undergo comprehensive safety training. This training should cover the properties of perchloric acid, potential hazards, proper handling techniques, and emergency response procedures. Regular refresher courses should be mandatory to maintain awareness and reinforce safety practices.

Personal protective equipment (PPE) is crucial when working with perchloric acid. Workers must wear chemical-resistant gloves, goggles, face shields, and acid-resistant aprons or suits. Respiratory protection may also be necessary, depending on the specific application and potential for vapor exposure.

The storage of perchloric acid requires special considerations. It should be kept in a cool, well-ventilated area, away from combustible materials and other chemicals. Dedicated storage cabinets with secondary containment should be used to prevent accidental spills or leaks from spreading.

In CVD processes, the use of perchloric acid should be confined to specially designed fume hoods or enclosed systems. These systems must be equipped with wash-down facilities to prevent the accumulation of explosive perchlorates. Regular cleaning and maintenance of these systems are essential to prevent the buildup of potentially hazardous residues.

Emergency response plans must be in place and regularly updated. This includes the availability of appropriate fire extinguishing agents, as water-based extinguishers can be ineffective or even dangerous when used on perchloric acid fires. Spill kits specifically designed for strong oxidizers should be readily accessible in all areas where perchloric acid is used or stored.

Proper waste management is another critical aspect of safety protocols. Perchloric acid waste must be segregated from other chemical waste streams and disposed of according to local regulations. Neutralization and dilution procedures should be clearly defined and followed meticulously.

Regular safety audits and inspections should be conducted to ensure compliance with established protocols. These audits should include checks on storage conditions, PPE usage, equipment integrity, and adherence to handling procedures. Any deviations or potential hazards identified during these audits must be addressed promptly.

Implementing a robust incident reporting and investigation system is essential for continuous improvement of safety measures. All incidents, near-misses, and potential hazards related to perchloric acid use in CVD processes should be thoroughly documented and analyzed to prevent future occurrences.

Environmental Impact of Perchloric Acid CVD Applications

The use of perchloric acid in Chemical Vapor Deposition (CVD) processes has raised significant environmental concerns due to its potential impacts on ecosystems and human health. Perchloric acid is a strong oxidizing agent and can persist in the environment, leading to long-term ecological effects if not properly managed.

One of the primary environmental risks associated with perchloric acid in CVD applications is its potential to contaminate water sources. When released into the environment, perchloric acid can form perchlorate ions, which are highly soluble and mobile in water systems. These ions can persist for extended periods and may accumulate in surface and groundwater, potentially affecting drinking water supplies.

The presence of perchlorates in water bodies can have detrimental effects on aquatic ecosystems. Studies have shown that elevated perchlorate levels can disrupt the endocrine systems of fish and amphibians, leading to developmental abnormalities and reduced reproductive success. This can have cascading effects throughout the food chain, impacting biodiversity and ecosystem stability.

Air pollution is another significant concern related to perchloric acid use in CVD processes. The volatility of perchloric acid can result in the release of acid vapors and aerosols into the atmosphere during manufacturing processes. These emissions can contribute to the formation of acid rain and smog, negatively impacting air quality and potentially harming vegetation and infrastructure in affected areas.

The disposal of perchloric acid waste from CVD applications also poses environmental challenges. Improper handling and disposal can lead to soil contamination, affecting soil chemistry and microbial communities. This can result in reduced soil fertility and potential bioaccumulation of perchlorates in plants, which may enter the food chain.

To mitigate these environmental impacts, stringent regulations and best practices have been developed for the use of perchloric acid in industrial processes, including CVD applications. These measures include the implementation of advanced air filtration systems, closed-loop recycling processes, and specialized waste treatment facilities to neutralize and safely dispose of perchloric acid residues.

Research into alternative chemicals and processes that can replace perchloric acid in CVD applications is ongoing. Some promising alternatives include the use of less hazardous oxidizing agents or the development of novel deposition techniques that eliminate the need for perchloric acid altogether. These efforts aim to reduce the environmental footprint of CVD processes while maintaining or improving the quality of the resulting thin films and coatings.

One of the primary environmental risks associated with perchloric acid in CVD applications is its potential to contaminate water sources. When released into the environment, perchloric acid can form perchlorate ions, which are highly soluble and mobile in water systems. These ions can persist for extended periods and may accumulate in surface and groundwater, potentially affecting drinking water supplies.

The presence of perchlorates in water bodies can have detrimental effects on aquatic ecosystems. Studies have shown that elevated perchlorate levels can disrupt the endocrine systems of fish and amphibians, leading to developmental abnormalities and reduced reproductive success. This can have cascading effects throughout the food chain, impacting biodiversity and ecosystem stability.

Air pollution is another significant concern related to perchloric acid use in CVD processes. The volatility of perchloric acid can result in the release of acid vapors and aerosols into the atmosphere during manufacturing processes. These emissions can contribute to the formation of acid rain and smog, negatively impacting air quality and potentially harming vegetation and infrastructure in affected areas.

The disposal of perchloric acid waste from CVD applications also poses environmental challenges. Improper handling and disposal can lead to soil contamination, affecting soil chemistry and microbial communities. This can result in reduced soil fertility and potential bioaccumulation of perchlorates in plants, which may enter the food chain.

To mitigate these environmental impacts, stringent regulations and best practices have been developed for the use of perchloric acid in industrial processes, including CVD applications. These measures include the implementation of advanced air filtration systems, closed-loop recycling processes, and specialized waste treatment facilities to neutralize and safely dispose of perchloric acid residues.

Research into alternative chemicals and processes that can replace perchloric acid in CVD applications is ongoing. Some promising alternatives include the use of less hazardous oxidizing agents or the development of novel deposition techniques that eliminate the need for perchloric acid altogether. These efforts aim to reduce the environmental footprint of CVD processes while maintaining or improving the quality of the resulting thin films and coatings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!