The Application of Perchloric Acid in Microelectronics Cleaning Processes

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perchloric Acid in Microelectronics: Background and Objectives

Perchloric acid has emerged as a crucial component in the microelectronics industry, particularly in cleaning processes. This powerful oxidizing agent has a rich history dating back to its discovery in the early 19th century. Initially, its applications were limited due to its highly reactive nature. However, as the microelectronics industry evolved, the need for ultra-clean surfaces became paramount, leading to the exploration of perchloric acid's potential in this field.

The development of integrated circuits and semiconductor devices in the mid-20th century marked a turning point in the application of perchloric acid. As device dimensions shrank and performance requirements increased, traditional cleaning methods proved inadequate. This technological shift prompted researchers to investigate more effective cleaning agents, with perchloric acid emerging as a promising candidate due to its strong oxidizing properties and ability to remove a wide range of contaminants.

Over the past few decades, the use of perchloric acid in microelectronics cleaning has seen significant advancements. Its ability to effectively remove organic residues, metal ions, and other impurities from semiconductor surfaces has made it an indispensable tool in the industry. The evolution of perchloric acid applications has closely followed the trajectory of Moore's Law, with cleaning processes becoming increasingly critical as device features continue to shrink.

The primary objective of utilizing perchloric acid in microelectronics cleaning processes is to achieve ultra-clean surfaces that are essential for optimal device performance and reliability. This includes removing submicron particles, organic contaminants, and metallic impurities that can interfere with device functionality. Additionally, the use of perchloric acid aims to improve yield rates in semiconductor manufacturing by minimizing defects caused by surface contamination.

Another key goal is to develop more efficient and environmentally friendly cleaning processes. While perchloric acid is highly effective, its use presents challenges in terms of safety and environmental impact. Therefore, ongoing research focuses on optimizing perchloric acid-based cleaning methods to reduce chemical consumption, minimize waste generation, and improve overall process efficiency.

As the microelectronics industry continues to push the boundaries of device miniaturization and performance, the role of perchloric acid in cleaning processes is expected to evolve further. Future objectives include developing novel formulations and application techniques that can address the cleaning requirements of next-generation devices, such as 3D integrated circuits and quantum computing components. Additionally, there is a growing emphasis on integrating perchloric acid-based cleaning processes with other advanced manufacturing techniques to create more streamlined and cost-effective production workflows.

The development of integrated circuits and semiconductor devices in the mid-20th century marked a turning point in the application of perchloric acid. As device dimensions shrank and performance requirements increased, traditional cleaning methods proved inadequate. This technological shift prompted researchers to investigate more effective cleaning agents, with perchloric acid emerging as a promising candidate due to its strong oxidizing properties and ability to remove a wide range of contaminants.

Over the past few decades, the use of perchloric acid in microelectronics cleaning has seen significant advancements. Its ability to effectively remove organic residues, metal ions, and other impurities from semiconductor surfaces has made it an indispensable tool in the industry. The evolution of perchloric acid applications has closely followed the trajectory of Moore's Law, with cleaning processes becoming increasingly critical as device features continue to shrink.

The primary objective of utilizing perchloric acid in microelectronics cleaning processes is to achieve ultra-clean surfaces that are essential for optimal device performance and reliability. This includes removing submicron particles, organic contaminants, and metallic impurities that can interfere with device functionality. Additionally, the use of perchloric acid aims to improve yield rates in semiconductor manufacturing by minimizing defects caused by surface contamination.

Another key goal is to develop more efficient and environmentally friendly cleaning processes. While perchloric acid is highly effective, its use presents challenges in terms of safety and environmental impact. Therefore, ongoing research focuses on optimizing perchloric acid-based cleaning methods to reduce chemical consumption, minimize waste generation, and improve overall process efficiency.

As the microelectronics industry continues to push the boundaries of device miniaturization and performance, the role of perchloric acid in cleaning processes is expected to evolve further. Future objectives include developing novel formulations and application techniques that can address the cleaning requirements of next-generation devices, such as 3D integrated circuits and quantum computing components. Additionally, there is a growing emphasis on integrating perchloric acid-based cleaning processes with other advanced manufacturing techniques to create more streamlined and cost-effective production workflows.

Market Demand Analysis for Advanced Cleaning Solutions

The microelectronics industry is experiencing a growing demand for advanced cleaning solutions, particularly in the application of perchloric acid for precision cleaning processes. This demand is driven by the continuous miniaturization of electronic components and the increasing complexity of semiconductor devices, which require more stringent cleaning standards to ensure optimal performance and reliability.

Market analysis indicates that the global semiconductor cleaning equipment market is projected to expand significantly in the coming years. This growth is fueled by the rapid advancement of technologies such as 5G, artificial intelligence, and the Internet of Things, all of which rely heavily on high-performance microelectronics. The demand for perchloric acid-based cleaning solutions is especially pronounced in the manufacturing of advanced logic and memory chips, where even microscopic contaminants can lead to critical defects.

The Asia-Pacific region, particularly countries like Taiwan, South Korea, and China, dominates the market demand for advanced cleaning solutions. This is due to the concentration of semiconductor fabrication facilities in these countries. However, there is also a notable increase in demand from emerging markets in Southeast Asia and India, as these regions seek to establish their presence in the global semiconductor industry.

In terms of specific applications, the demand for perchloric acid in microelectronics cleaning is highest in the production of high-performance computing chips, mobile processors, and memory devices. These segments require ultra-clean surfaces to achieve the necessary levels of performance and yield. The automotive and aerospace industries are also emerging as significant consumers of advanced cleaning solutions, driven by the increasing integration of electronic systems in vehicles and aircraft.

The market demand is further influenced by stringent environmental regulations and safety standards. This has led to a growing interest in eco-friendly and sustainable cleaning solutions that can match or exceed the performance of traditional perchloric acid-based processes. As a result, there is a parallel demand for research and development in alternative cleaning technologies that can offer similar levels of effectiveness while reducing environmental impact and safety risks.

End-users in the semiconductor industry are increasingly seeking integrated cleaning solutions that can be seamlessly incorporated into their existing production lines. This trend is driving demand for not just the cleaning chemicals themselves, but also for advanced equipment and process control systems that can optimize the use of perchloric acid in microelectronics cleaning.

Market analysis indicates that the global semiconductor cleaning equipment market is projected to expand significantly in the coming years. This growth is fueled by the rapid advancement of technologies such as 5G, artificial intelligence, and the Internet of Things, all of which rely heavily on high-performance microelectronics. The demand for perchloric acid-based cleaning solutions is especially pronounced in the manufacturing of advanced logic and memory chips, where even microscopic contaminants can lead to critical defects.

The Asia-Pacific region, particularly countries like Taiwan, South Korea, and China, dominates the market demand for advanced cleaning solutions. This is due to the concentration of semiconductor fabrication facilities in these countries. However, there is also a notable increase in demand from emerging markets in Southeast Asia and India, as these regions seek to establish their presence in the global semiconductor industry.

In terms of specific applications, the demand for perchloric acid in microelectronics cleaning is highest in the production of high-performance computing chips, mobile processors, and memory devices. These segments require ultra-clean surfaces to achieve the necessary levels of performance and yield. The automotive and aerospace industries are also emerging as significant consumers of advanced cleaning solutions, driven by the increasing integration of electronic systems in vehicles and aircraft.

The market demand is further influenced by stringent environmental regulations and safety standards. This has led to a growing interest in eco-friendly and sustainable cleaning solutions that can match or exceed the performance of traditional perchloric acid-based processes. As a result, there is a parallel demand for research and development in alternative cleaning technologies that can offer similar levels of effectiveness while reducing environmental impact and safety risks.

End-users in the semiconductor industry are increasingly seeking integrated cleaning solutions that can be seamlessly incorporated into their existing production lines. This trend is driving demand for not just the cleaning chemicals themselves, but also for advanced equipment and process control systems that can optimize the use of perchloric acid in microelectronics cleaning.

Current State and Challenges in Microelectronics Cleaning

The microelectronics industry has witnessed significant advancements in cleaning processes, with perchloric acid emerging as a crucial component. Currently, the application of perchloric acid in microelectronics cleaning is widespread due to its exceptional oxidizing properties and ability to remove stubborn contaminants from semiconductor surfaces.

The current state of microelectronics cleaning using perchloric acid involves highly controlled and precise processes. Manufacturers employ specialized equipment and facilities to handle this potent chemical safely. The cleaning process typically includes diluting perchloric acid to specific concentrations and applying it in combination with other chemicals or as part of multi-step cleaning procedures.

One of the primary challenges in using perchloric acid for microelectronics cleaning is ensuring worker safety and environmental protection. The highly reactive nature of perchloric acid necessitates stringent safety protocols, specialized handling equipment, and proper disposal methods. This requirement often leads to increased operational costs and complexity in manufacturing processes.

Another significant challenge is the potential for residue formation. While perchloric acid is effective in removing contaminants, it can sometimes leave behind perchlorate residues on the cleaned surfaces. These residues can interfere with subsequent manufacturing steps or affect the performance of the final microelectronic devices. Developing methods to minimize or eliminate these residues remains an ongoing challenge for the industry.

The increasing miniaturization of microelectronic components presents another hurdle. As device features become smaller, the cleaning process must be even more precise to avoid damaging delicate structures while still effectively removing contaminants. This requires continuous refinement of cleaning techniques and the development of new formulations that can clean at the nanoscale level without compromising device integrity.

Environmental concerns also pose a significant challenge to the use of perchloric acid in microelectronics cleaning. Stricter regulations on chemical usage and disposal have prompted the industry to seek more environmentally friendly alternatives or develop closed-loop systems that minimize waste and emissions. Balancing the effectiveness of perchloric acid with environmental sustainability remains a key focus area for researchers and manufacturers alike.

Furthermore, the industry faces challenges in optimizing the cleaning process for different types of materials and device structures. As new materials and complex 3D architectures are introduced in microelectronics, cleaning processes must be adapted to ensure compatibility and effectiveness across a wide range of scenarios. This requires ongoing research and development efforts to tailor cleaning solutions for specific applications and materials.

The current state of microelectronics cleaning using perchloric acid involves highly controlled and precise processes. Manufacturers employ specialized equipment and facilities to handle this potent chemical safely. The cleaning process typically includes diluting perchloric acid to specific concentrations and applying it in combination with other chemicals or as part of multi-step cleaning procedures.

One of the primary challenges in using perchloric acid for microelectronics cleaning is ensuring worker safety and environmental protection. The highly reactive nature of perchloric acid necessitates stringent safety protocols, specialized handling equipment, and proper disposal methods. This requirement often leads to increased operational costs and complexity in manufacturing processes.

Another significant challenge is the potential for residue formation. While perchloric acid is effective in removing contaminants, it can sometimes leave behind perchlorate residues on the cleaned surfaces. These residues can interfere with subsequent manufacturing steps or affect the performance of the final microelectronic devices. Developing methods to minimize or eliminate these residues remains an ongoing challenge for the industry.

The increasing miniaturization of microelectronic components presents another hurdle. As device features become smaller, the cleaning process must be even more precise to avoid damaging delicate structures while still effectively removing contaminants. This requires continuous refinement of cleaning techniques and the development of new formulations that can clean at the nanoscale level without compromising device integrity.

Environmental concerns also pose a significant challenge to the use of perchloric acid in microelectronics cleaning. Stricter regulations on chemical usage and disposal have prompted the industry to seek more environmentally friendly alternatives or develop closed-loop systems that minimize waste and emissions. Balancing the effectiveness of perchloric acid with environmental sustainability remains a key focus area for researchers and manufacturers alike.

Furthermore, the industry faces challenges in optimizing the cleaning process for different types of materials and device structures. As new materials and complex 3D architectures are introduced in microelectronics, cleaning processes must be adapted to ensure compatibility and effectiveness across a wide range of scenarios. This requires ongoing research and development efforts to tailor cleaning solutions for specific applications and materials.

Existing Perchloric Acid-based Cleaning Processes

01 Synthesis and production of perchloric acid

Methods for synthesizing and producing perchloric acid, including various chemical reactions and industrial processes. This may involve the use of specific catalysts, reactants, and equipment to ensure efficient and safe production of perchloric acid.- Synthesis and production of perchloric acid: Various methods and processes for synthesizing and producing perchloric acid, including electrochemical techniques, chemical reactions, and purification steps. These methods aim to improve efficiency, yield, and purity of the final product.

- Applications of perchloric acid in chemical analysis: Perchloric acid is widely used in chemical analysis, particularly in sample preparation and digestion processes. It is effective in breaking down complex organic compounds and extracting metals from various matrices for subsequent analysis.

- Safety measures and handling of perchloric acid: Due to its strong oxidizing properties, perchloric acid requires specific safety measures and handling procedures. This includes specialized equipment, storage conditions, and protective gear to prevent accidents and ensure safe usage in laboratory and industrial settings.

- Use of perchloric acid in battery technology: Perchloric acid and its derivatives are utilized in various aspects of battery technology, including electrolyte formulations, electrode materials, and performance enhancement of energy storage devices.

- Environmental and waste management of perchloric acid: Proper disposal and treatment of perchloric acid and its waste products are crucial for environmental protection. This includes neutralization techniques, recycling methods, and specialized waste management systems to minimize environmental impact and ensure regulatory compliance.

02 Applications of perchloric acid in chemical analysis

Utilization of perchloric acid in various analytical techniques and procedures. This includes its use as a strong oxidizing agent in chemical reactions, as well as its role in sample preparation and digestion for analytical chemistry applications.Expand Specific Solutions03 Safety measures and handling of perchloric acid

Protocols and equipment designed for the safe handling, storage, and disposal of perchloric acid. This includes specialized containment systems, personal protective equipment, and emergency response procedures to mitigate the risks associated with this highly corrosive and potentially explosive substance.Expand Specific Solutions04 Perchloric acid in battery technology

Use of perchloric acid in the development and manufacturing of batteries, particularly in electrolyte formulations. This may involve its role in improving battery performance, longevity, or specific electrochemical properties in various types of batteries.Expand Specific Solutions05 Purification and quality control of perchloric acid

Techniques and processes for purifying perchloric acid and ensuring its quality for various applications. This includes methods for removing impurities, concentration control, and analytical procedures for verifying the purity and concentration of perchloric acid samples.Expand Specific Solutions

Core Innovations in Perchloric Acid Application

Microelectronic cleaning compositions and methods offabricating semiconductor devices using the same

PatentInactiveKR1020060088380A

Innovation

- A microelectronic cleaning agent comprising specific concentrations of fluoride, acid, chelating agent, and surfactant, optimized to enhance etch selectivity between high-k dielectric and silicon oxide films, is developed.

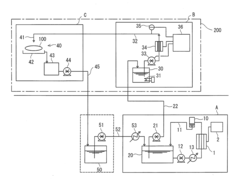

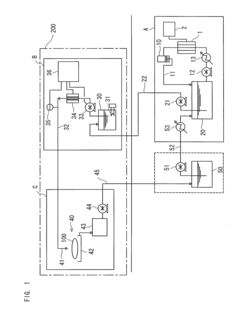

Cleaning system and cleaning method

PatentActiveUS20120291806A1

Innovation

- A cleaning system with an electrolytic part for producing peroxosulfuric acid, a circulation line, a supply line with a second reservoir positioned above the first reservoir, and a heating part in the supply line to minimize feeding pressure, using conductive diamond electrodes and controlled temperature ranges for efficient electrolysis and heating.

Environmental Impact and Safety Considerations

The application of perchloric acid in microelectronics cleaning processes raises significant environmental and safety concerns that must be carefully addressed. Perchloric acid is a highly reactive and corrosive substance, posing potential risks to both human health and the environment if not properly managed.

From an environmental perspective, the use of perchloric acid can lead to the release of harmful byproducts and contaminants. If not adequately treated, wastewater containing perchloric acid residues can cause severe damage to aquatic ecosystems and soil quality. The acid's strong oxidizing properties may also contribute to the formation of perchlorates, which are persistent environmental pollutants known to interfere with thyroid function in humans and animals.

Safety considerations are paramount when handling perchloric acid in microelectronics cleaning processes. The acid's explosive nature, especially when in contact with organic materials or at elevated temperatures, necessitates stringent safety protocols. Proper storage, handling, and disposal procedures must be implemented to prevent accidents and minimize exposure risks to workers.

To mitigate these risks, advanced treatment technologies and closed-loop systems are being developed to reduce perchloric acid emissions and improve waste management. These include ion exchange systems, advanced oxidation processes, and membrane filtration techniques designed to remove perchlorate ions from wastewater streams.

Regulatory bodies worldwide have established strict guidelines for the use and disposal of perchloric acid in industrial processes. Companies in the microelectronics sector must comply with these regulations, which often require comprehensive environmental impact assessments, regular monitoring of emissions, and implementation of best practices for chemical handling and storage.

The industry is also exploring alternative cleaning agents that could potentially replace perchloric acid in certain applications. Green chemistry initiatives are focusing on developing less hazardous and more environmentally friendly substitutes that maintain the high cleaning efficiency required in microelectronics manufacturing.

As the microelectronics industry continues to evolve, balancing the need for effective cleaning processes with environmental sustainability and worker safety remains a critical challenge. Ongoing research and development efforts are crucial to finding innovative solutions that minimize the environmental footprint and safety risks associated with perchloric acid use while maintaining the high standards of cleanliness required in microelectronics production.

From an environmental perspective, the use of perchloric acid can lead to the release of harmful byproducts and contaminants. If not adequately treated, wastewater containing perchloric acid residues can cause severe damage to aquatic ecosystems and soil quality. The acid's strong oxidizing properties may also contribute to the formation of perchlorates, which are persistent environmental pollutants known to interfere with thyroid function in humans and animals.

Safety considerations are paramount when handling perchloric acid in microelectronics cleaning processes. The acid's explosive nature, especially when in contact with organic materials or at elevated temperatures, necessitates stringent safety protocols. Proper storage, handling, and disposal procedures must be implemented to prevent accidents and minimize exposure risks to workers.

To mitigate these risks, advanced treatment technologies and closed-loop systems are being developed to reduce perchloric acid emissions and improve waste management. These include ion exchange systems, advanced oxidation processes, and membrane filtration techniques designed to remove perchlorate ions from wastewater streams.

Regulatory bodies worldwide have established strict guidelines for the use and disposal of perchloric acid in industrial processes. Companies in the microelectronics sector must comply with these regulations, which often require comprehensive environmental impact assessments, regular monitoring of emissions, and implementation of best practices for chemical handling and storage.

The industry is also exploring alternative cleaning agents that could potentially replace perchloric acid in certain applications. Green chemistry initiatives are focusing on developing less hazardous and more environmentally friendly substitutes that maintain the high cleaning efficiency required in microelectronics manufacturing.

As the microelectronics industry continues to evolve, balancing the need for effective cleaning processes with environmental sustainability and worker safety remains a critical challenge. Ongoing research and development efforts are crucial to finding innovative solutions that minimize the environmental footprint and safety risks associated with perchloric acid use while maintaining the high standards of cleanliness required in microelectronics production.

Regulatory Framework for Chemical Use in Electronics

The regulatory framework for chemical use in electronics is a complex and evolving landscape that significantly impacts the application of perchloric acid in microelectronics cleaning processes. At the global level, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a foundation for standardizing chemical hazard communication. This system influences national and regional regulations, ensuring a degree of consistency in the handling and labeling of chemicals like perchloric acid across different jurisdictions.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating chemical use through the Toxic Substances Control Act (TSCA). The TSCA mandates the reporting, record-keeping, and testing requirements for chemical substances, including those used in electronics manufacturing. Additionally, the Occupational Safety and Health Administration (OSHA) sets standards for workplace safety, which are particularly relevant for the handling of hazardous chemicals like perchloric acid in industrial settings.

The European Union's regulatory framework is notably stringent, with the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation serving as the cornerstone of chemical management. REACH requires companies to register chemical substances and provide safety data, which has significant implications for the use of perchloric acid in electronics manufacturing within the EU market. Furthermore, the Restriction of Hazardous Substances (RoHS) Directive specifically targets the electronics industry, limiting the use of certain hazardous substances in electrical and electronic equipment.

In Asia, countries like China and Japan have developed their own regulatory frameworks. China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law both aim to manage chemical risks, including those associated with electronics manufacturing processes. These regulations often align with international standards but may have unique requirements that manufacturers must navigate.

The semiconductor industry, being a major user of cleaning chemicals in microelectronics, has also developed its own set of guidelines and best practices. Organizations like the Semiconductor Equipment and Materials International (SEMI) provide standards that often go beyond regulatory requirements, addressing specific industry needs and promoting responsible chemical use.

As environmental concerns grow, regulations are increasingly focusing on the entire lifecycle of chemicals used in electronics. This includes not only the manufacturing process but also the disposal and recycling of electronic waste. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal has implications for the international movement of electronic waste containing residues of chemicals like perchloric acid.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating chemical use through the Toxic Substances Control Act (TSCA). The TSCA mandates the reporting, record-keeping, and testing requirements for chemical substances, including those used in electronics manufacturing. Additionally, the Occupational Safety and Health Administration (OSHA) sets standards for workplace safety, which are particularly relevant for the handling of hazardous chemicals like perchloric acid in industrial settings.

The European Union's regulatory framework is notably stringent, with the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation serving as the cornerstone of chemical management. REACH requires companies to register chemical substances and provide safety data, which has significant implications for the use of perchloric acid in electronics manufacturing within the EU market. Furthermore, the Restriction of Hazardous Substances (RoHS) Directive specifically targets the electronics industry, limiting the use of certain hazardous substances in electrical and electronic equipment.

In Asia, countries like China and Japan have developed their own regulatory frameworks. China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law both aim to manage chemical risks, including those associated with electronics manufacturing processes. These regulations often align with international standards but may have unique requirements that manufacturers must navigate.

The semiconductor industry, being a major user of cleaning chemicals in microelectronics, has also developed its own set of guidelines and best practices. Organizations like the Semiconductor Equipment and Materials International (SEMI) provide standards that often go beyond regulatory requirements, addressing specific industry needs and promoting responsible chemical use.

As environmental concerns grow, regulations are increasingly focusing on the entire lifecycle of chemicals used in electronics. This includes not only the manufacturing process but also the disposal and recycling of electronic waste. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal has implications for the international movement of electronic waste containing residues of chemicals like perchloric acid.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!