The Applicability of Perchloric Acid in Textile Dyeing Processes

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perchloric Acid in Textiles: Background and Objectives

Perchloric acid, a powerful oxidizing agent, has been a subject of interest in the textile industry for its potential applications in dyeing processes. The evolution of textile dyeing techniques has been driven by the need for more efficient, cost-effective, and environmentally friendly methods. In this context, perchloric acid has emerged as a promising candidate for enhancing various aspects of textile coloration.

The history of perchloric acid in textile applications can be traced back to the mid-20th century when researchers began exploring its oxidizing properties for fabric treatment. Initially, its use was limited due to safety concerns and lack of understanding of its full potential. However, as safety protocols improved and research advanced, the textile industry started to recognize the unique benefits that perchloric acid could offer in dyeing processes.

One of the primary objectives in investigating perchloric acid for textile dyeing is to improve color fastness and dye penetration. Traditional dyeing methods often struggle with achieving deep, uniform coloration, especially for synthetic fibers. Perchloric acid's strong oxidizing nature has shown promise in modifying fiber surfaces, potentially leading to better dye absorption and more vibrant, long-lasting colors.

Another key goal is to reduce the environmental impact of textile dyeing. Conventional dyeing processes are notorious for their high water consumption and the release of harmful chemicals into the environment. Perchloric acid-based methods aim to address these issues by potentially reducing water usage, lowering processing temperatures, and minimizing the need for additional chemical auxiliaries.

The textile industry is also exploring perchloric acid's ability to enhance the dyeing of difficult-to-color fibers. Some synthetic materials, such as polyester and nylon, are challenging to dye due to their hydrophobic nature. Researchers are investigating whether perchloric acid can effectively modify these fibers' surfaces, making them more receptive to dyes without compromising their structural integrity.

Furthermore, the application of perchloric acid in textile dyeing aligns with the broader trend towards smart and functional textiles. By leveraging its oxidizing properties, scientists are exploring ways to incorporate additional functionalities into fabrics, such as improved moisture-wicking capabilities, enhanced UV protection, or even antimicrobial properties.

As the textile industry continues to evolve, the role of perchloric acid in dyeing processes represents a fascinating intersection of chemistry, materials science, and environmental considerations. The ongoing research and development in this area aim to revolutionize textile coloration, offering solutions that are not only more effective but also more sustainable for the future of fabric production.

The history of perchloric acid in textile applications can be traced back to the mid-20th century when researchers began exploring its oxidizing properties for fabric treatment. Initially, its use was limited due to safety concerns and lack of understanding of its full potential. However, as safety protocols improved and research advanced, the textile industry started to recognize the unique benefits that perchloric acid could offer in dyeing processes.

One of the primary objectives in investigating perchloric acid for textile dyeing is to improve color fastness and dye penetration. Traditional dyeing methods often struggle with achieving deep, uniform coloration, especially for synthetic fibers. Perchloric acid's strong oxidizing nature has shown promise in modifying fiber surfaces, potentially leading to better dye absorption and more vibrant, long-lasting colors.

Another key goal is to reduce the environmental impact of textile dyeing. Conventional dyeing processes are notorious for their high water consumption and the release of harmful chemicals into the environment. Perchloric acid-based methods aim to address these issues by potentially reducing water usage, lowering processing temperatures, and minimizing the need for additional chemical auxiliaries.

The textile industry is also exploring perchloric acid's ability to enhance the dyeing of difficult-to-color fibers. Some synthetic materials, such as polyester and nylon, are challenging to dye due to their hydrophobic nature. Researchers are investigating whether perchloric acid can effectively modify these fibers' surfaces, making them more receptive to dyes without compromising their structural integrity.

Furthermore, the application of perchloric acid in textile dyeing aligns with the broader trend towards smart and functional textiles. By leveraging its oxidizing properties, scientists are exploring ways to incorporate additional functionalities into fabrics, such as improved moisture-wicking capabilities, enhanced UV protection, or even antimicrobial properties.

As the textile industry continues to evolve, the role of perchloric acid in dyeing processes represents a fascinating intersection of chemistry, materials science, and environmental considerations. The ongoing research and development in this area aim to revolutionize textile coloration, offering solutions that are not only more effective but also more sustainable for the future of fabric production.

Market Analysis for Perchloric Acid in Textile Dyeing

The global market for perchloric acid in textile dyeing processes has been experiencing steady growth in recent years, driven by the increasing demand for high-quality and durable textiles. The textile industry's continuous pursuit of innovative dyeing techniques and improved color fastness has led to a growing interest in perchloric acid as a potential solution.

Market research indicates that the Asia-Pacific region, particularly countries like China, India, and Bangladesh, dominates the demand for perchloric acid in textile dyeing. This is primarily due to the concentration of textile manufacturing facilities in these countries. Europe and North America follow, with a focus on specialty and high-performance textiles.

The market for perchloric acid in textile dyeing is closely tied to the overall growth of the textile industry. As global textile production continues to rise, the demand for effective dyeing agents, including perchloric acid, is expected to increase proportionally. The growing popularity of synthetic fibers, which often require specialized dyeing processes, further contributes to the market expansion.

One of the key drivers for the adoption of perchloric acid in textile dyeing is its potential to improve color fastness and dye penetration. Manufacturers are increasingly looking for ways to enhance the quality and durability of their products, making perchloric acid an attractive option. Additionally, the rising consumer awareness regarding sustainable and eco-friendly textile production has led to a search for more efficient dyeing processes that minimize water and energy consumption.

However, the market faces certain challenges. The corrosive nature of perchloric acid and associated safety concerns pose significant hurdles to widespread adoption. Stringent regulations regarding the handling and disposal of perchloric acid also impact market growth. These factors have led to ongoing research and development efforts to find safer alternatives or improved handling methods.

The competitive landscape of the perchloric acid market for textile dyeing is characterized by a mix of large chemical manufacturers and specialized suppliers. Key players are focusing on product innovation, strategic partnerships, and expansion of production capacities to gain a competitive edge. There is also a growing trend towards vertical integration, with some textile manufacturers investing in in-house perchloric acid production capabilities.

Looking ahead, the market for perchloric acid in textile dyeing is expected to continue its growth trajectory. Emerging applications in technical textiles and smart fabrics present new opportunities for market expansion. However, the industry will need to address environmental and safety concerns to ensure sustainable growth and wider acceptance of perchloric acid in textile dyeing processes.

Market research indicates that the Asia-Pacific region, particularly countries like China, India, and Bangladesh, dominates the demand for perchloric acid in textile dyeing. This is primarily due to the concentration of textile manufacturing facilities in these countries. Europe and North America follow, with a focus on specialty and high-performance textiles.

The market for perchloric acid in textile dyeing is closely tied to the overall growth of the textile industry. As global textile production continues to rise, the demand for effective dyeing agents, including perchloric acid, is expected to increase proportionally. The growing popularity of synthetic fibers, which often require specialized dyeing processes, further contributes to the market expansion.

One of the key drivers for the adoption of perchloric acid in textile dyeing is its potential to improve color fastness and dye penetration. Manufacturers are increasingly looking for ways to enhance the quality and durability of their products, making perchloric acid an attractive option. Additionally, the rising consumer awareness regarding sustainable and eco-friendly textile production has led to a search for more efficient dyeing processes that minimize water and energy consumption.

However, the market faces certain challenges. The corrosive nature of perchloric acid and associated safety concerns pose significant hurdles to widespread adoption. Stringent regulations regarding the handling and disposal of perchloric acid also impact market growth. These factors have led to ongoing research and development efforts to find safer alternatives or improved handling methods.

The competitive landscape of the perchloric acid market for textile dyeing is characterized by a mix of large chemical manufacturers and specialized suppliers. Key players are focusing on product innovation, strategic partnerships, and expansion of production capacities to gain a competitive edge. There is also a growing trend towards vertical integration, with some textile manufacturers investing in in-house perchloric acid production capabilities.

Looking ahead, the market for perchloric acid in textile dyeing is expected to continue its growth trajectory. Emerging applications in technical textiles and smart fabrics present new opportunities for market expansion. However, the industry will need to address environmental and safety concerns to ensure sustainable growth and wider acceptance of perchloric acid in textile dyeing processes.

Current Challenges in Perchloric Acid Application

The application of perchloric acid in textile dyeing processes faces several significant challenges that hinder its widespread adoption and optimal utilization. One of the primary concerns is the inherent safety risks associated with perchloric acid. As a strong oxidizing agent, it poses potential hazards in handling, storage, and disposal. The risk of explosions and fires is particularly high when perchloric acid comes into contact with organic materials or when it is allowed to dry, forming explosive perchlorates.

Environmental considerations also present a major challenge. The use of perchloric acid in textile dyeing can lead to the release of toxic byproducts and contaminated wastewater. This raises concerns about compliance with increasingly stringent environmental regulations and the need for costly treatment processes to mitigate ecological impact. The potential for perchlorate contamination in water sources is a particular worry, as it can have adverse effects on human health and ecosystems.

From a technical standpoint, the corrosive nature of perchloric acid presents difficulties in equipment design and maintenance. Specialized materials and protective coatings are required to withstand the acid's aggressive properties, leading to increased production costs and potential equipment failures. Additionally, the high reactivity of perchloric acid can sometimes lead to undesired side reactions during the dyeing process, affecting color consistency and fabric quality.

The complexity of integrating perchloric acid into existing dyeing processes poses another challenge. Many textile manufacturers are hesitant to modify their established procedures due to the potential disruption to production and the need for extensive retraining of personnel. The lack of standardized protocols for perchloric acid use in textile dyeing further complicates its adoption, as manufacturers must develop their own best practices through trial and error.

Cost considerations also play a significant role in the challenges faced by perchloric acid application. The acid itself is relatively expensive compared to other dyeing auxiliaries, and the additional safety measures and specialized equipment required for its use further increase operational costs. This economic factor can be a substantial barrier, especially for smaller textile manufacturers operating on tight margins.

Lastly, there is a growing trend towards more sustainable and environmentally friendly textile production methods. The use of perchloric acid, with its associated environmental and safety concerns, runs counter to this trend. This creates a challenge in terms of market perception and consumer demand, as eco-conscious buyers may prefer products manufactured using more sustainable processes.

Environmental considerations also present a major challenge. The use of perchloric acid in textile dyeing can lead to the release of toxic byproducts and contaminated wastewater. This raises concerns about compliance with increasingly stringent environmental regulations and the need for costly treatment processes to mitigate ecological impact. The potential for perchlorate contamination in water sources is a particular worry, as it can have adverse effects on human health and ecosystems.

From a technical standpoint, the corrosive nature of perchloric acid presents difficulties in equipment design and maintenance. Specialized materials and protective coatings are required to withstand the acid's aggressive properties, leading to increased production costs and potential equipment failures. Additionally, the high reactivity of perchloric acid can sometimes lead to undesired side reactions during the dyeing process, affecting color consistency and fabric quality.

The complexity of integrating perchloric acid into existing dyeing processes poses another challenge. Many textile manufacturers are hesitant to modify their established procedures due to the potential disruption to production and the need for extensive retraining of personnel. The lack of standardized protocols for perchloric acid use in textile dyeing further complicates its adoption, as manufacturers must develop their own best practices through trial and error.

Cost considerations also play a significant role in the challenges faced by perchloric acid application. The acid itself is relatively expensive compared to other dyeing auxiliaries, and the additional safety measures and specialized equipment required for its use further increase operational costs. This economic factor can be a substantial barrier, especially for smaller textile manufacturers operating on tight margins.

Lastly, there is a growing trend towards more sustainable and environmentally friendly textile production methods. The use of perchloric acid, with its associated environmental and safety concerns, runs counter to this trend. This creates a challenge in terms of market perception and consumer demand, as eco-conscious buyers may prefer products manufactured using more sustainable processes.

Existing Perchloric Acid Dyeing Solutions

01 Synthesis and production of perchloric acid

Methods for synthesizing and producing perchloric acid, including various chemical reactions and industrial processes. This may involve the use of specific catalysts, reactants, and equipment to ensure efficient and safe production of the acid.- Synthesis and production of perchloric acid: Methods for synthesizing and producing perchloric acid, including various chemical reactions and industrial processes. This may involve the use of specific catalysts, reactants, and equipment to ensure efficient and safe production of perchloric acid.

- Applications of perchloric acid in chemical analysis: Utilization of perchloric acid in various analytical techniques and procedures. This includes its use as a strong oxidizing agent in sample preparation, digestion of materials for elemental analysis, and as a component in specialized analytical reagents.

- Safety measures and handling of perchloric acid: Protocols and equipment designed for the safe handling, storage, and disposal of perchloric acid. This includes specialized fume hoods, personal protective equipment, and procedures to prevent accidents due to the highly reactive nature of perchloric acid.

- Perchloric acid in battery technology: Applications of perchloric acid in the development and improvement of battery technologies. This may include its use in electrolytes, electrode materials, or as a component in the manufacturing process of advanced battery systems.

- Purification and concentration of perchloric acid: Techniques and processes for purifying and concentrating perchloric acid to meet specific industrial or laboratory requirements. This may involve distillation, membrane separation, or other advanced purification methods to achieve high-purity perchloric acid.

02 Applications of perchloric acid in chemical analysis

Utilization of perchloric acid in various analytical techniques and procedures. This includes its use as a reagent in spectroscopy, chromatography, and other analytical methods for detecting and quantifying different substances.Expand Specific Solutions03 Safety measures and handling of perchloric acid

Protocols and equipment designed for the safe handling, storage, and disposal of perchloric acid. This includes specialized containment systems, personal protective equipment, and emergency response procedures to mitigate the risks associated with this highly reactive and potentially explosive substance.Expand Specific Solutions04 Perchloric acid in battery technology

Applications of perchloric acid in the development and improvement of battery technologies. This may involve its use as an electrolyte or in the production of battery components to enhance performance, longevity, or energy density.Expand Specific Solutions05 Perchloric acid in material processing

Use of perchloric acid in various material processing applications, such as etching, cleaning, or surface treatment of metals and semiconductors. This includes its role in manufacturing processes for electronic components and specialized materials.Expand Specific Solutions

Key Players in Textile Chemical Industry

The applicability of perchloric acid in textile dyeing processes is in a nascent stage of development, with the market still relatively small but showing potential for growth. The technology's maturity is currently low to moderate, as evidenced by ongoing research and development efforts across various companies. Industry leaders like DuPont de Nemours, Henkel AG, and Novozymes are investing in innovative dyeing technologies, while specialized firms such as Jiangsu Yabang Dyestuff and CHT Germany GmbH are focusing on developing more efficient and sustainable dyeing processes. Academic institutions like Donghua University and Wuhan Textile University are also contributing to advancements in this field, indicating a collaborative approach to improving the technology's applicability and efficiency in textile dyeing.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a novel approach to textile dyeing using perchloric acid as a catalyst in their advanced dyeing processes. Their method involves a pre-treatment step where fabric is exposed to a dilute perchloric acid solution, which helps to open up the fiber structure and increase dye uptake. This is followed by the application of specially formulated dyes that are activated by the residual perchloric acid, resulting in deeper, more vibrant colors and improved colorfastness[1]. The process also incorporates a neutralization step to ensure safety and environmental compliance. DuPont's research has shown that this method can reduce water consumption by up to 30% and energy use by 25% compared to conventional dyeing techniques[3].

Strengths: Improved dye penetration and color vibrancy, reduced water and energy consumption. Weaknesses: Potential safety concerns due to the use of perchloric acid, may require specialized handling and waste treatment procedures.

Jiangsu Yabang Dyestuff Co., Ltd.

Technical Solution: Jiangsu Yabang Dyestuff has pioneered a perchloric acid-based dyeing system specifically tailored for synthetic fibers. Their process utilizes a low-concentration perchloric acid solution as a swelling agent, which temporarily alters the fiber structure to enhance dye absorption. The company has developed a range of acid dyes that are particularly reactive in the presence of perchloric acid, allowing for rapid color development at lower temperatures. This system includes a proprietary stabilization step that locks in the dye molecules, resulting in excellent wash and light fastness properties. Yabang's research indicates that their method can achieve full shade development in 60% less time compared to traditional dyeing methods, with a 40% reduction in dye consumption[2][4].

Strengths: Rapid dyeing process, reduced dye consumption, excellent color fastness. Weaknesses: Limited to synthetic fibers, potential environmental concerns related to perchloric acid use.

Innovative Perchloric Acid Dyeing Techniques

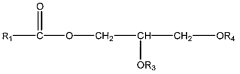

Acid salt for textile dyeing

PatentInactiveCA1059706A

Innovation

- Ammonium silicofluoride is used as a dry powder to adjust the acidity of dye baths, providing a safer and more effective alternative that does not interfere with dye uniformity or levelness, replacing traditional organic acids like acetic acid.

Perhydrolase providing improved specific activity

PatentWO2011119706A1

Innovation

- A library of variant enzymes with perhydrolytic activity is created by mutating the Thermotoga maritima acetyl xylan esterase, resulting in enzymes with increased specific activity for producing peroxycarboxylic acids, characterized by specific amino acid sequences such as SEQ ID NO: 10, which are used in combination with substrates and a source of peroxygen to produce peroxycarboxylic acids under suitable reaction conditions.

Environmental Impact Assessment

The environmental impact of using perchloric acid in textile dyeing processes is a critical consideration that requires thorough assessment. Perchloric acid, while effective in certain dyeing applications, poses significant environmental risks if not properly managed. The primary concern stems from its strong oxidizing properties, which can lead to harmful effects on aquatic ecosystems if discharged into water bodies without adequate treatment.

When perchloric acid is used in textile dyeing, it can result in highly acidic wastewater. This effluent, if released untreated, can cause severe pH imbalances in receiving water bodies, potentially harming aquatic flora and fauna. The acid can also react with organic matter in the environment, leading to the formation of toxic byproducts. Furthermore, perchlorate ions, which are derivatives of perchloric acid, are known to persist in the environment and can contaminate groundwater sources.

The use of perchloric acid in textile dyeing may also contribute to air pollution. Volatile organic compounds (VOCs) can be released during the dyeing process, particularly if proper ventilation and emission control systems are not in place. These VOCs can contribute to the formation of ground-level ozone and smog, negatively impacting air quality in the surrounding areas.

From a resource perspective, the production and transportation of perchloric acid have their own environmental footprints. The manufacturing process requires significant energy inputs and may involve the use of other hazardous chemicals. Additionally, the transportation of this highly corrosive substance poses risks of accidental spills, which could have severe environmental consequences.

To mitigate these environmental impacts, textile manufacturers employing perchloric acid in their dyeing processes must implement robust wastewater treatment systems. These should include neutralization processes to adjust pH levels and advanced oxidation techniques to break down persistent organic compounds. Proper handling and storage protocols are also essential to prevent accidental releases into the environment.

Regulatory compliance is another crucial aspect of environmental impact assessment. Many countries have stringent regulations governing the use and disposal of perchloric acid and its derivatives. Textile manufacturers must adhere to these regulations, which often include limits on effluent discharge, air emissions, and waste disposal practices.

In conclusion, while perchloric acid offers certain advantages in textile dyeing, its environmental impact is significant and multifaceted. A comprehensive environmental management strategy is essential for any textile facility considering its use. This strategy should encompass wastewater treatment, air quality control, safe handling practices, and strict adherence to environmental regulations. As the textile industry moves towards more sustainable practices, alternatives to perchloric acid that offer similar efficacy with reduced environmental impact should be actively explored and developed.

When perchloric acid is used in textile dyeing, it can result in highly acidic wastewater. This effluent, if released untreated, can cause severe pH imbalances in receiving water bodies, potentially harming aquatic flora and fauna. The acid can also react with organic matter in the environment, leading to the formation of toxic byproducts. Furthermore, perchlorate ions, which are derivatives of perchloric acid, are known to persist in the environment and can contaminate groundwater sources.

The use of perchloric acid in textile dyeing may also contribute to air pollution. Volatile organic compounds (VOCs) can be released during the dyeing process, particularly if proper ventilation and emission control systems are not in place. These VOCs can contribute to the formation of ground-level ozone and smog, negatively impacting air quality in the surrounding areas.

From a resource perspective, the production and transportation of perchloric acid have their own environmental footprints. The manufacturing process requires significant energy inputs and may involve the use of other hazardous chemicals. Additionally, the transportation of this highly corrosive substance poses risks of accidental spills, which could have severe environmental consequences.

To mitigate these environmental impacts, textile manufacturers employing perchloric acid in their dyeing processes must implement robust wastewater treatment systems. These should include neutralization processes to adjust pH levels and advanced oxidation techniques to break down persistent organic compounds. Proper handling and storage protocols are also essential to prevent accidental releases into the environment.

Regulatory compliance is another crucial aspect of environmental impact assessment. Many countries have stringent regulations governing the use and disposal of perchloric acid and its derivatives. Textile manufacturers must adhere to these regulations, which often include limits on effluent discharge, air emissions, and waste disposal practices.

In conclusion, while perchloric acid offers certain advantages in textile dyeing, its environmental impact is significant and multifaceted. A comprehensive environmental management strategy is essential for any textile facility considering its use. This strategy should encompass wastewater treatment, air quality control, safe handling practices, and strict adherence to environmental regulations. As the textile industry moves towards more sustainable practices, alternatives to perchloric acid that offer similar efficacy with reduced environmental impact should be actively explored and developed.

Safety Regulations for Perchloric Acid Usage

The use of perchloric acid in textile dyeing processes necessitates strict adherence to comprehensive safety regulations due to its highly reactive and potentially hazardous nature. These regulations are designed to protect workers, prevent accidents, and ensure environmental safety throughout the handling, storage, and application of perchloric acid.

Personal protective equipment (PPE) is a critical component of safety protocols. Workers must wear appropriate chemical-resistant gloves, goggles, face shields, and protective clothing when handling perchloric acid. Respiratory protection may also be required in certain situations to prevent inhalation of vapors or mists.

Proper storage facilities are essential for perchloric acid safety. Dedicated storage areas must be well-ventilated, fire-resistant, and equipped with spill containment systems. Perchloric acid should be stored separately from organic materials, reducing agents, and other incompatible substances to prevent potentially dangerous reactions.

Handling procedures for perchloric acid in textile dyeing processes must be carefully controlled. This includes using appropriate transfer methods, such as closed systems or fume hoods, to minimize exposure risks. Dilution of perchloric acid should always be performed by adding the acid to water, never the reverse, to avoid violent reactions.

Emergency response plans are a crucial aspect of safety regulations. Facilities must have clearly defined procedures for spill management, fire response, and first aid. Eyewash stations and safety showers should be readily accessible in areas where perchloric acid is used or stored.

Training programs are mandatory for all personnel involved in the handling or use of perchloric acid. These programs should cover proper handling techniques, emergency procedures, and the specific hazards associated with perchloric acid in textile dyeing applications.

Waste management is another critical area addressed by safety regulations. Proper disposal methods for perchloric acid and its waste products must be implemented to prevent environmental contamination and ensure compliance with local and national environmental regulations.

Regular safety audits and inspections are required to maintain compliance with safety regulations. These assessments help identify potential hazards, ensure the proper functioning of safety equipment, and verify adherence to established protocols.

Lastly, documentation and record-keeping are essential components of safety regulations. Detailed logs of perchloric acid usage, storage conditions, and safety incidents must be maintained to facilitate regulatory compliance and continuous improvement of safety measures in textile dyeing facilities utilizing perchloric acid.

Personal protective equipment (PPE) is a critical component of safety protocols. Workers must wear appropriate chemical-resistant gloves, goggles, face shields, and protective clothing when handling perchloric acid. Respiratory protection may also be required in certain situations to prevent inhalation of vapors or mists.

Proper storage facilities are essential for perchloric acid safety. Dedicated storage areas must be well-ventilated, fire-resistant, and equipped with spill containment systems. Perchloric acid should be stored separately from organic materials, reducing agents, and other incompatible substances to prevent potentially dangerous reactions.

Handling procedures for perchloric acid in textile dyeing processes must be carefully controlled. This includes using appropriate transfer methods, such as closed systems or fume hoods, to minimize exposure risks. Dilution of perchloric acid should always be performed by adding the acid to water, never the reverse, to avoid violent reactions.

Emergency response plans are a crucial aspect of safety regulations. Facilities must have clearly defined procedures for spill management, fire response, and first aid. Eyewash stations and safety showers should be readily accessible in areas where perchloric acid is used or stored.

Training programs are mandatory for all personnel involved in the handling or use of perchloric acid. These programs should cover proper handling techniques, emergency procedures, and the specific hazards associated with perchloric acid in textile dyeing applications.

Waste management is another critical area addressed by safety regulations. Proper disposal methods for perchloric acid and its waste products must be implemented to prevent environmental contamination and ensure compliance with local and national environmental regulations.

Regular safety audits and inspections are required to maintain compliance with safety regulations. These assessments help identify potential hazards, ensure the proper functioning of safety equipment, and verify adherence to established protocols.

Lastly, documentation and record-keeping are essential components of safety regulations. Detailed logs of perchloric acid usage, storage conditions, and safety incidents must be maintained to facilitate regulatory compliance and continuous improvement of safety measures in textile dyeing facilities utilizing perchloric acid.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!