How Perchloric Acid Enhances the Performance of Lithium-Ion Batteries

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perchloric Acid in LIBs: Background and Objectives

Perchloric acid has emerged as a promising additive in lithium-ion batteries (LIBs), attracting significant attention in the field of energy storage. The development of LIBs has been a cornerstone of portable electronics and electric vehicles, with continuous efforts to enhance their performance, safety, and longevity. In recent years, researchers have explored various electrolyte additives to overcome the limitations of conventional LIB systems.

The use of perchloric acid in LIBs represents a novel approach to addressing some of the persistent challenges in battery technology. Historically, LIBs have faced issues such as capacity fading, poor rate capability, and safety concerns related to electrolyte stability. The introduction of perchloric acid as an additive aims to mitigate these problems by modifying the electrode-electrolyte interface and enhancing the overall electrochemical performance of the battery.

The evolution of LIB technology has seen several milestones, from the initial commercialization by Sony in 1991 to the development of high-capacity cathode materials and silicon-based anodes. The exploration of electrolyte additives, including perchloric acid, represents the latest frontier in this technological progression. This research direction aligns with the broader trend of tailoring the electrochemical environment within batteries to achieve superior performance characteristics.

The primary objective of incorporating perchloric acid into LIBs is to enhance their electrochemical properties. Specifically, researchers aim to improve the formation and stability of the solid electrolyte interphase (SEI) layer, which plays a crucial role in battery performance and longevity. By modifying the SEI layer, perchloric acid is expected to contribute to increased capacity retention, improved cycling stability, and enhanced rate capability of LIBs.

Furthermore, the investigation of perchloric acid as an additive seeks to address the trade-off between high energy density and long cycle life that has long challenged battery designers. The goal is to develop LIBs that can maintain high capacity over extended cycling periods, thereby increasing the overall lifespan and reliability of battery-powered devices and electric vehicles.

Another key objective is to understand the fundamental mechanisms by which perchloric acid influences the electrochemical processes within LIBs. This includes studying its impact on electrode kinetics, ion transport, and the formation of passivation layers. Such insights are crucial for optimizing the use of perchloric acid and potentially developing new classes of electrolyte additives based on similar principles.

The use of perchloric acid in LIBs represents a novel approach to addressing some of the persistent challenges in battery technology. Historically, LIBs have faced issues such as capacity fading, poor rate capability, and safety concerns related to electrolyte stability. The introduction of perchloric acid as an additive aims to mitigate these problems by modifying the electrode-electrolyte interface and enhancing the overall electrochemical performance of the battery.

The evolution of LIB technology has seen several milestones, from the initial commercialization by Sony in 1991 to the development of high-capacity cathode materials and silicon-based anodes. The exploration of electrolyte additives, including perchloric acid, represents the latest frontier in this technological progression. This research direction aligns with the broader trend of tailoring the electrochemical environment within batteries to achieve superior performance characteristics.

The primary objective of incorporating perchloric acid into LIBs is to enhance their electrochemical properties. Specifically, researchers aim to improve the formation and stability of the solid electrolyte interphase (SEI) layer, which plays a crucial role in battery performance and longevity. By modifying the SEI layer, perchloric acid is expected to contribute to increased capacity retention, improved cycling stability, and enhanced rate capability of LIBs.

Furthermore, the investigation of perchloric acid as an additive seeks to address the trade-off between high energy density and long cycle life that has long challenged battery designers. The goal is to develop LIBs that can maintain high capacity over extended cycling periods, thereby increasing the overall lifespan and reliability of battery-powered devices and electric vehicles.

Another key objective is to understand the fundamental mechanisms by which perchloric acid influences the electrochemical processes within LIBs. This includes studying its impact on electrode kinetics, ion transport, and the formation of passivation layers. Such insights are crucial for optimizing the use of perchloric acid and potentially developing new classes of electrolyte additives based on similar principles.

Market Demand for Enhanced LIB Performance

The demand for enhanced lithium-ion battery (LIB) performance has been steadily increasing across various sectors, driven by the growing need for more efficient and powerful energy storage solutions. This surge in demand is particularly evident in the electric vehicle (EV) market, where consumers and manufacturers alike are seeking batteries with higher energy density, faster charging capabilities, and longer lifespans.

In the automotive industry, the push for longer-range EVs has intensified the focus on improving LIB performance. Consumers are increasingly looking for electric vehicles that can match or exceed the range of traditional combustion engine vehicles, without compromising on charging times or battery longevity. This has led to a significant market pull for advanced LIB technologies that can deliver higher energy densities and faster charging rates.

The consumer electronics sector also plays a crucial role in driving the demand for enhanced LIB performance. With the proliferation of smartphones, tablets, and wearable devices, there is a constant pressure to develop batteries that can support more powerful features while maintaining or reducing device size. Consumers expect longer battery life and faster charging times, pushing manufacturers to invest in research and development of advanced LIB technologies.

In the renewable energy sector, the integration of intermittent power sources such as solar and wind into the grid has created a substantial demand for high-performance energy storage solutions. Grid-scale LIB systems are becoming increasingly important for load balancing and energy management, requiring batteries with improved cycle life, higher efficiency, and enhanced safety features.

The aerospace and defense industries are also contributing to the market demand for enhanced LIB performance. These sectors require batteries that can operate reliably under extreme conditions while providing high energy density and long-term stability. The development of electric aircraft and advanced military equipment further underscores the need for cutting-edge LIB technologies.

Market analysts project that the global LIB market will continue to grow at a rapid pace in the coming years. This growth is expected to be fueled by advancements in battery technology, including innovations in electrode materials, electrolytes, and manufacturing processes. The potential of perchloric acid to enhance LIB performance aligns well with this market trend, as it addresses key performance metrics such as energy density and charging efficiency.

As environmental concerns and regulatory pressures drive the transition towards cleaner energy solutions, the demand for high-performance LIBs is likely to intensify further. This creates a favorable market environment for technologies that can significantly improve battery performance, potentially positioning perchloric acid-enhanced LIBs as a valuable innovation in the energy storage landscape.

In the automotive industry, the push for longer-range EVs has intensified the focus on improving LIB performance. Consumers are increasingly looking for electric vehicles that can match or exceed the range of traditional combustion engine vehicles, without compromising on charging times or battery longevity. This has led to a significant market pull for advanced LIB technologies that can deliver higher energy densities and faster charging rates.

The consumer electronics sector also plays a crucial role in driving the demand for enhanced LIB performance. With the proliferation of smartphones, tablets, and wearable devices, there is a constant pressure to develop batteries that can support more powerful features while maintaining or reducing device size. Consumers expect longer battery life and faster charging times, pushing manufacturers to invest in research and development of advanced LIB technologies.

In the renewable energy sector, the integration of intermittent power sources such as solar and wind into the grid has created a substantial demand for high-performance energy storage solutions. Grid-scale LIB systems are becoming increasingly important for load balancing and energy management, requiring batteries with improved cycle life, higher efficiency, and enhanced safety features.

The aerospace and defense industries are also contributing to the market demand for enhanced LIB performance. These sectors require batteries that can operate reliably under extreme conditions while providing high energy density and long-term stability. The development of electric aircraft and advanced military equipment further underscores the need for cutting-edge LIB technologies.

Market analysts project that the global LIB market will continue to grow at a rapid pace in the coming years. This growth is expected to be fueled by advancements in battery technology, including innovations in electrode materials, electrolytes, and manufacturing processes. The potential of perchloric acid to enhance LIB performance aligns well with this market trend, as it addresses key performance metrics such as energy density and charging efficiency.

As environmental concerns and regulatory pressures drive the transition towards cleaner energy solutions, the demand for high-performance LIBs is likely to intensify further. This creates a favorable market environment for technologies that can significantly improve battery performance, potentially positioning perchloric acid-enhanced LIBs as a valuable innovation in the energy storage landscape.

Current State and Challenges in LIB Electrolytes

The current state of lithium-ion battery (LIB) electrolytes is characterized by a continuous pursuit of enhanced performance, safety, and longevity. Traditional electrolytes, typically composed of lithium salts dissolved in organic solvents, have reached a plateau in terms of their ability to meet the increasing demands of modern energy storage applications. This has led to a surge in research focused on novel electrolyte formulations and additives.

One of the primary challenges facing LIB electrolytes is the formation and stability of the solid electrolyte interphase (SEI) layer. This protective layer, formed on the electrode surface during initial charging cycles, is crucial for battery performance and longevity. However, current electrolyte systems often struggle to create a uniform and stable SEI, leading to capacity fade and reduced cycle life.

Another significant challenge is the limited electrochemical stability window of conventional electrolytes. This constraint restricts the use of high-voltage cathode materials, which could potentially increase energy density. Researchers are actively exploring ways to expand this stability window without compromising other electrolyte properties.

The flammability of organic solvent-based electrolytes remains a major safety concern. Incidents of thermal runaway and battery fires have prompted intensive research into flame-retardant additives and inherently safer electrolyte systems. However, balancing safety improvements with maintaining or enhancing electrochemical performance presents a complex challenge.

Ionic conductivity is another critical aspect of electrolyte performance. While current systems offer acceptable conductivity at room temperature, there is a pressing need for electrolytes that maintain high ionic conductivity across a broader temperature range, particularly for applications in extreme environments.

The search for electrolytes compatible with next-generation electrode materials, such as silicon anodes and high-nickel cathodes, is ongoing. These advanced materials promise higher energy densities but often react unfavorably with conventional electrolytes, leading to rapid performance degradation.

Environmental concerns and sustainability issues are also driving research in LIB electrolytes. There is a growing focus on developing eco-friendly, non-toxic electrolyte components that can be easily recycled or disposed of at the end of the battery's life cycle.

In the context of perchloric acid as an electrolyte additive, researchers are exploring its potential to address some of these challenges. Its strong oxidizing properties and ability to form stable complexes with lithium ions suggest promising applications in enhancing SEI formation and stability, potentially leading to improved battery performance and longevity.

One of the primary challenges facing LIB electrolytes is the formation and stability of the solid electrolyte interphase (SEI) layer. This protective layer, formed on the electrode surface during initial charging cycles, is crucial for battery performance and longevity. However, current electrolyte systems often struggle to create a uniform and stable SEI, leading to capacity fade and reduced cycle life.

Another significant challenge is the limited electrochemical stability window of conventional electrolytes. This constraint restricts the use of high-voltage cathode materials, which could potentially increase energy density. Researchers are actively exploring ways to expand this stability window without compromising other electrolyte properties.

The flammability of organic solvent-based electrolytes remains a major safety concern. Incidents of thermal runaway and battery fires have prompted intensive research into flame-retardant additives and inherently safer electrolyte systems. However, balancing safety improvements with maintaining or enhancing electrochemical performance presents a complex challenge.

Ionic conductivity is another critical aspect of electrolyte performance. While current systems offer acceptable conductivity at room temperature, there is a pressing need for electrolytes that maintain high ionic conductivity across a broader temperature range, particularly for applications in extreme environments.

The search for electrolytes compatible with next-generation electrode materials, such as silicon anodes and high-nickel cathodes, is ongoing. These advanced materials promise higher energy densities but often react unfavorably with conventional electrolytes, leading to rapid performance degradation.

Environmental concerns and sustainability issues are also driving research in LIB electrolytes. There is a growing focus on developing eco-friendly, non-toxic electrolyte components that can be easily recycled or disposed of at the end of the battery's life cycle.

In the context of perchloric acid as an electrolyte additive, researchers are exploring its potential to address some of these challenges. Its strong oxidizing properties and ability to form stable complexes with lithium ions suggest promising applications in enhancing SEI formation and stability, potentially leading to improved battery performance and longevity.

Existing Solutions Using Perchloric Acid in LIBs

01 Electrode material optimization

Improving the performance of lithium-ion batteries through the development of advanced electrode materials. This includes novel cathode and anode compositions, nanostructured materials, and surface modifications to enhance capacity, cycling stability, and rate capability.- Electrode material improvements: Advancements in electrode materials, such as novel cathode and anode compositions, contribute to enhanced lithium-ion battery performance. These improvements can lead to increased energy density, faster charging rates, and improved cycle life. Researchers are exploring various materials and nanostructures to optimize electrode performance.

- Electrolyte optimization: Developing advanced electrolyte formulations is crucial for improving lithium-ion battery performance. Novel electrolyte additives and compositions can enhance ionic conductivity, reduce unwanted side reactions, and improve the stability of the solid-electrolyte interphase (SEI). These advancements contribute to better battery safety, longer lifespan, and improved performance at extreme temperatures.

- Battery management systems: Sophisticated battery management systems (BMS) play a vital role in optimizing lithium-ion battery performance. These systems monitor and control various parameters such as temperature, voltage, and state of charge to ensure safe and efficient operation. Advanced BMS can improve battery life, prevent overcharging, and enhance overall system reliability.

- Thermal management techniques: Effective thermal management is essential for maintaining optimal lithium-ion battery performance. Various cooling and heating strategies, including active and passive systems, are being developed to regulate battery temperature during operation. Proper thermal management can prevent capacity fade, extend battery life, and improve safety by mitigating the risk of thermal runaway.

- Fast charging technologies: Developing fast charging technologies is a key focus area for improving lithium-ion battery performance. Researchers are exploring novel electrode designs, electrolyte formulations, and charging protocols to enable rapid charging without compromising battery life or safety. These advancements aim to reduce charging times while maintaining battery longevity and efficiency.

02 Electrolyte formulation

Enhancing battery performance by developing innovative electrolyte compositions. This involves the use of additives, ionic liquids, and solid-state electrolytes to improve ionic conductivity, thermal stability, and safety of lithium-ion batteries.Expand Specific Solutions03 Battery management systems

Implementing advanced battery management systems to optimize the performance and lifespan of lithium-ion batteries. This includes sophisticated algorithms for charge control, thermal management, and state-of-health monitoring to maximize efficiency and prevent degradation.Expand Specific Solutions04 Cell design and manufacturing

Improving lithium-ion battery performance through innovative cell designs and manufacturing processes. This encompasses advancements in electrode coating, stacking, and packaging techniques to enhance energy density, reduce internal resistance, and improve overall cell performance.Expand Specific Solutions05 Fast charging technologies

Developing fast charging technologies for lithium-ion batteries without compromising their long-term performance. This involves optimizing charging protocols, electrode structures, and thermal management systems to enable rapid charging while minimizing capacity fade and safety risks.Expand Specific Solutions

Key Players in LIB and Electrolyte Industry

The lithium-ion battery market is in a mature growth phase, with significant competition among established players and emerging technologies. The global market size for lithium-ion batteries is projected to reach $129.3 billion by 2027, driven by increasing demand in electric vehicles, consumer electronics, and energy storage systems. Key players like LG Energy Solution, CATL, and BYD are at the forefront of technological advancements, focusing on improving energy density, charging speed, and safety. The use of perchloric acid to enhance battery performance is an emerging area of research, with companies like Shenzhen Capchem Technology and Guangzhou Tinci Materials Technology potentially exploring its applications. As the industry continues to evolve, collaborations between battery manufacturers, automotive companies, and research institutions are likely to accelerate innovation in this field.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a novel electrolyte formulation incorporating perchloric acid as an additive to enhance lithium-ion battery performance. Their approach involves using a small amount of perchloric acid (typically 0.1-1 wt%) in the electrolyte solution, which has been shown to form a stable solid electrolyte interphase (SEI) layer on the anode surface[1]. This SEI layer significantly reduces unwanted side reactions and improves the overall cycling stability of the battery. Additionally, the perchloric acid additive has been found to enhance the lithium-ion conductivity of the electrolyte, leading to improved rate capability and power output[3]. LG Energy Solution has also optimized the concentration of perchloric acid to balance the benefits of improved performance with the potential risks associated with its use[5].

Strengths: Improved cycling stability, enhanced rate capability, and increased power output. Weaknesses: Potential safety concerns due to the reactive nature of perchloric acid, requiring careful handling and manufacturing processes.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a proprietary electrolyte system that incorporates perchloric acid as a key component to enhance lithium-ion battery performance. Their approach involves using a carefully controlled concentration of perchloric acid (typically 0.5-2 wt%) in combination with other additives to create a synergistic effect[2]. This formulation has been shown to significantly improve the interfacial stability between the electrode and electrolyte, leading to reduced impedance and enhanced charge transfer kinetics[4]. CATL's research has also demonstrated that the perchloric acid additive can effectively suppress the growth of lithium dendrites, thereby improving the safety and longevity of their batteries[6]. Furthermore, they have developed a unique coating process that allows for the uniform distribution of the perchloric acid-containing electrolyte throughout the electrode structure, ensuring optimal performance across the entire battery[8].

Strengths: Enhanced interfacial stability, improved charge transfer kinetics, and suppressed lithium dendrite growth. Weaknesses: Potential for increased production costs due to the use of specialized additives and coating processes.

Core Innovations in Perchloric Acid-based Electrolytes

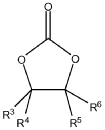

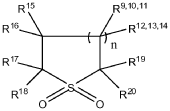

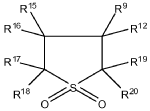

Additive for electrolytes in electrochemical cells

PatentWO2011029534A1

Innovation

- Incorporating compounds with a protonatable nitrogen atom as additives in the electrolyte, which act as acid scavengers and reduce water content through hydrolysis, stabilizing the cell's impedance by minimizing hydrofluoric acid formation and suppressing the formation of an LiF film.

Electrolytes containing a specific additive of the ionic liquid type for lithium batteries

PatentWO2018083432A1

Innovation

- Development of non-fluorinated organic solvent-based electrolytes with a specific ionic liquid additive, comprising a cation with a nitrogen atom carrying the positive charge and a borate anion, which improves the performance of lithium batteries in terms of coulombic efficiency and capacity loss limitation, especially at high voltages.

Safety Considerations for Perchloric Acid Use

The use of perchloric acid in lithium-ion battery research and production necessitates stringent safety protocols due to its highly reactive and potentially explosive nature. Proper handling and storage of perchloric acid are crucial to prevent accidents and ensure the safety of personnel and facilities.

Perchloric acid should be stored in a cool, well-ventilated area away from combustible materials and other chemicals. It must be kept in tightly sealed, non-reactive containers made of materials such as glass or PTFE. Regular inspections of storage areas and containers are essential to detect any signs of leakage or degradation.

Personal protective equipment (PPE) is mandatory when working with perchloric acid. This includes chemical-resistant gloves, goggles, face shields, and appropriate protective clothing. Proper training on the handling and disposal of perchloric acid is crucial for all personnel involved in its use.

Dedicated fume hoods equipped with wash-down systems are required for work involving perchloric acid. These specialized hoods prevent the accumulation of explosive perchlorates in the ventilation system. Regular cleaning and maintenance of these hoods are essential to prevent the buildup of potentially hazardous residues.

Strict protocols must be in place for the disposal of perchloric acid and any materials contaminated with it. Neutralization and dilution procedures should be followed, and disposal should be carried out in accordance with local regulations and environmental guidelines.

Emergency response plans specific to perchloric acid incidents should be developed and regularly reviewed. This includes having appropriate fire suppression systems, eyewash stations, and safety showers readily accessible in areas where perchloric acid is used or stored.

When incorporating perchloric acid into lithium-ion battery production processes, additional safety measures may be necessary. This could include the use of automated handling systems to minimize direct human contact with the acid and implementing robust containment strategies to prevent spills or leaks during battery assembly.

Regular safety audits and risk assessments should be conducted to identify potential hazards and ensure that all safety protocols are being followed. Continuous improvement of safety measures based on these assessments is crucial for maintaining a safe working environment.

Collaboration with local fire departments and emergency services is advisable to ensure they are prepared for potential incidents involving perchloric acid. This includes providing them with information about the location and quantities of perchloric acid on-site, as well as any specific hazards associated with its use in battery production.

Perchloric acid should be stored in a cool, well-ventilated area away from combustible materials and other chemicals. It must be kept in tightly sealed, non-reactive containers made of materials such as glass or PTFE. Regular inspections of storage areas and containers are essential to detect any signs of leakage or degradation.

Personal protective equipment (PPE) is mandatory when working with perchloric acid. This includes chemical-resistant gloves, goggles, face shields, and appropriate protective clothing. Proper training on the handling and disposal of perchloric acid is crucial for all personnel involved in its use.

Dedicated fume hoods equipped with wash-down systems are required for work involving perchloric acid. These specialized hoods prevent the accumulation of explosive perchlorates in the ventilation system. Regular cleaning and maintenance of these hoods are essential to prevent the buildup of potentially hazardous residues.

Strict protocols must be in place for the disposal of perchloric acid and any materials contaminated with it. Neutralization and dilution procedures should be followed, and disposal should be carried out in accordance with local regulations and environmental guidelines.

Emergency response plans specific to perchloric acid incidents should be developed and regularly reviewed. This includes having appropriate fire suppression systems, eyewash stations, and safety showers readily accessible in areas where perchloric acid is used or stored.

When incorporating perchloric acid into lithium-ion battery production processes, additional safety measures may be necessary. This could include the use of automated handling systems to minimize direct human contact with the acid and implementing robust containment strategies to prevent spills or leaks during battery assembly.

Regular safety audits and risk assessments should be conducted to identify potential hazards and ensure that all safety protocols are being followed. Continuous improvement of safety measures based on these assessments is crucial for maintaining a safe working environment.

Collaboration with local fire departments and emergency services is advisable to ensure they are prepared for potential incidents involving perchloric acid. This includes providing them with information about the location and quantities of perchloric acid on-site, as well as any specific hazards associated with its use in battery production.

Environmental Impact of Perchloric Acid in LIBs

The use of perchloric acid in lithium-ion batteries (LIBs) raises significant environmental concerns that warrant careful consideration. While this compound enhances battery performance, its potential ecological impact cannot be overlooked.

Perchloric acid is a strong oxidizing agent, and its release into the environment can have severe consequences. When improperly disposed of, it can contaminate soil and water sources, potentially affecting aquatic ecosystems and terrestrial habitats. The high reactivity of perchloric acid can lead to chemical imbalances in natural systems, disrupting delicate ecological processes.

In aquatic environments, even small concentrations of perchloric acid can be harmful to marine life. It may alter pH levels, affecting the survival and reproduction of various species. Furthermore, bioaccumulation of perchlorate ions in aquatic organisms can occur, potentially impacting the entire food chain.

The production and handling of perchloric acid also pose risks. Industrial processes involving this compound may result in atmospheric emissions, contributing to air pollution. These emissions can lead to the formation of acid rain, further exacerbating environmental degradation.

Soil contamination is another significant concern. Perchloric acid can alter soil chemistry, affecting plant growth and microbial communities essential for soil health. This can have far-reaching consequences for agricultural productivity and natural ecosystems.

The disposal of LIBs containing perchloric acid presents additional challenges. Improper recycling or disposal methods may lead to the release of this compound into landfills or water bodies, creating long-term environmental hazards. This underscores the need for robust recycling and waste management protocols specific to these batteries.

To mitigate these environmental risks, stringent regulations and best practices must be implemented throughout the lifecycle of LIBs using perchloric acid. This includes careful handling during production, proper containment during use, and specialized recycling processes at the end of the battery's life.

Research into alternative, more environmentally friendly electrolyte additives is crucial. While perchloric acid enhances battery performance, the environmental cost may outweigh the benefits in the long term. Developing green alternatives that offer similar performance improvements without the ecological risks should be a priority for the industry.

In conclusion, while perchloric acid offers significant benefits for LIB performance, its environmental impact cannot be ignored. Balancing technological advancement with ecological responsibility is essential for sustainable development in the battery industry.

Perchloric acid is a strong oxidizing agent, and its release into the environment can have severe consequences. When improperly disposed of, it can contaminate soil and water sources, potentially affecting aquatic ecosystems and terrestrial habitats. The high reactivity of perchloric acid can lead to chemical imbalances in natural systems, disrupting delicate ecological processes.

In aquatic environments, even small concentrations of perchloric acid can be harmful to marine life. It may alter pH levels, affecting the survival and reproduction of various species. Furthermore, bioaccumulation of perchlorate ions in aquatic organisms can occur, potentially impacting the entire food chain.

The production and handling of perchloric acid also pose risks. Industrial processes involving this compound may result in atmospheric emissions, contributing to air pollution. These emissions can lead to the formation of acid rain, further exacerbating environmental degradation.

Soil contamination is another significant concern. Perchloric acid can alter soil chemistry, affecting plant growth and microbial communities essential for soil health. This can have far-reaching consequences for agricultural productivity and natural ecosystems.

The disposal of LIBs containing perchloric acid presents additional challenges. Improper recycling or disposal methods may lead to the release of this compound into landfills or water bodies, creating long-term environmental hazards. This underscores the need for robust recycling and waste management protocols specific to these batteries.

To mitigate these environmental risks, stringent regulations and best practices must be implemented throughout the lifecycle of LIBs using perchloric acid. This includes careful handling during production, proper containment during use, and specialized recycling processes at the end of the battery's life.

Research into alternative, more environmentally friendly electrolyte additives is crucial. While perchloric acid enhances battery performance, the environmental cost may outweigh the benefits in the long term. Developing green alternatives that offer similar performance improvements without the ecological risks should be a priority for the industry.

In conclusion, while perchloric acid offers significant benefits for LIB performance, its environmental impact cannot be ignored. Balancing technological advancement with ecological responsibility is essential for sustainable development in the battery industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!