Environmental Safety Measures for Perchloric Acid Usage

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perchloric Acid Safety Background and Objectives

Perchloric acid, a powerful oxidizing agent, has been widely used in various industrial and laboratory applications for decades. Its unique properties make it invaluable in analytical chemistry, electropolishing, and rocket propellant production. However, the inherent risks associated with its use have necessitated the development of stringent safety measures to protect both human health and the environment.

The evolution of perchloric acid safety protocols can be traced back to the mid-20th century when its hazardous nature became fully recognized. Early incidents involving explosions and fires due to improper handling led to increased awareness and the gradual implementation of safety standards. Over time, these standards have become more comprehensive, addressing not only immediate workplace safety but also long-term environmental impacts.

In recent years, the focus has shifted towards developing more sustainable and environmentally friendly practices for perchloric acid usage. This trend aligns with broader global initiatives to reduce the environmental footprint of industrial processes and enhance workplace safety. The current objective in perchloric acid safety is to establish a balance between its continued use in critical applications and the minimization of potential risks to human health and the environment.

Key technological advancements have played a crucial role in improving perchloric acid safety. These include the development of specialized fume hoods, closed-loop recycling systems, and advanced personal protective equipment. Additionally, the integration of real-time monitoring systems and automated safety controls has significantly enhanced the ability to prevent and respond to potential incidents.

The regulatory landscape surrounding perchloric acid has also evolved, with many countries implementing strict guidelines for its storage, handling, and disposal. These regulations aim to standardize safety practices across industries and research institutions, ensuring a consistent approach to risk management. The harmonization of international standards has become a priority, facilitating global cooperation in addressing perchloric acid safety challenges.

Looking ahead, the field of perchloric acid safety is expected to continue evolving, driven by ongoing research and technological innovations. Emerging areas of focus include the development of safer alternatives for certain applications, improved waste treatment methods, and the integration of artificial intelligence in safety management systems. These advancements are anticipated to further reduce the environmental impact of perchloric acid usage while maintaining its critical role in various industries.

The evolution of perchloric acid safety protocols can be traced back to the mid-20th century when its hazardous nature became fully recognized. Early incidents involving explosions and fires due to improper handling led to increased awareness and the gradual implementation of safety standards. Over time, these standards have become more comprehensive, addressing not only immediate workplace safety but also long-term environmental impacts.

In recent years, the focus has shifted towards developing more sustainable and environmentally friendly practices for perchloric acid usage. This trend aligns with broader global initiatives to reduce the environmental footprint of industrial processes and enhance workplace safety. The current objective in perchloric acid safety is to establish a balance between its continued use in critical applications and the minimization of potential risks to human health and the environment.

Key technological advancements have played a crucial role in improving perchloric acid safety. These include the development of specialized fume hoods, closed-loop recycling systems, and advanced personal protective equipment. Additionally, the integration of real-time monitoring systems and automated safety controls has significantly enhanced the ability to prevent and respond to potential incidents.

The regulatory landscape surrounding perchloric acid has also evolved, with many countries implementing strict guidelines for its storage, handling, and disposal. These regulations aim to standardize safety practices across industries and research institutions, ensuring a consistent approach to risk management. The harmonization of international standards has become a priority, facilitating global cooperation in addressing perchloric acid safety challenges.

Looking ahead, the field of perchloric acid safety is expected to continue evolving, driven by ongoing research and technological innovations. Emerging areas of focus include the development of safer alternatives for certain applications, improved waste treatment methods, and the integration of artificial intelligence in safety management systems. These advancements are anticipated to further reduce the environmental impact of perchloric acid usage while maintaining its critical role in various industries.

Market Demand for Perchloric Acid Applications

The market demand for perchloric acid applications has been steadily growing across various industries due to its unique properties and versatile uses. In the chemical industry, perchloric acid serves as a powerful oxidizing agent and catalyst, driving demand in organic synthesis and analytical chemistry. The semiconductor sector relies on high-purity perchloric acid for etching and cleaning silicon wafers, a critical process in microchip production.

Aerospace and defense industries utilize perchloric acid in rocket propellants and explosives, contributing to a significant portion of the market demand. The increasing focus on space exploration and satellite launches has further bolstered this segment. In the pharmaceutical sector, perchloric acid finds applications in drug synthesis and as a reagent in analytical procedures, supporting the growing need for novel medications and diagnostic tools.

The automotive industry's shift towards electric vehicles has indirectly influenced perchloric acid demand. Its use in the production of lithium perchlorate, a component in some lithium-ion batteries, has seen an uptick. Additionally, the material testing and quality control sectors employ perchloric acid in various analytical techniques, including atomic absorption spectroscopy and electrochemical analysis.

Environmental concerns and stringent regulations have paradoxically both constrained and stimulated market growth. While safety measures have increased production costs, they have also spurred innovation in safer handling and application methods, opening new market opportunities. The development of specialized containment systems and safety equipment for perchloric acid handling has become a niche market in itself.

Geographically, North America and Europe have traditionally been the largest markets for perchloric acid, driven by their advanced chemical, pharmaceutical, and aerospace industries. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth in demand, fueled by rapid industrialization and increasing investments in research and development.

The global perchloric acid market is expected to continue its growth trajectory, with emerging applications in nanotechnology and advanced materials research potentially expanding its user base. However, the market's expansion is tempered by the need for strict safety protocols and the ongoing search for less hazardous alternatives in some applications. This balance between growing demand and safety considerations will likely shape the future market dynamics of perchloric acid applications.

Aerospace and defense industries utilize perchloric acid in rocket propellants and explosives, contributing to a significant portion of the market demand. The increasing focus on space exploration and satellite launches has further bolstered this segment. In the pharmaceutical sector, perchloric acid finds applications in drug synthesis and as a reagent in analytical procedures, supporting the growing need for novel medications and diagnostic tools.

The automotive industry's shift towards electric vehicles has indirectly influenced perchloric acid demand. Its use in the production of lithium perchlorate, a component in some lithium-ion batteries, has seen an uptick. Additionally, the material testing and quality control sectors employ perchloric acid in various analytical techniques, including atomic absorption spectroscopy and electrochemical analysis.

Environmental concerns and stringent regulations have paradoxically both constrained and stimulated market growth. While safety measures have increased production costs, they have also spurred innovation in safer handling and application methods, opening new market opportunities. The development of specialized containment systems and safety equipment for perchloric acid handling has become a niche market in itself.

Geographically, North America and Europe have traditionally been the largest markets for perchloric acid, driven by their advanced chemical, pharmaceutical, and aerospace industries. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth in demand, fueled by rapid industrialization and increasing investments in research and development.

The global perchloric acid market is expected to continue its growth trajectory, with emerging applications in nanotechnology and advanced materials research potentially expanding its user base. However, the market's expansion is tempered by the need for strict safety protocols and the ongoing search for less hazardous alternatives in some applications. This balance between growing demand and safety considerations will likely shape the future market dynamics of perchloric acid applications.

Current Challenges in Perchloric Acid Handling

The handling of perchloric acid presents significant challenges due to its highly reactive and potentially explosive nature. One of the primary concerns is the formation of explosive perchlorates when perchloric acid comes into contact with organic materials or dehydrating agents. This necessitates stringent control measures to prevent accidental reactions and ensure safe storage and usage.

Ventilation systems pose a particular challenge in perchloric acid handling. Standard fume hoods are often inadequate for perchloric acid work due to the potential for perchlorate buildup in ductwork. Specialized perchloric acid fume hoods with wash-down systems are required to prevent the accumulation of dangerous residues, but these systems are costly and require regular maintenance to ensure effectiveness.

Personal protective equipment (PPE) selection is another critical challenge. While perchloric acid requires robust protection, the PPE must also allow for dexterity and comfort to prevent accidents caused by impaired movement. Balancing protection with usability is an ongoing challenge in developing suitable PPE for perchloric acid handling.

The disposal of perchloric acid and its waste products presents significant environmental and safety challenges. Neutralization and dilution processes must be carefully controlled to prevent violent reactions. Additionally, the disposal of perchlorate-contaminated materials requires specialized procedures to prevent environmental contamination and potential explosive hazards.

Training and education of personnel working with perchloric acid remain ongoing challenges. The unique properties and hazards of perchloric acid necessitate comprehensive and continual training programs. Ensuring that all personnel, including temporary or contract workers, are adequately trained and follow strict safety protocols is crucial but often difficult to maintain consistently.

Emergency response planning for perchloric acid incidents presents unique challenges. The potential for rapid escalation of incidents involving perchloric acid requires specialized emergency procedures and equipment. Coordinating with local emergency responders and ensuring they are prepared for perchloric acid-related incidents is an essential but complex task.

Lastly, the regulatory landscape surrounding perchloric acid usage is complex and evolving. Keeping up with changing regulations and ensuring compliance across different jurisdictions can be challenging for organizations working with perchloric acid. This regulatory complexity adds an additional layer of difficulty to the already challenging task of safely handling and managing perchloric acid in research and industrial settings.

Ventilation systems pose a particular challenge in perchloric acid handling. Standard fume hoods are often inadequate for perchloric acid work due to the potential for perchlorate buildup in ductwork. Specialized perchloric acid fume hoods with wash-down systems are required to prevent the accumulation of dangerous residues, but these systems are costly and require regular maintenance to ensure effectiveness.

Personal protective equipment (PPE) selection is another critical challenge. While perchloric acid requires robust protection, the PPE must also allow for dexterity and comfort to prevent accidents caused by impaired movement. Balancing protection with usability is an ongoing challenge in developing suitable PPE for perchloric acid handling.

The disposal of perchloric acid and its waste products presents significant environmental and safety challenges. Neutralization and dilution processes must be carefully controlled to prevent violent reactions. Additionally, the disposal of perchlorate-contaminated materials requires specialized procedures to prevent environmental contamination and potential explosive hazards.

Training and education of personnel working with perchloric acid remain ongoing challenges. The unique properties and hazards of perchloric acid necessitate comprehensive and continual training programs. Ensuring that all personnel, including temporary or contract workers, are adequately trained and follow strict safety protocols is crucial but often difficult to maintain consistently.

Emergency response planning for perchloric acid incidents presents unique challenges. The potential for rapid escalation of incidents involving perchloric acid requires specialized emergency procedures and equipment. Coordinating with local emergency responders and ensuring they are prepared for perchloric acid-related incidents is an essential but complex task.

Lastly, the regulatory landscape surrounding perchloric acid usage is complex and evolving. Keeping up with changing regulations and ensuring compliance across different jurisdictions can be challenging for organizations working with perchloric acid. This regulatory complexity adds an additional layer of difficulty to the already challenging task of safely handling and managing perchloric acid in research and industrial settings.

Existing Safety Solutions for Perchloric Acid Use

01 Safe handling and storage of perchloric acid

Proper handling and storage techniques are crucial for ensuring environmental safety when dealing with perchloric acid. This includes using specialized containers, implementing safety protocols, and maintaining appropriate storage conditions to prevent leaks or accidents that could harm the environment.- Safe storage and handling of perchloric acid: Proper storage and handling techniques are crucial for ensuring environmental safety when dealing with perchloric acid. This includes using specialized containers, implementing safety measures, and following strict protocols to prevent leaks or spills that could harm the environment.

- Waste treatment and disposal methods: Effective waste treatment and disposal methods are essential for minimizing the environmental impact of perchloric acid. This involves neutralization processes, specialized disposal techniques, and the use of advanced treatment systems to ensure that perchloric acid waste is safely managed and does not contaminate soil or water sources.

- Monitoring and detection systems: Advanced monitoring and detection systems play a crucial role in maintaining environmental safety when working with perchloric acid. These systems can quickly identify leaks, spills, or unsafe concentrations of the acid in the air or water, allowing for prompt response and mitigation of potential environmental hazards.

- Protective equipment and safety measures: The use of appropriate protective equipment and implementation of safety measures are vital for preventing environmental contamination from perchloric acid. This includes specialized personal protective equipment, containment systems, and emergency response procedures to minimize the risk of accidental releases into the environment.

- Alternative chemicals and processes: Research into alternative chemicals and processes that can replace or reduce the use of perchloric acid is an important aspect of improving environmental safety. This involves developing new methodologies, identifying safer substitutes, and optimizing existing processes to minimize the environmental risks associated with perchloric acid use.

02 Waste treatment and disposal methods

Effective waste treatment and disposal methods are essential for minimizing the environmental impact of perchloric acid. This involves neutralization processes, specialized disposal techniques, and proper containment systems to prevent contamination of soil and water resources.Expand Specific Solutions03 Monitoring and detection systems

Advanced monitoring and detection systems are crucial for ensuring environmental safety in areas where perchloric acid is used or stored. These systems can quickly identify leaks, spills, or other potential hazards, allowing for rapid response and mitigation of environmental risks.Expand Specific Solutions04 Protective equipment and safety measures

Appropriate protective equipment and safety measures are necessary to safeguard both workers and the environment from the potential hazards of perchloric acid. This includes specialized personal protective equipment, emergency response protocols, and containment systems to prevent environmental contamination.Expand Specific Solutions05 Environmental remediation techniques

In cases of accidental release or contamination, environmental remediation techniques are crucial for mitigating the impact of perchloric acid on ecosystems. These may include specialized cleaning methods, soil treatment processes, and water purification techniques to restore affected areas.Expand Specific Solutions

Key Players in Perchloric Acid Industry

The environmental safety measures for perchloric acid usage market is in a growth phase, driven by increasing awareness of safety regulations and expanding industrial applications. The global market size is estimated to reach several hundred million dollars by 2025. Technologically, the field is moderately mature, with ongoing innovations focused on improving safety and efficiency. Key players like DuPont de Nemours, China Petroleum & Chemical Corp., and FMC Corp. are leading research and development efforts. Universities such as Zhejiang University and King Fahd University of Petroleum & Minerals are contributing to advancements through academic research. Specialized companies like Envirogen Technologies and Applied Intellectual Capital are developing niche solutions, indicating a diverse and competitive landscape.

Dorf Ketal Chemicals FZE

Technical Solution: Dorf Ketal has developed a range of specialized additives and handling systems for perchloric acid safety. Their approach includes the use of proprietary stabilizers that reduce the reactivity of perchloric acid, making it safer to handle and store[12]. They've also created advanced polymer coatings for storage tanks and transfer equipment that are highly resistant to perchloric acid corrosion. Dorf Ketal's environmental safety measures include the development of catalytic decomposition systems for perchloric acid waste streams, effectively breaking down the acid into less harmful components. They've implemented sophisticated process control systems that monitor and adjust acid concentrations in real-time, minimizing the risk of dangerous concentrations[13].

Strengths: Expertise in chemical additives and stabilizers, advanced corrosion-resistant materials. Weaknesses: May have a more limited focus on comprehensive safety systems compared to larger, more diversified companies.

Fluid Energy Group Ltd.

Technical Solution: Fluid Energy Group has focused on developing safer alternatives and handling methods for perchloric acid. They've created a range of non-perchloric acid-based solutions that can replace perchloric acid in many applications, reducing overall safety risks[10]. For cases where perchloric acid is still necessary, they've developed a patented encapsulation technology that significantly reduces vapor emissions and splash risks. Their safety systems include smart sensors that can detect minute quantities of perchloric acid in the air, triggering automated safety protocols. Fluid Energy Group has also implemented a comprehensive lifecycle management approach for perchloric acid, from production to disposal, ensuring environmental safety at every stage[11].

Strengths: Focus on safer alternatives, innovative encapsulation technology, comprehensive lifecycle management. Weaknesses: May face challenges in applications where perchloric acid alternatives are not yet viable.

Innovative Safety Technologies for Perchloric Acid

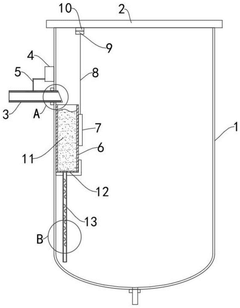

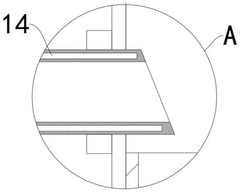

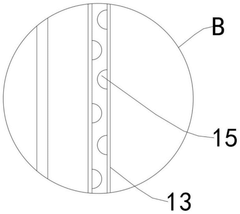

Feeding mechanism for perchloric acid feeding

PatentActiveCN221987109U

Innovation

- A feeding mechanism for perchloric acid feeding is designed, including sealed tank body, input tube, L-shaped pallet, feeding box, desiccant and air cooler, and the input tube and the high chlorine in transport are cooled through the air cooler. Acid solution, use desiccant to absorb moisture and slow down the drop rate of perchloric acid solution to avoid impact reactions.

Regulatory Framework for Perchloric Acid Handling

The regulatory framework for perchloric acid handling is a critical aspect of ensuring environmental safety in its usage. Governments and international organizations have established comprehensive guidelines and regulations to mitigate the risks associated with this highly reactive and potentially hazardous substance.

At the federal level in the United States, the Occupational Safety and Health Administration (OSHA) has set forth specific standards for the handling and storage of perchloric acid. These regulations, outlined in 29 CFR 1910.1000, mandate permissible exposure limits and require employers to implement engineering controls and work practices to minimize employee exposure.

The Environmental Protection Agency (EPA) also plays a crucial role in regulating perchloric acid under the Resource Conservation and Recovery Act (RCRA). This act classifies perchloric acid as a hazardous waste when disposed of and sets stringent requirements for its treatment, storage, and disposal.

On a state level, regulations may vary, with some states imposing additional requirements. For instance, California has implemented more stringent controls through its Division of Occupational Safety and Health (Cal/OSHA), which mandates specific ventilation systems for perchloric acid fume hoods.

Internationally, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Under this system, perchloric acid is classified as an oxidizer and corrosive substance, requiring specific labeling and safety data sheets.

The European Union regulates perchloric acid under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. This comprehensive framework ensures that manufacturers and importers assess and manage the risks associated with perchloric acid throughout its lifecycle.

In addition to governmental regulations, industry standards play a significant role in shaping best practices for perchloric acid handling. The National Fire Protection Association (NFPA) provides guidelines for the storage and use of perchloric acid in laboratory settings through its NFPA 45 standard.

Compliance with these regulatory frameworks is essential for organizations working with perchloric acid. Regular audits, employee training programs, and up-to-date safety protocols are necessary to ensure adherence to these regulations and maintain a safe working environment.

As environmental concerns continue to grow, it is likely that regulatory frameworks will evolve to address emerging issues. Future regulations may focus on more stringent emission controls, improved waste management practices, and enhanced monitoring of environmental impacts associated with perchloric acid usage.

At the federal level in the United States, the Occupational Safety and Health Administration (OSHA) has set forth specific standards for the handling and storage of perchloric acid. These regulations, outlined in 29 CFR 1910.1000, mandate permissible exposure limits and require employers to implement engineering controls and work practices to minimize employee exposure.

The Environmental Protection Agency (EPA) also plays a crucial role in regulating perchloric acid under the Resource Conservation and Recovery Act (RCRA). This act classifies perchloric acid as a hazardous waste when disposed of and sets stringent requirements for its treatment, storage, and disposal.

On a state level, regulations may vary, with some states imposing additional requirements. For instance, California has implemented more stringent controls through its Division of Occupational Safety and Health (Cal/OSHA), which mandates specific ventilation systems for perchloric acid fume hoods.

Internationally, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Under this system, perchloric acid is classified as an oxidizer and corrosive substance, requiring specific labeling and safety data sheets.

The European Union regulates perchloric acid under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. This comprehensive framework ensures that manufacturers and importers assess and manage the risks associated with perchloric acid throughout its lifecycle.

In addition to governmental regulations, industry standards play a significant role in shaping best practices for perchloric acid handling. The National Fire Protection Association (NFPA) provides guidelines for the storage and use of perchloric acid in laboratory settings through its NFPA 45 standard.

Compliance with these regulatory frameworks is essential for organizations working with perchloric acid. Regular audits, employee training programs, and up-to-date safety protocols are necessary to ensure adherence to these regulations and maintain a safe working environment.

As environmental concerns continue to grow, it is likely that regulatory frameworks will evolve to address emerging issues. Future regulations may focus on more stringent emission controls, improved waste management practices, and enhanced monitoring of environmental impacts associated with perchloric acid usage.

Environmental Impact Assessment of Perchloric Acid

The environmental impact assessment of perchloric acid usage is a critical component in ensuring the safe and responsible handling of this powerful oxidizing agent. Perchloric acid, widely used in various industrial and laboratory applications, poses significant environmental risks if not properly managed.

One of the primary environmental concerns associated with perchloric acid is its potential for contamination of soil and water resources. When released into the environment, perchloric acid can persist for extended periods, leading to long-term ecological damage. It can alter soil chemistry, affecting plant growth and microbial communities essential for ecosystem balance. In aquatic environments, perchloric acid can disrupt the natural pH balance, potentially harming fish and other aquatic organisms.

Atmospheric release of perchloric acid vapors presents another environmental challenge. These vapors can contribute to air pollution and, when combined with moisture in the air, form corrosive precipitation. This can lead to accelerated weathering of buildings and infrastructure, as well as damage to vegetation in affected areas.

The bioaccumulation potential of perchlorate, a byproduct of perchloric acid, is a significant concern in environmental impact assessments. Perchlorate can accumulate in plants and animals, potentially entering the food chain and affecting higher-level organisms, including humans. Studies have shown that perchlorate can interfere with thyroid function in various species, potentially leading to developmental and reproductive issues in wildlife populations.

To mitigate these environmental risks, comprehensive safety measures and proper disposal protocols are essential. Closed-loop systems and advanced scrubbing technologies can significantly reduce atmospheric emissions. Proper containment and storage facilities are crucial to prevent soil and water contamination. Additionally, specialized waste treatment processes, such as ion exchange or biological reduction methods, can effectively neutralize perchloric acid waste before disposal.

Environmental monitoring programs play a vital role in assessing the impact of perchloric acid usage. Regular testing of soil, water, and air quality in areas surrounding facilities that use or produce perchloric acid helps in early detection of potential contamination. This allows for timely intervention and remediation efforts to minimize long-term environmental damage.

The development and implementation of stringent regulatory frameworks are crucial in managing the environmental impact of perchloric acid. These regulations should encompass guidelines for handling, storage, transportation, and disposal of perchloric acid and its waste products. Compliance with these regulations, coupled with regular environmental audits, can significantly reduce the risk of adverse environmental impacts.

One of the primary environmental concerns associated with perchloric acid is its potential for contamination of soil and water resources. When released into the environment, perchloric acid can persist for extended periods, leading to long-term ecological damage. It can alter soil chemistry, affecting plant growth and microbial communities essential for ecosystem balance. In aquatic environments, perchloric acid can disrupt the natural pH balance, potentially harming fish and other aquatic organisms.

Atmospheric release of perchloric acid vapors presents another environmental challenge. These vapors can contribute to air pollution and, when combined with moisture in the air, form corrosive precipitation. This can lead to accelerated weathering of buildings and infrastructure, as well as damage to vegetation in affected areas.

The bioaccumulation potential of perchlorate, a byproduct of perchloric acid, is a significant concern in environmental impact assessments. Perchlorate can accumulate in plants and animals, potentially entering the food chain and affecting higher-level organisms, including humans. Studies have shown that perchlorate can interfere with thyroid function in various species, potentially leading to developmental and reproductive issues in wildlife populations.

To mitigate these environmental risks, comprehensive safety measures and proper disposal protocols are essential. Closed-loop systems and advanced scrubbing technologies can significantly reduce atmospheric emissions. Proper containment and storage facilities are crucial to prevent soil and water contamination. Additionally, specialized waste treatment processes, such as ion exchange or biological reduction methods, can effectively neutralize perchloric acid waste before disposal.

Environmental monitoring programs play a vital role in assessing the impact of perchloric acid usage. Regular testing of soil, water, and air quality in areas surrounding facilities that use or produce perchloric acid helps in early detection of potential contamination. This allows for timely intervention and remediation efforts to minimize long-term environmental damage.

The development and implementation of stringent regulatory frameworks are crucial in managing the environmental impact of perchloric acid. These regulations should encompass guidelines for handling, storage, transportation, and disposal of perchloric acid and its waste products. Compliance with these regulations, coupled with regular environmental audits, can significantly reduce the risk of adverse environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!