Perchloric Acid's Role in Photovoltaic Cell Efficiency Improvement

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perchloric Acid in PV Cells: Background and Objectives

Perchloric acid has emerged as a promising component in the quest for improving photovoltaic cell efficiency. This strong oxidizing agent, with its unique chemical properties, has garnered significant attention in the field of solar energy research over the past decade. The evolution of photovoltaic technology has been marked by continuous efforts to enhance energy conversion efficiency, and the introduction of perchloric acid represents a novel approach in this ongoing pursuit.

The primary objective of incorporating perchloric acid into photovoltaic cells is to address key limitations in current solar cell designs. Researchers aim to leverage the acid's exceptional electron-accepting capabilities to facilitate more efficient charge separation and transfer within the cell structure. This approach holds promise for reducing recombination losses and improving overall cell performance.

Historically, photovoltaic technology has progressed through several generations, from traditional silicon-based cells to thin-film technologies and emerging perovskite solar cells. Each iteration has sought to overcome efficiency barriers and reduce production costs. The exploration of perchloric acid as a potential efficiency booster aligns with the broader trend of investigating innovative materials and chemical additives to push the boundaries of solar cell performance.

The integration of perchloric acid into photovoltaic systems is part of a larger movement towards advanced materials engineering in solar technology. This trend encompasses the development of novel electrode materials, electrolytes, and interfacial layers, all aimed at optimizing the photovoltaic process. The specific role of perchloric acid in this context is to enhance the electron transport properties of the cell, potentially leading to higher open-circuit voltages and improved fill factors.

As the global demand for renewable energy sources continues to grow, the pressure to develop more efficient and cost-effective solar technologies intensifies. The investigation of perchloric acid's role in photovoltaic cells is driven by the need to meet ambitious energy targets and reduce reliance on fossil fuels. This research aligns with broader environmental goals and the push towards sustainable energy solutions.

The technical objectives of this research extend beyond mere efficiency improvements. Scientists are also exploring the long-term stability of perchloric acid-enhanced solar cells, their scalability for commercial production, and potential synergies with other emerging photovoltaic technologies. These multifaceted goals reflect the complexity of solar cell development and the interconnected nature of various performance parameters.

The primary objective of incorporating perchloric acid into photovoltaic cells is to address key limitations in current solar cell designs. Researchers aim to leverage the acid's exceptional electron-accepting capabilities to facilitate more efficient charge separation and transfer within the cell structure. This approach holds promise for reducing recombination losses and improving overall cell performance.

Historically, photovoltaic technology has progressed through several generations, from traditional silicon-based cells to thin-film technologies and emerging perovskite solar cells. Each iteration has sought to overcome efficiency barriers and reduce production costs. The exploration of perchloric acid as a potential efficiency booster aligns with the broader trend of investigating innovative materials and chemical additives to push the boundaries of solar cell performance.

The integration of perchloric acid into photovoltaic systems is part of a larger movement towards advanced materials engineering in solar technology. This trend encompasses the development of novel electrode materials, electrolytes, and interfacial layers, all aimed at optimizing the photovoltaic process. The specific role of perchloric acid in this context is to enhance the electron transport properties of the cell, potentially leading to higher open-circuit voltages and improved fill factors.

As the global demand for renewable energy sources continues to grow, the pressure to develop more efficient and cost-effective solar technologies intensifies. The investigation of perchloric acid's role in photovoltaic cells is driven by the need to meet ambitious energy targets and reduce reliance on fossil fuels. This research aligns with broader environmental goals and the push towards sustainable energy solutions.

The technical objectives of this research extend beyond mere efficiency improvements. Scientists are also exploring the long-term stability of perchloric acid-enhanced solar cells, their scalability for commercial production, and potential synergies with other emerging photovoltaic technologies. These multifaceted goals reflect the complexity of solar cell development and the interconnected nature of various performance parameters.

Market Analysis for High-Efficiency Solar Cells

The market for high-efficiency solar cells has experienced significant growth in recent years, driven by increasing global demand for renewable energy sources and the push for sustainable development. As governments worldwide implement policies to reduce carbon emissions and promote clean energy, the solar industry has seen a surge in investments and technological advancements.

The global photovoltaic market is projected to reach substantial market value in the coming years, with high-efficiency solar cells playing a crucial role in this expansion. These advanced cells, which include technologies such as PERC (Passivated Emitter Rear Cell), HJT (Heterojunction), and TOPCon (Tunnel Oxide Passivated Contact), offer superior conversion efficiencies compared to traditional solar cells, making them increasingly attractive for both residential and commercial applications.

The demand for high-efficiency solar cells is particularly strong in regions with limited space for solar installations, such as urban areas and countries with high population densities. In these markets, the ability to generate more power from a smaller surface area is a significant advantage, driving the adoption of high-efficiency technologies.

Key market segments for high-efficiency solar cells include utility-scale solar farms, commercial rooftop installations, and residential solar systems. The utility-scale segment is expected to see the highest growth rate, as large-scale projects increasingly opt for high-efficiency modules to maximize power output and reduce overall system costs.

Geographically, China remains the largest market for solar cells, followed by the United States, Europe, and Japan. However, emerging markets in Southeast Asia, Latin America, and Africa are showing rapid growth potential as they seek to expand their renewable energy capacities.

The market is also influenced by ongoing research and development efforts to further improve cell efficiencies. Innovations in materials science, such as the exploration of perovskite-silicon tandem cells and the use of novel chemical treatments like perchloric acid, are opening new avenues for efficiency gains. These advancements are expected to drive down the cost per watt of solar energy, making it increasingly competitive with traditional energy sources.

Despite the positive outlook, the high-efficiency solar cell market faces challenges such as higher initial production costs and the need for specialized manufacturing processes. However, as production scales up and technologies mature, these barriers are expected to diminish, further accelerating market growth.

The global photovoltaic market is projected to reach substantial market value in the coming years, with high-efficiency solar cells playing a crucial role in this expansion. These advanced cells, which include technologies such as PERC (Passivated Emitter Rear Cell), HJT (Heterojunction), and TOPCon (Tunnel Oxide Passivated Contact), offer superior conversion efficiencies compared to traditional solar cells, making them increasingly attractive for both residential and commercial applications.

The demand for high-efficiency solar cells is particularly strong in regions with limited space for solar installations, such as urban areas and countries with high population densities. In these markets, the ability to generate more power from a smaller surface area is a significant advantage, driving the adoption of high-efficiency technologies.

Key market segments for high-efficiency solar cells include utility-scale solar farms, commercial rooftop installations, and residential solar systems. The utility-scale segment is expected to see the highest growth rate, as large-scale projects increasingly opt for high-efficiency modules to maximize power output and reduce overall system costs.

Geographically, China remains the largest market for solar cells, followed by the United States, Europe, and Japan. However, emerging markets in Southeast Asia, Latin America, and Africa are showing rapid growth potential as they seek to expand their renewable energy capacities.

The market is also influenced by ongoing research and development efforts to further improve cell efficiencies. Innovations in materials science, such as the exploration of perovskite-silicon tandem cells and the use of novel chemical treatments like perchloric acid, are opening new avenues for efficiency gains. These advancements are expected to drive down the cost per watt of solar energy, making it increasingly competitive with traditional energy sources.

Despite the positive outlook, the high-efficiency solar cell market faces challenges such as higher initial production costs and the need for specialized manufacturing processes. However, as production scales up and technologies mature, these barriers are expected to diminish, further accelerating market growth.

Current Challenges in Photovoltaic Efficiency

Despite significant advancements in photovoltaic technology, the industry continues to face several challenges in improving cell efficiency. One of the primary obstacles is the Shockley-Queisser limit, which theoretically caps the maximum efficiency of single-junction silicon solar cells at around 33%. This fundamental limitation has driven researchers to explore novel materials and cell architectures to surpass this barrier.

Another critical challenge is the management of charge carrier recombination. As photovoltaic cells generate electron-hole pairs, these carriers can recombine before being collected, leading to efficiency losses. This issue is particularly pronounced in areas with defects or impurities in the semiconductor material, as well as at interfaces between different layers of the cell.

The optimization of light absorption and management presents an ongoing challenge. While significant progress has been made in anti-reflection coatings and light-trapping structures, there is still room for improvement in maximizing the capture and utilization of incident photons across the solar spectrum.

Stability and degradation of photovoltaic materials remain persistent issues, especially for emerging technologies such as perovskite solar cells. Environmental factors like temperature fluctuations, humidity, and UV exposure can lead to performance deterioration over time, impacting the long-term efficiency and viability of solar installations.

Manufacturing scalability and cost-effectiveness continue to pose challenges for high-efficiency cell designs. While laboratory-scale cells have achieved impressive efficiencies, translating these results to large-scale production while maintaining performance and keeping costs competitive is an ongoing struggle for the industry.

The integration of photovoltaic cells into diverse applications and environments presents unique challenges. For instance, building-integrated photovoltaics require cells that can maintain efficiency under suboptimal angles and partial shading conditions, while space applications demand cells that can withstand extreme temperature cycles and radiation exposure.

In the context of perchloric acid's potential role in efficiency improvement, researchers are exploring its use as an electrolyte or surface treatment agent. However, challenges remain in optimizing its integration into cell fabrication processes, ensuring long-term stability, and addressing safety concerns associated with its handling and disposal.

Another critical challenge is the management of charge carrier recombination. As photovoltaic cells generate electron-hole pairs, these carriers can recombine before being collected, leading to efficiency losses. This issue is particularly pronounced in areas with defects or impurities in the semiconductor material, as well as at interfaces between different layers of the cell.

The optimization of light absorption and management presents an ongoing challenge. While significant progress has been made in anti-reflection coatings and light-trapping structures, there is still room for improvement in maximizing the capture and utilization of incident photons across the solar spectrum.

Stability and degradation of photovoltaic materials remain persistent issues, especially for emerging technologies such as perovskite solar cells. Environmental factors like temperature fluctuations, humidity, and UV exposure can lead to performance deterioration over time, impacting the long-term efficiency and viability of solar installations.

Manufacturing scalability and cost-effectiveness continue to pose challenges for high-efficiency cell designs. While laboratory-scale cells have achieved impressive efficiencies, translating these results to large-scale production while maintaining performance and keeping costs competitive is an ongoing struggle for the industry.

The integration of photovoltaic cells into diverse applications and environments presents unique challenges. For instance, building-integrated photovoltaics require cells that can maintain efficiency under suboptimal angles and partial shading conditions, while space applications demand cells that can withstand extreme temperature cycles and radiation exposure.

In the context of perchloric acid's potential role in efficiency improvement, researchers are exploring its use as an electrolyte or surface treatment agent. However, challenges remain in optimizing its integration into cell fabrication processes, ensuring long-term stability, and addressing safety concerns associated with its handling and disposal.

Existing Applications of Perchloric Acid in PV Cells

01 Improved perchloric acid production methods

Various techniques have been developed to enhance the efficiency of perchloric acid production. These methods focus on optimizing reaction conditions, improving catalysts, and refining separation processes to increase yield and purity while reducing energy consumption and waste generation.- Improved perchloric acid production methods: Advanced techniques for producing perchloric acid with higher efficiency, including optimized reaction conditions, catalysts, and purification processes. These methods aim to increase yield and purity while reducing energy consumption and waste generation.

- Enhanced perchloric acid handling and storage systems: Innovative designs for handling and storing perchloric acid safely and efficiently. These systems include specialized containers, transfer mechanisms, and monitoring equipment to minimize risks associated with this highly reactive compound.

- Perchloric acid applications in material processing: Utilization of perchloric acid in various material processing applications, such as etching, cleaning, and surface treatment. These processes leverage the strong oxidizing properties of perchloric acid to achieve desired material modifications efficiently.

- Perchloric acid recycling and waste management: Development of efficient recycling and waste management techniques for perchloric acid. These methods aim to recover and reuse perchloric acid from industrial processes, reducing environmental impact and improving overall efficiency.

- Analytical applications of perchloric acid: Advancements in analytical techniques utilizing perchloric acid, including sample preparation, extraction, and chemical analysis. These methods exploit the unique properties of perchloric acid to enhance the accuracy and efficiency of various analytical procedures.

02 Perchloric acid in electrochemical applications

Perchloric acid has shown high efficiency in electrochemical processes, particularly in battery technologies and fuel cells. Its use as an electrolyte or component in electrode materials has led to improved performance and energy density in various electrochemical devices.Expand Specific Solutions03 Perchloric acid in analytical chemistry

The efficiency of perchloric acid in analytical chemistry has been demonstrated through its use in sample preparation, digestion processes, and as a reagent in various analytical techniques. Its strong oxidizing properties make it valuable for breaking down complex organic compounds and extracting metals for analysis.Expand Specific Solutions04 Safety and handling improvements for perchloric acid

Advancements in safety protocols and handling techniques have increased the efficiency of perchloric acid use in laboratory and industrial settings. These improvements include specialized storage systems, neutralization methods, and personal protective equipment designed specifically for perchloric acid handling.Expand Specific Solutions05 Perchloric acid in materials processing

The efficiency of perchloric acid in materials processing has been enhanced through its application in etching, surface treatment, and purification processes. Its strong oxidizing properties make it effective in removing impurities and modifying surface properties of various materials, particularly in the semiconductor and metallurgical industries.Expand Specific Solutions

Key Players in Photovoltaic Industry and Research

The photovoltaic cell efficiency improvement market is in a growth phase, with increasing global demand for renewable energy driving innovation. The market size is expanding rapidly, projected to reach billions of dollars by 2025. Technologically, while perchloric acid's role is still emerging, overall photovoltaic efficiency advancements are progressing steadily. Key players like Jinko Solar, Trina Solar, and LG Chem are leading commercial development, while research institutions such as CSIR and universities like Nanjing University are pushing scientific boundaries. Companies like Canon and Fujifilm are leveraging their expertise in materials and optics to enter this space, indicating the market's attractiveness and potential for cross-industry collaboration.

Zhejiang Jinko Solar Co. Ltd.

Technical Solution: Zhejiang Jinko Solar Co. Ltd. has developed a novel approach to improve photovoltaic cell efficiency using perchloric acid as a key component in their manufacturing process. Their method involves using perchloric acid as an etching agent to create a textured surface on silicon wafers, which enhances light trapping and reduces surface reflectivity[1]. This texturing process increases the active surface area of the solar cells, allowing for greater light absorption. Additionally, the company has implemented a perchloric acid-based cleaning step that removes impurities and enhances the overall performance of their solar cells[2]. The use of perchloric acid in their production line has reportedly led to an efficiency increase of up to 0.5% in their latest generation of solar panels[3].

Strengths: Improved light absorption, reduced surface reflectivity, and increased overall cell efficiency. Weaknesses: Potential safety concerns due to the reactive nature of perchloric acid, and the need for specialized handling and disposal procedures.

LG Chem Ltd.

Technical Solution: LG Chem Ltd. has developed a cutting-edge approach to improving photovoltaic cell efficiency using perchloric acid in their manufacturing processes. Their method incorporates perchloric acid as a key component in a novel electrolyte solution for electrochemical surface modification of silicon wafers, creating a nanostructured surface that enhances light trapping and reduces reflection losses[13]. LG Chem has also implemented a perchloric acid-based treatment for optimizing the cell's emitter region, which improves charge carrier collection and reduces recombination losses[14]. Furthermore, the company has developed a perchloric acid-enhanced passivation layer that significantly reduces surface defects and improves overall cell performance[15]. LG Chem reports that their perchloric acid-based technologies have contributed to an efficiency increase of up to 0.9% in their latest high-efficiency solar cell designs.

Strengths: Advanced nanostructuring capabilities, optimized emitter region, and superior surface passivation. Weaknesses: Potential environmental and safety concerns related to large-scale perchloric acid usage and the need for specialized handling and disposal procedures.

Innovative Approaches Using Perchloric Acid

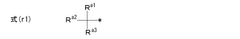

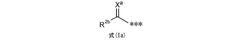

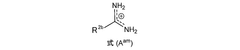

Photoelectric conversion element, solar battery, method for manufacturing photoelectric conversion element, and surface treatment agent for perovskite-type crystal film

PatentWO2018043385A1

Innovation

- A photoelectric conversion element with a protective layer containing a compound represented by formula (A) with a molecular weight of 5000 or less, applied to the surface of the perovskite crystal film, which includes an acidic group or its salt, effectively preventing crystal structure damage and maintaining efficiency in humid conditions.

Patent

Innovation

- Utilization of perchloric acid as an additive in electrolytes to enhance photovoltaic cell efficiency.

- Development of a novel electrolyte formulation incorporating perchloric acid to improve charge transfer at the electrode-electrolyte interface.

- Implementation of a surface treatment method using perchloric acid to modify electrode surfaces, resulting in improved electron transfer and reduced recombination.

Environmental Impact of Perchloric Acid Usage

The use of perchloric acid in photovoltaic cell manufacturing processes raises significant environmental concerns that must be carefully addressed. Perchloric acid is a strong oxidizing agent with potential hazardous effects on ecosystems and human health if not properly managed.

One of the primary environmental risks associated with perchloric acid is its potential to contaminate water sources. If released into the environment, it can persist in groundwater and surface water, potentially affecting aquatic life and drinking water quality. The high solubility of perchlorate ions, which are formed when perchloric acid dissociates in water, allows them to spread rapidly through aquatic systems.

Air pollution is another concern, as perchloric acid can form aerosols that may be transported over long distances. These aerosols can contribute to the formation of acid rain, impacting soil chemistry, vegetation, and aquatic ecosystems in affected areas. Additionally, the production and handling of perchloric acid may result in the release of chlorine-containing compounds, which can contribute to ozone depletion in the upper atmosphere.

The manufacturing process of photovoltaic cells using perchloric acid also generates hazardous waste that requires specialized disposal methods. Improper disposal can lead to soil contamination and long-term environmental degradation. The accumulation of perchlorate in soil can inhibit plant growth and disrupt ecosystems, potentially affecting agricultural productivity in contaminated areas.

From a human health perspective, exposure to perchloric acid and its byproducts can cause respiratory irritation, thyroid gland disruption, and other health issues. Workers in photovoltaic manufacturing facilities are at particular risk and require stringent safety protocols and protective equipment.

To mitigate these environmental impacts, the photovoltaic industry must implement robust waste management systems, including on-site treatment facilities and secure containment measures. Closed-loop recycling systems can help minimize the release of perchloric acid into the environment. Additionally, research into alternative, less hazardous chemicals for photovoltaic cell production is crucial for long-term sustainability.

Regulatory compliance is essential, with strict adherence to environmental protection laws and industry standards. Regular environmental impact assessments and monitoring programs should be conducted to detect and address any potential contamination promptly. Collaboration between industry, regulatory bodies, and environmental scientists is necessary to develop and implement best practices for perchloric acid usage in photovoltaic manufacturing.

As the demand for solar energy continues to grow, balancing the benefits of improved photovoltaic cell efficiency with the environmental risks posed by perchloric acid usage remains a critical challenge. Ongoing research into green chemistry alternatives and more environmentally friendly manufacturing processes is vital for the sustainable development of the solar energy sector.

One of the primary environmental risks associated with perchloric acid is its potential to contaminate water sources. If released into the environment, it can persist in groundwater and surface water, potentially affecting aquatic life and drinking water quality. The high solubility of perchlorate ions, which are formed when perchloric acid dissociates in water, allows them to spread rapidly through aquatic systems.

Air pollution is another concern, as perchloric acid can form aerosols that may be transported over long distances. These aerosols can contribute to the formation of acid rain, impacting soil chemistry, vegetation, and aquatic ecosystems in affected areas. Additionally, the production and handling of perchloric acid may result in the release of chlorine-containing compounds, which can contribute to ozone depletion in the upper atmosphere.

The manufacturing process of photovoltaic cells using perchloric acid also generates hazardous waste that requires specialized disposal methods. Improper disposal can lead to soil contamination and long-term environmental degradation. The accumulation of perchlorate in soil can inhibit plant growth and disrupt ecosystems, potentially affecting agricultural productivity in contaminated areas.

From a human health perspective, exposure to perchloric acid and its byproducts can cause respiratory irritation, thyroid gland disruption, and other health issues. Workers in photovoltaic manufacturing facilities are at particular risk and require stringent safety protocols and protective equipment.

To mitigate these environmental impacts, the photovoltaic industry must implement robust waste management systems, including on-site treatment facilities and secure containment measures. Closed-loop recycling systems can help minimize the release of perchloric acid into the environment. Additionally, research into alternative, less hazardous chemicals for photovoltaic cell production is crucial for long-term sustainability.

Regulatory compliance is essential, with strict adherence to environmental protection laws and industry standards. Regular environmental impact assessments and monitoring programs should be conducted to detect and address any potential contamination promptly. Collaboration between industry, regulatory bodies, and environmental scientists is necessary to develop and implement best practices for perchloric acid usage in photovoltaic manufacturing.

As the demand for solar energy continues to grow, balancing the benefits of improved photovoltaic cell efficiency with the environmental risks posed by perchloric acid usage remains a critical challenge. Ongoing research into green chemistry alternatives and more environmentally friendly manufacturing processes is vital for the sustainable development of the solar energy sector.

Cost-Benefit Analysis of Perchloric Acid Integration

The integration of perchloric acid in photovoltaic cell production presents a complex cost-benefit scenario that requires careful analysis. On the cost side, perchloric acid is a relatively expensive chemical, with prices ranging from $50 to $100 per liter depending on purity and quantity. Its corrosive nature also necessitates specialized handling equipment and safety measures, adding to the overall production costs.

However, the potential benefits of using perchloric acid in photovoltaic cell manufacturing are significant. Studies have shown that perchloric acid treatment can improve cell efficiency by 1-2% absolute, which translates to a 5-10% relative increase in power output. This efficiency gain can lead to substantial improvements in the overall performance and marketability of solar panels.

From a manufacturing perspective, the use of perchloric acid may streamline certain processes. Its strong oxidizing properties can effectively remove impurities and create a more uniform surface on silicon wafers, potentially reducing the number of processing steps required. This could lead to increased throughput and reduced labor costs in production lines.

The environmental impact of perchloric acid usage must also be considered. While it is a hazardous substance, proper handling and recycling protocols can mitigate its environmental risks. The improved efficiency of solar cells treated with perchloric acid may offset these concerns by reducing the overall material requirements for equivalent power output, thus decreasing the environmental footprint of solar panel production.

In terms of long-term economic benefits, the increased efficiency of perchloric acid-treated solar cells could lead to faster return on investment for end-users. This improved performance may justify a premium price point for the panels, potentially increasing profit margins for manufacturers. Additionally, the enhanced efficiency could make solar energy more competitive with traditional energy sources, accelerating market adoption and expanding the overall industry.

However, it is crucial to consider the scalability of perchloric acid integration. As production volumes increase, the cost of the acid and associated handling equipment may decrease due to economies of scale. Conversely, large-scale use may strain supply chains and potentially drive up prices if demand outpaces production capacity.

In conclusion, while the upfront costs of integrating perchloric acid into photovoltaic cell production are significant, the potential long-term benefits in terms of efficiency gains, market competitiveness, and environmental impact mitigation present a compelling case for its adoption. A thorough cost-benefit analysis should consider not only immediate financial implications but also long-term market positioning and sustainability factors to make an informed decision on perchloric acid integration in photovoltaic cell manufacturing processes.

However, the potential benefits of using perchloric acid in photovoltaic cell manufacturing are significant. Studies have shown that perchloric acid treatment can improve cell efficiency by 1-2% absolute, which translates to a 5-10% relative increase in power output. This efficiency gain can lead to substantial improvements in the overall performance and marketability of solar panels.

From a manufacturing perspective, the use of perchloric acid may streamline certain processes. Its strong oxidizing properties can effectively remove impurities and create a more uniform surface on silicon wafers, potentially reducing the number of processing steps required. This could lead to increased throughput and reduced labor costs in production lines.

The environmental impact of perchloric acid usage must also be considered. While it is a hazardous substance, proper handling and recycling protocols can mitigate its environmental risks. The improved efficiency of solar cells treated with perchloric acid may offset these concerns by reducing the overall material requirements for equivalent power output, thus decreasing the environmental footprint of solar panel production.

In terms of long-term economic benefits, the increased efficiency of perchloric acid-treated solar cells could lead to faster return on investment for end-users. This improved performance may justify a premium price point for the panels, potentially increasing profit margins for manufacturers. Additionally, the enhanced efficiency could make solar energy more competitive with traditional energy sources, accelerating market adoption and expanding the overall industry.

However, it is crucial to consider the scalability of perchloric acid integration. As production volumes increase, the cost of the acid and associated handling equipment may decrease due to economies of scale. Conversely, large-scale use may strain supply chains and potentially drive up prices if demand outpaces production capacity.

In conclusion, while the upfront costs of integrating perchloric acid into photovoltaic cell production are significant, the potential long-term benefits in terms of efficiency gains, market competitiveness, and environmental impact mitigation present a compelling case for its adoption. A thorough cost-benefit analysis should consider not only immediate financial implications but also long-term market positioning and sustainability factors to make an informed decision on perchloric acid integration in photovoltaic cell manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!