The Role of Perchloric Acid in the Formation of Conductive Polymers

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perchloric Acid in Conductive Polymers: Background and Objectives

Conductive polymers have emerged as a revolutionary class of materials in the field of organic electronics, offering unique properties that bridge the gap between traditional polymers and metals. The development of these materials has been a journey spanning several decades, with significant breakthroughs occurring in the late 20th century. Perchloric acid, a strong oxidizing agent, has played a crucial role in this evolution, particularly in the synthesis and doping processes of conductive polymers.

The primary objective of this technical research is to comprehensively examine the role of perchloric acid in the formation of conductive polymers. This investigation aims to elucidate the mechanisms by which perchloric acid influences the polymerization process, the resulting polymer structure, and the ultimate conductivity of the material. Understanding these interactions is vital for advancing the field and developing more efficient and tailored conductive polymers for various applications.

Historically, the discovery of conductive polymers can be traced back to the 1970s, with the groundbreaking work on polyacetylene by Alan J. Heeger, Alan MacDiarmid, and Hideki Shirakawa. This discovery opened up a new realm of possibilities in materials science and electronics. As research progressed, the importance of doping agents in enhancing conductivity became apparent, leading to the exploration of various acids, including perchloric acid, as potential dopants.

The technological trajectory in this field has been marked by continuous improvements in synthesis methods, polymer design, and doping techniques. Perchloric acid has emerged as a particularly effective agent due to its strong oxidizing properties and ability to facilitate the formation of charge carriers within the polymer structure. Its use has enabled the development of conductive polymers with higher conductivity, improved stability, and enhanced processability.

Current research trends focus on optimizing the use of perchloric acid in conductive polymer synthesis to achieve specific material properties. This includes investigating the impact of acid concentration, reaction conditions, and polymer composition on the final product characteristics. Additionally, there is growing interest in understanding the long-term effects of perchloric acid doping on polymer stability and performance, as well as exploring environmentally friendly alternatives that can match or exceed its effectiveness.

The potential applications of conductive polymers formed with the aid of perchloric acid span a wide range of industries. These include flexible electronics, organic solar cells, chemical sensors, and biomedical devices. As the demand for advanced materials in these sectors continues to grow, the role of perchloric acid in conductive polymer formation remains a critical area of study, with implications for both fundamental science and practical applications.

The primary objective of this technical research is to comprehensively examine the role of perchloric acid in the formation of conductive polymers. This investigation aims to elucidate the mechanisms by which perchloric acid influences the polymerization process, the resulting polymer structure, and the ultimate conductivity of the material. Understanding these interactions is vital for advancing the field and developing more efficient and tailored conductive polymers for various applications.

Historically, the discovery of conductive polymers can be traced back to the 1970s, with the groundbreaking work on polyacetylene by Alan J. Heeger, Alan MacDiarmid, and Hideki Shirakawa. This discovery opened up a new realm of possibilities in materials science and electronics. As research progressed, the importance of doping agents in enhancing conductivity became apparent, leading to the exploration of various acids, including perchloric acid, as potential dopants.

The technological trajectory in this field has been marked by continuous improvements in synthesis methods, polymer design, and doping techniques. Perchloric acid has emerged as a particularly effective agent due to its strong oxidizing properties and ability to facilitate the formation of charge carriers within the polymer structure. Its use has enabled the development of conductive polymers with higher conductivity, improved stability, and enhanced processability.

Current research trends focus on optimizing the use of perchloric acid in conductive polymer synthesis to achieve specific material properties. This includes investigating the impact of acid concentration, reaction conditions, and polymer composition on the final product characteristics. Additionally, there is growing interest in understanding the long-term effects of perchloric acid doping on polymer stability and performance, as well as exploring environmentally friendly alternatives that can match or exceed its effectiveness.

The potential applications of conductive polymers formed with the aid of perchloric acid span a wide range of industries. These include flexible electronics, organic solar cells, chemical sensors, and biomedical devices. As the demand for advanced materials in these sectors continues to grow, the role of perchloric acid in conductive polymer formation remains a critical area of study, with implications for both fundamental science and practical applications.

Market Analysis for Conductive Polymer Applications

The conductive polymer market has experienced significant growth in recent years, driven by the increasing demand for lightweight, flexible, and cost-effective electronic components. The global market for conductive polymers is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many traditional materials sectors.

Key application areas for conductive polymers include organic light-emitting diodes (OLEDs), solar cells, antistatic coatings, electromagnetic shielding, and sensors. The OLED market, in particular, has seen rapid expansion due to the adoption of OLED displays in smartphones, televisions, and other consumer electronics. This growth has directly contributed to the increased demand for conductive polymers used in these devices.

The automotive industry has emerged as a significant consumer of conductive polymers, utilizing them in various applications such as touch screens, sensors, and electromagnetic interference (EMI) shielding. As the automotive sector continues to embrace electrification and advanced driver assistance systems (ADAS), the demand for conductive polymers is expected to rise further.

In the healthcare sector, conductive polymers are finding applications in biosensors, drug delivery systems, and tissue engineering. The biocompatibility and flexibility of these materials make them particularly attractive for medical devices and implants. This sector is anticipated to be a major growth driver for conductive polymers in the coming years.

The energy storage market, including batteries and supercapacitors, represents another significant opportunity for conductive polymers. As the world transitions towards renewable energy sources and electric vehicles, the demand for high-performance energy storage solutions continues to grow, benefiting the conductive polymer market.

Geographically, Asia-Pacific leads the market for conductive polymers, driven by the strong presence of electronics manufacturing in countries like China, Japan, and South Korea. North America and Europe follow, with increasing adoption in automotive and healthcare sectors contributing to market growth in these regions.

Despite the positive outlook, challenges remain in the conductive polymer market. These include the need for improved stability and conductivity of the polymers, as well as competition from traditional conductive materials like metals. However, ongoing research and development efforts, including the use of perchloric acid in polymer synthesis, are addressing these challenges and opening up new possibilities for conductive polymer applications.

Key application areas for conductive polymers include organic light-emitting diodes (OLEDs), solar cells, antistatic coatings, electromagnetic shielding, and sensors. The OLED market, in particular, has seen rapid expansion due to the adoption of OLED displays in smartphones, televisions, and other consumer electronics. This growth has directly contributed to the increased demand for conductive polymers used in these devices.

The automotive industry has emerged as a significant consumer of conductive polymers, utilizing them in various applications such as touch screens, sensors, and electromagnetic interference (EMI) shielding. As the automotive sector continues to embrace electrification and advanced driver assistance systems (ADAS), the demand for conductive polymers is expected to rise further.

In the healthcare sector, conductive polymers are finding applications in biosensors, drug delivery systems, and tissue engineering. The biocompatibility and flexibility of these materials make them particularly attractive for medical devices and implants. This sector is anticipated to be a major growth driver for conductive polymers in the coming years.

The energy storage market, including batteries and supercapacitors, represents another significant opportunity for conductive polymers. As the world transitions towards renewable energy sources and electric vehicles, the demand for high-performance energy storage solutions continues to grow, benefiting the conductive polymer market.

Geographically, Asia-Pacific leads the market for conductive polymers, driven by the strong presence of electronics manufacturing in countries like China, Japan, and South Korea. North America and Europe follow, with increasing adoption in automotive and healthcare sectors contributing to market growth in these regions.

Despite the positive outlook, challenges remain in the conductive polymer market. These include the need for improved stability and conductivity of the polymers, as well as competition from traditional conductive materials like metals. However, ongoing research and development efforts, including the use of perchloric acid in polymer synthesis, are addressing these challenges and opening up new possibilities for conductive polymer applications.

Current Challenges in Conductive Polymer Synthesis

The synthesis of conductive polymers faces several significant challenges that hinder their widespread application and commercialization. One of the primary issues is the lack of control over the polymerization process, particularly when using perchloric acid as an oxidizing agent. The highly reactive nature of perchloric acid often leads to uncontrolled chain growth and branching, resulting in polymers with inconsistent properties and reduced conductivity.

Another major challenge is the limited solubility and processability of conductive polymers. Many of these materials are insoluble in common solvents, making it difficult to process them into thin films or other desired forms. This limitation severely restricts their potential applications in flexible electronics and other emerging fields. The use of perchloric acid in the synthesis process can exacerbate this issue by creating highly crosslinked structures that further reduce solubility.

The stability of conductive polymers in ambient conditions remains a significant concern. Exposure to oxygen and moisture can lead to degradation of the polymer backbone, resulting in a loss of conductivity over time. This is particularly problematic when perchloric acid is used in the synthesis, as it can leave residual acid within the polymer matrix, accelerating the degradation process.

Achieving high and consistent conductivity across different batches of synthesized polymers is another persistent challenge. The conductivity of these materials is highly dependent on the degree of doping, which can be difficult to control precisely. The use of perchloric acid as a dopant can lead to overoxidation of the polymer chains, potentially reducing overall conductivity.

The environmental and safety concerns associated with the use of perchloric acid in conductive polymer synthesis cannot be overlooked. Its strong oxidizing properties make it hazardous to handle, and strict safety protocols are required. This not only increases the complexity of the synthesis process but also raises concerns about the scalability of production methods using this acid.

Furthermore, the long-term stability of doping achieved through perchloric acid remains questionable. Over time, the dopant molecules may leach out of the polymer matrix, leading to a gradual decrease in conductivity. This poses significant challenges for the development of reliable and long-lasting conductive polymer-based devices.

Lastly, the cost-effectiveness of using perchloric acid in large-scale production of conductive polymers is a major hurdle. The acid's high reactivity necessitates specialized equipment and handling procedures, driving up production costs. This economic factor, combined with the aforementioned technical challenges, presents a significant barrier to the widespread adoption of conductive polymers in commercial applications.

Another major challenge is the limited solubility and processability of conductive polymers. Many of these materials are insoluble in common solvents, making it difficult to process them into thin films or other desired forms. This limitation severely restricts their potential applications in flexible electronics and other emerging fields. The use of perchloric acid in the synthesis process can exacerbate this issue by creating highly crosslinked structures that further reduce solubility.

The stability of conductive polymers in ambient conditions remains a significant concern. Exposure to oxygen and moisture can lead to degradation of the polymer backbone, resulting in a loss of conductivity over time. This is particularly problematic when perchloric acid is used in the synthesis, as it can leave residual acid within the polymer matrix, accelerating the degradation process.

Achieving high and consistent conductivity across different batches of synthesized polymers is another persistent challenge. The conductivity of these materials is highly dependent on the degree of doping, which can be difficult to control precisely. The use of perchloric acid as a dopant can lead to overoxidation of the polymer chains, potentially reducing overall conductivity.

The environmental and safety concerns associated with the use of perchloric acid in conductive polymer synthesis cannot be overlooked. Its strong oxidizing properties make it hazardous to handle, and strict safety protocols are required. This not only increases the complexity of the synthesis process but also raises concerns about the scalability of production methods using this acid.

Furthermore, the long-term stability of doping achieved through perchloric acid remains questionable. Over time, the dopant molecules may leach out of the polymer matrix, leading to a gradual decrease in conductivity. This poses significant challenges for the development of reliable and long-lasting conductive polymer-based devices.

Lastly, the cost-effectiveness of using perchloric acid in large-scale production of conductive polymers is a major hurdle. The acid's high reactivity necessitates specialized equipment and handling procedures, driving up production costs. This economic factor, combined with the aforementioned technical challenges, presents a significant barrier to the widespread adoption of conductive polymers in commercial applications.

Existing Methodologies Using Perchloric Acid

01 Measurement of perchloric acid conductivity

Various methods and devices are used to measure the conductivity of perchloric acid solutions. These may include specialized electrodes, conductivity meters, or other analytical instruments designed to accurately determine the electrical conductivity of perchloric acid under different conditions.- Measurement of perchloric acid conductivity: Various methods and devices are used to measure the conductivity of perchloric acid solutions. These may include specialized electrodes, conductivity meters, or other analytical instruments designed to accurately determine the electrical conductivity of perchloric acid under different conditions.

- Applications of perchloric acid conductivity: The conductivity of perchloric acid is utilized in various applications, including electrochemistry, battery technology, and analytical chemistry. Its high conductivity makes it useful as an electrolyte in certain electrochemical processes and as a component in some types of batteries or fuel cells.

- Factors affecting perchloric acid conductivity: Several factors can influence the conductivity of perchloric acid, including concentration, temperature, and the presence of impurities. Understanding these factors is crucial for optimizing the use of perchloric acid in various applications and ensuring accurate conductivity measurements.

- Safety considerations in handling perchloric acid: Due to its strong oxidizing properties and potential reactivity, special safety measures are required when handling perchloric acid, especially in conductivity-related applications. This includes the use of appropriate personal protective equipment, specialized storage containers, and proper disposal methods.

- Comparison of perchloric acid conductivity with other acids: Studies have been conducted to compare the conductivity of perchloric acid with other strong acids, such as sulfuric or hydrochloric acid. These comparisons help in understanding the unique properties of perchloric acid and its suitability for specific applications where high conductivity is required.

02 Applications of perchloric acid conductivity

The conductivity of perchloric acid is utilized in various applications, including electrochemistry, battery technology, and analytical chemistry. Its high conductivity makes it useful as an electrolyte in certain electrochemical processes and as a component in some types of batteries or fuel cells.Expand Specific Solutions03 Factors affecting perchloric acid conductivity

Several factors can influence the conductivity of perchloric acid, including concentration, temperature, and the presence of impurities. Understanding these factors is crucial for accurately measuring and utilizing perchloric acid's conductive properties in various applications.Expand Specific Solutions04 Safety considerations in handling perchloric acid

Due to its strong oxidizing properties and potential reactivity, special safety measures are required when handling perchloric acid, especially in conductivity measurements. This includes using appropriate personal protective equipment, specialized laboratory equipment, and following strict safety protocols.Expand Specific Solutions05 Comparison with other acids' conductivity

The conductivity of perchloric acid is often compared to that of other strong acids to understand its unique properties and potential applications. This comparison helps in selecting the most suitable acid for specific conductivity-related applications in various fields of chemistry and engineering.Expand Specific Solutions

Key Players in Conductive Polymer Industry

The development of conductive polymers using perchloric acid is in a growth phase, with increasing market size and technological advancements. The global conductive polymers market is expanding rapidly, driven by applications in electronics, energy storage, and smart materials. While the technology is maturing, there's still room for innovation and improvement in performance and manufacturing processes. Key players like Resonac Holdings Corp., Murata Manufacturing Co. Ltd., and TDK Corp. are investing in research and development to enhance the properties and applications of conductive polymers. Emerging companies such as Eamex Corp. and Shenzhen Capchem Technology Co., Ltd. are also contributing to the field with specialized products and novel approaches. Academic institutions like Tokyo Institute of Technology and the University of Kansas are collaborating with industry partners to push the boundaries of conductive polymer technology.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has developed a novel approach to synthesizing conductive polymers using perchloric acid as a key component. Their method involves the electrochemical polymerization of monomers in the presence of perchloric acid, which acts as both an electrolyte and a dopant[1]. This process results in the formation of highly conductive polymer films with enhanced stability and conductivity. The CNRS team has optimized the concentration of perchloric acid and polymerization conditions to achieve a balance between conductivity and mechanical properties[3]. They have also explored the use of perchloric acid in combination with other dopants to create hybrid conductive polymers with tailored properties for specific applications[5].

Strengths: High conductivity, improved stability, and versatility in polymer synthesis. Weaknesses: Potential safety concerns due to the use of perchloric acid, which requires careful handling and specialized equipment.

University of Akron

Technical Solution: The University of Akron has made significant advancements in the use of perchloric acid for conductive polymer synthesis. Their research focuses on the development of nanostructured conductive polymers using a perchloric acid-based template approach[2]. This method involves the creation of nanoporous templates using perchloric acid as an etching agent, followed by the in-situ polymerization of conductive monomers within these templates[4]. The resulting nanostructured polymers exhibit enhanced surface area and improved charge transport properties. Additionally, the University of Akron team has investigated the role of perchloric acid in controlling the morphology and crystallinity of conductive polymers, leading to materials with superior electrical and mechanical characteristics[6].

Strengths: Precise control over polymer nanostructure, enhanced surface area, and improved charge transport. Weaknesses: Complex synthesis process and potential scalability issues for large-scale production.

Innovative Approaches in Perchloric Acid Utilization

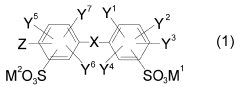

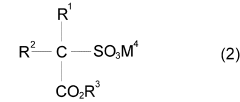

Conductive polymers formed from conjugated backbone polymers doped with non-oxidizing protonic acids

PatentInactiveUS5185100A

Innovation

- Doping conjugated backbone polymers with non-oxidizing protonic acids, such as organic sulfonic acids, which have a pKa less than 4, to achieve conductivities greater than 10^-3 ohm^-1 cm^-1 and improve thermal and environmental stability, allowing for the formation of conductive films and fibers in various solvents.

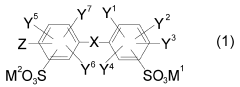

Conductive polymer composition, and conductor

PatentInactiveJP2013185137A

Innovation

- A conductive polymer composition is developed by blending PEDOT/PSS dispersion with an anionic surfactant having a specific structure in a specific ratio, which unfolds the spherical structure of PEDOT molecules, facilitating easier charge transfer through intermolecular hopping.

Safety Considerations in Perchloric Acid Handling

Perchloric acid plays a crucial role in the formation of conductive polymers, but its handling requires utmost caution due to its highly reactive and potentially explosive nature. Proper safety measures are essential to mitigate risks associated with its use in research and industrial settings.

Personal protective equipment (PPE) is paramount when working with perchloric acid. This includes chemical-resistant gloves, goggles, face shields, and lab coats. Specialized respirators may be necessary when handling large quantities or in poorly ventilated areas. All PPE must be regularly inspected and replaced as needed to ensure optimal protection.

Storage of perchloric acid demands specific considerations. It should be kept in a cool, dry place, away from direct sunlight and heat sources. Glass or PTFE containers are preferred, as perchloric acid can react with many metals. Secondary containment is crucial to prevent spills from spreading. Inventory management is vital to minimize the quantity stored on-site and ensure proper rotation of stock.

Dedicated fume hoods equipped with wash-down systems are essential for handling perchloric acid. These specialized hoods prevent the accumulation of explosive perchlorates in the ventilation system. Regular cleaning and maintenance of these hoods are critical to prevent the buildup of potentially hazardous residues.

Proper waste disposal is another critical aspect of perchloric acid safety. Neutralization and dilution procedures must be followed strictly before disposal. Mixing perchloric acid waste with organic solvents or other incompatible materials must be avoided at all costs, as this can lead to violent reactions or explosions.

Training and education of personnel working with perchloric acid are fundamental to maintaining a safe working environment. This includes understanding the chemical properties, potential hazards, proper handling techniques, and emergency response procedures. Regular refresher courses and safety drills should be conducted to ensure all staff members are up-to-date with the latest safety protocols.

Emergency response planning is crucial when working with perchloric acid. This includes having readily available spill kits, eyewash stations, and safety showers. Clear evacuation procedures and communication protocols must be established and regularly practiced. Additionally, local emergency services should be informed about the presence and quantities of perchloric acid on-site.

Implementing a robust safety culture is essential for organizations working with perchloric acid. This involves fostering an environment where safety is prioritized, near-misses are reported and analyzed, and continuous improvement in safety practices is encouraged. Regular safety audits and risk assessments should be conducted to identify and address potential hazards proactively.

Personal protective equipment (PPE) is paramount when working with perchloric acid. This includes chemical-resistant gloves, goggles, face shields, and lab coats. Specialized respirators may be necessary when handling large quantities or in poorly ventilated areas. All PPE must be regularly inspected and replaced as needed to ensure optimal protection.

Storage of perchloric acid demands specific considerations. It should be kept in a cool, dry place, away from direct sunlight and heat sources. Glass or PTFE containers are preferred, as perchloric acid can react with many metals. Secondary containment is crucial to prevent spills from spreading. Inventory management is vital to minimize the quantity stored on-site and ensure proper rotation of stock.

Dedicated fume hoods equipped with wash-down systems are essential for handling perchloric acid. These specialized hoods prevent the accumulation of explosive perchlorates in the ventilation system. Regular cleaning and maintenance of these hoods are critical to prevent the buildup of potentially hazardous residues.

Proper waste disposal is another critical aspect of perchloric acid safety. Neutralization and dilution procedures must be followed strictly before disposal. Mixing perchloric acid waste with organic solvents or other incompatible materials must be avoided at all costs, as this can lead to violent reactions or explosions.

Training and education of personnel working with perchloric acid are fundamental to maintaining a safe working environment. This includes understanding the chemical properties, potential hazards, proper handling techniques, and emergency response procedures. Regular refresher courses and safety drills should be conducted to ensure all staff members are up-to-date with the latest safety protocols.

Emergency response planning is crucial when working with perchloric acid. This includes having readily available spill kits, eyewash stations, and safety showers. Clear evacuation procedures and communication protocols must be established and regularly practiced. Additionally, local emergency services should be informed about the presence and quantities of perchloric acid on-site.

Implementing a robust safety culture is essential for organizations working with perchloric acid. This involves fostering an environment where safety is prioritized, near-misses are reported and analyzed, and continuous improvement in safety practices is encouraged. Regular safety audits and risk assessments should be conducted to identify and address potential hazards proactively.

Environmental Impact of Perchloric Acid Use

The use of perchloric acid in the formation of conductive polymers raises significant environmental concerns that warrant careful consideration. Perchloric acid is a strong oxidizing agent and highly corrosive substance, which can pose serious risks to ecosystems and human health if not properly managed. When used in polymer synthesis processes, there is potential for perchlorate contamination of water sources and soil.

Perchlorate ions are highly soluble and mobile in aqueous environments, making them difficult to contain and remove once released. They can persist in groundwater for extended periods, potentially affecting drinking water supplies. Studies have shown that perchlorate exposure can interfere with iodide uptake in the thyroid gland, potentially disrupting hormone production and metabolism in humans and wildlife.

The manufacturing processes involving perchloric acid may also generate hazardous waste streams containing perchlorate salts and other byproducts. Improper disposal of these wastes can lead to environmental contamination and long-term ecological impacts. Additionally, accidental spills or releases during transportation and handling of perchloric acid pose risks to soil and water quality in affected areas.

To mitigate these environmental risks, stringent safety protocols and waste management practices must be implemented in facilities using perchloric acid for conductive polymer synthesis. This includes proper containment systems, specialized handling procedures, and advanced treatment technologies for perchlorate-containing wastewater. Closed-loop recycling systems and alternative synthesis methods that reduce or eliminate perchloric acid use should be explored to minimize environmental footprint.

Regulatory agencies have established guidelines for perchlorate levels in drinking water and environmental media. Compliance with these standards requires ongoing monitoring and remediation efforts in areas where perchloric acid is used extensively. The development of more sensitive analytical techniques has improved the detection and quantification of trace perchlorate contamination, enabling better environmental assessment and management.

Research into green chemistry alternatives for conductive polymer synthesis is crucial for reducing reliance on perchloric acid and other environmentally hazardous reagents. Sustainable approaches, such as electrochemical polymerization methods or the use of less toxic oxidizing agents, are being investigated to achieve comparable polymer properties with reduced environmental impact. These efforts align with broader industry trends towards more environmentally friendly manufacturing processes and materials.

Perchlorate ions are highly soluble and mobile in aqueous environments, making them difficult to contain and remove once released. They can persist in groundwater for extended periods, potentially affecting drinking water supplies. Studies have shown that perchlorate exposure can interfere with iodide uptake in the thyroid gland, potentially disrupting hormone production and metabolism in humans and wildlife.

The manufacturing processes involving perchloric acid may also generate hazardous waste streams containing perchlorate salts and other byproducts. Improper disposal of these wastes can lead to environmental contamination and long-term ecological impacts. Additionally, accidental spills or releases during transportation and handling of perchloric acid pose risks to soil and water quality in affected areas.

To mitigate these environmental risks, stringent safety protocols and waste management practices must be implemented in facilities using perchloric acid for conductive polymer synthesis. This includes proper containment systems, specialized handling procedures, and advanced treatment technologies for perchlorate-containing wastewater. Closed-loop recycling systems and alternative synthesis methods that reduce or eliminate perchloric acid use should be explored to minimize environmental footprint.

Regulatory agencies have established guidelines for perchlorate levels in drinking water and environmental media. Compliance with these standards requires ongoing monitoring and remediation efforts in areas where perchloric acid is used extensively. The development of more sensitive analytical techniques has improved the detection and quantification of trace perchlorate contamination, enabling better environmental assessment and management.

Research into green chemistry alternatives for conductive polymer synthesis is crucial for reducing reliance on perchloric acid and other environmentally hazardous reagents. Sustainable approaches, such as electrochemical polymerization methods or the use of less toxic oxidizing agents, are being investigated to achieve comparable polymer properties with reduced environmental impact. These efforts align with broader industry trends towards more environmentally friendly manufacturing processes and materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!