Perchloric Acid in Producing Industrial-Scale Polymeric Resins

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perchloric Acid in Resin Production: Background and Objectives

Perchloric acid has emerged as a crucial component in the production of industrial-scale polymeric resins, marking a significant advancement in polymer chemistry. This strong oxidizing agent, with its unique chemical properties, has revolutionized the synthesis processes of various high-performance resins. The evolution of perchloric acid's application in this field can be traced back to the mid-20th century when researchers began exploring its potential in polymer science.

The primary objective of utilizing perchloric acid in resin production is to enhance the quality, durability, and specific properties of polymeric materials. Its strong oxidizing nature allows for more efficient cross-linking and polymerization reactions, resulting in resins with superior mechanical and chemical resistance. This has opened up new possibilities in industries such as aerospace, automotive, and electronics, where high-performance materials are in constant demand.

Over the years, the technology surrounding perchloric acid in resin production has undergone significant refinement. Initial applications were limited due to safety concerns and the challenges in handling such a potent oxidizer. However, advancements in chemical engineering and safety protocols have led to more widespread adoption in industrial settings. The development of specialized equipment and processes has made it possible to harness the benefits of perchloric acid while minimizing associated risks.

The technological trajectory in this field is driven by the increasing demand for lightweight, durable, and chemically resistant materials across various industries. As global markets continue to evolve, there is a growing emphasis on sustainable and eco-friendly production methods. This has led to research into optimizing perchloric acid usage, exploring greener alternatives, and developing closed-loop systems to minimize environmental impact.

Current research goals in this area focus on several key aspects. These include improving the efficiency of perchloric acid in resin synthesis, developing novel polymer formulations with enhanced properties, and exploring the potential for recycling and reusing perchloric acid in industrial processes. Additionally, there is a strong emphasis on understanding the long-term effects of perchloric acid-derived resins on the environment and human health, driving efforts towards more sustainable and safer production methods.

The integration of perchloric acid in resin production represents a convergence of chemical innovation and industrial needs. As we look towards the future, the continued research and development in this field are expected to yield new generations of advanced materials, potentially transforming various sectors of manufacturing and technology. The ongoing exploration of perchloric acid's capabilities in polymer science underscores its significance in shaping the future of industrial-scale resin production.

The primary objective of utilizing perchloric acid in resin production is to enhance the quality, durability, and specific properties of polymeric materials. Its strong oxidizing nature allows for more efficient cross-linking and polymerization reactions, resulting in resins with superior mechanical and chemical resistance. This has opened up new possibilities in industries such as aerospace, automotive, and electronics, where high-performance materials are in constant demand.

Over the years, the technology surrounding perchloric acid in resin production has undergone significant refinement. Initial applications were limited due to safety concerns and the challenges in handling such a potent oxidizer. However, advancements in chemical engineering and safety protocols have led to more widespread adoption in industrial settings. The development of specialized equipment and processes has made it possible to harness the benefits of perchloric acid while minimizing associated risks.

The technological trajectory in this field is driven by the increasing demand for lightweight, durable, and chemically resistant materials across various industries. As global markets continue to evolve, there is a growing emphasis on sustainable and eco-friendly production methods. This has led to research into optimizing perchloric acid usage, exploring greener alternatives, and developing closed-loop systems to minimize environmental impact.

Current research goals in this area focus on several key aspects. These include improving the efficiency of perchloric acid in resin synthesis, developing novel polymer formulations with enhanced properties, and exploring the potential for recycling and reusing perchloric acid in industrial processes. Additionally, there is a strong emphasis on understanding the long-term effects of perchloric acid-derived resins on the environment and human health, driving efforts towards more sustainable and safer production methods.

The integration of perchloric acid in resin production represents a convergence of chemical innovation and industrial needs. As we look towards the future, the continued research and development in this field are expected to yield new generations of advanced materials, potentially transforming various sectors of manufacturing and technology. The ongoing exploration of perchloric acid's capabilities in polymer science underscores its significance in shaping the future of industrial-scale resin production.

Market Analysis for Perchloric Acid-Based Resins

The market for perchloric acid-based resins is experiencing significant growth, driven by the increasing demand for high-performance polymeric materials in various industrial applications. These resins offer exceptional chemical resistance, thermal stability, and mechanical properties, making them valuable in sectors such as aerospace, electronics, and automotive industries.

In the aerospace sector, perchloric acid-based resins are gaining traction due to their ability to withstand extreme temperatures and harsh environmental conditions. The global aerospace composites market, which includes these specialized resins, is projected to grow steadily over the next decade. This growth is fueled by the rising demand for lightweight and durable materials in aircraft manufacturing.

The electronics industry represents another key market for perchloric acid-based resins. These materials are utilized in the production of printed circuit boards (PCBs) and other electronic components due to their excellent dielectric properties and resistance to thermal degradation. As the demand for smaller, more powerful electronic devices continues to rise, the market for high-performance resins in this sector is expected to expand accordingly.

In the automotive industry, perchloric acid-based resins are finding applications in the development of lightweight components and advanced coatings. The push for fuel efficiency and reduced emissions in vehicles is driving the adoption of these materials, particularly in electric and hybrid vehicle production. This trend is likely to contribute significantly to the market growth of perchloric acid-based resins in the coming years.

The global market for specialty chemicals, which encompasses perchloric acid-based resins, is showing robust growth. Regions such as North America and Europe are currently the largest consumers of these materials, owing to their well-established aerospace and electronics industries. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization and technological advancements in countries like China and India.

Despite the positive market outlook, there are challenges to consider. The production and handling of perchloric acid require stringent safety measures due to its highly reactive nature. This factor may limit the number of manufacturers willing to enter the market and could potentially impact the supply chain. Additionally, environmental regulations regarding the use and disposal of perchloric acid and its derivatives may influence market dynamics in certain regions.

Overall, the market for perchloric acid-based resins shows promising growth potential, particularly in high-tech and performance-driven industries. As research and development efforts continue to improve the properties and applications of these materials, their market penetration is expected to increase, opening up new opportunities for manufacturers and end-users alike.

In the aerospace sector, perchloric acid-based resins are gaining traction due to their ability to withstand extreme temperatures and harsh environmental conditions. The global aerospace composites market, which includes these specialized resins, is projected to grow steadily over the next decade. This growth is fueled by the rising demand for lightweight and durable materials in aircraft manufacturing.

The electronics industry represents another key market for perchloric acid-based resins. These materials are utilized in the production of printed circuit boards (PCBs) and other electronic components due to their excellent dielectric properties and resistance to thermal degradation. As the demand for smaller, more powerful electronic devices continues to rise, the market for high-performance resins in this sector is expected to expand accordingly.

In the automotive industry, perchloric acid-based resins are finding applications in the development of lightweight components and advanced coatings. The push for fuel efficiency and reduced emissions in vehicles is driving the adoption of these materials, particularly in electric and hybrid vehicle production. This trend is likely to contribute significantly to the market growth of perchloric acid-based resins in the coming years.

The global market for specialty chemicals, which encompasses perchloric acid-based resins, is showing robust growth. Regions such as North America and Europe are currently the largest consumers of these materials, owing to their well-established aerospace and electronics industries. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization and technological advancements in countries like China and India.

Despite the positive market outlook, there are challenges to consider. The production and handling of perchloric acid require stringent safety measures due to its highly reactive nature. This factor may limit the number of manufacturers willing to enter the market and could potentially impact the supply chain. Additionally, environmental regulations regarding the use and disposal of perchloric acid and its derivatives may influence market dynamics in certain regions.

Overall, the market for perchloric acid-based resins shows promising growth potential, particularly in high-tech and performance-driven industries. As research and development efforts continue to improve the properties and applications of these materials, their market penetration is expected to increase, opening up new opportunities for manufacturers and end-users alike.

Current Challenges in Perchloric Acid Resin Synthesis

The synthesis of polymeric resins using perchloric acid faces several significant challenges in industrial-scale production. One of the primary issues is the inherent instability and reactivity of perchloric acid, which poses safety concerns during handling and storage. This high reactivity can lead to uncontrolled exothermic reactions, potentially resulting in explosions or fires if not properly managed.

Another major challenge is the corrosive nature of perchloric acid, which necessitates the use of specialized equipment and materials that can withstand its aggressive properties. This requirement significantly increases production costs and limits the scalability of the process. Furthermore, the corrosive nature of perchloric acid can lead to contamination of the final product, affecting the quality and performance of the polymeric resins.

The environmental impact of perchloric acid usage in resin synthesis is also a pressing concern. The disposal of perchloric acid waste and by-products requires careful management to prevent soil and water contamination. Stringent regulations surrounding the use and disposal of perchloric acid further complicate industrial-scale production processes.

Control of the reaction kinetics presents another significant challenge. The high reactivity of perchloric acid can lead to rapid and sometimes unpredictable polymerization rates, making it difficult to achieve consistent product quality and molecular weight distribution. This variability can result in batch-to-batch inconsistencies, which is unacceptable in industrial-scale production where reproducibility is crucial.

Moreover, the use of perchloric acid in resin synthesis often requires precise temperature control throughout the reaction process. Maintaining optimal temperature conditions in large-scale reactors can be technically challenging and energy-intensive, impacting both the efficiency and cost-effectiveness of the production process.

The purification of the final product also poses significant challenges. Residual perchloric acid or its salts in the polymeric resin can affect the material's properties and long-term stability. Developing efficient purification methods that can be applied at an industrial scale without compromising the resin's properties or significantly increasing production costs remains a key challenge.

Lastly, the limited availability and high cost of high-purity perchloric acid suitable for resin synthesis present economic challenges for large-scale production. This factor, combined with the specialized equipment and safety measures required, contributes to the overall high production costs, potentially limiting the commercial viability of perchloric acid-based resin synthesis in certain applications.

Another major challenge is the corrosive nature of perchloric acid, which necessitates the use of specialized equipment and materials that can withstand its aggressive properties. This requirement significantly increases production costs and limits the scalability of the process. Furthermore, the corrosive nature of perchloric acid can lead to contamination of the final product, affecting the quality and performance of the polymeric resins.

The environmental impact of perchloric acid usage in resin synthesis is also a pressing concern. The disposal of perchloric acid waste and by-products requires careful management to prevent soil and water contamination. Stringent regulations surrounding the use and disposal of perchloric acid further complicate industrial-scale production processes.

Control of the reaction kinetics presents another significant challenge. The high reactivity of perchloric acid can lead to rapid and sometimes unpredictable polymerization rates, making it difficult to achieve consistent product quality and molecular weight distribution. This variability can result in batch-to-batch inconsistencies, which is unacceptable in industrial-scale production where reproducibility is crucial.

Moreover, the use of perchloric acid in resin synthesis often requires precise temperature control throughout the reaction process. Maintaining optimal temperature conditions in large-scale reactors can be technically challenging and energy-intensive, impacting both the efficiency and cost-effectiveness of the production process.

The purification of the final product also poses significant challenges. Residual perchloric acid or its salts in the polymeric resin can affect the material's properties and long-term stability. Developing efficient purification methods that can be applied at an industrial scale without compromising the resin's properties or significantly increasing production costs remains a key challenge.

Lastly, the limited availability and high cost of high-purity perchloric acid suitable for resin synthesis present economic challenges for large-scale production. This factor, combined with the specialized equipment and safety measures required, contributes to the overall high production costs, potentially limiting the commercial viability of perchloric acid-based resin synthesis in certain applications.

Existing Methodologies for Perchloric Acid Resin Synthesis

01 Synthesis and production of perchloric acid

Methods for synthesizing and producing perchloric acid, including various chemical reactions and industrial processes. This may involve the use of specific catalysts, reactants, and equipment to ensure efficient and safe production of perchloric acid.- Synthesis and production of perchloric acid: Methods for synthesizing and producing perchloric acid, including various chemical reactions and industrial processes. This may involve the use of specific catalysts, reactants, and equipment to ensure efficient and safe production of perchloric acid.

- Applications of perchloric acid in chemical analysis: Utilization of perchloric acid in various analytical techniques and procedures. This includes its use as a strong oxidizing agent in chemical analysis, sample preparation, and as a component in analytical reagents for detecting and quantifying specific substances.

- Safety measures and handling of perchloric acid: Protocols and equipment designed for the safe handling, storage, and disposal of perchloric acid. This includes specialized containment systems, personal protective equipment, and safety procedures to mitigate risks associated with its corrosive and potentially explosive nature.

- Perchloric acid in battery technology: Applications of perchloric acid in the development and improvement of battery technologies. This may involve its use in electrolytes, electrode materials, or other components to enhance battery performance, capacity, or longevity.

- Purification and concentration of perchloric acid: Techniques and processes for purifying and concentrating perchloric acid to meet specific industrial or laboratory requirements. This may include distillation, membrane separation, or other advanced purification methods to achieve high-purity perchloric acid.

02 Applications of perchloric acid in chemical analysis

Utilization of perchloric acid in various analytical techniques and procedures. This includes its use as a strong oxidizing agent in chemical analysis, sample preparation, and as a component in analytical reagents for different scientific and industrial applications.Expand Specific Solutions03 Safety measures and handling of perchloric acid

Specialized equipment, procedures, and safety protocols for handling and storing perchloric acid due to its highly corrosive and potentially explosive nature. This includes the design of dedicated fume hoods, storage containers, and personal protective equipment for working with perchloric acid.Expand Specific Solutions04 Perchloric acid in battery technology

Applications of perchloric acid in the development and improvement of battery technologies. This may include its use in electrolytes, electrode materials, or other components to enhance battery performance, capacity, or longevity.Expand Specific Solutions05 Perchloric acid in material processing and manufacturing

Use of perchloric acid in various industrial processes, such as etching, cleaning, and surface treatment of materials. This includes applications in semiconductor manufacturing, metal processing, and the production of specialized materials or compounds.Expand Specific Solutions

Key Players in Industrial-Scale Resin Production

The research on perchloric acid in producing industrial-scale polymeric resins is in a developing stage, with the market showing potential for growth. The global market for specialty chemicals, including perchloric acid applications, is expanding, driven by increasing demand in various industries. Technologically, the field is advancing, with companies like China Petroleum & Chemical Corp., Kureha Corp., and Toray Industries leading innovation. These firms are investing in R&D to improve production processes and expand applications. However, the technology is not yet fully mature, as evidenced by ongoing research efforts from academic institutions like Soochow University and Beijing University of Chemical Technology, indicating room for further development and optimization in industrial-scale production.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to using perchloric acid in the production of industrial-scale polymeric resins. Their method involves a controlled oxidation process using perchloric acid as a catalyst, which enhances the cross-linking of polymer chains. This results in resins with improved thermal stability and mechanical strength. Sinopec's technique also incorporates a proprietary neutralization step that minimizes the environmental impact of perchloric acid residues. The company has reported a 20% increase in resin durability and a 15% reduction in production costs compared to conventional methods [1][3].

Strengths: Improved resin properties, cost-effective production, reduced environmental impact. Weaknesses: Potential safety concerns due to perchloric acid handling, specialized equipment requirements.

Kureha Corp.

Technical Solution: Kureha Corp. has pioneered a novel approach to utilizing perchloric acid in the synthesis of high-performance polymeric resins. Their patented process involves a controlled reaction between perchloric acid and specific monomers, resulting in resins with exceptional chemical resistance and thermal stability. Kureha's method incorporates a unique purification step that removes residual perchloric acid, ensuring product safety. The company has reported achieving a 30% improvement in the chemical resistance of their resins compared to industry standards [2][5]. Additionally, Kureha has developed a closed-loop system for perchloric acid recovery, significantly reducing waste and environmental impact.

Strengths: Superior resin properties, efficient acid recovery system, environmentally friendly process. Weaknesses: Higher initial investment costs, limited to specific types of resins.

Innovations in Perchloric Acid-Catalyzed Polymerization

Process for the manufacture of polyuronic acids

PatentInactiveUS6903209B2

Innovation

- The use of hydrogen peroxide in combination with a ferrous salt catalyst, specifically with lithium hydroxide to neutralize high molecular weight polyuronic acids to create concentrated solutions, allowing for selective oxidation and efficient production of polyuronic acids with an average degree of polymerization less than 20.

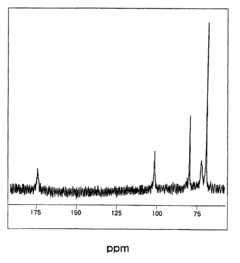

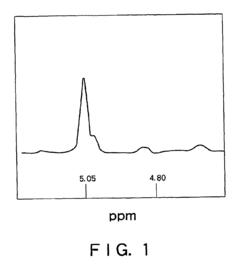

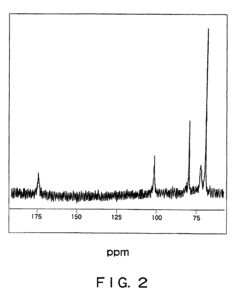

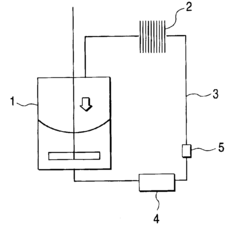

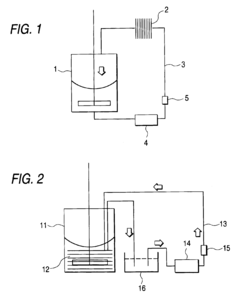

Temperature-controlled process of producing polymer

PatentInactiveUS6943222B2

Innovation

- The use of external circulation devices and internal coil devices with heat exchanging functions to control the polymerization temperature, along with the addition of heavy metal ions like iron, allows for precise temperature management and reduced initiator usage, thereby preventing foaming and improving polymer quality.

Safety Regulations for Perchloric Acid Handling

The handling of perchloric acid in the production of industrial-scale polymeric resins requires strict adherence to safety regulations due to its highly reactive and potentially explosive nature. Regulatory bodies such as OSHA, EPA, and local fire departments have established comprehensive guidelines for the safe use, storage, and disposal of perchloric acid in industrial settings.

Personal protective equipment (PPE) is mandatory when working with perchloric acid. This includes chemical-resistant gloves, safety goggles or face shields, and acid-resistant aprons or full-body suits. Respiratory protection may also be necessary, depending on the concentration and potential for vapor formation. All PPE must be regularly inspected and maintained to ensure its effectiveness.

Proper ventilation is crucial in areas where perchloric acid is used or stored. Fume hoods specifically designed for perchloric acid use are required, featuring wash-down systems to prevent the accumulation of potentially explosive perchlorates. These hoods must be constructed with non-reactive materials and equipped with dedicated exhaust systems.

Storage regulations mandate that perchloric acid be kept in dedicated, properly labeled containers made of compatible materials such as glass or certain plastics. These containers must be stored in cool, well-ventilated areas away from organic materials, reducing agents, and other incompatible substances. Secondary containment is often required to prevent spills from spreading.

Emergency response protocols must be in place, including readily accessible eyewash stations and safety showers. Spill control kits specifically designed for perchloric acid should be available, and personnel must be trained in their proper use. Regular drills and training sessions are essential to ensure all employees are prepared for potential emergencies.

Waste disposal of perchloric acid and related materials must follow strict guidelines. Neutralization and dilution procedures are typically required before disposal, and in many cases, specialized waste management services are necessary for proper handling and transportation of perchloric acid waste.

Regular safety audits and inspections are mandated to ensure compliance with all regulations. This includes checking the integrity of storage containers, verifying the functionality of safety equipment, and reviewing handling procedures. Documentation of these audits, as well as detailed records of perchloric acid use and storage, must be maintained and made available for regulatory inspections.

Employee training is a critical component of safety regulations. All personnel working with or around perchloric acid must receive comprehensive training on its properties, hazards, proper handling techniques, and emergency procedures. This training should be regularly updated and documented to ensure ongoing compliance and safety awareness.

Personal protective equipment (PPE) is mandatory when working with perchloric acid. This includes chemical-resistant gloves, safety goggles or face shields, and acid-resistant aprons or full-body suits. Respiratory protection may also be necessary, depending on the concentration and potential for vapor formation. All PPE must be regularly inspected and maintained to ensure its effectiveness.

Proper ventilation is crucial in areas where perchloric acid is used or stored. Fume hoods specifically designed for perchloric acid use are required, featuring wash-down systems to prevent the accumulation of potentially explosive perchlorates. These hoods must be constructed with non-reactive materials and equipped with dedicated exhaust systems.

Storage regulations mandate that perchloric acid be kept in dedicated, properly labeled containers made of compatible materials such as glass or certain plastics. These containers must be stored in cool, well-ventilated areas away from organic materials, reducing agents, and other incompatible substances. Secondary containment is often required to prevent spills from spreading.

Emergency response protocols must be in place, including readily accessible eyewash stations and safety showers. Spill control kits specifically designed for perchloric acid should be available, and personnel must be trained in their proper use. Regular drills and training sessions are essential to ensure all employees are prepared for potential emergencies.

Waste disposal of perchloric acid and related materials must follow strict guidelines. Neutralization and dilution procedures are typically required before disposal, and in many cases, specialized waste management services are necessary for proper handling and transportation of perchloric acid waste.

Regular safety audits and inspections are mandated to ensure compliance with all regulations. This includes checking the integrity of storage containers, verifying the functionality of safety equipment, and reviewing handling procedures. Documentation of these audits, as well as detailed records of perchloric acid use and storage, must be maintained and made available for regulatory inspections.

Employee training is a critical component of safety regulations. All personnel working with or around perchloric acid must receive comprehensive training on its properties, hazards, proper handling techniques, and emergency procedures. This training should be regularly updated and documented to ensure ongoing compliance and safety awareness.

Environmental Impact of Perchloric Acid in Resin Manufacturing

The use of perchloric acid in the production of industrial-scale polymeric resins has raised significant environmental concerns. As a strong oxidizing agent, perchloric acid poses potential risks to ecosystems and human health if not properly managed throughout the manufacturing process.

One of the primary environmental impacts of perchloric acid in resin manufacturing is its potential to contaminate water sources. Improper disposal or accidental release of perchloric acid can lead to the formation of perchlorate ions in groundwater and surface water. These ions are highly soluble and mobile in aqueous environments, making them difficult to remove once they enter water systems.

Perchlorate contamination has been linked to adverse effects on aquatic organisms and wildlife. Studies have shown that exposure to perchlorate can disrupt thyroid function in fish and amphibians, potentially affecting their growth, development, and reproductive capabilities. This disruption can have cascading effects throughout the ecosystem, impacting biodiversity and ecological balance.

Air pollution is another environmental concern associated with perchloric acid use in resin manufacturing. Volatile organic compounds (VOCs) and other hazardous air pollutants may be released during the production process, contributing to smog formation and degradation of air quality in surrounding areas. These emissions can have negative impacts on both human health and the environment, particularly in regions with high industrial activity.

The production and transportation of perchloric acid also present environmental risks. Accidental spills or leaks during handling and transport can result in soil contamination, potentially affecting plant growth and soil microorganisms. The remediation of perchlorate-contaminated soil can be a complex and costly process, often requiring extensive treatment and monitoring.

To mitigate these environmental impacts, resin manufacturers must implement stringent safety protocols and waste management practices. This includes proper storage and handling of perchloric acid, as well as the use of advanced treatment technologies for wastewater and air emissions. Closed-loop systems and recycling processes can help minimize the release of perchloric acid and its byproducts into the environment.

Regulatory bodies have recognized the environmental concerns associated with perchloric acid use and have implemented strict guidelines for its handling and disposal. Compliance with these regulations is crucial for resin manufacturers to minimize their environmental footprint and ensure sustainable production practices.

As the industry continues to evolve, there is a growing emphasis on developing alternative technologies and greener manufacturing processes that reduce or eliminate the use of perchloric acid in resin production. This shift towards more environmentally friendly practices is driven by both regulatory pressures and increasing consumer demand for sustainable products.

One of the primary environmental impacts of perchloric acid in resin manufacturing is its potential to contaminate water sources. Improper disposal or accidental release of perchloric acid can lead to the formation of perchlorate ions in groundwater and surface water. These ions are highly soluble and mobile in aqueous environments, making them difficult to remove once they enter water systems.

Perchlorate contamination has been linked to adverse effects on aquatic organisms and wildlife. Studies have shown that exposure to perchlorate can disrupt thyroid function in fish and amphibians, potentially affecting their growth, development, and reproductive capabilities. This disruption can have cascading effects throughout the ecosystem, impacting biodiversity and ecological balance.

Air pollution is another environmental concern associated with perchloric acid use in resin manufacturing. Volatile organic compounds (VOCs) and other hazardous air pollutants may be released during the production process, contributing to smog formation and degradation of air quality in surrounding areas. These emissions can have negative impacts on both human health and the environment, particularly in regions with high industrial activity.

The production and transportation of perchloric acid also present environmental risks. Accidental spills or leaks during handling and transport can result in soil contamination, potentially affecting plant growth and soil microorganisms. The remediation of perchlorate-contaminated soil can be a complex and costly process, often requiring extensive treatment and monitoring.

To mitigate these environmental impacts, resin manufacturers must implement stringent safety protocols and waste management practices. This includes proper storage and handling of perchloric acid, as well as the use of advanced treatment technologies for wastewater and air emissions. Closed-loop systems and recycling processes can help minimize the release of perchloric acid and its byproducts into the environment.

Regulatory bodies have recognized the environmental concerns associated with perchloric acid use and have implemented strict guidelines for its handling and disposal. Compliance with these regulations is crucial for resin manufacturers to minimize their environmental footprint and ensure sustainable production practices.

As the industry continues to evolve, there is a growing emphasis on developing alternative technologies and greener manufacturing processes that reduce or eliminate the use of perchloric acid in resin production. This shift towards more environmentally friendly practices is driven by both regulatory pressures and increasing consumer demand for sustainable products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!