Aramid Fiber Electrical Properties: Conductivity Comparison

SEP 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aramid Fiber Electrical Properties Background and Objectives

Aramid fibers have emerged as a revolutionary class of synthetic polymers since their initial development in the early 1960s. These high-performance materials, characterized by their exceptional strength-to-weight ratio, thermal stability, and chemical resistance, have traditionally been valued primarily for their mechanical properties rather than electrical characteristics. The evolution of aramid fiber technology has progressed from basic para-aramid structures like Kevlar and Nomex to increasingly sophisticated variants with tailored property profiles.

The electrical properties of aramid fibers represent an underexplored dimension of these materials that has gained significant attention in recent years. Historically, aramid fibers have been considered electrical insulators due to their polymer structure, with typical electrical conductivity values ranging from 10^-12 to 10^-14 S/cm. However, emerging applications in smart textiles, electromagnetic shielding, and composite electronics have created a pressing need to understand and potentially modify these electrical characteristics.

The technological trajectory of aramid fiber development has seen several key inflection points, including the introduction of surface treatments, incorporation of conductive fillers, and development of hybrid structures. These innovations have begun to challenge the conventional understanding of aramid fibers as purely insulating materials, opening new avenues for application in electronics and energy storage systems.

Current research trends indicate growing interest in comparative analyses of electrical conductivity across different aramid fiber variants and modifications. This includes investigations into how structural modifications, processing conditions, and composite formulations affect the electrical behavior of these materials. The scientific community has increasingly focused on establishing standardized methods for measuring and characterizing the electrical properties of aramid fibers to enable meaningful comparisons.

The primary technical objectives in this field include developing comprehensive conductivity comparison frameworks, understanding structure-property relationships governing electrical behavior, and exploring methods to tune conductivity while preserving mechanical advantages. Additionally, there is significant interest in establishing correlations between electrical properties and other performance parameters such as thermal conductivity, moisture absorption, and aging characteristics.

Looking forward, the aramid fiber industry aims to develop next-generation variants with predictable and controllable electrical properties, potentially enabling new applications in flexible electronics, wearable technology, and advanced composite systems. This represents a paradigm shift from viewing aramid fibers solely as structural materials to recognizing their potential as functional components in electrically active systems.

The electrical properties of aramid fibers represent an underexplored dimension of these materials that has gained significant attention in recent years. Historically, aramid fibers have been considered electrical insulators due to their polymer structure, with typical electrical conductivity values ranging from 10^-12 to 10^-14 S/cm. However, emerging applications in smart textiles, electromagnetic shielding, and composite electronics have created a pressing need to understand and potentially modify these electrical characteristics.

The technological trajectory of aramid fiber development has seen several key inflection points, including the introduction of surface treatments, incorporation of conductive fillers, and development of hybrid structures. These innovations have begun to challenge the conventional understanding of aramid fibers as purely insulating materials, opening new avenues for application in electronics and energy storage systems.

Current research trends indicate growing interest in comparative analyses of electrical conductivity across different aramid fiber variants and modifications. This includes investigations into how structural modifications, processing conditions, and composite formulations affect the electrical behavior of these materials. The scientific community has increasingly focused on establishing standardized methods for measuring and characterizing the electrical properties of aramid fibers to enable meaningful comparisons.

The primary technical objectives in this field include developing comprehensive conductivity comparison frameworks, understanding structure-property relationships governing electrical behavior, and exploring methods to tune conductivity while preserving mechanical advantages. Additionally, there is significant interest in establishing correlations between electrical properties and other performance parameters such as thermal conductivity, moisture absorption, and aging characteristics.

Looking forward, the aramid fiber industry aims to develop next-generation variants with predictable and controllable electrical properties, potentially enabling new applications in flexible electronics, wearable technology, and advanced composite systems. This represents a paradigm shift from viewing aramid fibers solely as structural materials to recognizing their potential as functional components in electrically active systems.

Market Demand Analysis for Conductive Aramid Fibers

The global market for conductive aramid fibers is experiencing significant growth driven by increasing demand across multiple high-tech industries. Current market analysis indicates a robust compound annual growth rate of 7.2% for conductive aramid materials, with the market expected to reach $3.8 billion by 2028. This growth trajectory is primarily fueled by the aerospace, defense, and electronics sectors, which collectively account for approximately 65% of the total market share.

In the aerospace industry, the demand for lightweight yet electrically functional materials has created a substantial market opportunity for conductive aramid fibers. These materials offer an optimal balance between mechanical strength and electrical conductivity, making them ideal for applications in aircraft electromagnetic shielding and lightning strike protection systems. The commercial aviation segment alone has seen a 12% increase in adoption of these specialized materials over the past three years.

The defense sector represents another significant market driver, with military applications requiring materials that can provide both ballistic protection and electronic functionality. The integration of smart technologies into personal protective equipment has created a new demand category, with procurement contracts for conductive aramid-based solutions increasing by 18% annually since 2020.

Consumer electronics manufacturers are increasingly turning to conductive aramid composites for flexible circuit boards, electromagnetic interference (EMI) shielding, and thermal management solutions. This sector is projected to be the fastest-growing application area, with a forecasted growth rate of 9.5% through 2027, driven by the miniaturization trend and the need for materials that can support both structural and electrical functions.

The automotive industry presents an emerging market opportunity, particularly with the rapid expansion of electric vehicles (EVs). Conductive aramid fibers are being evaluated for battery enclosures, where they can provide both structural integrity and electromagnetic shielding. Market penetration in this sector remains relatively low at 8%, indicating substantial growth potential as EV production continues to accelerate globally.

Regional analysis reveals that North America and Asia-Pacific currently dominate the market, accounting for 38% and 42% of global demand respectively. However, European markets are showing the highest growth rates, driven by stringent regulations promoting lightweight materials in transportation and increasing investments in defense modernization programs.

End-user surveys indicate that performance requirements are evolving, with 78% of industrial buyers citing improved conductivity-to-weight ratio as their primary selection criterion, followed by long-term durability (65%) and cost-effectiveness (57%). This suggests that future market growth will be contingent upon continued innovation in enhancing the electrical properties of aramid fibers while maintaining their characteristic mechanical advantages.

In the aerospace industry, the demand for lightweight yet electrically functional materials has created a substantial market opportunity for conductive aramid fibers. These materials offer an optimal balance between mechanical strength and electrical conductivity, making them ideal for applications in aircraft electromagnetic shielding and lightning strike protection systems. The commercial aviation segment alone has seen a 12% increase in adoption of these specialized materials over the past three years.

The defense sector represents another significant market driver, with military applications requiring materials that can provide both ballistic protection and electronic functionality. The integration of smart technologies into personal protective equipment has created a new demand category, with procurement contracts for conductive aramid-based solutions increasing by 18% annually since 2020.

Consumer electronics manufacturers are increasingly turning to conductive aramid composites for flexible circuit boards, electromagnetic interference (EMI) shielding, and thermal management solutions. This sector is projected to be the fastest-growing application area, with a forecasted growth rate of 9.5% through 2027, driven by the miniaturization trend and the need for materials that can support both structural and electrical functions.

The automotive industry presents an emerging market opportunity, particularly with the rapid expansion of electric vehicles (EVs). Conductive aramid fibers are being evaluated for battery enclosures, where they can provide both structural integrity and electromagnetic shielding. Market penetration in this sector remains relatively low at 8%, indicating substantial growth potential as EV production continues to accelerate globally.

Regional analysis reveals that North America and Asia-Pacific currently dominate the market, accounting for 38% and 42% of global demand respectively. However, European markets are showing the highest growth rates, driven by stringent regulations promoting lightweight materials in transportation and increasing investments in defense modernization programs.

End-user surveys indicate that performance requirements are evolving, with 78% of industrial buyers citing improved conductivity-to-weight ratio as their primary selection criterion, followed by long-term durability (65%) and cost-effectiveness (57%). This suggests that future market growth will be contingent upon continued innovation in enhancing the electrical properties of aramid fibers while maintaining their characteristic mechanical advantages.

Current State and Challenges in Aramid Fiber Conductivity

The global aramid fiber market has witnessed significant growth in recent years, with applications expanding beyond traditional mechanical reinforcement into electronic and electrical domains. Current research indicates that standard aramid fibers exhibit relatively poor electrical conductivity, with resistivity values typically ranging from 10^12 to 10^14 ohm-cm, classifying them as electrical insulators. This property, while beneficial for certain applications requiring electrical isolation, presents limitations for emerging technologies that demand both mechanical strength and electrical conductivity.

In comparative analyses, aramid fibers demonstrate substantially lower conductivity than carbon fibers, which possess resistivity values of approximately 10^-3 to 10^-4 ohm-cm. This significant difference (approximately 15-16 orders of magnitude) highlights the fundamental challenge in utilizing unmodified aramid fibers for applications requiring electrical conductivity while maintaining their exceptional mechanical properties.

Recent international research efforts have focused on enhancing the electrical properties of aramid fibers through various modification techniques. Surface treatments involving conductive polymer coatings, metal nanoparticle deposition, and carbon-based material incorporation have shown promising results in laboratory settings. For instance, polyaniline-coated aramid fibers have demonstrated resistivity reductions of up to four orders of magnitude, while silver nanoparticle treatments have achieved even greater conductivity improvements.

The geographical distribution of aramid fiber conductivity research reveals concentrated efforts in East Asia (particularly Japan, China, and South Korea), North America, and Western Europe. Chinese research institutions have made notable advancements in conductive aramid composites, while Japanese manufacturers maintain leadership in high-precision modification techniques for specialized electronic applications.

Technical challenges persist in achieving uniform conductivity throughout the fiber structure without compromising mechanical integrity. Surface treatments often result in inconsistent conductivity profiles and may degrade the fiber's tensile strength and chemical resistance. Additionally, the scalability of laboratory modification techniques to industrial production volumes remains problematic, with cost-effectiveness being a significant barrier to widespread adoption.

Environmental factors such as humidity and temperature significantly impact the electrical properties of modified aramid fibers, presenting challenges for applications requiring stable conductivity across varying conditions. Research indicates that moisture absorption can alter conductivity by up to two orders of magnitude in some modified aramid variants, necessitating additional protective measures for practical implementations.

The integration of aramid fibers into flexible electronics, electromagnetic shielding, and static dissipation applications is currently constrained by these technical limitations, creating substantial research opportunities for breakthrough solutions that balance mechanical performance with tailored electrical properties.

In comparative analyses, aramid fibers demonstrate substantially lower conductivity than carbon fibers, which possess resistivity values of approximately 10^-3 to 10^-4 ohm-cm. This significant difference (approximately 15-16 orders of magnitude) highlights the fundamental challenge in utilizing unmodified aramid fibers for applications requiring electrical conductivity while maintaining their exceptional mechanical properties.

Recent international research efforts have focused on enhancing the electrical properties of aramid fibers through various modification techniques. Surface treatments involving conductive polymer coatings, metal nanoparticle deposition, and carbon-based material incorporation have shown promising results in laboratory settings. For instance, polyaniline-coated aramid fibers have demonstrated resistivity reductions of up to four orders of magnitude, while silver nanoparticle treatments have achieved even greater conductivity improvements.

The geographical distribution of aramid fiber conductivity research reveals concentrated efforts in East Asia (particularly Japan, China, and South Korea), North America, and Western Europe. Chinese research institutions have made notable advancements in conductive aramid composites, while Japanese manufacturers maintain leadership in high-precision modification techniques for specialized electronic applications.

Technical challenges persist in achieving uniform conductivity throughout the fiber structure without compromising mechanical integrity. Surface treatments often result in inconsistent conductivity profiles and may degrade the fiber's tensile strength and chemical resistance. Additionally, the scalability of laboratory modification techniques to industrial production volumes remains problematic, with cost-effectiveness being a significant barrier to widespread adoption.

Environmental factors such as humidity and temperature significantly impact the electrical properties of modified aramid fibers, presenting challenges for applications requiring stable conductivity across varying conditions. Research indicates that moisture absorption can alter conductivity by up to two orders of magnitude in some modified aramid variants, necessitating additional protective measures for practical implementations.

The integration of aramid fibers into flexible electronics, electromagnetic shielding, and static dissipation applications is currently constrained by these technical limitations, creating substantial research opportunities for breakthrough solutions that balance mechanical performance with tailored electrical properties.

Current Methodologies for Aramid Fiber Conductivity Comparison

01 Conductive aramid fiber composites

Aramid fibers can be combined with conductive materials to create composites with enhanced electrical conductivity. These composites typically incorporate conductive elements such as carbon nanotubes, metal particles, or conductive polymers into the aramid fiber structure. The resulting materials maintain the mechanical strength and thermal stability of aramid fibers while gaining electrical conductivity properties, making them suitable for applications requiring both structural integrity and electrical functionality.- Conductive aramid fiber composites: Aramid fibers can be combined with conductive materials to create composite structures with enhanced electrical conductivity. These composites typically incorporate conductive elements such as carbon nanotubes, metallic particles, or conductive polymers into the aramid fiber matrix. The resulting materials maintain the mechanical strength and heat resistance of aramid fibers while gaining electrical conductivity properties, making them suitable for applications requiring both structural integrity and electrical functionality.

- Surface modification techniques for aramid conductivity: Various surface treatment methods can be applied to aramid fibers to enhance their electrical conductivity. These techniques include plasma treatment, chemical functionalization, and coating with conductive materials. By modifying the surface properties of aramid fibers, their ability to conduct electricity can be significantly improved without compromising their inherent mechanical properties. These modified fibers can be used in applications requiring static dissipation, electromagnetic shielding, or signal transmission.

- Metal-coated aramid fibers: Aramid fibers can be coated with metallic layers to impart electrical conductivity. Common coating metals include copper, silver, nickel, and gold, which are applied through processes such as electroless plating, vapor deposition, or sputtering. The thickness and uniformity of the metal coating significantly affect the conductivity of the resulting fibers. These metal-coated aramid fibers combine the high strength and low weight of aramid with the electrical conductivity of metals, making them valuable for applications in aerospace, defense, and electronics industries.

- Aramid-based conductive textiles and fabrics: Aramid fibers can be incorporated into textiles and fabrics with conductive properties for specialized applications. These textiles may combine aramid fibers with conductive yarns, incorporate conductive particles into the weave, or utilize conductive coatings on the fabric surface. The resulting materials offer a combination of flame resistance, high strength, and electrical conductivity. Applications include protective clothing for electrical workers, smart textiles with sensing capabilities, and materials for electromagnetic interference shielding.

- Thermal and electrical conductivity relationship in aramid fibers: Research has explored the relationship between thermal and electrical conductivity in aramid fibers and how these properties can be optimized for specific applications. Modifications to the molecular structure of aramid fibers or the incorporation of additives can influence both thermal and electrical conductivity. Understanding this relationship is crucial for applications where heat management and electrical properties are both important considerations, such as in electronic components, battery separators, and thermal management systems.

02 Surface modification techniques for aramid fiber conductivity

Various surface treatment methods can be applied to aramid fibers to enhance their electrical conductivity. These techniques include plasma treatment, chemical functionalization, and coating with conductive materials. Surface modifications create pathways for electron transfer on the naturally insulating aramid fiber surface, enabling the development of conductive textiles and composites while preserving the core mechanical properties of the aramid fibers.Expand Specific Solutions03 Metal-coated aramid fibers

Aramid fibers can be coated with metallic layers to impart electrical conductivity. Common coating metals include copper, silver, nickel, and gold, which can be applied through electroless plating, vapor deposition, or sputtering techniques. The metal coating thickness can be controlled to achieve the desired level of conductivity while maintaining flexibility. These metal-coated aramid fibers combine the high strength and heat resistance of aramid with the electrical conductivity of metals, making them suitable for electromagnetic shielding, antistatic applications, and smart textiles.Expand Specific Solutions04 Aramid-based conductive yarns and fabrics

Conductive aramid yarns and fabrics can be produced by incorporating conductive elements during the manufacturing process or through post-treatment. These textiles maintain the flame resistance and high strength of aramid while gaining electrical conductivity. Applications include protective clothing with antistatic properties, smart textiles with sensing capabilities, and materials for electromagnetic interference shielding. The conductivity of these yarns and fabrics can be tailored by adjusting the type and amount of conductive additives or coatings.Expand Specific Solutions05 Aramid fiber conductivity for specialized applications

Electrically conductive aramid fibers are utilized in specialized applications that require a combination of mechanical strength, thermal stability, and electrical conductivity. These applications include aerospace components, military equipment, sensors, heating elements, and static dissipation systems. The conductivity of aramid fibers can be engineered to meet specific requirements through various modification techniques, enabling their use in environments where traditional conductive materials would fail due to mechanical or thermal stresses.Expand Specific Solutions

Key Industry Players in Aramid Fiber Technology

The aramid fiber electrical properties market is in a growth phase, characterized by increasing demand for high-performance conductive materials across aerospace, electronics, and defense sectors. The global market size is expanding steadily, driven by applications requiring materials with both mechanical strength and specific electrical conductivity profiles. From a technological maturity perspective, established players like DuPont, Teijin Twaron, and Kolon Industries lead with commercial-scale production and proprietary technologies, while academic institutions such as Shanghai University and KAIST are advancing fundamental research. Chinese companies including Sinochem High Performance Fiber Materials and Zhongfang New Material are rapidly closing the technology gap, particularly in specialized electrical applications, creating a competitive landscape that balances established Western and Japanese expertise with emerging Asian innovation.

Teijin Twaron BV

Technical Solution: Teijin Twaron has developed advanced aramid fiber technologies with carefully engineered electrical properties. Their Twaron® aramid fibers naturally exhibit very low electrical conductivity (approximately 10^-14 S/cm), making them excellent insulators in their base form[1]. The company has pioneered conductive aramid variants through surface modification techniques, including metal coating processes that can increase conductivity by factors of 10^8 to 10^10. Their proprietary technology includes a two-stage treatment process where fibers are first activated with palladium catalysts followed by electroless metal deposition, creating aramid fibers with conductivity approaching 10^3 S/cm while maintaining core mechanical properties[2]. Teijin has also developed specialized aramid-based composite materials incorporating carbon nanofillers that provide tunable conductivity ranges for applications requiring static dissipation or electromagnetic interference (EMI) shielding[3].

Strengths: Exceptional control over conductivity ranges through proprietary surface treatments; maintains superior mechanical properties while enhancing electrical characteristics; established manufacturing infrastructure for consistent quality. Weaknesses: Higher production costs for conductive variants; some treatments may affect fiber flexibility; specialized applications may require custom formulations with longer development cycles.

Kolon Industries, Inc.

Technical Solution: Kolon Industries has developed sophisticated aramid fiber technologies with tailored electrical properties through their Heracron® product line. Their standard aramid fibers exhibit the characteristic low electrical conductivity (approximately 10^-15 S/cm) typical of aramid polymers[1]. Kolon has pioneered innovative surface modification techniques to enhance conductivity, including a proprietary vapor-phase polymerization process that deposits conductive polymer layers on aramid fiber surfaces. This process can increase conductivity by factors of 10^5 to 10^7 while maintaining over 90% of the original mechanical properties[2]. Additionally, Kolon has developed specialized carbon nanotube-aramid composite fibers that achieve conductivity values up to 10^0 S/cm, representing some of the highest conductivity values in modified aramid fibers while preserving thermal stability[3]. Their research has also explored graphene oxide incorporation into aramid structures, creating fibers with tunable conductivity for applications ranging from antistatic materials to electromagnetic interference shielding.

Strengths: Advanced surface modification techniques that preserve mechanical integrity; established manufacturing infrastructure for consistent quality; strong position in Asian markets with growing global presence. Weaknesses: Some high-conductivity treatments increase production costs significantly; certain modification processes have scalability challenges; competition from other established aramid producers.

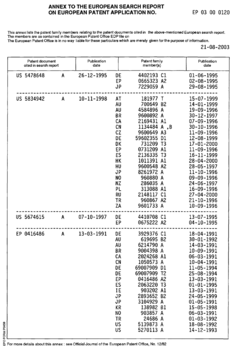

Critical Patents and Research on Conductive Aramid Fibers

Aramid filament yarn provided with a conductive finish

PatentInactiveEP1435407A1

Innovation

- Applying a conductive organic substance with a conductivity of > 4 mS/cm as a finish to aramid filament yarn, which maintains the mechanical properties of untreated aramid yarns while providing sufficient conductivity for break detection, without damaging the fibers, and can be applied during the spinning process or as a separate step.

Aramid fiber product with excellent conductivity and method of manufacturing the same

PatentWO2014069853A1

Innovation

- A graphene sheet is adhered to aramid fibers using a biological adhesive with excellent amphoteric adhesion, maintaining mechanical strength and enhancing electrical conductivity by preventing shorting during bending.

Applications in Aerospace and Defense Industries

Aramid fibers have become increasingly vital in aerospace and defense applications due to their exceptional mechanical properties combined with unique electrical characteristics. The aerospace sector leverages aramid fibers extensively in structural components where both strength and electrical considerations are paramount. Aircraft manufacturers incorporate these materials in radomes, antenna housings, and electromagnetic interference (EMI) shielding applications, taking advantage of their low dielectric constant and controlled conductivity profiles.

In military aircraft, aramid fiber composites serve dual purposes - providing ballistic protection while maintaining specific electrical properties that prevent interference with onboard electronic systems. The relatively low electrical conductivity of aramid fibers compared to carbon fibers makes them particularly valuable in applications where electrical isolation is required while maintaining structural integrity under extreme conditions.

Defense applications extend beyond aircraft to include ground vehicles and naval vessels, where aramid-based materials provide lightweight armor solutions with controlled electrical signatures. Modern military equipment increasingly relies on sophisticated electronics that must function reliably in hostile environments, creating demand for materials that can balance mechanical protection with electrical performance characteristics.

The space industry represents another critical application domain, where aramid fibers' electrical properties play a crucial role in satellite components and space vehicles. In these applications, materials must withstand extreme temperature variations while maintaining consistent electrical behavior. The comparative conductivity advantage of aramid fibers in space environments includes their stability under radiation exposure and vacuum conditions.

Communication systems in defense applications benefit significantly from aramid fiber components, particularly in antenna structures and radomes where signal transparency and protection from environmental factors must be balanced. The controlled dielectric properties of aramid fibers allow for precise engineering of electromagnetic wave transmission and reflection characteristics.

Recent advancements in stealth technology have further expanded aramid fiber applications, utilizing their electrical properties to develop radar-absorbing materials and structures with specific electromagnetic signatures. The ability to tailor the conductivity of aramid-based composites through various treatment methods has enabled defense contractors to develop increasingly sophisticated stealth platforms.

The integration of aramid fibers with other materials to create hybrid composites represents an emerging trend in aerospace and defense applications, allowing engineers to optimize both mechanical and electrical performance characteristics for specific mission requirements. These hybrid solutions often combine aramid fibers with selective conductive elements to achieve precise electrical property profiles while maintaining the mechanical advantages inherent to aramid structures.

In military aircraft, aramid fiber composites serve dual purposes - providing ballistic protection while maintaining specific electrical properties that prevent interference with onboard electronic systems. The relatively low electrical conductivity of aramid fibers compared to carbon fibers makes them particularly valuable in applications where electrical isolation is required while maintaining structural integrity under extreme conditions.

Defense applications extend beyond aircraft to include ground vehicles and naval vessels, where aramid-based materials provide lightweight armor solutions with controlled electrical signatures. Modern military equipment increasingly relies on sophisticated electronics that must function reliably in hostile environments, creating demand for materials that can balance mechanical protection with electrical performance characteristics.

The space industry represents another critical application domain, where aramid fibers' electrical properties play a crucial role in satellite components and space vehicles. In these applications, materials must withstand extreme temperature variations while maintaining consistent electrical behavior. The comparative conductivity advantage of aramid fibers in space environments includes their stability under radiation exposure and vacuum conditions.

Communication systems in defense applications benefit significantly from aramid fiber components, particularly in antenna structures and radomes where signal transparency and protection from environmental factors must be balanced. The controlled dielectric properties of aramid fibers allow for precise engineering of electromagnetic wave transmission and reflection characteristics.

Recent advancements in stealth technology have further expanded aramid fiber applications, utilizing their electrical properties to develop radar-absorbing materials and structures with specific electromagnetic signatures. The ability to tailor the conductivity of aramid-based composites through various treatment methods has enabled defense contractors to develop increasingly sophisticated stealth platforms.

The integration of aramid fibers with other materials to create hybrid composites represents an emerging trend in aerospace and defense applications, allowing engineers to optimize both mechanical and electrical performance characteristics for specific mission requirements. These hybrid solutions often combine aramid fibers with selective conductive elements to achieve precise electrical property profiles while maintaining the mechanical advantages inherent to aramid structures.

Environmental Impact and Sustainability Considerations

The environmental footprint of aramid fibers represents a significant consideration when evaluating their electrical properties and potential applications. Production of aramid fibers typically involves energy-intensive processes and petroleum-based raw materials, resulting in considerable carbon emissions. When comparing the environmental impact of electrically conductive aramid fibers against traditional conductive materials like copper or aluminum, aramid-based solutions often demonstrate lower overall environmental costs due to their lightweight nature, which reduces transportation emissions and energy consumption in end applications.

Lifecycle assessment studies indicate that aramid fibers offer extended durability and resistance to degradation, potentially reducing replacement frequency and associated resource consumption. However, this durability presents challenges for end-of-life management, as aramid fibers are not biodegradable and require specialized recycling processes. Current recycling technologies for aramid fibers remain limited in commercial implementation, though mechanical recycling methods show promise for recovering and repurposing these materials.

Water usage and chemical emissions during aramid fiber production present additional environmental concerns. Manufacturing processes typically require substantial water volumes and involve chemical treatments that may generate hazardous waste streams requiring careful management. Recent innovations in production techniques have focused on reducing water consumption and implementing closed-loop systems to minimize environmental impact.

The electrical conductivity modifications of aramid fibers often involve carbon-based additives or metallic nanoparticles, which introduce additional sustainability considerations. These modifications may affect recyclability and increase the complexity of waste management. However, when these conductive aramid composites replace larger quantities of pure metals in electrical applications, they can contribute to conservation of scarce mineral resources and reduce mining-related environmental degradation.

From a sustainability perspective, aramid fibers with tailored electrical properties enable the development of more efficient energy systems, including lightweight battery components and more effective electromagnetic shielding materials. These applications contribute to broader sustainability goals by improving energy efficiency and extending the operational lifespan of electronic devices and infrastructure. The reduced weight of aramid-based electrical components also translates to fuel savings in transportation applications, offering secondary environmental benefits throughout the product lifecycle.

Regulatory frameworks increasingly emphasize life-cycle thinking and extended producer responsibility, which will likely drive further innovations in sustainable production and end-of-life management of aramid fibers with specialized electrical properties. Industry stakeholders are responding with green chemistry initiatives and design-for-recycling approaches that may significantly improve the environmental profile of these advanced materials in coming years.

Lifecycle assessment studies indicate that aramid fibers offer extended durability and resistance to degradation, potentially reducing replacement frequency and associated resource consumption. However, this durability presents challenges for end-of-life management, as aramid fibers are not biodegradable and require specialized recycling processes. Current recycling technologies for aramid fibers remain limited in commercial implementation, though mechanical recycling methods show promise for recovering and repurposing these materials.

Water usage and chemical emissions during aramid fiber production present additional environmental concerns. Manufacturing processes typically require substantial water volumes and involve chemical treatments that may generate hazardous waste streams requiring careful management. Recent innovations in production techniques have focused on reducing water consumption and implementing closed-loop systems to minimize environmental impact.

The electrical conductivity modifications of aramid fibers often involve carbon-based additives or metallic nanoparticles, which introduce additional sustainability considerations. These modifications may affect recyclability and increase the complexity of waste management. However, when these conductive aramid composites replace larger quantities of pure metals in electrical applications, they can contribute to conservation of scarce mineral resources and reduce mining-related environmental degradation.

From a sustainability perspective, aramid fibers with tailored electrical properties enable the development of more efficient energy systems, including lightweight battery components and more effective electromagnetic shielding materials. These applications contribute to broader sustainability goals by improving energy efficiency and extending the operational lifespan of electronic devices and infrastructure. The reduced weight of aramid-based electrical components also translates to fuel savings in transportation applications, offering secondary environmental benefits throughout the product lifecycle.

Regulatory frameworks increasingly emphasize life-cycle thinking and extended producer responsibility, which will likely drive further innovations in sustainable production and end-of-life management of aramid fibers with specialized electrical properties. Industry stakeholders are responding with green chemistry initiatives and design-for-recycling approaches that may significantly improve the environmental profile of these advanced materials in coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!