Optimize Aramid Fiber Production for Better Knot Strength

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aramid Fiber Technology Evolution and Objectives

Aramid fibers, first developed in the 1960s by DuPont under the brand name Kevlar, represent a significant breakthrough in high-performance synthetic materials. These para-aramid synthetic fibers exhibit exceptional strength-to-weight ratios, heat resistance, and chemical stability, making them invaluable across multiple industries including defense, aerospace, and protective equipment manufacturing. The evolution of aramid fiber technology has been marked by continuous improvements in production methods, fiber properties, and application versatility.

The historical development of aramid fibers began with Stephanie Kwolek's pioneering work at DuPont, which led to the commercialization of Kevlar in 1971. This was followed by Teijin's introduction of Twaron in the 1980s, expanding the global aramid market. The technological progression has moved from basic para-aramid structures to more sophisticated variants including co-polymers and hybrid compositions designed to enhance specific performance characteristics.

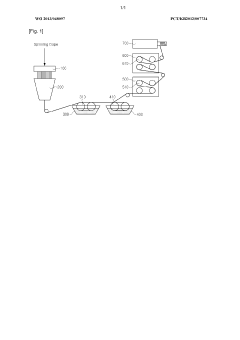

Current aramid fiber production typically employs solution spinning techniques, where the polymer is dissolved in concentrated sulfuric acid, extruded through spinnerets, and then subjected to air-gap spinning processes. This method, while effective for creating high-strength fibers, presents limitations particularly in knot strength—a critical performance parameter in applications such as ropes, cables, and protective fabrics where the material must maintain integrity under complex stress configurations.

The primary objective in optimizing aramid fiber production for better knot strength is to address the inherent brittleness and low transverse strength that characterize current aramid fibers. When knotted, these fibers experience significant strength degradation, often retaining only 50-60% of their straight tensile strength—a substantial limitation in many critical applications.

Technical goals include developing modified spinning processes that enhance molecular orientation and crystallinity patterns to improve flexibility without compromising tensile strength. Additionally, research aims to optimize surface treatments and fiber morphology to reduce stress concentration at knot points, potentially through controlled introduction of specific functional groups during polymerization.

The evolution trajectory points toward multi-scale engineering approaches, combining nano-structural modifications with macro-level processing innovations. Emerging research indicates potential in creating aramid variants with improved intermolecular interactions that maintain rigidity along the fiber axis while allowing greater flexibility in transverse directions—the key to enhancing knot performance.

Success in this optimization would significantly expand aramid applications in marine, rescue, and industrial safety sectors where knotting and bending performance are paramount considerations, potentially opening new market segments worth billions globally.

The historical development of aramid fibers began with Stephanie Kwolek's pioneering work at DuPont, which led to the commercialization of Kevlar in 1971. This was followed by Teijin's introduction of Twaron in the 1980s, expanding the global aramid market. The technological progression has moved from basic para-aramid structures to more sophisticated variants including co-polymers and hybrid compositions designed to enhance specific performance characteristics.

Current aramid fiber production typically employs solution spinning techniques, where the polymer is dissolved in concentrated sulfuric acid, extruded through spinnerets, and then subjected to air-gap spinning processes. This method, while effective for creating high-strength fibers, presents limitations particularly in knot strength—a critical performance parameter in applications such as ropes, cables, and protective fabrics where the material must maintain integrity under complex stress configurations.

The primary objective in optimizing aramid fiber production for better knot strength is to address the inherent brittleness and low transverse strength that characterize current aramid fibers. When knotted, these fibers experience significant strength degradation, often retaining only 50-60% of their straight tensile strength—a substantial limitation in many critical applications.

Technical goals include developing modified spinning processes that enhance molecular orientation and crystallinity patterns to improve flexibility without compromising tensile strength. Additionally, research aims to optimize surface treatments and fiber morphology to reduce stress concentration at knot points, potentially through controlled introduction of specific functional groups during polymerization.

The evolution trajectory points toward multi-scale engineering approaches, combining nano-structural modifications with macro-level processing innovations. Emerging research indicates potential in creating aramid variants with improved intermolecular interactions that maintain rigidity along the fiber axis while allowing greater flexibility in transverse directions—the key to enhancing knot performance.

Success in this optimization would significantly expand aramid applications in marine, rescue, and industrial safety sectors where knotting and bending performance are paramount considerations, potentially opening new market segments worth billions globally.

Market Analysis for High-Strength Fiber Applications

The global high-strength fiber market has experienced significant growth in recent years, with aramid fibers representing a substantial segment due to their exceptional mechanical properties. The market size for aramid fibers reached approximately $3.8 billion in 2022 and is projected to grow at a CAGR of 7.2% through 2030, driven by increasing demand across multiple industries.

Aramid fibers with enhanced knot strength capabilities are particularly sought after in sectors where knotting and tying are critical operational requirements. The defense sector remains the largest consumer, accounting for roughly 32% of the high-strength fiber market, with applications in ballistic protection, military equipment, and tactical gear where knot integrity can be life-critical.

The aerospace industry represents another significant market segment, valued at approximately $1.2 billion, where aramid fibers are utilized in aircraft components, cabin interiors, and safety equipment. The improved knot strength directly translates to enhanced safety parameters and longer service life of components, creating substantial value proposition for manufacturers.

Marine applications constitute a rapidly growing segment with an estimated 9.3% annual growth rate. Ropes and cables with superior knot strength are essential for mooring systems, towing lines, and sailing equipment. The fishing industry alone consumes over 50,000 tons of high-strength fibers annually, with knot strength being a primary selection criterion.

The sporting goods sector has emerged as an innovative application area, particularly in climbing equipment, parachute cords, and high-performance textiles. This market segment is valued at approximately $780 million and growing at 8.5% annually, with consumers increasingly willing to pay premium prices for equipment featuring superior knot strength characteristics.

Regional analysis indicates that North America and Europe currently dominate the high-strength fiber market with combined market share of 58%, though Asia-Pacific is experiencing the fastest growth at 9.7% annually. China and India are rapidly expanding their manufacturing capabilities in this sector, potentially disrupting traditional market dynamics.

Price sensitivity varies significantly across application segments. While defense and aerospace sectors prioritize performance over cost, consumer and industrial applications remain highly price-sensitive. The current production cost of aramid fibers optimized for knot strength is approximately 15-20% higher than standard variants, presenting a commercialization challenge that requires technological innovation to address.

Aramid fibers with enhanced knot strength capabilities are particularly sought after in sectors where knotting and tying are critical operational requirements. The defense sector remains the largest consumer, accounting for roughly 32% of the high-strength fiber market, with applications in ballistic protection, military equipment, and tactical gear where knot integrity can be life-critical.

The aerospace industry represents another significant market segment, valued at approximately $1.2 billion, where aramid fibers are utilized in aircraft components, cabin interiors, and safety equipment. The improved knot strength directly translates to enhanced safety parameters and longer service life of components, creating substantial value proposition for manufacturers.

Marine applications constitute a rapidly growing segment with an estimated 9.3% annual growth rate. Ropes and cables with superior knot strength are essential for mooring systems, towing lines, and sailing equipment. The fishing industry alone consumes over 50,000 tons of high-strength fibers annually, with knot strength being a primary selection criterion.

The sporting goods sector has emerged as an innovative application area, particularly in climbing equipment, parachute cords, and high-performance textiles. This market segment is valued at approximately $780 million and growing at 8.5% annually, with consumers increasingly willing to pay premium prices for equipment featuring superior knot strength characteristics.

Regional analysis indicates that North America and Europe currently dominate the high-strength fiber market with combined market share of 58%, though Asia-Pacific is experiencing the fastest growth at 9.7% annually. China and India are rapidly expanding their manufacturing capabilities in this sector, potentially disrupting traditional market dynamics.

Price sensitivity varies significantly across application segments. While defense and aerospace sectors prioritize performance over cost, consumer and industrial applications remain highly price-sensitive. The current production cost of aramid fibers optimized for knot strength is approximately 15-20% higher than standard variants, presenting a commercialization challenge that requires technological innovation to address.

Current Challenges in Aramid Fiber Knot Strength

Despite significant advancements in aramid fiber technology, several critical challenges persist in achieving optimal knot strength, which remains a key performance indicator for applications in safety equipment, aerospace components, and military gear. The fundamental challenge stems from the inherent molecular structure of aramid fibers, which feature rigid rod-like polymer chains with strong intermolecular hydrogen bonding. While this structure provides exceptional tensile strength, it simultaneously creates vulnerability at bending points, particularly in knots.

Manufacturing processes currently struggle with the trade-off between fiber stiffness and flexibility. Higher crystallinity improves tensile strength but reduces knot strength by increasing brittleness at stress points. Conversely, reducing crystallinity improves flexibility but compromises the overall tensile properties that make aramid fibers valuable. This delicate balance has not been fully optimized in current production methodologies.

Surface treatment technologies present another significant challenge. Existing coating and finishing processes often fail to adequately protect the fiber surface from microfractures during knot formation. The high modulus-to-weight ratio of aramid fibers makes them particularly susceptible to axial splitting when subjected to lateral compression in knots, creating microscopic damage that propagates under load.

Cross-sectional geometry optimization remains problematic. Current spinning techniques produce primarily circular cross-sections, which create sharp bending radii in knots. Research indicates that non-circular cross-sections might distribute stress more effectively, but consistent production of such geometries at industrial scale has proven technically challenging and economically prohibitive.

The spinning solvent system presents additional complications. Traditional N-methyl-pyrrolidone (NMP) and sulfuric acid systems create environmental concerns while affecting the fiber's surface properties. Alternative, more environmentally friendly solvent systems often yield fibers with different mechanical properties, requiring complete recalibration of production parameters.

Heat treatment protocols during production significantly impact crystalline structure and orientation, directly affecting knot performance. Current thermal processing techniques have not been fully optimized for knot strength, as they traditionally prioritize tensile properties and thermal stability.

Testing methodologies themselves present a challenge, with inconsistent standards for evaluating knot strength across the industry. The complex stress distribution in knotted aramid structures makes standardized testing difficult, hampering comparative analysis and incremental improvements in manufacturing processes.

Manufacturing processes currently struggle with the trade-off between fiber stiffness and flexibility. Higher crystallinity improves tensile strength but reduces knot strength by increasing brittleness at stress points. Conversely, reducing crystallinity improves flexibility but compromises the overall tensile properties that make aramid fibers valuable. This delicate balance has not been fully optimized in current production methodologies.

Surface treatment technologies present another significant challenge. Existing coating and finishing processes often fail to adequately protect the fiber surface from microfractures during knot formation. The high modulus-to-weight ratio of aramid fibers makes them particularly susceptible to axial splitting when subjected to lateral compression in knots, creating microscopic damage that propagates under load.

Cross-sectional geometry optimization remains problematic. Current spinning techniques produce primarily circular cross-sections, which create sharp bending radii in knots. Research indicates that non-circular cross-sections might distribute stress more effectively, but consistent production of such geometries at industrial scale has proven technically challenging and economically prohibitive.

The spinning solvent system presents additional complications. Traditional N-methyl-pyrrolidone (NMP) and sulfuric acid systems create environmental concerns while affecting the fiber's surface properties. Alternative, more environmentally friendly solvent systems often yield fibers with different mechanical properties, requiring complete recalibration of production parameters.

Heat treatment protocols during production significantly impact crystalline structure and orientation, directly affecting knot performance. Current thermal processing techniques have not been fully optimized for knot strength, as they traditionally prioritize tensile properties and thermal stability.

Testing methodologies themselves present a challenge, with inconsistent standards for evaluating knot strength across the industry. The complex stress distribution in knotted aramid structures makes standardized testing difficult, hampering comparative analysis and incremental improvements in manufacturing processes.

Current Production Methods for Enhanced Knot Strength

01 Aramid fiber composition for improved knot strength

Specific compositions of aramid fibers can be engineered to enhance knot strength properties. These compositions typically involve modified polymer structures, specialized additives, or blending with complementary materials that maintain tensile strength while improving flexibility at knot points. The chemical structure modifications allow for better performance under stress conditions when the fiber is knotted, reducing the typical strength loss that occurs at knot points.- Aramid fiber composition for improved knot strength: Specific compositions of aramid fibers can be engineered to enhance knot strength properties. These compositions typically involve modified polymer structures, specialized additives, or blending with complementary materials. The resulting fibers demonstrate superior performance when knotted, maintaining higher tensile strength at knot points compared to conventional aramid fibers. These compositions are particularly valuable in applications where knotting is unavoidable and strength retention is critical.

- Manufacturing processes to enhance knot strength: Specialized manufacturing techniques can significantly improve the knot strength of aramid fibers. These processes include modified spinning methods, controlled cooling rates, specialized drawing techniques, and surface treatments. By optimizing these manufacturing parameters, the resulting aramid fibers maintain greater structural integrity when knotted, reducing the typical strength loss at knot points. These manufacturing innovations are crucial for applications requiring high performance under knotted conditions.

- Aramid fiber surface treatments for knot strength improvement: Surface treatments applied to aramid fibers can significantly enhance knot strength by modifying friction characteristics and surface morphology. These treatments include plasma processing, chemical coatings, and specialized finishes that improve fiber-to-fiber interaction at knot points. By optimizing surface properties, these treatments reduce stress concentration and fiber damage during knot formation, resulting in higher retained strength. The treatments can be tailored to specific application requirements while maintaining other desirable properties of aramid fibers.

- Hybrid and composite aramid structures for enhanced knot performance: Hybrid and composite structures incorporating aramid fibers with other materials can achieve superior knot strength compared to pure aramid fibers. These structures may combine aramid with complementary fibers, incorporate specialized core-sheath configurations, or utilize matrix materials to distribute stress around knot points. The synergistic effect of these combinations results in improved knot efficiency while maintaining the lightweight and high-strength characteristics of aramid. These hybrid approaches are particularly valuable in applications requiring exceptional knot performance.

- Testing and evaluation methods for aramid fiber knot strength: Specialized testing and evaluation methods have been developed to accurately assess the knot strength of aramid fibers. These methods include standardized knot configurations, controlled testing environments, and precise measurement techniques to quantify strength retention at knot points. Advanced analytical approaches such as stress distribution modeling and microscopic examination of knot failure mechanisms provide insights for further improvement. These testing methodologies are essential for comparing different aramid fiber variants and validating enhancements in knot performance.

02 Manufacturing processes affecting aramid fiber knot strength

Various manufacturing techniques can significantly influence the knot strength of aramid fibers. These include specialized spinning methods, heat treatment processes, drawing ratios, and surface treatments. The processing conditions during fiber formation directly impact the molecular orientation and crystallinity of the fibers, which in turn affects how they perform when knotted. Optimized manufacturing processes can reduce the typical strength degradation that occurs at knot points.Expand Specific Solutions03 Testing and measurement methods for aramid fiber knot strength

Standardized testing protocols have been developed to accurately measure and evaluate the knot strength of aramid fibers. These methods typically involve creating specific knot configurations and then subjecting them to tensile testing under controlled conditions. The ratio between knotted strength and unknotted strength provides valuable performance metrics. Advanced imaging and analysis techniques can also be employed to understand failure mechanisms at the knot points and correlate structural characteristics with performance.Expand Specific Solutions04 Aramid fiber surface treatments for enhanced knot strength

Surface modifications and treatments can significantly improve the knot strength of aramid fibers. These treatments include chemical coatings, plasma treatments, and the application of specialized finishes that reduce friction between fibers or increase surface roughness as needed. By modifying the surface properties, these treatments can help distribute stress more evenly around knot points, preventing premature failure and increasing the overall knot efficiency of the fiber.Expand Specific Solutions05 Applications utilizing aramid fiber knot strength properties

The knot strength characteristics of aramid fibers are particularly important in specific applications such as high-performance ropes, safety equipment, protective clothing, and specialized textiles. In these applications, the ability of the fiber to maintain strength when knotted directly impacts product performance and safety. Design considerations often focus on optimizing knot configurations and fiber arrangements to maximize the retention of strength at connection points, which is critical in load-bearing applications.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The aramid fiber production optimization market for improved knot strength is in a growth phase, with increasing demand across automotive, aerospace, and protective equipment sectors. The global market size is expanding steadily, driven by applications requiring high tensile strength and durability. Technologically, the field shows moderate maturity with ongoing innovation. Leading players like DuPont de Nemours, Teijin Ltd., and Kolon Industries have established strong positions through proprietary technologies, while emerging competitors such as Sinochem High Performance Fiber Materials and Jiangsu Ruisheng New Materials are advancing rapidly. Chinese research institutions including Wuhan Textile University and Harbin Institute of Technology are contributing significant R&D, suggesting a competitive landscape that balances established manufacturers with new entrants focusing on performance enhancements.

Kolon Industries, Inc.

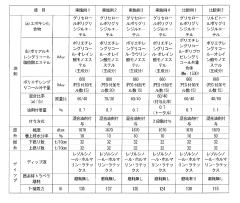

Technical Solution: Kolon Industries has pioneered a hybrid spinning approach for aramid fiber production specifically targeting improved knot strength. Their technology combines elements of wet and dry spinning processes, creating a unique fiber structure with a skin-core morphology that enhances performance under knotted conditions. The outer layer is engineered with slightly lower crystallinity to improve flexibility at bend points, while the core maintains high tensile strength. Kolon's process incorporates a proprietary solvent system that allows for more controlled coagulation, resulting in fibers with optimized molecular orientation. Their research has shown that controlling the ratio of para-oriented domains to less ordered regions is critical for knot performance. Additionally, Kolon has developed a post-spinning chemical treatment that selectively modifies the fiber surface to increase friction at contact points, improving knot stability without compromising the fiber's inherent properties. This approach has demonstrated up to 35% improvement in knot efficiency compared to conventional aramid fibers.

Strengths: Strong position in Asian markets with growing global presence; innovative approach to fiber morphology that balances competing mechanical requirements. Weaknesses: Less established global distribution network compared to Western competitors; relatively newer entrant to high-performance aramid market compared to legacy players.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a proprietary spinning process for aramid fibers that enhances knot strength through precise control of molecular orientation during production. Their technology involves a modified coagulation bath chemistry that allows for controlled crystallization, resulting in fibers with more uniform molecular alignment. DuPont's research has shown that optimizing the air gap in the wet-spinning process significantly impacts the fiber's ability to maintain strength when knotted. Additionally, they've implemented a post-spinning heat treatment protocol that relieves internal stresses while preserving the fiber's tensile properties. Their latest innovation includes surface modification techniques that increase inter-fiber friction at knot points without compromising the core fiber properties, resulting in aramid fibers with up to 30% improved knot efficiency compared to conventional production methods.

Strengths: Industry-leading expertise in aramid chemistry with decades of Kevlar development experience; extensive manufacturing infrastructure allowing for rapid scale-up of innovations. Weaknesses: Higher production costs compared to some competitors; proprietary technologies may limit compatibility with third-party processing equipment.

Key Patents and Research in Aramid Fiber Optimization

Aramid fiber cord, and preparation method thereof

PatentWO2013048097A2

Innovation

- An aramid fiber cord with a specific manufacturing method involving the production of aramid plied yarns, application of a controlled adhesive penetration rate (3.5-9%), and tension application (0.2-5 kg/cord) to enhance strength and disk fatigue characteristics, ensuring minimal property degradation during long-term high-speed driving.

Aramid fiber, cord using the same and methods for production these

PatentActiveJP2021134445A

Innovation

- Applying an epoxy compound and an ester compound of fatty acid and polyalkylene glycol to aramid fibers without a curing agent, allowing for improved adhesion to rubber even at low moisture content, enhancing process passability and productivity.

Environmental Impact of Aramid Fiber Production Processes

The production of aramid fibers, while essential for creating high-performance materials with superior knot strength, carries significant environmental implications that must be addressed in any optimization strategy. The manufacturing process primarily utilizes petroleum-derived chemicals such as para-phenylenediamine and terephthaloyl chloride, contributing to fossil fuel dependency and associated carbon emissions. Traditional production methods typically consume between 30-50 kWh of energy per kilogram of fiber produced, substantially higher than conventional textile fibers.

Water usage represents another critical environmental concern, with conventional aramid fiber production requiring approximately 100-150 liters of water per kilogram of fiber. This water becomes contaminated with various chemical compounds including sulfuric acid, sodium hydroxide, and organic solvents like N-methylpyrrolidone (NMP), necessitating extensive treatment before discharge.

Emissions from aramid fiber production facilities include volatile organic compounds (VOCs), nitrogen oxides (NOx), and particulate matter. These air pollutants contribute to local air quality degradation and potential health impacts for surrounding communities. Additionally, the strong acids used in production can create acidic waste streams that require neutralization and proper disposal.

Recent advancements in green chemistry approaches have demonstrated potential for reducing environmental impacts while maintaining or improving knot strength properties. Solvent recovery systems have achieved recycling rates of up to 95% for certain production chemicals, significantly reducing waste generation. Closed-loop water systems have demonstrated potential water usage reductions of 60-70% compared to conventional processes.

Life cycle assessment (LCA) studies indicate that optimizing production for better knot strength can actually reduce environmental impacts when considering the full product lifecycle. Stronger fibers typically result in longer-lasting products that require less frequent replacement, offsetting initial production impacts through extended service life.

Regulatory frameworks worldwide are increasingly focusing on chemical management in textile production. The European Union's REACH regulations and similar frameworks in other regions are driving manufacturers toward more environmentally responsible production methods that eliminate substances of very high concern (SVHCs) while maintaining performance characteristics like knot strength.

Water usage represents another critical environmental concern, with conventional aramid fiber production requiring approximately 100-150 liters of water per kilogram of fiber. This water becomes contaminated with various chemical compounds including sulfuric acid, sodium hydroxide, and organic solvents like N-methylpyrrolidone (NMP), necessitating extensive treatment before discharge.

Emissions from aramid fiber production facilities include volatile organic compounds (VOCs), nitrogen oxides (NOx), and particulate matter. These air pollutants contribute to local air quality degradation and potential health impacts for surrounding communities. Additionally, the strong acids used in production can create acidic waste streams that require neutralization and proper disposal.

Recent advancements in green chemistry approaches have demonstrated potential for reducing environmental impacts while maintaining or improving knot strength properties. Solvent recovery systems have achieved recycling rates of up to 95% for certain production chemicals, significantly reducing waste generation. Closed-loop water systems have demonstrated potential water usage reductions of 60-70% compared to conventional processes.

Life cycle assessment (LCA) studies indicate that optimizing production for better knot strength can actually reduce environmental impacts when considering the full product lifecycle. Stronger fibers typically result in longer-lasting products that require less frequent replacement, offsetting initial production impacts through extended service life.

Regulatory frameworks worldwide are increasingly focusing on chemical management in textile production. The European Union's REACH regulations and similar frameworks in other regions are driving manufacturers toward more environmentally responsible production methods that eliminate substances of very high concern (SVHCs) while maintaining performance characteristics like knot strength.

Quality Control Standards and Testing Methodologies

Quality control in aramid fiber production represents a critical component for achieving optimal knot strength. The industry has established comprehensive testing protocols that evaluate fiber performance under various stress conditions. ASTM D7269 and ISO 2062 standards serve as the primary frameworks for testing aramid fiber tensile properties, with specific modifications for knot strength assessment. These standards mandate precise testing environments with controlled temperature (23±2°C) and humidity (65±4%), ensuring consistent and comparable results across different production batches.

Knot strength testing typically employs specialized dynamometers that measure the breaking force of knotted fiber samples at a constant rate of extension. The industry standard requires a minimum of 30 samples per batch to ensure statistical significance, with results typically expressed as a percentage of the fiber's straight tensile strength. Quality control protocols mandate that aramid fibers maintain at least 45-55% of their original tensile strength when knotted, though premium grades often achieve 60-65%.

Non-destructive testing methodologies have gained prominence in recent years, including optical coherence tomography (OCT) and ultrasonic inspection techniques. These methods allow manufacturers to detect structural inconsistencies without compromising fiber integrity. Advanced image analysis software can identify microfibrillar alignment issues that correlate strongly with reduced knot performance, enabling real-time production adjustments.

Statistical process control (SPC) charts have become essential tools in aramid fiber quality management, tracking key parameters such as fiber diameter consistency, surface roughness, and cross-sectional uniformity. Manufacturers implementing Six Sigma methodologies typically maintain process capability indices (Cpk) above 1.33 for critical knot strength parameters, ensuring 99.99% of production meets minimum specifications.

Emerging quality control technologies include artificial intelligence systems that can predict knot strength based on multiple production parameters. These systems analyze data from spinning conditions, coagulation bath chemistry, and drawing ratios to optimize production settings in real-time. Additionally, digital twin modeling allows manufacturers to simulate how process adjustments will affect final knot performance before implementing changes on the production line.

Certification requirements for high-performance applications, particularly in aerospace and military sectors, mandate comprehensive documentation of quality control procedures. This includes traceability of raw materials, detailed process parameter logs, and retention of test samples from each production batch for a minimum of five years. Third-party verification through laboratories accredited under ISO/IEC 17025 provides additional assurance of compliance with industry standards.

Knot strength testing typically employs specialized dynamometers that measure the breaking force of knotted fiber samples at a constant rate of extension. The industry standard requires a minimum of 30 samples per batch to ensure statistical significance, with results typically expressed as a percentage of the fiber's straight tensile strength. Quality control protocols mandate that aramid fibers maintain at least 45-55% of their original tensile strength when knotted, though premium grades often achieve 60-65%.

Non-destructive testing methodologies have gained prominence in recent years, including optical coherence tomography (OCT) and ultrasonic inspection techniques. These methods allow manufacturers to detect structural inconsistencies without compromising fiber integrity. Advanced image analysis software can identify microfibrillar alignment issues that correlate strongly with reduced knot performance, enabling real-time production adjustments.

Statistical process control (SPC) charts have become essential tools in aramid fiber quality management, tracking key parameters such as fiber diameter consistency, surface roughness, and cross-sectional uniformity. Manufacturers implementing Six Sigma methodologies typically maintain process capability indices (Cpk) above 1.33 for critical knot strength parameters, ensuring 99.99% of production meets minimum specifications.

Emerging quality control technologies include artificial intelligence systems that can predict knot strength based on multiple production parameters. These systems analyze data from spinning conditions, coagulation bath chemistry, and drawing ratios to optimize production settings in real-time. Additionally, digital twin modeling allows manufacturers to simulate how process adjustments will affect final knot performance before implementing changes on the production line.

Certification requirements for high-performance applications, particularly in aerospace and military sectors, mandate comprehensive documentation of quality control procedures. This includes traceability of raw materials, detailed process parameter logs, and retention of test samples from each production batch for a minimum of five years. Third-party verification through laboratories accredited under ISO/IEC 17025 provides additional assurance of compliance with industry standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!