Aramid Fiber vs PBO: Maximize Flame Resistance

SEP 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aramid and PBO Fiber Development History and Objectives

The development of high-performance fibers for flame resistance applications has seen significant evolution over the past several decades. Aramid fibers, first developed in the early 1960s by DuPont, represented a revolutionary advancement in synthetic fiber technology. The commercial introduction of Kevlar in 1971 marked a pivotal moment in flame-resistant material development, offering unprecedented thermal stability and mechanical strength. Concurrently, Teijin's Twaron and later Technora expanded the aramid fiber family, each with specific property enhancements targeting different application requirements.

The technological trajectory of aramid fibers has been characterized by continuous improvements in manufacturing processes, resulting in fibers with increasingly refined molecular orientation, crystallinity, and interfacial properties. These advancements have progressively enhanced flame resistance capabilities while maintaining critical mechanical properties such as tensile strength and modulus.

PBO (poly(p-phenylene-2,6-benzobisoxazole)) fiber, commercially known as Zylon, emerged in the 1990s as a next-generation high-performance fiber. Developed by Toyobo, PBO represented a significant leap forward in thermal resistance properties, exhibiting decomposition temperatures approximately 100°C higher than para-aramids. This advancement addressed limitations in aramid's thermal performance ceiling, particularly for extreme temperature applications.

The evolution of both fiber technologies has been driven by increasingly demanding requirements across multiple industries, including aerospace, military, firefighting, and industrial safety. Historical development patterns reveal a consistent focus on improving key performance metrics: limiting oxygen index (LOI), time-to-ignition, heat release rate, and char yield—all critical parameters for flame resistance applications.

Recent technological objectives have centered on addressing specific limitations of each fiber type. For aramids, research has focused on improving UV resistance, reducing moisture sensitivity, and enhancing interfacial properties with matrix materials. For PBO, significant efforts have targeted its susceptibility to strength degradation under certain environmental conditions, particularly hydrolytic stability issues that have limited its broader adoption despite superior thermal properties.

The current technological landscape aims to optimize the balance between flame resistance performance and practical considerations such as processability, long-term durability, and cost-effectiveness. Both fiber technologies continue to evolve toward multi-functional capabilities, where flame resistance is integrated with other performance attributes such as cut resistance, chemical protection, and comfort—reflecting the increasingly complex demands of modern protective applications.

Understanding this developmental history provides essential context for evaluating the comparative advantages of aramid and PBO fibers for maximizing flame resistance in contemporary applications, while also illuminating potential future innovation pathways.

The technological trajectory of aramid fibers has been characterized by continuous improvements in manufacturing processes, resulting in fibers with increasingly refined molecular orientation, crystallinity, and interfacial properties. These advancements have progressively enhanced flame resistance capabilities while maintaining critical mechanical properties such as tensile strength and modulus.

PBO (poly(p-phenylene-2,6-benzobisoxazole)) fiber, commercially known as Zylon, emerged in the 1990s as a next-generation high-performance fiber. Developed by Toyobo, PBO represented a significant leap forward in thermal resistance properties, exhibiting decomposition temperatures approximately 100°C higher than para-aramids. This advancement addressed limitations in aramid's thermal performance ceiling, particularly for extreme temperature applications.

The evolution of both fiber technologies has been driven by increasingly demanding requirements across multiple industries, including aerospace, military, firefighting, and industrial safety. Historical development patterns reveal a consistent focus on improving key performance metrics: limiting oxygen index (LOI), time-to-ignition, heat release rate, and char yield—all critical parameters for flame resistance applications.

Recent technological objectives have centered on addressing specific limitations of each fiber type. For aramids, research has focused on improving UV resistance, reducing moisture sensitivity, and enhancing interfacial properties with matrix materials. For PBO, significant efforts have targeted its susceptibility to strength degradation under certain environmental conditions, particularly hydrolytic stability issues that have limited its broader adoption despite superior thermal properties.

The current technological landscape aims to optimize the balance between flame resistance performance and practical considerations such as processability, long-term durability, and cost-effectiveness. Both fiber technologies continue to evolve toward multi-functional capabilities, where flame resistance is integrated with other performance attributes such as cut resistance, chemical protection, and comfort—reflecting the increasingly complex demands of modern protective applications.

Understanding this developmental history provides essential context for evaluating the comparative advantages of aramid and PBO fibers for maximizing flame resistance in contemporary applications, while also illuminating potential future innovation pathways.

Market Demand Analysis for High-Performance Flame-Resistant Fibers

The global market for high-performance flame-resistant fibers has experienced significant growth in recent years, driven by stringent safety regulations across industries and increasing awareness of workplace safety. The demand for advanced flame-resistant materials like Aramid Fiber and PBO (Polybenzoxazole) continues to expand, particularly in sectors where fire hazards pose substantial risks to human life and property.

Industrial safety represents the largest market segment, with oil and gas, mining, and chemical processing industries requiring flame-resistant protective clothing for workers operating in hazardous environments. According to market research, the industrial protective clothing market reached $9.2 billion in 2022, with flame-resistant segments showing annual growth rates of 6.8%.

The military and defense sector constitutes another major demand driver, where these high-performance fibers are utilized in ballistic protection, aircraft components, and combat uniforms. The defense applications market for advanced fibers is projected to reach $5.7 billion by 2027, with flame resistance being a critical performance parameter alongside ballistic protection.

Aerospace and automotive industries are increasingly adopting these materials for their exceptional thermal stability and mechanical properties. The aerospace composites market, where flame resistance is paramount for passenger safety, is growing at 7.4% annually, creating sustained demand for advanced fibers that can withstand extreme conditions.

Regional analysis reveals that North America currently dominates the market for flame-resistant fibers, accounting for approximately 38% of global consumption. However, the Asia-Pacific region is experiencing the fastest growth rate at 8.2% annually, driven by rapid industrialization, increasing safety regulations, and growing manufacturing activities in China, India, and Southeast Asian countries.

End-user preferences are shifting toward materials that offer multi-hazard protection rather than single-attribute performance. This trend favors materials like PBO and advanced aramids that provide flame resistance alongside other protective properties such as cut resistance, chemical protection, and durability.

Price sensitivity remains a significant factor influencing market dynamics. While PBO offers superior flame resistance compared to aramid fibers, its substantially higher cost (typically 3-4 times that of aramid) limits widespread adoption. This creates a tiered market where premium solutions like PBO are reserved for critical applications where performance justifies the cost premium.

Future market growth is expected to be driven by innovations that reduce production costs while maintaining or enhancing performance characteristics. Materials that can demonstrate quantifiable improvements in flame resistance while offering competitive pricing will likely capture significant market share in the coming years.

Industrial safety represents the largest market segment, with oil and gas, mining, and chemical processing industries requiring flame-resistant protective clothing for workers operating in hazardous environments. According to market research, the industrial protective clothing market reached $9.2 billion in 2022, with flame-resistant segments showing annual growth rates of 6.8%.

The military and defense sector constitutes another major demand driver, where these high-performance fibers are utilized in ballistic protection, aircraft components, and combat uniforms. The defense applications market for advanced fibers is projected to reach $5.7 billion by 2027, with flame resistance being a critical performance parameter alongside ballistic protection.

Aerospace and automotive industries are increasingly adopting these materials for their exceptional thermal stability and mechanical properties. The aerospace composites market, where flame resistance is paramount for passenger safety, is growing at 7.4% annually, creating sustained demand for advanced fibers that can withstand extreme conditions.

Regional analysis reveals that North America currently dominates the market for flame-resistant fibers, accounting for approximately 38% of global consumption. However, the Asia-Pacific region is experiencing the fastest growth rate at 8.2% annually, driven by rapid industrialization, increasing safety regulations, and growing manufacturing activities in China, India, and Southeast Asian countries.

End-user preferences are shifting toward materials that offer multi-hazard protection rather than single-attribute performance. This trend favors materials like PBO and advanced aramids that provide flame resistance alongside other protective properties such as cut resistance, chemical protection, and durability.

Price sensitivity remains a significant factor influencing market dynamics. While PBO offers superior flame resistance compared to aramid fibers, its substantially higher cost (typically 3-4 times that of aramid) limits widespread adoption. This creates a tiered market where premium solutions like PBO are reserved for critical applications where performance justifies the cost premium.

Future market growth is expected to be driven by innovations that reduce production costs while maintaining or enhancing performance characteristics. Materials that can demonstrate quantifiable improvements in flame resistance while offering competitive pricing will likely capture significant market share in the coming years.

Current Technical Status and Challenges in Flame-Resistant Fiber Technology

The global flame-resistant fiber market has witnessed significant advancements in recent years, with aramid fibers and polybenzoxazole (PBO) fibers emerging as leading materials. Currently, aramid fibers dominate the market with approximately 65% share, primarily due to their established manufacturing processes and relatively lower production costs. Major producers include DuPont (Kevlar), Teijin (Twaron), and Kolon Industries (Heracron), with production capacities exceeding 70,000 tons annually worldwide.

PBO fibers, represented primarily by Toyobo's Zylon, occupy a smaller but growing segment of approximately 15% market share. Despite limited production facilities concentrated in Japan and the United States, PBO has demonstrated superior thermal performance with decomposition temperatures reaching 650°C compared to aramid's 500°C threshold. This performance advantage has driven increased adoption in specialized high-temperature applications despite significantly higher costs.

Recent technological developments have focused on enhancing the flame resistance properties of both fiber types. For aramid fibers, innovations include modified polymer structures with increased aromatic content and improved spinning techniques that enhance crystallinity. These advancements have improved thermal stability by approximately 10-15% over traditional aramid formulations. Similarly, PBO fiber technology has evolved with new precursor materials and cross-linking agents that further elevate its already superior flame resistance.

The primary technical challenges facing both fiber types center around balancing flame resistance with other critical performance parameters. For aramid fibers, researchers struggle with improving UV resistance without compromising thermal stability, as current formulations experience up to 50% strength degradation after prolonged UV exposure. Moisture absorption, typically 4-6% for aramids, also remains problematic as it can affect dimensional stability in flame-resistant applications.

PBO fibers face more severe challenges regarding hydrolytic stability, with strength losses of up to 35% reported after exposure to humid conditions for extended periods. Additionally, the complex manufacturing process for PBO involves highly toxic precursors and solvents, creating significant environmental and safety concerns that limit production scaling.

Cost-effectiveness represents another major hurdle, particularly for PBO fibers which can cost 5-8 times more than comparable aramid products. This price differential has restricted PBO adoption to only the most demanding applications where performance requirements justify the premium. Meanwhile, aramid fiber production faces challenges in reducing energy consumption, which currently averages 120-150 kWh per kilogram of fiber produced.

Geographically, flame-resistant fiber technology development remains concentrated in a few countries. Japan leads in PBO innovation with over 60% of related patents, while the United States and Western Europe dominate aramid fiber technology advancement. Emerging economies, particularly China and India, are rapidly developing manufacturing capabilities but still lag in fundamental research and innovation.

PBO fibers, represented primarily by Toyobo's Zylon, occupy a smaller but growing segment of approximately 15% market share. Despite limited production facilities concentrated in Japan and the United States, PBO has demonstrated superior thermal performance with decomposition temperatures reaching 650°C compared to aramid's 500°C threshold. This performance advantage has driven increased adoption in specialized high-temperature applications despite significantly higher costs.

Recent technological developments have focused on enhancing the flame resistance properties of both fiber types. For aramid fibers, innovations include modified polymer structures with increased aromatic content and improved spinning techniques that enhance crystallinity. These advancements have improved thermal stability by approximately 10-15% over traditional aramid formulations. Similarly, PBO fiber technology has evolved with new precursor materials and cross-linking agents that further elevate its already superior flame resistance.

The primary technical challenges facing both fiber types center around balancing flame resistance with other critical performance parameters. For aramid fibers, researchers struggle with improving UV resistance without compromising thermal stability, as current formulations experience up to 50% strength degradation after prolonged UV exposure. Moisture absorption, typically 4-6% for aramids, also remains problematic as it can affect dimensional stability in flame-resistant applications.

PBO fibers face more severe challenges regarding hydrolytic stability, with strength losses of up to 35% reported after exposure to humid conditions for extended periods. Additionally, the complex manufacturing process for PBO involves highly toxic precursors and solvents, creating significant environmental and safety concerns that limit production scaling.

Cost-effectiveness represents another major hurdle, particularly for PBO fibers which can cost 5-8 times more than comparable aramid products. This price differential has restricted PBO adoption to only the most demanding applications where performance requirements justify the premium. Meanwhile, aramid fiber production faces challenges in reducing energy consumption, which currently averages 120-150 kWh per kilogram of fiber produced.

Geographically, flame-resistant fiber technology development remains concentrated in a few countries. Japan leads in PBO innovation with over 60% of related patents, while the United States and Western Europe dominate aramid fiber technology advancement. Emerging economies, particularly China and India, are rapidly developing manufacturing capabilities but still lag in fundamental research and innovation.

Comparative Analysis of Aramid vs PBO Flame Resistance Properties

01 Comparative flame resistance properties of Aramid and PBO fibers

Aramid fibers and PBO (Polybenzoxazole) fibers both exhibit excellent flame resistance properties, but with distinct characteristics. PBO fibers generally demonstrate superior thermal stability and flame resistance compared to aramid fibers, with higher limiting oxygen index (LOI) values and decomposition temperatures. Aramid fibers, while still highly flame resistant, typically char rather than melt when exposed to flame. These comparative properties make them suitable for different applications requiring flame resistance, with selection depending on specific performance requirements and environmental conditions.- Comparative flame resistance properties of Aramid and PBO fibers: Aramid fibers and PBO (Polybenzoxazole) fibers both exhibit excellent flame resistance properties, but with distinct characteristics. PBO fibers generally demonstrate superior thermal stability and flame resistance compared to aramid fibers, with higher limiting oxygen index (LOI) values and decomposition temperatures. These comparative advantages make PBO particularly suitable for extreme high-temperature applications where aramid fibers might reach their performance limits. The inherent molecular structure of both fiber types contributes to their self-extinguishing properties when removed from flame sources.

- Composite materials combining Aramid and PBO fibers: Composite materials that combine aramid and PBO fibers leverage the complementary properties of both materials to achieve enhanced flame resistance. These hybrid composites often demonstrate improved mechanical properties while maintaining excellent thermal stability. The synergistic effect of combining these fibers results in materials that can withstand higher temperatures and provide better protection against flame spread than single-fiber materials. Applications include protective clothing, industrial filtration systems, and components for aerospace and automotive industries where both heat resistance and mechanical strength are required.

- Manufacturing processes for flame-resistant Aramid and PBO textiles: Specialized manufacturing processes are employed to produce flame-resistant textiles from aramid and PBO fibers. These processes include specific spinning techniques, heat treatment protocols, and surface modifications that enhance the inherent flame-resistant properties of the fibers. The manufacturing methods often involve precise control of processing parameters such as temperature, tension, and chemical treatments to optimize the flame resistance performance. Advanced weaving and knitting techniques are also utilized to create textile structures that maximize protection against heat and flame while maintaining comfort and flexibility.

- Flame-resistant coatings and treatments for Aramid and PBO materials: Various coatings and chemical treatments can be applied to aramid and PBO materials to further enhance their flame resistance properties. These treatments include the application of flame retardant chemicals, silicone-based coatings, and phosphorus-containing compounds that create additional barriers against heat and flame. Some treatments focus on reducing the emission of toxic gases during combustion, while others aim to improve the char formation that protects underlying materials. These enhanced materials find applications in firefighting equipment, military gear, and industrial safety products where maximum flame protection is critical.

- Applications of flame-resistant Aramid and PBO fiber products: Flame-resistant aramid and PBO fiber products are utilized across numerous high-performance applications where fire protection is critical. These applications include protective clothing for firefighters and industrial workers, heat shields in aerospace and automotive industries, electrical insulation materials, and reinforcement components in high-temperature environments. The selection between aramid and PBO fibers for specific applications depends on factors such as required temperature resistance, mechanical property needs, exposure duration, and cost considerations. Recent innovations have expanded their use in emerging fields such as energy storage systems and advanced electronics where thermal management is essential.

02 Blended fiber compositions for enhanced flame resistance

Blending aramid fibers or PBO fibers with other materials can enhance overall flame resistance properties while addressing specific application requirements. These blends often combine the inherent flame resistance of aramid or PBO with complementary properties from other fibers such as carbon fibers, glass fibers, or flame-retardant treated natural fibers. The resulting composite materials maintain high flame resistance while potentially improving other characteristics such as mechanical strength, flexibility, or cost-effectiveness. The specific blend ratios are typically optimized based on the intended application and required performance standards.Expand Specific Solutions03 Manufacturing processes for flame-resistant aramid and PBO fibers

Specialized manufacturing processes are employed to produce flame-resistant aramid and PBO fibers with optimized properties. These processes typically involve solution spinning techniques, where polymer solutions are extruded through spinnerets and subjected to specific temperature and tension conditions. Post-processing treatments such as heat setting, surface modifications, or chemical treatments may be applied to further enhance flame resistance properties. The manufacturing parameters significantly influence the final fiber properties, including crystallinity, orientation, and thermal stability, which directly affect flame resistance performance.Expand Specific Solutions04 Applications of flame-resistant aramid and PBO fibers in protective equipment

Flame-resistant aramid and PBO fibers are extensively used in various protective equipment applications where fire safety is critical. These applications include firefighting gear, military protective clothing, industrial safety equipment, and heat-resistant gloves. The fibers can be processed into fabrics, composites, or other forms to create protective barriers against heat and flame. Their inherent flame resistance, combined with other properties such as high strength-to-weight ratio and durability, makes them ideal for situations where personnel protection from fire hazards is essential.Expand Specific Solutions05 Surface treatments and coatings to enhance flame resistance

Various surface treatments and coating technologies can be applied to aramid and PBO fibers to further enhance their flame resistance properties. These treatments may include application of flame retardant chemicals, ceramic coatings, or other specialized compounds that create additional thermal barriers. Some treatments focus on reducing the generation of toxic gases during combustion, while others aim to improve char formation or increase the limiting oxygen index. These surface modifications can be tailored to specific end-use requirements while maintaining the inherent mechanical properties of the base fibers.Expand Specific Solutions

Key Manufacturers and Competitive Landscape in Advanced Fiber Industry

The flame resistance market for high-performance fibers is currently in a growth phase, with aramid fibers dominating but PBO (poly-p-phenylene-2,6-benzobisoxazole) gaining traction due to superior thermal properties. The global market size for flame-resistant materials is expanding rapidly, driven by stringent safety regulations across industries. DuPont leads the aramid sector with its Kevlar and Nomex brands, while Toyobo's Zylon (PBO) offers higher temperature resistance despite higher costs. Research institutions like Donghua University and companies including W.L. Gore, Kaneka, and State Grid are advancing applications in protective clothing, military equipment, and industrial safety. Chinese manufacturers such as Zhonglan Chenguang are emerging as significant competitors, challenging traditional market leaders through increased R&D investment.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered extensive research comparing Aramid Fiber (Nomex® and Kevlar®) with PBO (Zylon®) for flame resistance applications. Their technical approach involves molecular structure optimization of meta-aramid fibers to achieve superior thermal stability. DuPont's Nomex® undergoes a proprietary crystallization process that creates a more compact molecular structure, enabling it to withstand temperatures up to 370°C without significant degradation. Their comparative testing demonstrates that while PBO initially shows higher LOI (Limiting Oxygen Index) values of 68% compared to aramids' 28-30%, aramid fibers maintain structural integrity for longer periods under sustained flame exposure. DuPont has developed specialized blends of different aramid variants to optimize both initial flame resistance and long-term thermal protection, particularly important in firefighting gear and industrial safety applications.

Strengths: DuPont's aramid fibers demonstrate exceptional long-term thermal stability and maintain mechanical properties after heat exposure better than PBO. Their established manufacturing infrastructure allows for consistent quality control and scalable production. Weaknesses: Aramid fibers generally have lower initial flame resistance metrics compared to PBO and require higher material thickness to achieve equivalent short-duration protection levels.

Kaneka Corp.

Technical Solution: Kaneka Corporation has developed advanced PBO fiber technology (marketed as Zylon®) specifically engineered for extreme flame resistance applications. Their technical approach focuses on the rigid rod-like molecular structure of PBO (poly-p-phenylene benzobisoxazole), which provides inherently superior thermal properties. Kaneka's manufacturing process involves precise control of polymerization conditions and specialized post-treatment techniques that enhance flame resistance while addressing PBO's known sensitivity to UV and moisture. Their comparative testing against aramid fibers shows that Zylon® maintains tensile strength at temperatures up to 650°C, significantly outperforming aramids in short-duration extreme heat scenarios. Kaneka has also developed proprietary coating technologies to mitigate PBO's hydrolytic degradation issues, extending the functional lifespan of their flame-resistant materials while maintaining the superior initial flame resistance properties.

Strengths: Kaneka's PBO fibers demonstrate exceptional initial flame resistance with LOI values more than twice that of standard aramids, and maintain mechanical integrity at temperatures 200-300°C higher than aramid alternatives. Weaknesses: Despite improvements, PBO still exhibits vulnerability to strength loss through hydrolysis and UV exposure over time, requiring additional protective measures for long-term applications in variable environmental conditions.

Critical Patents and Research in High-Temperature Resistant Fiber Development

Thermally protective materials

PatentActiveEP3434476A1

Innovation

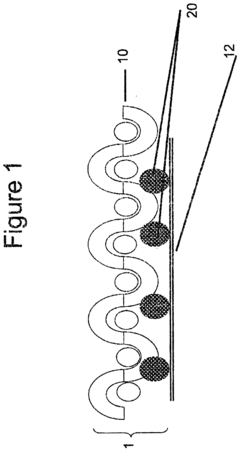

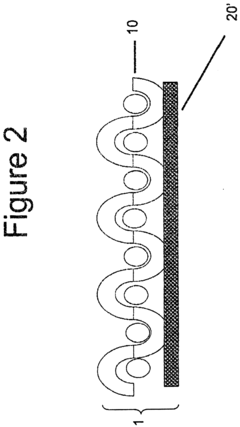

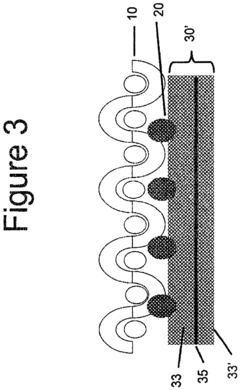

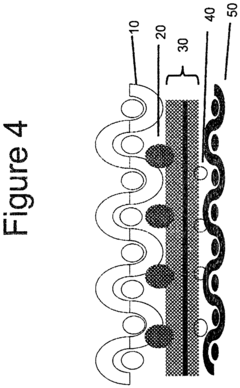

- A polymer resin-expandable graphite mixture is applied to thermally stable textiles, which expands by at least 200% when exposed to 300°C, providing enhanced thermal protective performance while maintaining breathability and flexibility, and is applied in a discontinuous pattern to optimize surface coverage and spacing for effective heat dissipation.

pbo fiber showing improved mechanical properties even when exposed to high temperature and high relative humidity

PatentInactiveJP2015519482A

Innovation

- A treatment method involving supercritical CO2 with 3-glycidoxypropylmethyldimethoxysilane (scCO2 + Additive B) is used to infuse PBO fibers, reacting with or removing residual phosphoric acid, thereby enhancing their mechanical properties under high temperature and humidity conditions.

Safety Standards and Certification Requirements for Flame-Resistant Materials

The global landscape for flame-resistant materials is governed by a complex network of safety standards and certification requirements that vary by region, industry, and application. For aramid fibers and PBO (Polybenzoxazole), compliance with these standards is crucial for market acceptance and legal usage in high-risk environments.

In the United States, the National Fire Protection Association (NFPA) establishes several key standards including NFPA 1971 for firefighting gear and NFPA 2112 for industrial flame-resistant clothing. These standards specify minimum performance requirements for heat transfer, flame resistance, and thermal stability. Both aramid fibers and PBO must undergo rigorous testing under these protocols, with PBO typically demonstrating superior performance in extreme temperature scenarios.

The European Union enforces the EN ISO 11612 standard, which classifies flame-resistant materials based on their performance across multiple hazard categories. Materials receive ratings from A1/A2 (limited flame spread) through F (molten metal splash resistance). Aramid fibers generally achieve strong ratings across categories B-E, while PBO excels particularly in categories B (convective heat) and C (radiant heat).

For military applications, MIL-DTL-32102 in the United States and similar standards internationally establish stringent requirements for flame resistance in combat uniforms and protective equipment. These standards often include additional requirements for durability after repeated laundering, which can affect the long-term performance comparison between aramid fibers and PBO.

The testing methodologies for certification include vertical flame tests (ASTM D6413), thermal protective performance tests (ASTM F2700), and heat transfer performance evaluations (ASTM F2702). PBO typically demonstrates 30-40% higher thermal protective performance values compared to aramid fibers in these standardized tests, though this advantage comes with significantly higher material costs.

Industrial sectors such as oil and gas, electrical utilities, and chemical manufacturing often have additional industry-specific standards like ASTM F1506 for electrical arc protection. The certification process for these standards requires manufacturers to submit materials for independent laboratory testing and maintain documentation of compliance, creating substantial barriers to entry for new materials and technologies.

Emerging markets are increasingly adopting international standards, with ISO 11612 and ISO 16073 becoming global benchmarks for flame-resistant protective clothing. This harmonization of standards is gradually reducing regional variations, though significant differences in implementation and enforcement remain between developed and developing economies.

In the United States, the National Fire Protection Association (NFPA) establishes several key standards including NFPA 1971 for firefighting gear and NFPA 2112 for industrial flame-resistant clothing. These standards specify minimum performance requirements for heat transfer, flame resistance, and thermal stability. Both aramid fibers and PBO must undergo rigorous testing under these protocols, with PBO typically demonstrating superior performance in extreme temperature scenarios.

The European Union enforces the EN ISO 11612 standard, which classifies flame-resistant materials based on their performance across multiple hazard categories. Materials receive ratings from A1/A2 (limited flame spread) through F (molten metal splash resistance). Aramid fibers generally achieve strong ratings across categories B-E, while PBO excels particularly in categories B (convective heat) and C (radiant heat).

For military applications, MIL-DTL-32102 in the United States and similar standards internationally establish stringent requirements for flame resistance in combat uniforms and protective equipment. These standards often include additional requirements for durability after repeated laundering, which can affect the long-term performance comparison between aramid fibers and PBO.

The testing methodologies for certification include vertical flame tests (ASTM D6413), thermal protective performance tests (ASTM F2700), and heat transfer performance evaluations (ASTM F2702). PBO typically demonstrates 30-40% higher thermal protective performance values compared to aramid fibers in these standardized tests, though this advantage comes with significantly higher material costs.

Industrial sectors such as oil and gas, electrical utilities, and chemical manufacturing often have additional industry-specific standards like ASTM F1506 for electrical arc protection. The certification process for these standards requires manufacturers to submit materials for independent laboratory testing and maintain documentation of compliance, creating substantial barriers to entry for new materials and technologies.

Emerging markets are increasingly adopting international standards, with ISO 11612 and ISO 16073 becoming global benchmarks for flame-resistant protective clothing. This harmonization of standards is gradually reducing regional variations, though significant differences in implementation and enforcement remain between developed and developing economies.

Environmental Impact and Sustainability of Advanced Flame-Resistant Fibers

The environmental footprint of flame-resistant fibers has become increasingly important as industries seek sustainable solutions without compromising safety performance. Both Aramid and PBO fibers present distinct environmental considerations throughout their lifecycle, from raw material extraction to end-of-life management.

Aramid fiber production involves petroleum-based precursors and energy-intensive manufacturing processes, resulting in significant carbon emissions. The production requires hazardous chemicals such as sulfuric acid and N-methylpyrrolidone, which pose environmental risks if not properly managed. However, aramid fibers demonstrate excellent durability, extending product lifespans and reducing replacement frequency, which partially offsets their initial environmental impact.

PBO fiber manufacturing similarly demands substantial energy inputs but utilizes different chemical pathways involving polyphosphoric acid as a condensation medium. This process generates different waste streams compared to aramid production, with potentially higher toxicity concerns in some aspects. The environmental advantage of PBO lies in its superior performance characteristics, potentially allowing for reduced material usage to achieve equivalent protection levels.

Recycling capabilities represent a critical sustainability factor for both materials. Aramid fibers benefit from more established recycling infrastructure, with mechanical recycling methods already implemented in some regions. These recycled aramids find applications in composite reinforcement and non-critical applications. PBO recycling technology remains less developed, creating challenges for circular economy integration.

Water consumption patterns differ significantly between these advanced fibers. Aramid production typically requires substantial water for processing and cooling, while PBO manufacturing may have lower direct water requirements but potentially higher impacts on water quality due to specific chemical effluents. Both industries have been implementing water recycling systems to mitigate these impacts.

Biodegradability presents challenges for both fiber types, as their exceptional chemical resistance translates to persistence in natural environments. Neither aramid nor PBO fibers readily degrade under natural conditions, raising concerns about microfiber pollution. Research into biodegradable flame-resistant alternatives and controlled degradation catalysts represents an emerging field addressing this limitation.

Carbon footprint assessments indicate that the extended service life of these materials often compensates for manufacturing impacts when compared to less durable alternatives requiring frequent replacement. Life cycle analyses suggest that optimizing production efficiency, implementing closed-loop manufacturing systems, and developing effective end-of-life management strategies offer the most promising pathways toward improving the sustainability profile of advanced flame-resistant fibers.

Aramid fiber production involves petroleum-based precursors and energy-intensive manufacturing processes, resulting in significant carbon emissions. The production requires hazardous chemicals such as sulfuric acid and N-methylpyrrolidone, which pose environmental risks if not properly managed. However, aramid fibers demonstrate excellent durability, extending product lifespans and reducing replacement frequency, which partially offsets their initial environmental impact.

PBO fiber manufacturing similarly demands substantial energy inputs but utilizes different chemical pathways involving polyphosphoric acid as a condensation medium. This process generates different waste streams compared to aramid production, with potentially higher toxicity concerns in some aspects. The environmental advantage of PBO lies in its superior performance characteristics, potentially allowing for reduced material usage to achieve equivalent protection levels.

Recycling capabilities represent a critical sustainability factor for both materials. Aramid fibers benefit from more established recycling infrastructure, with mechanical recycling methods already implemented in some regions. These recycled aramids find applications in composite reinforcement and non-critical applications. PBO recycling technology remains less developed, creating challenges for circular economy integration.

Water consumption patterns differ significantly between these advanced fibers. Aramid production typically requires substantial water for processing and cooling, while PBO manufacturing may have lower direct water requirements but potentially higher impacts on water quality due to specific chemical effluents. Both industries have been implementing water recycling systems to mitigate these impacts.

Biodegradability presents challenges for both fiber types, as their exceptional chemical resistance translates to persistence in natural environments. Neither aramid nor PBO fibers readily degrade under natural conditions, raising concerns about microfiber pollution. Research into biodegradable flame-resistant alternatives and controlled degradation catalysts represents an emerging field addressing this limitation.

Carbon footprint assessments indicate that the extended service life of these materials often compensates for manufacturing impacts when compared to less durable alternatives requiring frequent replacement. Life cycle analyses suggest that optimizing production efficiency, implementing closed-loop manufacturing systems, and developing effective end-of-life management strategies offer the most promising pathways toward improving the sustainability profile of advanced flame-resistant fibers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!