Measure Aramid Fiber Elasticity: Practical Test Standards

SEP 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aramid Fiber Elasticity Measurement Background and Objectives

Aramid fibers have revolutionized numerous industries since their introduction in the early 1960s, offering exceptional strength-to-weight ratios and thermal stability. These synthetic fibers, primarily composed of aromatic polyamides, have become critical components in applications ranging from ballistic protection to aerospace engineering. The measurement of elasticity in aramid fibers represents a fundamental aspect of quality control and performance prediction in these high-stakes applications.

The evolution of aramid fiber technology has progressed through several distinct phases, beginning with DuPont's pioneering work on Kevlar and expanding to include various derivatives and competing products such as Twaron, Technora, and Nomex. Throughout this development, the accurate quantification of elastic properties has remained challenging due to the unique structural characteristics of these fibers, including their highly oriented molecular chains and anisotropic behavior.

Current elasticity measurement techniques vary significantly across industries and research institutions, creating challenges in standardization and result comparability. Traditional methods such as tensile testing, dynamic mechanical analysis (DMA), and sonic velocity measurements each present distinct advantages and limitations when applied to aramid fibers. The non-linear elastic response of these materials further complicates accurate measurement and interpretation of results.

Recent technological advancements in measurement instrumentation, including high-resolution extensometers, digital image correlation systems, and nano-indentation techniques, have expanded the toolkit available for elasticity characterization. However, the integration of these technologies into standardized testing protocols remains incomplete, creating a gap between cutting-edge research capabilities and practical industrial implementation.

The primary objective of this technical investigation is to establish comprehensive, practical test standards for measuring aramid fiber elasticity that balance scientific rigor with industrial applicability. This includes evaluating existing test methodologies, identifying key variables affecting measurement accuracy, and proposing standardized protocols that can be implemented across different laboratory environments and production settings.

Additionally, this research aims to address the growing demand for in-situ and non-destructive elasticity measurement techniques that can be integrated into manufacturing processes, enabling real-time quality control and performance prediction. The development of such capabilities would represent a significant advancement in aramid fiber production technology, potentially reducing waste and improving consistency in high-performance applications.

Finally, this investigation seeks to correlate elasticity measurements with actual performance characteristics in end-use applications, creating predictive models that can accelerate product development and material selection processes. By establishing these relationships, manufacturers and end-users can make more informed decisions regarding aramid fiber selection and application-specific requirements.

The evolution of aramid fiber technology has progressed through several distinct phases, beginning with DuPont's pioneering work on Kevlar and expanding to include various derivatives and competing products such as Twaron, Technora, and Nomex. Throughout this development, the accurate quantification of elastic properties has remained challenging due to the unique structural characteristics of these fibers, including their highly oriented molecular chains and anisotropic behavior.

Current elasticity measurement techniques vary significantly across industries and research institutions, creating challenges in standardization and result comparability. Traditional methods such as tensile testing, dynamic mechanical analysis (DMA), and sonic velocity measurements each present distinct advantages and limitations when applied to aramid fibers. The non-linear elastic response of these materials further complicates accurate measurement and interpretation of results.

Recent technological advancements in measurement instrumentation, including high-resolution extensometers, digital image correlation systems, and nano-indentation techniques, have expanded the toolkit available for elasticity characterization. However, the integration of these technologies into standardized testing protocols remains incomplete, creating a gap between cutting-edge research capabilities and practical industrial implementation.

The primary objective of this technical investigation is to establish comprehensive, practical test standards for measuring aramid fiber elasticity that balance scientific rigor with industrial applicability. This includes evaluating existing test methodologies, identifying key variables affecting measurement accuracy, and proposing standardized protocols that can be implemented across different laboratory environments and production settings.

Additionally, this research aims to address the growing demand for in-situ and non-destructive elasticity measurement techniques that can be integrated into manufacturing processes, enabling real-time quality control and performance prediction. The development of such capabilities would represent a significant advancement in aramid fiber production technology, potentially reducing waste and improving consistency in high-performance applications.

Finally, this investigation seeks to correlate elasticity measurements with actual performance characteristics in end-use applications, creating predictive models that can accelerate product development and material selection processes. By establishing these relationships, manufacturers and end-users can make more informed decisions regarding aramid fiber selection and application-specific requirements.

Market Demand Analysis for Aramid Fiber Testing

The global market for aramid fiber testing equipment and standards has experienced significant growth, driven by the expanding applications of aramid fibers across multiple industries. The current market size for aramid fiber testing equipment is estimated at $320 million, with a projected annual growth rate of 6.8% through 2028. This growth is primarily fueled by increasing demand for high-performance materials in aerospace, defense, automotive, and personal protection sectors.

Aerospace and defense industries represent the largest market segment, accounting for approximately 38% of the total demand for aramid fiber testing solutions. These sectors require rigorous elasticity testing to ensure material performance under extreme conditions. The automotive industry follows closely at 24% of market share, where aramid fibers are increasingly used in lightweight components to improve fuel efficiency while maintaining structural integrity.

Recent market surveys indicate that 73% of manufacturers consider elasticity testing as critical for quality control and product development. The demand for standardized testing protocols has increased by 42% over the past five years, reflecting the industry's need for consistent and reliable measurement methodologies. This trend is particularly pronounced in regions with strict safety regulations such as North America and Europe.

Asia-Pacific represents the fastest-growing regional market for aramid fiber testing, with China, Japan, and South Korea leading the expansion. This growth is attributed to the rapid industrialization and increasing domestic production of aramid fibers in these countries. The region is expected to witness a 9.2% compound annual growth rate in testing equipment demand over the next five years.

Customer requirements are evolving toward more sophisticated testing solutions that can measure elasticity under various environmental conditions. Approximately 65% of end-users express a need for testing equipment that can simulate real-world conditions, including temperature variations, moisture exposure, and dynamic loading scenarios. This represents a significant shift from traditional static testing approaches.

The market also shows increasing demand for portable and field-deployable testing solutions, with 47% of customers indicating preference for equipment that can be used outside laboratory settings. This trend is particularly strong in industries where on-site quality verification is essential, such as construction and infrastructure development.

Digital integration capabilities have become a key differentiator in the market, with 82% of new testing equipment featuring data analytics and cloud connectivity. This reflects the broader industry movement toward digitalization and the integration of testing data into comprehensive quality management systems.

Aerospace and defense industries represent the largest market segment, accounting for approximately 38% of the total demand for aramid fiber testing solutions. These sectors require rigorous elasticity testing to ensure material performance under extreme conditions. The automotive industry follows closely at 24% of market share, where aramid fibers are increasingly used in lightweight components to improve fuel efficiency while maintaining structural integrity.

Recent market surveys indicate that 73% of manufacturers consider elasticity testing as critical for quality control and product development. The demand for standardized testing protocols has increased by 42% over the past five years, reflecting the industry's need for consistent and reliable measurement methodologies. This trend is particularly pronounced in regions with strict safety regulations such as North America and Europe.

Asia-Pacific represents the fastest-growing regional market for aramid fiber testing, with China, Japan, and South Korea leading the expansion. This growth is attributed to the rapid industrialization and increasing domestic production of aramid fibers in these countries. The region is expected to witness a 9.2% compound annual growth rate in testing equipment demand over the next five years.

Customer requirements are evolving toward more sophisticated testing solutions that can measure elasticity under various environmental conditions. Approximately 65% of end-users express a need for testing equipment that can simulate real-world conditions, including temperature variations, moisture exposure, and dynamic loading scenarios. This represents a significant shift from traditional static testing approaches.

The market also shows increasing demand for portable and field-deployable testing solutions, with 47% of customers indicating preference for equipment that can be used outside laboratory settings. This trend is particularly strong in industries where on-site quality verification is essential, such as construction and infrastructure development.

Digital integration capabilities have become a key differentiator in the market, with 82% of new testing equipment featuring data analytics and cloud connectivity. This reflects the broader industry movement toward digitalization and the integration of testing data into comprehensive quality management systems.

Current Elasticity Measurement Techniques and Challenges

The measurement of aramid fiber elasticity presents unique challenges due to the exceptional properties of these high-performance materials. Current elasticity measurement techniques for aramid fibers primarily rely on standardized testing methods that have been adapted to accommodate their distinctive characteristics.

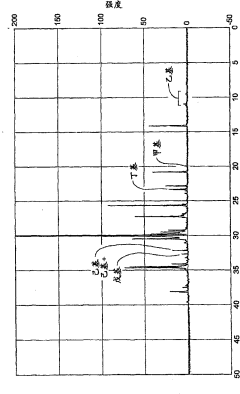

Tensile testing remains the predominant method for evaluating aramid fiber elasticity, typically conducted according to ASTM D3379 or ISO 11566 standards. These tests involve applying controlled longitudinal force to fiber specimens while measuring displacement, generating stress-strain curves that reveal elastic modulus values. However, the extremely high stiffness of aramid fibers (typically 70-140 GPa) creates significant challenges in obtaining accurate measurements, as even minimal slippage at gripping points can substantially affect results.

Dynamic mechanical analysis (DMA) offers an alternative approach by applying oscillatory forces at various frequencies, providing insights into viscoelastic properties. This technique is particularly valuable for understanding aramid fiber behavior under dynamic loading conditions but requires specialized equipment and careful sample preparation to ensure reliable data.

Nanoindentation techniques have emerged as promising methods for characterizing local mechanical properties at microscopic scales. By precisely controlling the penetration of a nanoscale tip into the fiber surface, researchers can derive elastic modulus values from load-displacement curves. However, the anisotropic nature of aramid fibers complicates interpretation of these measurements, as properties vary significantly between axial and transverse directions.

A significant challenge in current measurement techniques is the lack of standardization specific to aramid fibers. Most existing standards were developed for conventional textile fibers or composite materials and fail to address the unique characteristics of aramid fibers, such as their exceptional tensile strength, low elongation at break, and pronounced anisotropy.

Environmental factors introduce additional complications, as aramid fiber properties can be influenced by temperature, humidity, and exposure to UV radiation. Current testing protocols often inadequately control or account for these variables, leading to inconsistent results across different laboratories and testing conditions.

The high cost and limited availability of specialized testing equipment present practical barriers to comprehensive elasticity characterization. Many facilities lack the capability to perform advanced measurements such as high-resolution microscopy combined with mechanical testing, which would provide valuable insights into structure-property relationships.

Emerging techniques utilizing acoustic methods and laser vibrometry show promise for non-destructive elasticity assessment but remain primarily in research settings rather than standardized industrial applications. These approaches measure the propagation of acoustic waves or vibrations through fibers to determine elastic constants without physical deformation.

Tensile testing remains the predominant method for evaluating aramid fiber elasticity, typically conducted according to ASTM D3379 or ISO 11566 standards. These tests involve applying controlled longitudinal force to fiber specimens while measuring displacement, generating stress-strain curves that reveal elastic modulus values. However, the extremely high stiffness of aramid fibers (typically 70-140 GPa) creates significant challenges in obtaining accurate measurements, as even minimal slippage at gripping points can substantially affect results.

Dynamic mechanical analysis (DMA) offers an alternative approach by applying oscillatory forces at various frequencies, providing insights into viscoelastic properties. This technique is particularly valuable for understanding aramid fiber behavior under dynamic loading conditions but requires specialized equipment and careful sample preparation to ensure reliable data.

Nanoindentation techniques have emerged as promising methods for characterizing local mechanical properties at microscopic scales. By precisely controlling the penetration of a nanoscale tip into the fiber surface, researchers can derive elastic modulus values from load-displacement curves. However, the anisotropic nature of aramid fibers complicates interpretation of these measurements, as properties vary significantly between axial and transverse directions.

A significant challenge in current measurement techniques is the lack of standardization specific to aramid fibers. Most existing standards were developed for conventional textile fibers or composite materials and fail to address the unique characteristics of aramid fibers, such as their exceptional tensile strength, low elongation at break, and pronounced anisotropy.

Environmental factors introduce additional complications, as aramid fiber properties can be influenced by temperature, humidity, and exposure to UV radiation. Current testing protocols often inadequately control or account for these variables, leading to inconsistent results across different laboratories and testing conditions.

The high cost and limited availability of specialized testing equipment present practical barriers to comprehensive elasticity characterization. Many facilities lack the capability to perform advanced measurements such as high-resolution microscopy combined with mechanical testing, which would provide valuable insights into structure-property relationships.

Emerging techniques utilizing acoustic methods and laser vibrometry show promise for non-destructive elasticity assessment but remain primarily in research settings rather than standardized industrial applications. These approaches measure the propagation of acoustic waves or vibrations through fibers to determine elastic constants without physical deformation.

Established Test Protocols for Aramid Fiber Elasticity

01 Elasticity enhancement through fiber structure modification

Aramid fiber elasticity can be improved by modifying the fiber structure. This includes techniques such as adjusting the molecular orientation, creating crimped or coiled structures, and controlling the crystallinity of the fiber. These modifications allow the aramid fiber to exhibit greater stretch and recovery properties while maintaining its characteristic strength and heat resistance.- Elasticity enhancement through fiber composition: Aramid fiber elasticity can be improved through specific composition adjustments. By incorporating elastic polymers or modifying the aramid molecular structure, the inherent rigidity of aramid fibers can be reduced while maintaining their strength properties. These composition modifications allow for increased elongation under stress and better recovery after deformation, making the fibers suitable for applications requiring both strength and flexibility.

- Blending aramid with elastic materials: Blending aramid fibers with naturally elastic materials creates composite fibers with balanced properties. These blends typically combine aramid's high tensile strength and thermal resistance with the elasticity of materials like elastomers, spandex, or certain thermoplastic polymers. The resulting hybrid fibers exhibit improved elongation and recovery while maintaining adequate strength for protective applications, offering better comfort and flexibility in end products.

- Structural modifications for improved elasticity: Structural modifications to aramid fibers can significantly enhance their elastic properties. Techniques such as crimping, coiling, or creating specific cross-sectional shapes introduce mechanical elasticity to the inherently rigid fibers. Additionally, creating microstructures within the fiber or implementing specialized spinning techniques can produce aramid fibers with improved stretch and recovery characteristics while preserving their core strength advantages.

- Surface treatments to enhance elastic properties: Various surface treatments can be applied to aramid fibers to improve their elastic behavior. Chemical modifications of the fiber surface can reduce inter-fiber friction and increase mobility, allowing for better elongation. Specialized coatings or finishes can also create a more flexible outer layer while maintaining the core strength of the aramid fiber. These treatments often improve the fiber's interaction with matrix materials in composites, enhancing overall elasticity.

- Processing techniques for elasticity optimization: Advanced processing techniques can optimize the elasticity of aramid fibers during manufacturing. Controlled heat treatment, specialized drawing processes, and precise tension control during fiber formation can significantly influence the elastic properties. Post-production treatments such as specific winding methods, relaxation processes, or mechanical conditioning can further enhance the elastic behavior of aramid fibers while preserving their high-performance characteristics.

02 Blending aramid with elastic polymers

Combining aramid fibers with elastic polymers creates composite materials with enhanced elasticity. These blends incorporate the high tensile strength and thermal stability of aramid with the flexibility and stretch properties of elastomeric materials. The resulting hybrid fibers maintain critical protective properties while offering improved comfort and movement range for applications in protective clothing and technical textiles.Expand Specific Solutions03 Surface treatment methods for improved elasticity

Various surface treatments can enhance the elastic properties of aramid fibers. These include chemical modifications, plasma treatments, and coating applications that alter the fiber surface characteristics. Such treatments can reduce fiber stiffness, improve interfacial bonding with elastic matrices, and enhance the overall flexibility and elastic recovery of aramid-based materials without significantly compromising their strength.Expand Specific Solutions04 Composite yarn structures with aramid components

Specialized yarn structures incorporating aramid fibers with other elastic components can achieve enhanced elasticity. These include core-sheath structures, twisted composite yarns, and braided configurations where aramid provides strength while other components contribute elasticity. The specific arrangement of fibers within these composite yarn structures allows for controlled stretch and recovery while maintaining the protective benefits of aramid.Expand Specific Solutions05 Heat and pressure treatments for elasticity modification

Applying specific heat and pressure treatments to aramid fibers can modify their elastic properties. These processes include controlled thermal relaxation, steam treatment, and compression techniques that alter the internal structure of the fibers. Such treatments can reduce internal stresses, modify crystallinity, and create microstructural changes that enhance the fiber's ability to stretch and recover while preserving its fundamental mechanical properties.Expand Specific Solutions

Leading Organizations in Aramid Fiber Testing Standards

The aramid fiber elasticity measurement market is currently in a growth phase, with increasing demand driven by applications in aerospace, automotive, and protective equipment industries. The global market size for aramid fibers is expanding steadily, expected to reach significant valuation as technical standards for elasticity measurement become more critical. In terms of technical maturity, companies like DuPont de Nemours (Kevlar pioneer), Teijin, and Kolon Industries lead with established testing protocols, while 3M Innovative Properties and Asahi Kasei contribute significant advancements in measurement technologies. Research institutions such as Cornell University and University of Massachusetts Amherst are developing next-generation standards, while specialized manufacturers like Hyosung Advanced Materials and Toyobo are implementing proprietary testing methodologies to differentiate their high-performance aramid products in competitive markets.

3M Innovative Properties Co.

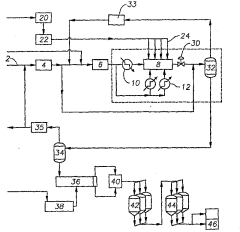

Technical Solution: 3M has developed a proprietary elasticity measurement system for aramid fibers that integrates acoustic emission monitoring with traditional tensile testing. Their approach utilizes piezoelectric sensors to detect microscopic structural changes during elastic deformation, providing insights into the fiber's internal mechanics beyond what conventional strain measurements reveal. The system incorporates multi-axis force sensors that simultaneously measure axial and torsional responses, capturing the complex elasticity behavior of aramid fibers. 3M's testing protocol includes cyclic loading sequences at incrementally increasing loads to characterize elasticity degradation and recovery, critical for applications requiring repeated loading. Their methodology also incorporates real-time Raman spectroscopy to monitor molecular alignment changes during elastic deformation, establishing correlations between macroscopic elasticity and molecular structure.

Strengths: Integration of acoustic emission technology provides unique insights into internal fiber mechanics; multi-axis measurement capabilities capture complex elasticity behavior; spectroscopic correlation adds molecular-level understanding. Weaknesses: Equipment complexity limits widespread adoption; requires specialized expertise to interpret acoustic emission data correctly.

Kolon Industries, Inc.

Technical Solution: Kolon Industries has developed a comprehensive aramid fiber elasticity measurement system that combines traditional tensile testing with advanced fiber optic sensing technology. Their methodology employs fiber Bragg grating sensors embedded alongside aramid fiber bundles to provide distributed strain measurements with spatial resolution of approximately 1mm along the fiber length. This approach enables detection of localized elasticity variations that might be missed by conventional extensometers. Kolon's testing protocol incorporates multi-frequency dynamic mechanical analysis (0.01-100 Hz) to characterize frequency-dependent elastic properties, critical for applications involving vibration or impact. Their system features environmental chambers capable of simulating extreme conditions (-60°C to 300°C) while maintaining measurement precision, allowing elasticity characterization across the full operational range of aramid applications.

Strengths: Distributed sensing provides detailed spatial elasticity mapping; frequency-dependent characterization capabilities; excellent environmental range for testing under extreme conditions. Weaknesses: Fiber optic integration adds complexity to sample preparation; system requires frequent recalibration to maintain measurement accuracy.

Key Technical Standards and Testing Innovations

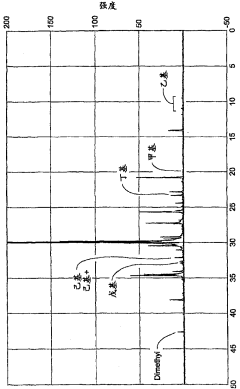

Polymers of ethylene and, optionally, copolymerizable esters, films using such polymers and stretch hood packaging processes using such films

PatentInactiveCN1849348B

Innovation

- Using a new type of ethylene polymer as the core layer with low melt index, rich short chain branches and suitable density, combined with the design of multi-layer film structure and skin layer, including low density ethylene copolymer and anti-blocking agent, to improve the film's performance Elastic recovery rate and friction coefficient.

Environmental Factors Affecting Aramid Fiber Testing Accuracy

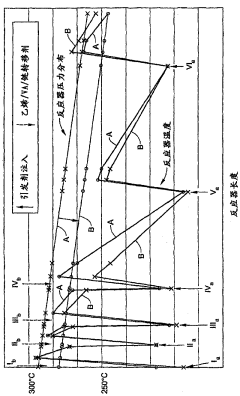

Environmental conditions significantly impact the accuracy and reliability of aramid fiber elasticity measurements, necessitating careful control and documentation during testing procedures. Temperature variations represent one of the most critical factors affecting test results, as aramid fibers demonstrate altered mechanical properties across different thermal environments. Research indicates that testing conducted outside the standard temperature range of 20-25°C can lead to elasticity measurement deviations of up to 8%, with higher temperatures typically resulting in decreased tensile strength and increased elongation characteristics.

Humidity levels similarly influence test outcomes, with aramid fibers exhibiting hygroscopic properties that affect their dimensional stability and mechanical performance. Testing environments with relative humidity exceeding 65% have been documented to cause moisture absorption that can alter fiber elasticity measurements by 3-7%, depending on exposure duration and fiber type. This moisture-induced variability necessitates pre-conditioning protocols and humidity-controlled testing chambers for standardized measurements.

Atmospheric pressure, though less impactful than temperature and humidity, can affect measurement precision in high-altitude testing facilities. Barometric pressure variations may influence the behavior of pneumatic testing equipment and potentially alter the stress-strain relationship during elasticity measurements, particularly for high-precision applications requiring detection of subtle elasticity differences.

Light exposure represents another environmental consideration, as prolonged UV radiation can degrade aramid fiber structure through photochemical reactions. Testing facilities with excessive natural light or unfiltered artificial lighting may introduce progressive degradation in test specimens, particularly during extended testing sequences or when using the same calibration samples repeatedly.

Airborne contaminants present in testing environments, including dust particles, chemical vapors, and industrial pollutants, can interact with fiber surfaces and testing equipment. These interactions may alter surface friction characteristics during testing and potentially contaminate gripping mechanisms, leading to slippage and inconsistent elasticity measurements. High-precision testing facilities typically implement HEPA filtration systems and positive pressure environments to mitigate these effects.

Vibration interference from nearby equipment or building systems can introduce measurement artifacts, particularly in highly sensitive testing apparatus utilizing laser extensometry or optical strain measurement techniques. Isolation platforms and vibration-dampening foundations are increasingly becoming standard requirements for advanced aramid fiber testing laboratories to ensure measurement integrity.

Humidity levels similarly influence test outcomes, with aramid fibers exhibiting hygroscopic properties that affect their dimensional stability and mechanical performance. Testing environments with relative humidity exceeding 65% have been documented to cause moisture absorption that can alter fiber elasticity measurements by 3-7%, depending on exposure duration and fiber type. This moisture-induced variability necessitates pre-conditioning protocols and humidity-controlled testing chambers for standardized measurements.

Atmospheric pressure, though less impactful than temperature and humidity, can affect measurement precision in high-altitude testing facilities. Barometric pressure variations may influence the behavior of pneumatic testing equipment and potentially alter the stress-strain relationship during elasticity measurements, particularly for high-precision applications requiring detection of subtle elasticity differences.

Light exposure represents another environmental consideration, as prolonged UV radiation can degrade aramid fiber structure through photochemical reactions. Testing facilities with excessive natural light or unfiltered artificial lighting may introduce progressive degradation in test specimens, particularly during extended testing sequences or when using the same calibration samples repeatedly.

Airborne contaminants present in testing environments, including dust particles, chemical vapors, and industrial pollutants, can interact with fiber surfaces and testing equipment. These interactions may alter surface friction characteristics during testing and potentially contaminate gripping mechanisms, leading to slippage and inconsistent elasticity measurements. High-precision testing facilities typically implement HEPA filtration systems and positive pressure environments to mitigate these effects.

Vibration interference from nearby equipment or building systems can introduce measurement artifacts, particularly in highly sensitive testing apparatus utilizing laser extensometry or optical strain measurement techniques. Isolation platforms and vibration-dampening foundations are increasingly becoming standard requirements for advanced aramid fiber testing laboratories to ensure measurement integrity.

Cross-Industry Applications and Testing Requirements

Aramid fibers have demonstrated remarkable versatility across multiple industries due to their exceptional strength-to-weight ratio and thermal stability. In aerospace applications, testing requirements focus on tensile strength under extreme temperature variations and resistance to UV degradation. Standards such as ASTM D7269 specifically address the performance evaluation of aramid composites in aircraft structures, where elasticity measurements must account for vibration damping properties and fatigue resistance under cyclical loading.

The automotive sector implements different testing protocols, prioritizing impact resistance and energy absorption capabilities. Aramid fiber components in vehicles undergo standardized crash tests following ISO 6603 guidelines, with elasticity measurements serving as critical indicators for predicting deformation behavior during collisions. Manufacturers require consistent testing methodologies that can accurately simulate real-world stress conditions while maintaining reproducibility across different production batches.

In protective equipment manufacturing, aramid fiber elasticity testing emphasizes ballistic performance and puncture resistance. NIJ Standard 0101.06 for body armor testing incorporates specific elasticity measurement protocols that evaluate material response under high-velocity impact. These tests must account for the unique viscoelastic properties of aramid fibers, which exhibit different elastic behaviors under varying strain rates—a characteristic particularly relevant for ballistic applications.

The marine industry presents distinct challenges for aramid fiber testing, as materials must withstand prolonged exposure to saltwater while maintaining structural integrity. Testing standards like ISO 12215 address the specific requirements for marine applications, incorporating elasticity measurements under wet conditions and after prolonged environmental exposure. These tests typically employ cyclic loading protocols that simulate wave action and evaluate creep behavior under sustained loads.

Construction and infrastructure applications necessitate long-term performance evaluation, with testing requirements focused on creep resistance and dimensional stability under constant loading. ASTM D7205 provides guidelines for tensile testing of fiber-reinforced polymer composites used in structural applications, where elasticity measurements must account for environmental factors such as freeze-thaw cycles and alkaline exposure that can significantly alter material properties over time.

Standardization bodies including ISO, ASTM, and industry-specific organizations have developed specialized test methods that address the unique requirements of each application domain. These cross-industry testing protocols share common elements—precise specimen preparation, controlled environmental conditions, and calibrated measurement systems—while incorporating application-specific parameters that reflect real-world usage scenarios.

The automotive sector implements different testing protocols, prioritizing impact resistance and energy absorption capabilities. Aramid fiber components in vehicles undergo standardized crash tests following ISO 6603 guidelines, with elasticity measurements serving as critical indicators for predicting deformation behavior during collisions. Manufacturers require consistent testing methodologies that can accurately simulate real-world stress conditions while maintaining reproducibility across different production batches.

In protective equipment manufacturing, aramid fiber elasticity testing emphasizes ballistic performance and puncture resistance. NIJ Standard 0101.06 for body armor testing incorporates specific elasticity measurement protocols that evaluate material response under high-velocity impact. These tests must account for the unique viscoelastic properties of aramid fibers, which exhibit different elastic behaviors under varying strain rates—a characteristic particularly relevant for ballistic applications.

The marine industry presents distinct challenges for aramid fiber testing, as materials must withstand prolonged exposure to saltwater while maintaining structural integrity. Testing standards like ISO 12215 address the specific requirements for marine applications, incorporating elasticity measurements under wet conditions and after prolonged environmental exposure. These tests typically employ cyclic loading protocols that simulate wave action and evaluate creep behavior under sustained loads.

Construction and infrastructure applications necessitate long-term performance evaluation, with testing requirements focused on creep resistance and dimensional stability under constant loading. ASTM D7205 provides guidelines for tensile testing of fiber-reinforced polymer composites used in structural applications, where elasticity measurements must account for environmental factors such as freeze-thaw cycles and alkaline exposure that can significantly alter material properties over time.

Standardization bodies including ISO, ASTM, and industry-specific organizations have developed specialized test methods that address the unique requirements of each application domain. These cross-industry testing protocols share common elements—precise specimen preparation, controlled environmental conditions, and calibrated measurement systems—while incorporating application-specific parameters that reflect real-world usage scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!