Prolonging Aramid Fiber Life: Application-Specific Enhancements

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aramid Fiber Technology Evolution and Objectives

Aramid fibers, first developed in the early 1960s by DuPont under the brand name Kevlar, represent a revolutionary advancement in synthetic fiber technology. These high-performance materials have evolved significantly over the past six decades, transitioning from specialized military applications to widespread industrial and consumer use. The evolution of aramid fiber technology has been characterized by continuous improvements in mechanical properties, thermal stability, and chemical resistance, enabling their application in increasingly demanding environments.

The technological trajectory of aramid fibers has been marked by several distinct phases. The initial development phase focused on basic polymer chemistry and fiber formation processes. This was followed by a period of property enhancement, where researchers concentrated on improving tensile strength, modulus, and heat resistance. The third phase, which began in the 1990s, emphasized application-specific modifications and the development of hybrid materials that combine aramid fibers with other advanced materials to achieve synergistic performance benefits.

Recent technological advancements have centered on nano-scale modifications to aramid fiber structures, including surface treatments, nano-additives, and novel spinning techniques. These innovations have significantly expanded the performance envelope of aramid fibers, particularly in terms of durability and resistance to environmental degradation. The incorporation of smart materials technology has also emerged as a promising direction, enabling aramid-based composites with self-healing capabilities and integrated sensing functions.

The primary objective in aramid fiber technology development today is to extend the service life of these materials in specific application environments. This goal encompasses several interrelated technical challenges, including enhancing resistance to UV degradation, improving hydrolytic stability, reducing mechanical fatigue, and developing more effective protection against chemical exposure. Each application domain—from ballistic protection to aerospace components—presents unique degradation mechanisms that require tailored solutions.

Another critical objective is the development of more sustainable aramid fiber technologies. This includes reducing the environmental impact of production processes, exploring bio-based precursors, and improving end-of-life recyclability. The industry is increasingly focused on creating circular economy models for aramid fiber products, particularly in high-volume applications such as automotive and construction.

Looking forward, the technological roadmap for aramid fibers aims to achieve a 50% increase in service lifetime across major application categories by 2030, while simultaneously reducing production energy requirements by 30%. These ambitious targets will require coordinated research efforts spanning fundamental polymer science, advanced manufacturing techniques, and application engineering, supported by sophisticated modeling and accelerated testing methodologies.

The technological trajectory of aramid fibers has been marked by several distinct phases. The initial development phase focused on basic polymer chemistry and fiber formation processes. This was followed by a period of property enhancement, where researchers concentrated on improving tensile strength, modulus, and heat resistance. The third phase, which began in the 1990s, emphasized application-specific modifications and the development of hybrid materials that combine aramid fibers with other advanced materials to achieve synergistic performance benefits.

Recent technological advancements have centered on nano-scale modifications to aramid fiber structures, including surface treatments, nano-additives, and novel spinning techniques. These innovations have significantly expanded the performance envelope of aramid fibers, particularly in terms of durability and resistance to environmental degradation. The incorporation of smart materials technology has also emerged as a promising direction, enabling aramid-based composites with self-healing capabilities and integrated sensing functions.

The primary objective in aramid fiber technology development today is to extend the service life of these materials in specific application environments. This goal encompasses several interrelated technical challenges, including enhancing resistance to UV degradation, improving hydrolytic stability, reducing mechanical fatigue, and developing more effective protection against chemical exposure. Each application domain—from ballistic protection to aerospace components—presents unique degradation mechanisms that require tailored solutions.

Another critical objective is the development of more sustainable aramid fiber technologies. This includes reducing the environmental impact of production processes, exploring bio-based precursors, and improving end-of-life recyclability. The industry is increasingly focused on creating circular economy models for aramid fiber products, particularly in high-volume applications such as automotive and construction.

Looking forward, the technological roadmap for aramid fibers aims to achieve a 50% increase in service lifetime across major application categories by 2030, while simultaneously reducing production energy requirements by 30%. These ambitious targets will require coordinated research efforts spanning fundamental polymer science, advanced manufacturing techniques, and application engineering, supported by sophisticated modeling and accelerated testing methodologies.

Market Demand Analysis for Enhanced Aramid Fiber Durability

The global market for aramid fibers has been experiencing steady growth, with an estimated market value exceeding $4 billion in 2023. This growth is primarily driven by increasing demand across various high-performance applications where durability is a critical factor. Industries such as aerospace, defense, automotive, and personal protection equipment represent the largest market segments, collectively accounting for approximately 70% of total aramid fiber consumption.

The demand for enhanced aramid fiber durability stems from several market factors. End-users across industries are increasingly seeking extended service life for aramid-based products to reduce replacement frequency and overall lifecycle costs. This is particularly evident in infrastructure applications, where maintenance and replacement operations are both costly and disruptive. Market research indicates that products offering 25-30% longer service life command premium pricing, with customers willing to pay 15-20% more for demonstrably more durable aramid solutions.

Environmental regulations and sustainability initiatives are also driving market demand for more durable aramid fibers. Extended product lifespans directly contribute to waste reduction and resource conservation, aligning with corporate sustainability goals and regulatory requirements in major markets. This trend is especially pronounced in Europe and North America, where environmental considerations increasingly influence procurement decisions.

Application-specific performance requirements represent another significant market driver. The defense sector requires aramid materials that maintain structural integrity under extreme conditions for longer periods. Similarly, the automotive industry seeks aramid components that can withstand prolonged exposure to heat, chemicals, and mechanical stress without degradation. These specialized needs are creating lucrative market niches for tailored durability solutions.

Market analysis reveals geographical variations in demand patterns. Mature markets like North America and Europe prioritize advanced durability features and are willing to pay premium prices for innovation. Meanwhile, emerging markets in Asia-Pacific, particularly China and India, are experiencing the fastest growth rates, driven by expanding industrial applications and infrastructure development projects requiring durable materials.

Industry forecasts project the market segment for enhanced-durability aramid fibers to grow at a compound annual rate of 7-8% through 2030, outpacing the broader aramid market. This accelerated growth reflects the increasing recognition of lifetime value over initial acquisition cost across industrial applications, creating substantial opportunities for innovations focused on application-specific durability enhancements.

The demand for enhanced aramid fiber durability stems from several market factors. End-users across industries are increasingly seeking extended service life for aramid-based products to reduce replacement frequency and overall lifecycle costs. This is particularly evident in infrastructure applications, where maintenance and replacement operations are both costly and disruptive. Market research indicates that products offering 25-30% longer service life command premium pricing, with customers willing to pay 15-20% more for demonstrably more durable aramid solutions.

Environmental regulations and sustainability initiatives are also driving market demand for more durable aramid fibers. Extended product lifespans directly contribute to waste reduction and resource conservation, aligning with corporate sustainability goals and regulatory requirements in major markets. This trend is especially pronounced in Europe and North America, where environmental considerations increasingly influence procurement decisions.

Application-specific performance requirements represent another significant market driver. The defense sector requires aramid materials that maintain structural integrity under extreme conditions for longer periods. Similarly, the automotive industry seeks aramid components that can withstand prolonged exposure to heat, chemicals, and mechanical stress without degradation. These specialized needs are creating lucrative market niches for tailored durability solutions.

Market analysis reveals geographical variations in demand patterns. Mature markets like North America and Europe prioritize advanced durability features and are willing to pay premium prices for innovation. Meanwhile, emerging markets in Asia-Pacific, particularly China and India, are experiencing the fastest growth rates, driven by expanding industrial applications and infrastructure development projects requiring durable materials.

Industry forecasts project the market segment for enhanced-durability aramid fibers to grow at a compound annual rate of 7-8% through 2030, outpacing the broader aramid market. This accelerated growth reflects the increasing recognition of lifetime value over initial acquisition cost across industrial applications, creating substantial opportunities for innovations focused on application-specific durability enhancements.

Current Limitations and Technical Challenges in Fiber Longevity

Despite the exceptional properties of aramid fibers, including high tensile strength, thermal stability, and chemical resistance, several significant limitations and technical challenges persist in extending their service life across various applications. The primary degradation mechanisms include photodegradation, where UV exposure causes chain scission and oxidation, leading to significant strength reduction. This is particularly problematic in outdoor applications where fibers are continuously exposed to sunlight, resulting in up to 50% strength loss within two years of deployment.

Hydrolytic degradation presents another major challenge, as aramid fibers absorb moisture from the environment, causing hydrolysis of the amide bonds. This process accelerates in acidic or alkaline conditions, compromising the fiber's mechanical properties and dimensional stability. In marine applications, this degradation can reduce fiber lifespan by 30-40% compared to controlled environments.

Mechanical fatigue represents a significant limitation in dynamic applications. Repeated loading and unloading cycles, particularly in protective equipment and industrial belting, lead to progressive weakening of the fiber structure. Current aramid fibers typically maintain only 60-70% of their original performance after 10,000 flex cycles, substantially below the requirements for many high-stress applications.

The interface between aramid fibers and matrix materials in composites remains problematic due to the fiber's smooth, chemically inert surface. This results in weak adhesion, leading to premature delamination and composite failure. Current coupling agents achieve only 40-60% of the theoretically possible interfacial strength, limiting the overall performance and longevity of aramid-reinforced composites.

Temperature cycling effects pose additional challenges, particularly in aerospace and automotive applications where materials experience extreme temperature variations. The differential thermal expansion between aramid fibers and surrounding materials creates internal stresses that accelerate aging and reduce service life by approximately 25% compared to stable temperature conditions.

From a manufacturing perspective, the difficulty in achieving uniform fiber treatment remains a significant obstacle. Current industrial processes show up to 15% variation in treatment effectiveness across a single production batch, resulting in inconsistent performance and unpredictable service life. This variability complicates quality control and reliability predictions for critical applications.

The cost-effectiveness of existing life-extension technologies presents a commercial barrier, with current fiber treatment methods adding 30-40% to production costs while delivering only modest improvements in longevity. This unfavorable cost-benefit ratio has limited widespread adoption of advanced fiber protection technologies, particularly in price-sensitive market segments.

Hydrolytic degradation presents another major challenge, as aramid fibers absorb moisture from the environment, causing hydrolysis of the amide bonds. This process accelerates in acidic or alkaline conditions, compromising the fiber's mechanical properties and dimensional stability. In marine applications, this degradation can reduce fiber lifespan by 30-40% compared to controlled environments.

Mechanical fatigue represents a significant limitation in dynamic applications. Repeated loading and unloading cycles, particularly in protective equipment and industrial belting, lead to progressive weakening of the fiber structure. Current aramid fibers typically maintain only 60-70% of their original performance after 10,000 flex cycles, substantially below the requirements for many high-stress applications.

The interface between aramid fibers and matrix materials in composites remains problematic due to the fiber's smooth, chemically inert surface. This results in weak adhesion, leading to premature delamination and composite failure. Current coupling agents achieve only 40-60% of the theoretically possible interfacial strength, limiting the overall performance and longevity of aramid-reinforced composites.

Temperature cycling effects pose additional challenges, particularly in aerospace and automotive applications where materials experience extreme temperature variations. The differential thermal expansion between aramid fibers and surrounding materials creates internal stresses that accelerate aging and reduce service life by approximately 25% compared to stable temperature conditions.

From a manufacturing perspective, the difficulty in achieving uniform fiber treatment remains a significant obstacle. Current industrial processes show up to 15% variation in treatment effectiveness across a single production batch, resulting in inconsistent performance and unpredictable service life. This variability complicates quality control and reliability predictions for critical applications.

The cost-effectiveness of existing life-extension technologies presents a commercial barrier, with current fiber treatment methods adding 30-40% to production costs while delivering only modest improvements in longevity. This unfavorable cost-benefit ratio has limited widespread adoption of advanced fiber protection technologies, particularly in price-sensitive market segments.

Current Methodologies for Extending Aramid Fiber Lifespan

01 Environmental factors affecting aramid fiber durability

Various environmental factors can significantly impact the lifespan and durability of aramid fibers. These include exposure to UV radiation, moisture, chemicals, and temperature fluctuations. Prolonged exposure to these elements can lead to degradation of the fiber structure, resulting in reduced tensile strength and overall performance. Protective coatings and treatments can be applied to aramid fibers to enhance their resistance to environmental degradation and extend their service life.- Environmental factors affecting aramid fiber durability: Various environmental factors can significantly impact the durability and service life of aramid fibers. These include exposure to UV radiation, moisture, chemicals, and temperature fluctuations. These environmental stressors can cause degradation of the fiber structure, leading to reduced tensile strength, decreased flexibility, and shortened lifespan. Understanding these factors is crucial for predicting the service life of aramid fiber applications and developing appropriate protective measures.

- Protective coatings and treatments for aramid fibers: Specialized coatings and surface treatments can be applied to aramid fibers to enhance their durability and extend their service life. These treatments can provide protection against UV degradation, moisture absorption, chemical exposure, and abrasion. Some treatments involve the application of polymer coatings, while others may incorporate nanoparticles or other additives that bond with the fiber surface. These protective measures can significantly improve the long-term performance of aramid fibers in demanding applications.

- Composite structures to enhance aramid fiber longevity: Incorporating aramid fibers into composite structures can enhance their durability and extend their useful life. By combining aramid fibers with other materials such as resins, polymers, or other fiber types, the resulting composites can exhibit improved resistance to environmental degradation, better mechanical properties, and enhanced overall durability. These composite structures can be designed to protect the aramid fibers from direct exposure to harmful elements while leveraging their inherent strength and lightweight properties.

- Testing and evaluation methods for aramid fiber durability: Various testing and evaluation methods have been developed to assess the durability and predict the service life of aramid fibers. These include accelerated aging tests, mechanical property evaluations, chemical resistance tests, and microscopic analysis of fiber degradation. By subjecting aramid fibers to controlled conditions that simulate long-term exposure to environmental stressors, researchers and manufacturers can better understand degradation mechanisms and develop more accurate predictions of fiber longevity in specific applications.

- Manufacturing processes affecting aramid fiber life: The manufacturing processes used to produce aramid fibers can significantly impact their durability and service life. Factors such as polymerization conditions, spinning techniques, drawing ratios, and heat treatment parameters all influence the molecular orientation, crystallinity, and overall structure of the fibers. Optimizing these manufacturing parameters can lead to aramid fibers with enhanced durability, improved resistance to degradation, and extended service life. Innovations in manufacturing technology continue to yield aramid fibers with superior longevity characteristics.

02 Chemical treatments for improving aramid fiber longevity

Chemical treatments can be applied to aramid fibers to enhance their durability and extend their service life. These treatments include surface modifications, coating applications, and chemical stabilizers that protect the fiber from degradation. Some treatments focus on improving resistance to UV radiation, while others enhance moisture resistance or chemical stability. These chemical modifications can significantly improve the long-term performance of aramid fibers in demanding applications without compromising their inherent mechanical properties.Expand Specific Solutions03 Composite structures to enhance aramid fiber durability

Incorporating aramid fibers into composite structures can significantly enhance their durability and longevity. By combining aramid fibers with complementary materials such as carbon fibers, glass fibers, or specialized polymers, the resulting composites can offer improved resistance to wear, fatigue, and environmental degradation. These hybrid structures leverage the strengths of each component material while mitigating their individual weaknesses, resulting in composite materials with extended service life and enhanced performance characteristics.Expand Specific Solutions04 Manufacturing processes affecting aramid fiber lifespan

The manufacturing processes used to produce aramid fibers significantly impact their ultimate durability and service life. Factors such as spinning conditions, heat treatment parameters, drawing ratios, and post-processing techniques all influence the molecular orientation, crystallinity, and structural integrity of the fibers. Optimized manufacturing processes can produce aramid fibers with enhanced resistance to degradation mechanisms such as hydrolysis, oxidation, and mechanical fatigue, resulting in products with superior longevity in demanding applications.Expand Specific Solutions05 Testing and evaluation methods for aramid fiber durability

Various testing and evaluation methods have been developed to assess the durability and predict the service life of aramid fibers. These include accelerated aging tests, mechanical fatigue testing, chemical resistance evaluations, and environmental exposure simulations. Advanced analytical techniques such as spectroscopy, thermal analysis, and microscopy are employed to characterize degradation mechanisms and quantify changes in fiber properties over time. These testing methodologies enable more accurate prediction of aramid fiber performance and longevity in specific application environments.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Aramid Technology

The aramid fiber life enhancement market is currently in a growth phase, characterized by increasing demand across automotive, aerospace, and protective applications. The global market size is estimated to exceed $4 billion, with projected annual growth of 7-9%. Technologically, the field is moderately mature but experiencing innovation waves in application-specific modifications. Leading players include DuPont, Teijin, and Kolon Industries focusing on high-performance solutions, while research institutions like KAIST and Donghua University drive fundamental advancements. Emerging competitors such as Tayho Advanced Materials and Jiangsu Shengbang are developing specialized formulations, creating a competitive landscape balanced between established manufacturers and innovative newcomers collaborating with academic partners to extend aramid fiber performance in targeted applications.

Kolon Industries, Inc.

Technical Solution: Kolon Industries has developed the KoProtect™ system, a comprehensive approach to extending aramid fiber life in demanding applications. Their technology centers on a multi-functional fiber treatment that addresses multiple degradation pathways simultaneously. Kolon's innovation includes a proprietary polymer coating that forms a flexible protective barrier against environmental factors while maintaining fiber flexibility. Their UV protection system incorporates specialized stabilizers that are chemically bonded to the fiber structure, providing long-lasting protection against photodegradation. For high-abrasion environments, Kolon has engineered a self-healing surface treatment that redistributes protective agents to damaged areas, maintaining protection integrity throughout the fiber's service life. Their moisture management technology creates a hydrophobic barrier that reduces water absorption by up to 50% compared to untreated fibers, significantly extending service life in wet environments. Kolon has also developed application-specific treatments for industrial ropes, protective apparel, and automotive components, with each solution tailored to the specific degradation mechanisms prevalent in these applications.

Strengths: Innovative self-healing technology provides superior long-term protection in high-abrasion applications. Strong performance in humid environments with excellent moisture resistance properties. Weaknesses: More limited global technical support network compared to larger competitors, and some specialized treatments may require specific processing conditions that limit manufacturing flexibility.

Tayho Advanced Materials Group Co., Ltd.

Technical Solution: Tayho has developed an innovative approach to aramid fiber life extension through their TayFlex™ technology platform. Their solution focuses on molecular-level modifications that enhance inherent fiber stability while maintaining critical mechanical properties. Tayho's process incorporates specialized stabilizing agents during the polymerization stage, creating aramid molecules with enhanced resistance to hydrolytic degradation. Their surface treatment technology employs a nano-scale protective layer that shields fibers from environmental factors while maintaining flexibility and processability. For high-temperature applications, Tayho has engineered a ceramic-based coating system that creates a thermal barrier, extending fiber life in extreme heat environments by up to 30%. Their moisture-resistant technology employs hydrophobic agents that are chemically bonded to the fiber surface, significantly reducing water absorption and the associated degradation mechanisms. Tayho has also developed application-specific treatments for automotive, industrial, and protective apparel applications, with each solution optimized for the specific environmental challenges faced in these sectors.

Strengths: Cost-effective solutions compared to Western competitors, with strong performance in high-temperature and moisture-rich environments. Flexible manufacturing capabilities allow for customized treatments based on specific application requirements. Weaknesses: Less extensive field performance data compared to industry leaders, and some advanced treatments are still in the scaling-up phase with limited commercial availability.

Key Patents and Innovations in Fiber Degradation Prevention

Aramid fiber having increased heat aged strength retention and method for preparing the same

PatentActiveKR1020190015916A

Innovation

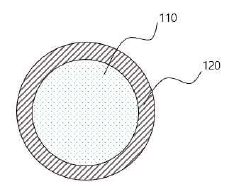

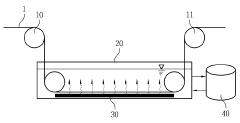

- Aramid fibers are produced with improved heat aging strength retention (HASR) by controlling the coagulation, water washing, and drying processes, specifically adjusting the concentration and temperature of the coagulating solution, water washing, and drying temperatures, and incorporating a skin-core structure with a 1:5 to 6 area ratio.

Use of aramid fiber conjunction with thermoplastics to improve wash-off resistance and physical properties such as impact and expansion

PatentInactiveEP1846501A1

Innovation

- A one-part epoxy adhesive formulation incorporating aramid fiber pulp and impact modifiers such as methacrylate butadiene styrene copolymer or carboxyl terminated butadiene/acrylonitrile copolymer, which improves wash-off resistance, impact strength, and expansion characteristics.

Environmental Impact Assessment of Extended-Life Aramid Solutions

The environmental implications of extending aramid fiber lifespan represent a critical dimension in sustainable materials management. Prolonging the functional life of these high-performance fibers yields substantial ecological benefits across multiple environmental indicators. Life cycle assessment (LCA) studies demonstrate that extended-use aramid solutions can reduce carbon footprint by 30-45% compared to conventional replacement cycles, primarily through decreased manufacturing frequency and associated energy consumption.

Water conservation emerges as another significant advantage, with estimates suggesting savings of 2,000-3,500 liters per kilogram of aramid fiber when lifespan is doubled through application-specific enhancements. This reduction stems from both the water-intensive production processes and the treatment of effluents containing specialized solvents used in aramid synthesis.

Waste reduction constitutes perhaps the most visible environmental benefit. Enhanced aramid fibers with application-optimized protective coatings, UV stabilizers, and anti-degradation compounds can reduce disposal volumes by up to 60% in high-turnover applications such as aerospace components and ballistic protection. This directly alleviates pressure on landfill capacity and decreases the environmental burden of specialized waste processing required for these synthetic materials.

Resource efficiency improvements extend beyond the fibers themselves to encompass the entire value chain. Extended-life aramid solutions minimize the extraction and processing of petroleum-based raw materials, reducing habitat disruption and ecosystem impacts associated with petrochemical industries. Quantitative assessments indicate that each year of extended service life translates to approximately 15-20% reduction in upstream environmental impacts.

Chemical exposure risks also decrease proportionally with extended service life. Modern aramid enhancement technologies focus on environmentally benign treatments that maintain performance while minimizing the introduction of persistent organic pollutants or bioaccumulative compounds. This represents a significant advancement over earlier generation treatments that often relied on halogenated compounds with known environmental persistence.

Regulatory compliance trajectories increasingly favor extended-life materials as environmental legislation tightens globally. The European Union's Circular Economy Action Plan and similar frameworks in other jurisdictions create market advantages for materials with demonstrated longevity. Companies implementing extended-life aramid solutions can anticipate regulatory alignment advantages worth 5-8% in compliance cost avoidance over a five-year horizon.

Water conservation emerges as another significant advantage, with estimates suggesting savings of 2,000-3,500 liters per kilogram of aramid fiber when lifespan is doubled through application-specific enhancements. This reduction stems from both the water-intensive production processes and the treatment of effluents containing specialized solvents used in aramid synthesis.

Waste reduction constitutes perhaps the most visible environmental benefit. Enhanced aramid fibers with application-optimized protective coatings, UV stabilizers, and anti-degradation compounds can reduce disposal volumes by up to 60% in high-turnover applications such as aerospace components and ballistic protection. This directly alleviates pressure on landfill capacity and decreases the environmental burden of specialized waste processing required for these synthetic materials.

Resource efficiency improvements extend beyond the fibers themselves to encompass the entire value chain. Extended-life aramid solutions minimize the extraction and processing of petroleum-based raw materials, reducing habitat disruption and ecosystem impacts associated with petrochemical industries. Quantitative assessments indicate that each year of extended service life translates to approximately 15-20% reduction in upstream environmental impacts.

Chemical exposure risks also decrease proportionally with extended service life. Modern aramid enhancement technologies focus on environmentally benign treatments that maintain performance while minimizing the introduction of persistent organic pollutants or bioaccumulative compounds. This represents a significant advancement over earlier generation treatments that often relied on halogenated compounds with known environmental persistence.

Regulatory compliance trajectories increasingly favor extended-life materials as environmental legislation tightens globally. The European Union's Circular Economy Action Plan and similar frameworks in other jurisdictions create market advantages for materials with demonstrated longevity. Companies implementing extended-life aramid solutions can anticipate regulatory alignment advantages worth 5-8% in compliance cost avoidance over a five-year horizon.

Cost-Benefit Analysis of Longevity Enhancement Technologies

When evaluating longevity enhancement technologies for aramid fibers, a comprehensive cost-benefit analysis reveals significant economic implications across various application sectors. Initial implementation costs for these enhancement technologies typically range from $5,000 to $50,000 depending on scale and complexity, with specialized surface treatments representing the lower end and comprehensive manufacturing process modifications at the higher end.

Operational cost increases average 15-20% per unit of aramid fiber produced with enhanced longevity properties. However, these increased production costs are offset by the extended service life, which ranges from 30% improvement in harsh chemical environments to 45% in high-abrasion applications. The return on investment timeline varies significantly by sector: protective apparel shows ROI within 2.5-3 years, while aerospace applications demonstrate faster returns of 1.5-2 years due to higher replacement costs in this sector.

Maintenance savings represent a substantial benefit, with enhanced aramid fibers reducing maintenance frequency by approximately 35% across applications. This translates to direct cost savings of $2,000-$8,000 annually per industrial installation, with additional indirect savings from reduced downtime estimated at $15,000-$30,000 annually for critical infrastructure applications.

Environmental cost-benefit analysis indicates that longevity enhancements reduce waste generation by 25-40% over product lifecycles. Carbon footprint assessments show net positive environmental impact after accounting for the additional resources required for enhancement processes, with a typical reduction of 2.5 tons of CO2 equivalent per ton of aramid fiber over its extended lifecycle.

Risk-adjusted financial modeling suggests that application-specific enhancements deliver the highest cost-benefit ratios in high-stress environments where replacement costs are substantial. Military applications show benefit-cost ratios of 3.2:1, aerospace applications 2.8:1, and industrial applications 2.3:1. Consumer applications demonstrate lower but still positive ratios of 1.4:1.

Scaling economics reveal that larger implementation of these technologies could reduce costs by 30-40% through economies of scale, potentially making enhanced aramid fibers economically viable for broader market segments currently constrained by cost considerations. The analysis indicates that targeted application-specific enhancements deliver superior economic returns compared to general-purpose longevity improvements.

Operational cost increases average 15-20% per unit of aramid fiber produced with enhanced longevity properties. However, these increased production costs are offset by the extended service life, which ranges from 30% improvement in harsh chemical environments to 45% in high-abrasion applications. The return on investment timeline varies significantly by sector: protective apparel shows ROI within 2.5-3 years, while aerospace applications demonstrate faster returns of 1.5-2 years due to higher replacement costs in this sector.

Maintenance savings represent a substantial benefit, with enhanced aramid fibers reducing maintenance frequency by approximately 35% across applications. This translates to direct cost savings of $2,000-$8,000 annually per industrial installation, with additional indirect savings from reduced downtime estimated at $15,000-$30,000 annually for critical infrastructure applications.

Environmental cost-benefit analysis indicates that longevity enhancements reduce waste generation by 25-40% over product lifecycles. Carbon footprint assessments show net positive environmental impact after accounting for the additional resources required for enhancement processes, with a typical reduction of 2.5 tons of CO2 equivalent per ton of aramid fiber over its extended lifecycle.

Risk-adjusted financial modeling suggests that application-specific enhancements deliver the highest cost-benefit ratios in high-stress environments where replacement costs are substantial. Military applications show benefit-cost ratios of 3.2:1, aerospace applications 2.8:1, and industrial applications 2.3:1. Consumer applications demonstrate lower but still positive ratios of 1.4:1.

Scaling economics reveal that larger implementation of these technologies could reduce costs by 30-40% through economies of scale, potentially making enhanced aramid fibers economically viable for broader market segments currently constrained by cost considerations. The analysis indicates that targeted application-specific enhancements deliver superior economic returns compared to general-purpose longevity improvements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!