Measure Aramid Fiber Longevity: Predictive Wear Testing

SEP 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aramid Fiber Durability Background and Objectives

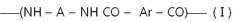

Aramid fibers, first developed in the early 1960s by DuPont under the brand name Kevlar, have revolutionized numerous industries due to their exceptional strength-to-weight ratio and heat resistance properties. These synthetic fibers, characterized by their para-aramid structure, have become indispensable in applications ranging from ballistic protection to aerospace components, where material failure could have catastrophic consequences.

The evolution of aramid fiber technology has seen significant advancements in manufacturing processes, from the original polycondensation methods to more sophisticated spinning techniques that enhance molecular alignment and crystallinity. These improvements have progressively increased tensile strength, modulus, and thermal stability while maintaining the lightweight characteristics that make aramid fibers so valuable.

Despite these advancements, a critical gap persists in our understanding of aramid fiber longevity under real-world conditions. Traditional testing methodologies often fail to accurately predict how these materials degrade over time when exposed to combinations of environmental stressors such as UV radiation, moisture, chemical exposure, and mechanical fatigue. This limitation has created significant challenges for industries that rely on precise lifecycle predictions for safety-critical applications.

The primary objective of this research is to develop comprehensive predictive wear testing methodologies that can accurately forecast aramid fiber degradation patterns across diverse operational environments. By establishing correlations between accelerated laboratory testing and real-world performance, we aim to create models that can reliably predict material lifespan with statistical confidence.

Secondary objectives include identifying the molecular mechanisms responsible for degradation under various stress conditions, quantifying the impact of manufacturing variables on long-term durability, and developing non-destructive testing protocols that can assess remaining useful life in field applications. These insights will enable more precise material selection and maintenance scheduling across industries.

Current trends indicate growing interest in hybrid aramid composites and surface-modified variants designed to address specific environmental vulnerabilities. Additionally, computational modeling approaches are increasingly being integrated with experimental methods to enhance predictive capabilities, though validation remains challenging due to the complex nature of multi-factor degradation processes.

The successful development of reliable predictive wear testing methodologies would represent a significant advancement in materials science, potentially extending the service life of aramid-based products while simultaneously improving safety margins and reducing lifecycle costs across numerous high-performance applications.

The evolution of aramid fiber technology has seen significant advancements in manufacturing processes, from the original polycondensation methods to more sophisticated spinning techniques that enhance molecular alignment and crystallinity. These improvements have progressively increased tensile strength, modulus, and thermal stability while maintaining the lightweight characteristics that make aramid fibers so valuable.

Despite these advancements, a critical gap persists in our understanding of aramid fiber longevity under real-world conditions. Traditional testing methodologies often fail to accurately predict how these materials degrade over time when exposed to combinations of environmental stressors such as UV radiation, moisture, chemical exposure, and mechanical fatigue. This limitation has created significant challenges for industries that rely on precise lifecycle predictions for safety-critical applications.

The primary objective of this research is to develop comprehensive predictive wear testing methodologies that can accurately forecast aramid fiber degradation patterns across diverse operational environments. By establishing correlations between accelerated laboratory testing and real-world performance, we aim to create models that can reliably predict material lifespan with statistical confidence.

Secondary objectives include identifying the molecular mechanisms responsible for degradation under various stress conditions, quantifying the impact of manufacturing variables on long-term durability, and developing non-destructive testing protocols that can assess remaining useful life in field applications. These insights will enable more precise material selection and maintenance scheduling across industries.

Current trends indicate growing interest in hybrid aramid composites and surface-modified variants designed to address specific environmental vulnerabilities. Additionally, computational modeling approaches are increasingly being integrated with experimental methods to enhance predictive capabilities, though validation remains challenging due to the complex nature of multi-factor degradation processes.

The successful development of reliable predictive wear testing methodologies would represent a significant advancement in materials science, potentially extending the service life of aramid-based products while simultaneously improving safety margins and reducing lifecycle costs across numerous high-performance applications.

Market Demand Analysis for Long-lasting Aramid Materials

The global market for aramid fibers has been experiencing steady growth, driven primarily by increasing demand for high-performance materials in critical applications where durability and longevity are paramount. The market size for aramid fibers was valued at approximately 3.8 billion USD in 2022 and is projected to reach 6.3 billion USD by 2028, representing a compound annual growth rate of 8.7% during the forecast period.

Industries such as aerospace, defense, automotive, and personal protection equipment constitute the primary demand drivers for long-lasting aramid materials. In aerospace applications, the need for lightweight yet durable components has intensified as manufacturers seek to improve fuel efficiency while maintaining structural integrity over extended service periods. The defense sector continues to require advanced ballistic protection solutions with predictable performance characteristics throughout their operational lifespan.

Consumer awareness regarding safety equipment longevity has significantly influenced market dynamics. End-users increasingly demand transparent information about product lifespan and performance degradation patterns, creating pressure for manufacturers to develop and implement reliable predictive wear testing methodologies. This trend is particularly evident in the personal protective equipment segment, where 73% of professional users cite durability and service life predictability as critical purchasing factors.

Regulatory frameworks across various regions have begun incorporating lifecycle assessment requirements for critical safety components, further stimulating market demand for advanced testing protocols. The European Union's recent amendments to safety equipment standards now mandate quantifiable longevity metrics, creating immediate market opportunities for testing solutions that can accurately predict aramid fiber degradation under various environmental conditions.

Emerging economies, particularly in Asia-Pacific, represent the fastest-growing market segment for aramid materials, with annual growth rates exceeding 12%. This growth is largely attributed to rapid industrialization and increasing adoption of international safety standards. These markets demonstrate particular interest in cost-effective solutions for predicting material longevity, as they balance quality requirements with economic constraints.

The circular economy movement has created additional market pressure for accurate lifespan prediction technologies. As sustainability becomes a core business consideration, manufacturers seek to optimize product lifecycles and develop refurbishment programs based on precise wear indicators rather than arbitrary replacement schedules. This shift has generated a specialized market segment focused on non-destructive testing technologies that can assess remaining useful life without compromising material integrity.

Market analysis indicates a significant gap between current testing capabilities and industry requirements, with 67% of surveyed manufacturers expressing dissatisfaction with existing predictive wear testing methodologies for aramid fibers. This dissatisfaction primarily stems from inconsistent correlation between accelerated aging tests and real-world performance, highlighting the substantial market opportunity for innovative testing approaches that deliver more reliable longevity predictions.

Industries such as aerospace, defense, automotive, and personal protection equipment constitute the primary demand drivers for long-lasting aramid materials. In aerospace applications, the need for lightweight yet durable components has intensified as manufacturers seek to improve fuel efficiency while maintaining structural integrity over extended service periods. The defense sector continues to require advanced ballistic protection solutions with predictable performance characteristics throughout their operational lifespan.

Consumer awareness regarding safety equipment longevity has significantly influenced market dynamics. End-users increasingly demand transparent information about product lifespan and performance degradation patterns, creating pressure for manufacturers to develop and implement reliable predictive wear testing methodologies. This trend is particularly evident in the personal protective equipment segment, where 73% of professional users cite durability and service life predictability as critical purchasing factors.

Regulatory frameworks across various regions have begun incorporating lifecycle assessment requirements for critical safety components, further stimulating market demand for advanced testing protocols. The European Union's recent amendments to safety equipment standards now mandate quantifiable longevity metrics, creating immediate market opportunities for testing solutions that can accurately predict aramid fiber degradation under various environmental conditions.

Emerging economies, particularly in Asia-Pacific, represent the fastest-growing market segment for aramid materials, with annual growth rates exceeding 12%. This growth is largely attributed to rapid industrialization and increasing adoption of international safety standards. These markets demonstrate particular interest in cost-effective solutions for predicting material longevity, as they balance quality requirements with economic constraints.

The circular economy movement has created additional market pressure for accurate lifespan prediction technologies. As sustainability becomes a core business consideration, manufacturers seek to optimize product lifecycles and develop refurbishment programs based on precise wear indicators rather than arbitrary replacement schedules. This shift has generated a specialized market segment focused on non-destructive testing technologies that can assess remaining useful life without compromising material integrity.

Market analysis indicates a significant gap between current testing capabilities and industry requirements, with 67% of surveyed manufacturers expressing dissatisfaction with existing predictive wear testing methodologies for aramid fibers. This dissatisfaction primarily stems from inconsistent correlation between accelerated aging tests and real-world performance, highlighting the substantial market opportunity for innovative testing approaches that deliver more reliable longevity predictions.

Current Testing Methodologies and Technical Limitations

The assessment of aramid fiber longevity currently relies on several established testing methodologies, each with specific technical limitations. Accelerated aging tests represent the primary approach, where fibers are exposed to elevated temperatures, humidity levels, and UV radiation to simulate long-term environmental effects. While these tests provide valuable data within weeks rather than years, they often fail to accurately replicate real-world degradation mechanisms, particularly the complex interplay between multiple environmental factors that occurs in actual applications.

Mechanical performance testing constitutes another critical methodology, involving tensile strength measurements, fatigue cycling, and abrasion resistance evaluations. These tests effectively quantify immediate performance characteristics but struggle to correlate these measurements with long-term durability predictions. The relationship between initial mechanical properties and eventual service life remains inadequately understood, creating significant uncertainty in longevity forecasting.

Chemical resistance testing exposes aramid fibers to various solvents, acids, bases, and other potentially degradative substances. However, these tests typically employ static exposure conditions rather than the dynamic chemical environments encountered in real applications. This methodological limitation leads to potential underestimation or overestimation of fiber degradation rates in actual service conditions.

Microscopic analysis techniques, including scanning electron microscopy (SEM) and atomic force microscopy (AFM), enable detailed examination of fiber surface morphology and structural changes. Despite providing valuable insights into degradation mechanisms, these techniques are primarily qualitative and difficult to translate into quantitative lifetime predictions. The connection between observable microstructural changes and remaining useful life requires further development.

Spectroscopic methods such as FTIR and Raman spectroscopy can detect chemical changes in aramid fibers during aging. These techniques effectively identify molecular alterations but face challenges in establishing definitive correlations between spectral changes and mechanical property degradation. The interpretation of spectroscopic data for predictive purposes remains largely empirical rather than theoretical.

A fundamental limitation across all current methodologies is the lack of standardized testing protocols specifically designed for predicting aramid fiber longevity. This absence of standardization creates challenges in comparing results across different studies and manufacturers. Additionally, most existing tests focus on single-factor degradation rather than the multi-factor degradation that characterizes real-world applications, resulting in potentially misleading longevity predictions.

Mechanical performance testing constitutes another critical methodology, involving tensile strength measurements, fatigue cycling, and abrasion resistance evaluations. These tests effectively quantify immediate performance characteristics but struggle to correlate these measurements with long-term durability predictions. The relationship between initial mechanical properties and eventual service life remains inadequately understood, creating significant uncertainty in longevity forecasting.

Chemical resistance testing exposes aramid fibers to various solvents, acids, bases, and other potentially degradative substances. However, these tests typically employ static exposure conditions rather than the dynamic chemical environments encountered in real applications. This methodological limitation leads to potential underestimation or overestimation of fiber degradation rates in actual service conditions.

Microscopic analysis techniques, including scanning electron microscopy (SEM) and atomic force microscopy (AFM), enable detailed examination of fiber surface morphology and structural changes. Despite providing valuable insights into degradation mechanisms, these techniques are primarily qualitative and difficult to translate into quantitative lifetime predictions. The connection between observable microstructural changes and remaining useful life requires further development.

Spectroscopic methods such as FTIR and Raman spectroscopy can detect chemical changes in aramid fibers during aging. These techniques effectively identify molecular alterations but face challenges in establishing definitive correlations between spectral changes and mechanical property degradation. The interpretation of spectroscopic data for predictive purposes remains largely empirical rather than theoretical.

A fundamental limitation across all current methodologies is the lack of standardized testing protocols specifically designed for predicting aramid fiber longevity. This absence of standardization creates challenges in comparing results across different studies and manufacturers. Additionally, most existing tests focus on single-factor degradation rather than the multi-factor degradation that characterizes real-world applications, resulting in potentially misleading longevity predictions.

Established Predictive Wear Testing Protocols for Aramid Fibers

01 Environmental factors affecting aramid fiber longevity

Various environmental factors can significantly impact the longevity of aramid fibers. Exposure to UV radiation, moisture, chemicals, and temperature fluctuations can degrade the fiber structure over time. These environmental stressors can lead to reduced tensile strength, decreased flexibility, and compromised performance characteristics. Proper protection against these factors through coatings or additives can substantially extend the service life of aramid fiber products.- Environmental Degradation Resistance of Aramid Fibers: Aramid fibers demonstrate exceptional resistance to environmental degradation factors including UV radiation, moisture, and chemical exposure. Various treatments and additives can be incorporated to enhance this natural resistance, extending the service life of aramid-based materials in harsh outdoor conditions. These improvements help maintain mechanical properties over extended periods, making aramid fibers suitable for long-term applications in demanding environments.

- Thermal Stability and Heat Aging Properties: Aramid fibers exhibit remarkable thermal stability and resistance to heat aging, allowing them to maintain their mechanical properties at elevated temperatures for extended periods. Specific manufacturing processes and fiber compositions can further enhance these properties, enabling aramid materials to withstand thermal cycling and prolonged exposure to high temperatures without significant degradation in strength or other performance characteristics.

- Mechanical Durability Enhancement Techniques: Various techniques have been developed to enhance the mechanical durability of aramid fibers, including specialized coating processes, fiber surface treatments, and composite formulations. These methods improve resistance to abrasion, fatigue, and repeated stress cycles, significantly extending the operational lifespan of aramid-based materials in applications subject to continuous mechanical stresses and friction.

- Chemical Modification for Longevity Improvement: Chemical modifications to aramid fiber structures or surfaces can substantially improve their longevity characteristics. These modifications include cross-linking agents, stabilizing additives, and specialized polymer blends that enhance resistance to hydrolysis, oxidation, and other degradation mechanisms. Such treatments create more durable aramid materials with extended service life in chemically aggressive environments while maintaining core performance properties.

- Lifecycle Assessment and Aging Prediction Methods: Advanced methods for lifecycle assessment and aging prediction have been developed specifically for aramid fiber materials. These include accelerated aging tests, computational models, and real-time monitoring techniques that accurately predict the long-term performance and degradation patterns of aramid fibers under various conditions. Such methods enable more precise estimation of service life and maintenance requirements for aramid-based products in critical applications.

02 Protective treatments for extending aramid fiber lifespan

Specialized treatments can be applied to aramid fibers to enhance their durability and extend their functional lifespan. These treatments include UV stabilizers, moisture-resistant coatings, and chemical protection layers that shield the fibers from degradation factors. Advanced surface modifications can improve resistance to abrasion, chemical exposure, and thermal stress, thereby maintaining the fiber's mechanical properties for longer periods under challenging operating conditions.Expand Specific Solutions03 Composite structures for improved aramid durability

Incorporating aramid fibers into composite structures with complementary materials can significantly enhance their longevity. By combining aramid with other high-performance fibers, polymers, or reinforcing agents, the resulting composite can exhibit superior resistance to degradation factors while maintaining or improving mechanical properties. These hybrid structures can distribute stress more effectively, reducing wear on the aramid components and extending the overall service life of the material system.Expand Specific Solutions04 Manufacturing techniques affecting aramid fiber longevity

The manufacturing process significantly influences the long-term durability of aramid fibers. Factors such as polymerization conditions, spinning parameters, heat treatment protocols, and post-processing techniques can all affect the molecular orientation, crystallinity, and cross-linking of the polymer chains. Optimized manufacturing methods can produce aramid fibers with enhanced resistance to degradation mechanisms, resulting in products with extended service life and maintained performance characteristics over time.Expand Specific Solutions05 Testing and prediction methods for aramid fiber longevity

Various testing methodologies and predictive models have been developed to assess and forecast the longevity of aramid fibers under different conditions. These include accelerated aging tests, mechanical property evaluations, spectroscopic analyses, and computational modeling approaches. By understanding the degradation mechanisms and establishing correlations between laboratory tests and real-world performance, manufacturers and users can better predict the service life of aramid fiber products and develop appropriate maintenance or replacement schedules.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Aramid Testing

The aramid fiber longevity testing market is in a growth phase, with increasing demand driven by applications in aerospace, automotive, and protective equipment sectors. The global market size for aramid fibers is projected to reach approximately $5-6 billion by 2025, with predictive wear testing becoming a critical component for quality assurance. Leading players like DuPont de Nemours and Teijin dominate the technological landscape, having developed sophisticated testing methodologies for fiber degradation prediction. Kolon Industries and SABIC are advancing in specialized testing protocols, while academic institutions such as Korea Advanced Institute of Science & Technology and Nanjing University of Aeronautics & Astronautics contribute significant research innovations. The technology maturity varies across applications, with aerospace testing protocols being most advanced, while emerging applications in automotive and renewable energy sectors are driving new testing methodologies.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed comprehensive accelerated aging protocols for their Kevlar® aramid fiber products that combine multiple environmental stressors (UV exposure, temperature cycling, moisture, and mechanical load) to predict long-term performance. Their proprietary Accelerated Weathering System simulates decades of real-world exposure in weeks, utilizing specialized equipment that can apply cyclic loading while simultaneously exposing fibers to controlled environmental conditions. DuPont employs advanced spectroscopic techniques including FTIR and Raman spectroscopy to monitor chemical changes at the molecular level during degradation, correlating these changes with mechanical property losses. Their predictive models incorporate machine learning algorithms trained on decades of field data from various applications, enabling accurate prediction of aramid fiber performance across different environments and stress conditions.

Strengths: Extensive historical database spanning 50+ years of aramid fiber performance data; proprietary testing equipment specifically designed for aramid fibers; advanced correlation between molecular changes and mechanical properties. Weaknesses: Testing protocols may be overly conservative, potentially overestimating degradation in some applications; requires significant time investment even with acceleration factors.

Kolon Industries, Inc.

Technical Solution: Kolon Industries has pioneered a multi-parameter approach to aramid fiber longevity testing through their Advanced Fiber Lifecycle Assessment (AFLA) system. This technology combines mechanical cycling with environmental exposure chambers to simulate real-world conditions. Their methodology incorporates high-frequency mechanical testing that can apply up to 10 million load cycles while simultaneously exposing fibers to UV radiation, chemical agents, and temperature fluctuations. Kolon's system features real-time monitoring of fiber properties using embedded sensors that detect subtle changes in tensile strength, modulus, and dimensional stability. Their predictive algorithms incorporate data from both accelerated testing and field performance, with particular emphasis on applications in extreme environments such as deep-sea oil exploration where their aramid fibers face unique degradation mechanisms. The company has developed specialized testing protocols for different end-use applications, recognizing that wear mechanisms differ significantly between automotive, aerospace, and industrial applications.

Strengths: Highly customizable testing protocols for specific application environments; excellent correlation between accelerated testing and field performance; sophisticated real-time monitoring capabilities. Weaknesses: Testing equipment requires significant capital investment; some predictive models are application-specific and don't transfer well to novel use cases.

Key Scientific Advancements in Fiber Degradation Modeling

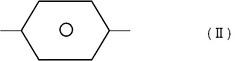

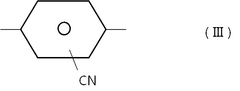

High-elongation copolymerized aramid fiber

PatentWO2017026748A1

Innovation

- Aramid copolymer fibers with an aromatic group substituted by a cyano group (-CN) are produced using a process that quickly extracts organic solvents during coagulation and washing, reducing crystallinity and crystal size, thereby loosening the fiber structure and enhancing elongation to 4.0-6.5%.

Environmental Factors Affecting Aramid Fiber Performance

Aramid fibers, known for their exceptional strength-to-weight ratio, are significantly influenced by various environmental factors that can accelerate degradation and reduce their operational lifespan. Temperature variations represent one of the most critical factors affecting aramid fiber performance. While these fibers maintain excellent mechanical properties at room temperature, prolonged exposure to temperatures exceeding 150°C can initiate thermal degradation processes, leading to chain scission and subsequent reduction in tensile strength. Conversely, extremely low temperatures may cause fiber embrittlement, particularly in applications where dynamic loading occurs.

Ultraviolet (UV) radiation presents another substantial challenge to aramid fiber longevity. When exposed to sunlight or artificial UV sources, aramid fibers undergo photodegradation, which manifests as yellowing, surface embrittlement, and progressive strength loss. Research indicates that after 1000 hours of accelerated UV exposure, certain aramid variants may lose up to 30% of their original tensile strength, highlighting the necessity for UV protection strategies in outdoor applications.

Moisture absorption and hydrolytic degradation constitute significant concerns for aramid fiber performance in humid environments. These fibers can absorb between 4-6% moisture by weight, which may temporarily alter their dimensional stability and electrical properties. More critically, prolonged exposure to moisture, especially in combination with elevated temperatures, can catalyze hydrolysis reactions that permanently compromise the polymer backbone structure.

Chemical exposure represents another environmental factor with profound implications for aramid fiber durability. While these fibers demonstrate remarkable resistance to many organic solvents and petroleum-based products, they exhibit vulnerability to strong acids and bases. For instance, concentrated sulfuric acid can cause rapid degradation through acid hydrolysis, while strong alkalis may attack amide linkages within the polymer structure, resulting in molecular weight reduction and strength loss.

Mechanical abrasion, often exacerbated by environmental particulates, significantly impacts aramid fiber performance in real-world applications. Sand, dust, and other abrasive particles can accelerate wear mechanisms, particularly in dynamic applications such as ropes, cables, and protective garments. The combination of mechanical stress with environmental factors creates synergistic degradation effects that can dramatically reduce service life beyond what individual factors might suggest.

Microbial attack, though less commonly discussed, presents a legitimate concern in certain applications. Under specific conditions of temperature and humidity, certain microorganisms can colonize aramid fiber surfaces, potentially secreting enzymes capable of breaking down the polymer structure. This biological degradation mechanism becomes particularly relevant in geotextile applications or marine environments where fibers remain in constant contact with soil or water containing diverse microbial populations.

Ultraviolet (UV) radiation presents another substantial challenge to aramid fiber longevity. When exposed to sunlight or artificial UV sources, aramid fibers undergo photodegradation, which manifests as yellowing, surface embrittlement, and progressive strength loss. Research indicates that after 1000 hours of accelerated UV exposure, certain aramid variants may lose up to 30% of their original tensile strength, highlighting the necessity for UV protection strategies in outdoor applications.

Moisture absorption and hydrolytic degradation constitute significant concerns for aramid fiber performance in humid environments. These fibers can absorb between 4-6% moisture by weight, which may temporarily alter their dimensional stability and electrical properties. More critically, prolonged exposure to moisture, especially in combination with elevated temperatures, can catalyze hydrolysis reactions that permanently compromise the polymer backbone structure.

Chemical exposure represents another environmental factor with profound implications for aramid fiber durability. While these fibers demonstrate remarkable resistance to many organic solvents and petroleum-based products, they exhibit vulnerability to strong acids and bases. For instance, concentrated sulfuric acid can cause rapid degradation through acid hydrolysis, while strong alkalis may attack amide linkages within the polymer structure, resulting in molecular weight reduction and strength loss.

Mechanical abrasion, often exacerbated by environmental particulates, significantly impacts aramid fiber performance in real-world applications. Sand, dust, and other abrasive particles can accelerate wear mechanisms, particularly in dynamic applications such as ropes, cables, and protective garments. The combination of mechanical stress with environmental factors creates synergistic degradation effects that can dramatically reduce service life beyond what individual factors might suggest.

Microbial attack, though less commonly discussed, presents a legitimate concern in certain applications. Under specific conditions of temperature and humidity, certain microorganisms can colonize aramid fiber surfaces, potentially secreting enzymes capable of breaking down the polymer structure. This biological degradation mechanism becomes particularly relevant in geotextile applications or marine environments where fibers remain in constant contact with soil or water containing diverse microbial populations.

Standardization and Quality Assurance Frameworks

The standardization of aramid fiber testing methodologies represents a critical foundation for ensuring consistent quality assessment across the industry. Currently, several international standards organizations, including ISO, ASTM, and EN, have established specific protocols for evaluating aramid fiber properties. These frameworks provide structured approaches to measure tensile strength, modulus, elongation, and resistance to environmental factors, creating a common language for quality assurance.

Quality control in aramid fiber production necessitates comprehensive testing regimes that incorporate both destructive and non-destructive evaluation techniques. Leading manufacturers have implemented multi-stage quality verification processes, beginning with raw material inspection and continuing through intermediate processing stages to final product validation. These systems typically include statistical process control (SPC) methodologies to monitor production variations and identify potential quality issues before they manifest in the final product.

Certification programs for aramid fiber products have evolved significantly in recent years, with third-party verification becoming increasingly important for market acceptance. Organizations such as Underwriters Laboratories (UL) and TÜV offer specialized certification services that validate compliance with industry standards and performance requirements. These certifications serve as external validation of product quality and reliability, particularly important in safety-critical applications where aramid fibers are commonly deployed.

Predictive wear testing for aramid fibers requires standardized accelerated aging protocols that can reliably simulate long-term environmental exposure and mechanical stress. Current frameworks include cyclic loading tests, UV exposure chambers, chemical resistance evaluations, and thermal aging procedures. The challenge lies in correlating accelerated test results with real-world performance, necessitating careful validation studies and correlation factors.

Emerging trends in quality assurance frameworks include the integration of digital monitoring systems and real-time analytics. Industry 4.0 principles are being applied to aramid fiber testing, with continuous monitoring systems that track fiber properties throughout the manufacturing process. These systems enable predictive quality control by identifying subtle variations that might impact long-term performance before products leave the production facility.

International harmonization efforts are underway to align testing methodologies across different regional standards, facilitating global trade and ensuring consistent quality expectations worldwide. These initiatives aim to reduce redundant testing requirements while maintaining rigorous quality standards, particularly important as aramid fiber applications expand into new markets and industries with varying regulatory environments.

Quality control in aramid fiber production necessitates comprehensive testing regimes that incorporate both destructive and non-destructive evaluation techniques. Leading manufacturers have implemented multi-stage quality verification processes, beginning with raw material inspection and continuing through intermediate processing stages to final product validation. These systems typically include statistical process control (SPC) methodologies to monitor production variations and identify potential quality issues before they manifest in the final product.

Certification programs for aramid fiber products have evolved significantly in recent years, with third-party verification becoming increasingly important for market acceptance. Organizations such as Underwriters Laboratories (UL) and TÜV offer specialized certification services that validate compliance with industry standards and performance requirements. These certifications serve as external validation of product quality and reliability, particularly important in safety-critical applications where aramid fibers are commonly deployed.

Predictive wear testing for aramid fibers requires standardized accelerated aging protocols that can reliably simulate long-term environmental exposure and mechanical stress. Current frameworks include cyclic loading tests, UV exposure chambers, chemical resistance evaluations, and thermal aging procedures. The challenge lies in correlating accelerated test results with real-world performance, necessitating careful validation studies and correlation factors.

Emerging trends in quality assurance frameworks include the integration of digital monitoring systems and real-time analytics. Industry 4.0 principles are being applied to aramid fiber testing, with continuous monitoring systems that track fiber properties throughout the manufacturing process. These systems enable predictive quality control by identifying subtle variations that might impact long-term performance before products leave the production facility.

International harmonization efforts are underway to align testing methodologies across different regional standards, facilitating global trade and ensuring consistent quality expectations worldwide. These initiatives aim to reduce redundant testing requirements while maintaining rigorous quality standards, particularly important as aramid fiber applications expand into new markets and industries with varying regulatory environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!