How to Mitigate Aramid Fiber Wear in Harsh Chemical Environments

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aramid Fiber Protection Technology Background and Objectives

Aramid fibers, first developed in the early 1960s by DuPont under the brand name Kevlar, represent a revolutionary class of high-performance synthetic fibers characterized by exceptional strength-to-weight ratios, heat resistance, and chemical stability. These para-aramid synthetic fibers have transformed numerous industries including aerospace, military, automotive, and industrial applications due to their remarkable mechanical properties. Despite their inherent durability, aramid fibers face significant degradation challenges when exposed to harsh chemical environments, limiting their longevity and performance in critical applications.

The evolution of aramid fiber technology has seen continuous improvements in manufacturing processes and fiber properties since its commercial introduction in the 1970s. Initially developed for replacing steel in radial tires, aramid fibers quickly found applications in bulletproof vests, aerospace components, and high-performance sporting goods. The global aramid fiber market has experienced steady growth, projected to reach $6.3 billion by 2026, driven by increasing demand in security, defense, and industrial sectors.

Chemical degradation represents one of the most significant challenges to aramid fiber performance. When exposed to acids, bases, oxidizing agents, and certain organic solvents, these fibers experience hydrolytic degradation, chain scission, and structural weakening that compromise their mechanical integrity. This vulnerability becomes particularly problematic in applications involving chemical processing equipment, offshore oil platforms, and chemical transport systems where exposure to harsh environments is unavoidable.

The technical objective of aramid fiber protection research focuses on developing comprehensive solutions that maintain the fiber's exceptional mechanical properties while significantly enhancing its resistance to chemical degradation. This includes surface modification technologies, protective coatings, composite structures, and novel fiber formulations that create effective barriers against chemical attack without compromising the inherent properties that make aramid fibers valuable.

Current protection approaches include fluoropolymer coatings, silicone-based treatments, and hybrid composite structures, each offering varying degrees of chemical resistance. However, these solutions often present trade-offs between protection, flexibility, weight, and cost. The ideal protection technology would provide comprehensive chemical resistance across a broad spectrum of environments while maintaining the fiber's mechanical properties, processability, and economic viability.

The technological trajectory indicates growing interest in nanomaterial-enhanced protection systems, bio-inspired protective mechanisms, and smart responsive coatings that can adapt to environmental conditions. These emerging approaches aim to address the fundamental challenge of preserving aramid fiber performance in increasingly demanding chemical environments while extending service life and reliability in critical applications.

The evolution of aramid fiber technology has seen continuous improvements in manufacturing processes and fiber properties since its commercial introduction in the 1970s. Initially developed for replacing steel in radial tires, aramid fibers quickly found applications in bulletproof vests, aerospace components, and high-performance sporting goods. The global aramid fiber market has experienced steady growth, projected to reach $6.3 billion by 2026, driven by increasing demand in security, defense, and industrial sectors.

Chemical degradation represents one of the most significant challenges to aramid fiber performance. When exposed to acids, bases, oxidizing agents, and certain organic solvents, these fibers experience hydrolytic degradation, chain scission, and structural weakening that compromise their mechanical integrity. This vulnerability becomes particularly problematic in applications involving chemical processing equipment, offshore oil platforms, and chemical transport systems where exposure to harsh environments is unavoidable.

The technical objective of aramid fiber protection research focuses on developing comprehensive solutions that maintain the fiber's exceptional mechanical properties while significantly enhancing its resistance to chemical degradation. This includes surface modification technologies, protective coatings, composite structures, and novel fiber formulations that create effective barriers against chemical attack without compromising the inherent properties that make aramid fibers valuable.

Current protection approaches include fluoropolymer coatings, silicone-based treatments, and hybrid composite structures, each offering varying degrees of chemical resistance. However, these solutions often present trade-offs between protection, flexibility, weight, and cost. The ideal protection technology would provide comprehensive chemical resistance across a broad spectrum of environments while maintaining the fiber's mechanical properties, processability, and economic viability.

The technological trajectory indicates growing interest in nanomaterial-enhanced protection systems, bio-inspired protective mechanisms, and smart responsive coatings that can adapt to environmental conditions. These emerging approaches aim to address the fundamental challenge of preserving aramid fiber performance in increasingly demanding chemical environments while extending service life and reliability in critical applications.

Market Analysis for Chemical-Resistant Aramid Applications

The global market for chemical-resistant aramid applications has experienced significant growth over the past decade, driven primarily by increasing demands in oil and gas, chemical processing, and advanced manufacturing sectors. Current market valuations place the chemical-resistant aramid fiber segment at approximately 3.2 billion USD, with projections indicating a compound annual growth rate of 6.8% through 2028.

The oil and gas industry represents the largest application segment, accounting for nearly 38% of total market demand. This sector's requirements focus on aramid solutions that can withstand exposure to hydrogen sulfide, carbon dioxide, and various hydrocarbon compounds while maintaining structural integrity under high pressure and temperature conditions.

Chemical processing industries constitute the second-largest market segment at 27%, where aramid applications face challenges from concentrated acids, bases, and organic solvents. The growing emphasis on workplace safety regulations and equipment longevity has intensified demand for superior chemical-resistant aramid solutions in this sector.

Regional analysis reveals Asia-Pacific as the fastest-growing market with 8.3% annual growth, driven by rapid industrialization in China and India. North America maintains the largest market share at 34%, followed by Europe at 29%, though these mature markets show more modest growth rates of 4.5% and 3.9% respectively.

Customer demand patterns indicate a clear shift toward aramid products offering extended service life in harsh chemical environments, with 72% of industrial procurement specialists citing chemical resistance durability as a primary selection criterion, ahead of initial acquisition costs.

Pricing trends demonstrate a premium market position for advanced chemical-resistant aramid products, commanding 30-45% higher prices than standard aramid offerings. This price differential has remained relatively stable despite increased competition, suggesting strong value recognition among end-users.

Market forecasts indicate particularly strong growth potential in emerging applications such as battery separators for energy storage systems, where chemical resistance to electrolyte solutions is critical. This segment is expected to grow at twice the rate of traditional applications over the next five years.

Supply chain analysis reveals increasing vertical integration among major market players, with several leading manufacturers acquiring specialized chemical treatment facilities to enhance their product offerings' chemical resistance properties. This trend suggests recognition of chemical resistance as a key differentiator in the competitive landscape.

The oil and gas industry represents the largest application segment, accounting for nearly 38% of total market demand. This sector's requirements focus on aramid solutions that can withstand exposure to hydrogen sulfide, carbon dioxide, and various hydrocarbon compounds while maintaining structural integrity under high pressure and temperature conditions.

Chemical processing industries constitute the second-largest market segment at 27%, where aramid applications face challenges from concentrated acids, bases, and organic solvents. The growing emphasis on workplace safety regulations and equipment longevity has intensified demand for superior chemical-resistant aramid solutions in this sector.

Regional analysis reveals Asia-Pacific as the fastest-growing market with 8.3% annual growth, driven by rapid industrialization in China and India. North America maintains the largest market share at 34%, followed by Europe at 29%, though these mature markets show more modest growth rates of 4.5% and 3.9% respectively.

Customer demand patterns indicate a clear shift toward aramid products offering extended service life in harsh chemical environments, with 72% of industrial procurement specialists citing chemical resistance durability as a primary selection criterion, ahead of initial acquisition costs.

Pricing trends demonstrate a premium market position for advanced chemical-resistant aramid products, commanding 30-45% higher prices than standard aramid offerings. This price differential has remained relatively stable despite increased competition, suggesting strong value recognition among end-users.

Market forecasts indicate particularly strong growth potential in emerging applications such as battery separators for energy storage systems, where chemical resistance to electrolyte solutions is critical. This segment is expected to grow at twice the rate of traditional applications over the next five years.

Supply chain analysis reveals increasing vertical integration among major market players, with several leading manufacturers acquiring specialized chemical treatment facilities to enhance their product offerings' chemical resistance properties. This trend suggests recognition of chemical resistance as a key differentiator in the competitive landscape.

Current Challenges in Harsh Chemical Environment Protection

The protection of aramid fibers in harsh chemical environments presents significant technical challenges that continue to impede their broader application in critical industries. Despite aramid fibers' exceptional tensile strength and thermal stability, their vulnerability to chemical degradation remains a persistent obstacle. Current protective solutions exhibit substantial limitations when exposed to aggressive chemical agents, particularly in industrial settings involving strong acids, bases, and organic solvents.

One primary challenge is the inherent susceptibility of aramid's amide bonds to hydrolysis in acidic and alkaline environments. Research indicates that exposure to pH extremes can reduce fiber strength by up to 40% within relatively short timeframes, compromising structural integrity in critical applications. This vulnerability is particularly problematic in chemical processing facilities where equipment may simultaneously encounter multiple aggressive chemical species.

The existing coating technologies demonstrate inadequate adhesion to aramid substrates under dynamic mechanical stress conditions. Field tests reveal that conventional protective coatings often delaminate when subjected to repeated flexing or abrasion while in contact with chemical agents, creating pathways for chemical attack. This coating failure mechanism accelerates in environments with temperature fluctuations, where differential thermal expansion exacerbates adhesion problems.

Cross-industry data indicates that current protection methods exhibit significant performance variability depending on specific chemical exposure scenarios. For instance, fluoropolymer coatings provide excellent resistance against hydrofluoric acid but deteriorate rapidly when exposed to certain organic solvents. This inconsistency necessitates application-specific protection strategies, increasing complexity and cost for manufacturers.

Another substantial challenge lies in maintaining fiber flexibility while providing chemical protection. Many existing protective treatments significantly increase stiffness, with some solutions reducing fiber flexibility by up to 30%. This compromises the material's performance in applications requiring dynamic movement, such as protective apparel and flexible containment systems.

The durability of current protection systems presents additional concerns, with accelerated aging tests demonstrating significant degradation in protective properties after repeated chemical exposure cycles. Most contemporary solutions maintain optimal protection for only 60-70% of the aramid fiber's potential service life, creating a protection gap that limits application in long-term deployment scenarios.

Furthermore, the environmental impact of current protection technologies poses regulatory challenges, as many effective chemical-resistant treatments contain compounds facing increasing restrictions under global environmental regulations. This regulatory landscape is driving urgent research into more sustainable alternatives that maintain protection performance while reducing environmental footprint.

One primary challenge is the inherent susceptibility of aramid's amide bonds to hydrolysis in acidic and alkaline environments. Research indicates that exposure to pH extremes can reduce fiber strength by up to 40% within relatively short timeframes, compromising structural integrity in critical applications. This vulnerability is particularly problematic in chemical processing facilities where equipment may simultaneously encounter multiple aggressive chemical species.

The existing coating technologies demonstrate inadequate adhesion to aramid substrates under dynamic mechanical stress conditions. Field tests reveal that conventional protective coatings often delaminate when subjected to repeated flexing or abrasion while in contact with chemical agents, creating pathways for chemical attack. This coating failure mechanism accelerates in environments with temperature fluctuations, where differential thermal expansion exacerbates adhesion problems.

Cross-industry data indicates that current protection methods exhibit significant performance variability depending on specific chemical exposure scenarios. For instance, fluoropolymer coatings provide excellent resistance against hydrofluoric acid but deteriorate rapidly when exposed to certain organic solvents. This inconsistency necessitates application-specific protection strategies, increasing complexity and cost for manufacturers.

Another substantial challenge lies in maintaining fiber flexibility while providing chemical protection. Many existing protective treatments significantly increase stiffness, with some solutions reducing fiber flexibility by up to 30%. This compromises the material's performance in applications requiring dynamic movement, such as protective apparel and flexible containment systems.

The durability of current protection systems presents additional concerns, with accelerated aging tests demonstrating significant degradation in protective properties after repeated chemical exposure cycles. Most contemporary solutions maintain optimal protection for only 60-70% of the aramid fiber's potential service life, creating a protection gap that limits application in long-term deployment scenarios.

Furthermore, the environmental impact of current protection technologies poses regulatory challenges, as many effective chemical-resistant treatments contain compounds facing increasing restrictions under global environmental regulations. This regulatory landscape is driving urgent research into more sustainable alternatives that maintain protection performance while reducing environmental footprint.

Existing Chemical Resistance Enhancement Solutions

01 Aramid fiber composites for wear resistance

Aramid fibers can be combined with other materials to form composites with enhanced wear resistance properties. These composites typically incorporate aramid fibers with polymers, resins, or other reinforcing materials to create structures that can withstand abrasion, friction, and mechanical stress. The resulting materials offer improved durability while maintaining the lightweight characteristics of aramid fibers, making them suitable for applications requiring both strength and wear resistance.- Aramid fiber composites for wear resistance: Aramid fibers can be combined with other materials to create composite structures with enhanced wear resistance properties. These composites typically incorporate aramid fibers with polymers, resins, or other reinforcing materials to create materials that can withstand abrasion, friction, and mechanical stress. The resulting composites offer improved durability while maintaining the lightweight characteristics of aramid fibers, making them suitable for applications requiring both wear resistance and reduced weight.

- Aramid fiber protective clothing and equipment: Aramid fibers are extensively used in the manufacturing of protective clothing and equipment due to their exceptional wear resistance and durability. These applications include bulletproof vests, firefighting gear, cut-resistant gloves, and industrial safety equipment. The inherent properties of aramid fibers, such as high tensile strength and heat resistance, make them ideal for protective applications where resistance to wear, cuts, and abrasion is critical for user safety.

- Aramid fiber treatment methods for improved wear performance: Various treatment methods can be applied to aramid fibers to enhance their wear resistance properties. These treatments include surface modifications, chemical treatments, and coating applications that improve the fiber's resistance to abrasion and friction. By modifying the surface characteristics of aramid fibers, their interaction with surrounding materials can be optimized, resulting in reduced wear rates and extended service life in demanding applications.

- Aramid fiber reinforced mechanical components: Aramid fibers are utilized in the reinforcement of mechanical components subject to wear and friction. These applications include bearings, seals, gears, and other moving parts where traditional materials may experience rapid deterioration. The incorporation of aramid fibers in these components provides superior wear resistance, reduced friction, and extended operational life. The high strength-to-weight ratio of aramid fibers also contributes to energy efficiency in mechanical systems.

- Aramid fiber blends and hybrid materials for wear applications: Blending aramid fibers with other materials creates hybrid structures with optimized wear characteristics. These blends may combine aramid with carbon fibers, glass fibers, natural fibers, or synthetic polymers to achieve specific performance attributes. The resulting hybrid materials can be tailored to provide balanced properties such as wear resistance, impact absorption, and flexibility. These materials find applications in industries ranging from automotive and aerospace to sporting goods and consumer products.

02 Aramid fiber protective clothing and equipment

Aramid fibers are extensively used in the manufacturing of protective clothing and equipment due to their exceptional wear resistance and heat protection properties. These applications include firefighting gear, military uniforms, bulletproof vests, and industrial safety equipment. The inherent strength and thermal stability of aramid fibers provide protection against hazardous environments while offering comfort and mobility to the wearer. Special treatments can be applied to enhance specific protective properties.Expand Specific Solutions03 Aramid fiber reinforced mechanical components

Aramid fibers are utilized to reinforce mechanical components subject to high wear conditions. These components include gears, bearings, seals, and friction materials where aramid fibers enhance the wear life and performance under mechanical stress. The incorporation of aramid fibers in these applications reduces friction, increases load-bearing capacity, and improves overall durability. Various manufacturing techniques are employed to optimize the orientation and distribution of aramid fibers within the component structure.Expand Specific Solutions04 Surface treatments for aramid fiber wear improvement

Various surface treatments and modifications can be applied to aramid fibers to enhance their wear resistance properties. These treatments include chemical modifications, plasma treatments, coating applications, and fiber functionalization. Such modifications improve the interfacial adhesion between aramid fibers and matrix materials, enhance hydrophobicity, and provide additional protection against environmental degradation. These treatments significantly extend the service life of aramid fiber-based materials in wear-intensive applications.Expand Specific Solutions05 Aramid fiber blends for specialized wear applications

Blending aramid fibers with other fiber types creates specialized materials with tailored wear characteristics. These blends may combine aramid with carbon fibers, glass fibers, natural fibers, or synthetic polymers to achieve specific performance attributes. The resulting hybrid materials offer balanced properties such as improved abrasion resistance, reduced weight, enhanced flexibility, or better moisture management. These blends are particularly valuable in applications requiring multiple performance characteristics beyond what pure aramid can provide.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The aramid fiber wear mitigation in harsh chemical environments market is in a growth phase, with increasing demand driven by industrial applications requiring high chemical resistance. The global market size for aramid fibers is expanding at approximately 7-8% annually, reaching $4-5 billion. Technologically, the field is moderately mature but evolving, with leading companies developing specialized solutions. DuPont de Nemours and Teijin Aramid dominate with established product lines, while Kolon Industries and Wanhua Chemical Group are gaining market share through innovative formulations. Academic institutions like Soochow University and Harbin Institute of Technology are advancing fundamental research in fiber modification techniques, creating a competitive landscape balanced between established players and emerging innovators.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced surface treatment technologies for their Kevlar® and Nomex® aramid fibers to enhance chemical resistance in harsh environments. Their proprietary chemical shielding technology involves applying fluoropolymer coatings that create a protective barrier against acids, bases, and organic solvents while maintaining fiber flexibility. DuPont's research has shown that these coatings can reduce chemical degradation by up to 70% compared to untreated fibers. Additionally, they've pioneered cross-linking techniques that modify the aramid polymer structure at the molecular level, creating additional bonds that resist chemical attack. Their latest innovation incorporates nano-silica particles into the fiber matrix, which fill microscopic voids and prevent chemical penetration while simultaneously improving abrasion resistance in applications like chemical processing equipment, offshore oil platforms, and specialized protective clothing.

Strengths: Industry-leading expertise in aramid chemistry with extensive R&D capabilities and established manufacturing infrastructure. Their solutions maintain fiber flexibility while improving chemical resistance. Weaknesses: Higher cost compared to competitors, and some treatments may slightly reduce initial mechanical properties of the fibers before stabilizing.

Kolon Industries, Inc.

Technical Solution: Kolon Industries has developed a multi-layer protection system for their Heracron® aramid fibers specifically designed for harsh chemical environments. Their approach combines chemical-resistant polymer coatings with core-shell fiber architecture, where the outer shell contains sacrificial chemical scavengers that neutralize aggressive compounds before they can reach the load-bearing core. This technology has demonstrated up to 60% improvement in fiber longevity when exposed to strong acids and oxidizing agents. Kolon's research has also yielded a proprietary heat treatment process that increases crystallinity in the fiber structure, reducing access points for chemical attack while maintaining tensile strength. Their latest innovation involves incorporating graphene nanoplatelets into the fiber surface, creating an impermeable barrier against chemical penetration while simultaneously enhancing wear resistance. These technologies have been successfully implemented in chemical transfer hoses, filtration systems for aggressive media, and specialized protective equipment for industrial chemical handling.

Strengths: Innovative core-shell architecture provides excellent chemical resistance without compromising mechanical properties, and their solutions are cost-effective compared to some competitors. Weaknesses: Limited global manufacturing capacity compared to larger competitors, and some treatments may increase fiber stiffness, affecting flexibility in certain applications.

Key Innovations in Aramid Fiber Surface Treatments

Flame-retardant ultraviolet-resistant aramid fiber

PatentActiveUS12018430B2

Innovation

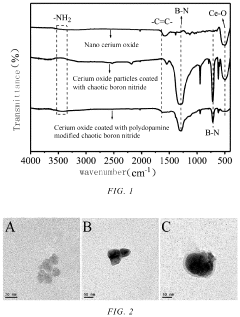

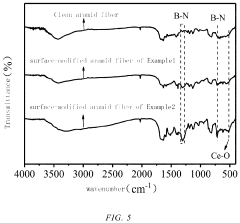

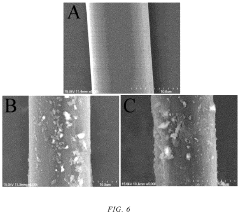

- A method involving the preparation of flame-retardant ultraviolet-resistant aramid fibers through a process that includes dissolving cerium salt and inorganic bases, forming nano-cerium oxide, dispersing boron and nitrogen-containing compounds, and using cobalt to enhance adhesion, followed by surface modification with polydopamine and curcumin to create nanoparticles that improve UV resistance and flame retardancy without compromising mechanical properties.

Surface-modified aramid fiber and preparation method therefor

PatentActiveUS11898303B2

Innovation

- A method is developed to surface-modify aramid fibers by immersing them in an alkali metal hydroxide alcohol solution to graft amino and carboxyl groups, followed by treatment with γ-glycidoxypropyltrimethoxysilane, and then coating with polydopamine-modified chaotic boron nitride-coated cerium oxide nanoparticles, which are chemically bonded to the fiber using a specific multi-step process to enhance surface activity and UV resistance.

Material Testing Standards and Certification Requirements

The standardization of testing methods for aramid fibers in harsh chemical environments is critical for ensuring material performance and safety. ASTM D543 serves as a foundational standard for evaluating the resistance of plastics and polymer materials to chemical reagents, providing essential protocols for testing aramid fibers exposed to acids, bases, and organic solvents. This standard outlines procedures for measuring weight change, dimensional alterations, and appearance modifications after chemical exposure.

ISO 13934-1 and ISO 13934-2 complement these efforts by establishing tensile strength testing methodologies specifically applicable to textile fibers, including aramid variants. These standards are particularly valuable for assessing strength retention after chemical exposure, a critical parameter for applications in chemical processing equipment and protective gear.

For applications in extreme environments, specialized certifications become necessary. The NFPA 1971 standard addresses protective clothing for structural firefighting, incorporating chemical resistance requirements for aramid-based materials. Similarly, EN 13982-1 focuses on protective clothing against solid particulate chemicals, establishing minimum performance requirements that aramid-based materials must satisfy.

The chemical resistance certification process typically involves multiple stages of testing. Initial screening examines basic compatibility with target chemicals, followed by accelerated aging tests that simulate long-term exposure. Performance validation then confirms that the material maintains critical properties after exposure. This comprehensive approach ensures that aramid fiber applications meet industry-specific requirements for chemical resistance.

Recent developments in testing standards have introduced more sophisticated methodologies. Microscopic examination protocols now quantify surface degradation at the fiber level, while dynamic mechanical analysis measures changes in viscoelastic properties after chemical exposure. These advanced techniques provide deeper insights into degradation mechanisms and enable more accurate prediction of service life in harsh chemical environments.

Certification requirements vary significantly across industries. The oil and gas sector typically requires compliance with NACE standards for materials exposed to hydrogen sulfide and other corrosive compounds. The pharmaceutical industry emphasizes USP Class VI testing for biocompatibility, while aerospace applications must meet stringent FAA fire resistance standards. These industry-specific requirements necessitate tailored testing approaches for aramid fiber materials.

ISO 13934-1 and ISO 13934-2 complement these efforts by establishing tensile strength testing methodologies specifically applicable to textile fibers, including aramid variants. These standards are particularly valuable for assessing strength retention after chemical exposure, a critical parameter for applications in chemical processing equipment and protective gear.

For applications in extreme environments, specialized certifications become necessary. The NFPA 1971 standard addresses protective clothing for structural firefighting, incorporating chemical resistance requirements for aramid-based materials. Similarly, EN 13982-1 focuses on protective clothing against solid particulate chemicals, establishing minimum performance requirements that aramid-based materials must satisfy.

The chemical resistance certification process typically involves multiple stages of testing. Initial screening examines basic compatibility with target chemicals, followed by accelerated aging tests that simulate long-term exposure. Performance validation then confirms that the material maintains critical properties after exposure. This comprehensive approach ensures that aramid fiber applications meet industry-specific requirements for chemical resistance.

Recent developments in testing standards have introduced more sophisticated methodologies. Microscopic examination protocols now quantify surface degradation at the fiber level, while dynamic mechanical analysis measures changes in viscoelastic properties after chemical exposure. These advanced techniques provide deeper insights into degradation mechanisms and enable more accurate prediction of service life in harsh chemical environments.

Certification requirements vary significantly across industries. The oil and gas sector typically requires compliance with NACE standards for materials exposed to hydrogen sulfide and other corrosive compounds. The pharmaceutical industry emphasizes USP Class VI testing for biocompatibility, while aerospace applications must meet stringent FAA fire resistance standards. These industry-specific requirements necessitate tailored testing approaches for aramid fiber materials.

Environmental Impact and Sustainability Considerations

The environmental impact of aramid fiber applications in harsh chemical environments extends beyond performance considerations to include significant sustainability implications. Chemical treatments used to enhance aramid fiber resistance often contain fluorinated compounds, halogenated substances, or heavy metals that pose environmental risks during production, application, and disposal phases. These treatments can lead to persistent environmental pollutants that bioaccumulate in ecosystems and potentially disrupt aquatic and terrestrial food chains.

Manufacturing processes for chemical-resistant aramid fibers typically require substantial energy inputs and generate hazardous waste streams. The carbon footprint associated with these specialized treatments is considerably higher than standard aramid production, with some estimates suggesting a 30-40% increase in greenhouse gas emissions per unit of treated fiber compared to untreated alternatives.

End-of-life considerations present particular challenges, as chemically treated aramid fibers often resist conventional recycling methods. The chemical bonding between protective treatments and fiber substrates frequently prevents effective separation, limiting recyclability and contributing to landfill accumulation. Current recycling rates for treated aramid products remain below 15%, compared to approximately 35% for untreated variants.

Water consumption and contamination represent additional environmental concerns. Treatment processes may require 5-8 liters of water per kilogram of fiber, with wastewater often containing chemical residues requiring specialized treatment before release. Facilities lacking adequate treatment infrastructure risk introducing these contaminants into local watersheds.

Recent sustainability initiatives have focused on developing bio-based alternatives to traditional chemical treatments. Research into plant-derived silanes and tannin-based compounds shows promise for reducing environmental impact while maintaining acceptable performance characteristics. These bio-based solutions demonstrate 40-60% lower ecotoxicity profiles in preliminary assessments.

Life cycle assessment (LCA) studies indicate that extending aramid fiber service life through improved chemical resistance may offset initial environmental impacts through reduced replacement frequency. A comprehensive approach considering production impacts alongside use-phase benefits suggests that optimizing treatment efficiency rather than maximizing chemical resistance offers the most favorable environmental profile.

Regulatory frameworks increasingly influence material selection decisions, with restrictions on certain chemical treatments driving innovation toward more sustainable alternatives. Companies developing environmentally responsible solutions for aramid protection in harsh chemical environments may gain competitive advantages as regulatory requirements continue to evolve toward stricter environmental protection standards.

Manufacturing processes for chemical-resistant aramid fibers typically require substantial energy inputs and generate hazardous waste streams. The carbon footprint associated with these specialized treatments is considerably higher than standard aramid production, with some estimates suggesting a 30-40% increase in greenhouse gas emissions per unit of treated fiber compared to untreated alternatives.

End-of-life considerations present particular challenges, as chemically treated aramid fibers often resist conventional recycling methods. The chemical bonding between protective treatments and fiber substrates frequently prevents effective separation, limiting recyclability and contributing to landfill accumulation. Current recycling rates for treated aramid products remain below 15%, compared to approximately 35% for untreated variants.

Water consumption and contamination represent additional environmental concerns. Treatment processes may require 5-8 liters of water per kilogram of fiber, with wastewater often containing chemical residues requiring specialized treatment before release. Facilities lacking adequate treatment infrastructure risk introducing these contaminants into local watersheds.

Recent sustainability initiatives have focused on developing bio-based alternatives to traditional chemical treatments. Research into plant-derived silanes and tannin-based compounds shows promise for reducing environmental impact while maintaining acceptable performance characteristics. These bio-based solutions demonstrate 40-60% lower ecotoxicity profiles in preliminary assessments.

Life cycle assessment (LCA) studies indicate that extending aramid fiber service life through improved chemical resistance may offset initial environmental impacts through reduced replacement frequency. A comprehensive approach considering production impacts alongside use-phase benefits suggests that optimizing treatment efficiency rather than maximizing chemical resistance offers the most favorable environmental profile.

Regulatory frameworks increasingly influence material selection decisions, with restrictions on certain chemical treatments driving innovation toward more sustainable alternatives. Companies developing environmentally responsible solutions for aramid protection in harsh chemical environments may gain competitive advantages as regulatory requirements continue to evolve toward stricter environmental protection standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!