Aramid Fiber vs PTFE: Evaluate Temperature Tolerance

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temperature Materials Background and Objectives

The evolution of high-temperature materials has been a critical focus in industrial applications for decades. Since the 1960s, materials science has continuously sought to develop substances capable of withstanding extreme thermal conditions while maintaining structural integrity. Aramid fibers emerged in the late 1960s as revolutionary synthetic polymers with exceptional heat resistance, while polytetrafluoroethylene (PTFE) was discovered earlier in 1938, gaining prominence for its unique combination of chemical inertness and thermal stability.

The global high-temperature materials market has experienced significant growth, reaching approximately $7.2 billion in 2022 with projections to exceed $10 billion by 2028. This expansion is primarily driven by increasing demands in aerospace, automotive, electronics, and industrial processing sectors where thermal management is critical to operational efficiency and safety.

Temperature tolerance represents one of the most crucial parameters in material selection for extreme environment applications. Aramid fibers typically demonstrate continuous use temperature ranges of 200-250°C with short-term exposure capabilities up to 400°C before significant degradation occurs. Conversely, PTFE exhibits remarkable stability at continuous operating temperatures of 260°C, with brief exposure tolerance up to 300°C, though its mechanical properties begin to deteriorate at these upper limits.

The primary objective of this technical evaluation is to conduct a comprehensive comparative analysis of aramid fibers and PTFE regarding their temperature tolerance profiles. This assessment aims to identify the specific thermal performance boundaries, degradation mechanisms, and failure modes of both materials under various temperature conditions and exposure durations.

Additionally, this research seeks to establish clear selection criteria for engineers and product developers when choosing between these materials for high-temperature applications. The evaluation will consider not only maximum temperature thresholds but also critical factors including mechanical property retention, dimensional stability, and chemical resistance at elevated temperatures.

The findings from this investigation will support strategic material selection decisions across multiple industries, particularly in applications where thermal performance represents a critical design parameter. Furthermore, this analysis will identify potential research directions for enhancing the temperature tolerance of both materials through modifications, additives, or composite formulations to address existing limitations in extreme thermal environments.

The global high-temperature materials market has experienced significant growth, reaching approximately $7.2 billion in 2022 with projections to exceed $10 billion by 2028. This expansion is primarily driven by increasing demands in aerospace, automotive, electronics, and industrial processing sectors where thermal management is critical to operational efficiency and safety.

Temperature tolerance represents one of the most crucial parameters in material selection for extreme environment applications. Aramid fibers typically demonstrate continuous use temperature ranges of 200-250°C with short-term exposure capabilities up to 400°C before significant degradation occurs. Conversely, PTFE exhibits remarkable stability at continuous operating temperatures of 260°C, with brief exposure tolerance up to 300°C, though its mechanical properties begin to deteriorate at these upper limits.

The primary objective of this technical evaluation is to conduct a comprehensive comparative analysis of aramid fibers and PTFE regarding their temperature tolerance profiles. This assessment aims to identify the specific thermal performance boundaries, degradation mechanisms, and failure modes of both materials under various temperature conditions and exposure durations.

Additionally, this research seeks to establish clear selection criteria for engineers and product developers when choosing between these materials for high-temperature applications. The evaluation will consider not only maximum temperature thresholds but also critical factors including mechanical property retention, dimensional stability, and chemical resistance at elevated temperatures.

The findings from this investigation will support strategic material selection decisions across multiple industries, particularly in applications where thermal performance represents a critical design parameter. Furthermore, this analysis will identify potential research directions for enhancing the temperature tolerance of both materials through modifications, additives, or composite formulations to address existing limitations in extreme thermal environments.

Market Demand Analysis for Heat-Resistant Fibers

The global market for heat-resistant fibers has experienced significant growth in recent years, driven by increasing demand across multiple industries including aerospace, automotive, electronics, and industrial manufacturing. Heat-resistant fibers, particularly aramid fibers and PTFE (polytetrafluoroethylene), have become critical materials for applications requiring thermal stability under extreme conditions.

Market research indicates that the heat-resistant fiber market is projected to grow at a compound annual growth rate of 8.2% through 2028, with the global market value expected to reach 14.5 billion USD by that time. This growth is primarily fueled by expanding applications in personal protective equipment, filtration systems, and advanced composites for high-temperature environments.

Aramid fibers have established a strong market presence due to their exceptional strength-to-weight ratio combined with heat resistance capabilities. The demand for aramid fibers is particularly robust in the defense and aerospace sectors, where materials must withstand both mechanical stress and thermal extremes. The automotive industry represents another significant market segment, with increasing requirements for heat-resistant components in engine compartments and exhaust systems.

PTFE fibers, while occupying a smaller market share than aramids, have carved out a specialized niche due to their superior chemical resistance and exceptional temperature tolerance. The demand for PTFE is growing steadily in chemical processing, electronics manufacturing, and industrial filtration applications where exposure to corrosive substances at elevated temperatures is common.

Regional analysis reveals that North America and Europe currently dominate the market for high-performance heat-resistant fibers, accounting for approximately 60% of global consumption. However, the Asia-Pacific region is emerging as the fastest-growing market, with China, Japan, and South Korea leading industrial adoption of these advanced materials.

Consumer trends indicate a growing preference for materials that offer multiple performance attributes beyond heat resistance alone. This has created market opportunities for hybrid or composite solutions that combine the temperature tolerance of materials like PTFE with complementary properties such as electrical insulation or chemical resistance.

The filtration industry represents one of the fastest-growing application segments for heat-resistant fibers, with increasing environmental regulations driving demand for high-performance filter media capable of operating in high-temperature industrial processes. Similarly, the electronics industry's push toward miniaturization has intensified the need for materials that can maintain integrity under the thermal stress generated by densely packed components.

Market research indicates that the heat-resistant fiber market is projected to grow at a compound annual growth rate of 8.2% through 2028, with the global market value expected to reach 14.5 billion USD by that time. This growth is primarily fueled by expanding applications in personal protective equipment, filtration systems, and advanced composites for high-temperature environments.

Aramid fibers have established a strong market presence due to their exceptional strength-to-weight ratio combined with heat resistance capabilities. The demand for aramid fibers is particularly robust in the defense and aerospace sectors, where materials must withstand both mechanical stress and thermal extremes. The automotive industry represents another significant market segment, with increasing requirements for heat-resistant components in engine compartments and exhaust systems.

PTFE fibers, while occupying a smaller market share than aramids, have carved out a specialized niche due to their superior chemical resistance and exceptional temperature tolerance. The demand for PTFE is growing steadily in chemical processing, electronics manufacturing, and industrial filtration applications where exposure to corrosive substances at elevated temperatures is common.

Regional analysis reveals that North America and Europe currently dominate the market for high-performance heat-resistant fibers, accounting for approximately 60% of global consumption. However, the Asia-Pacific region is emerging as the fastest-growing market, with China, Japan, and South Korea leading industrial adoption of these advanced materials.

Consumer trends indicate a growing preference for materials that offer multiple performance attributes beyond heat resistance alone. This has created market opportunities for hybrid or composite solutions that combine the temperature tolerance of materials like PTFE with complementary properties such as electrical insulation or chemical resistance.

The filtration industry represents one of the fastest-growing application segments for heat-resistant fibers, with increasing environmental regulations driving demand for high-performance filter media capable of operating in high-temperature industrial processes. Similarly, the electronics industry's push toward miniaturization has intensified the need for materials that can maintain integrity under the thermal stress generated by densely packed components.

Current State and Challenges in Thermal Resistance

The global thermal resistance materials market is witnessing significant advancements, with aramid fibers and polytetrafluoroethylene (PTFE) emerging as leading contenders for high-temperature applications. Current research indicates that aramid fibers typically maintain structural integrity up to 370-425°C in short-term exposure scenarios, while exhibiting continuous service temperature capabilities of approximately 200-250°C. In contrast, PTFE demonstrates remarkable thermal stability with a continuous operating temperature range of 260-280°C and short-term exposure tolerance up to 300°C.

Recent technological developments have enhanced the thermal resistance properties of both materials. Advanced aramid fiber variants incorporating heat-stabilizing additives have shown improved performance in extreme temperature environments. Similarly, modified PTFE formulations with reinforcing fillers have demonstrated enhanced thermal stability and reduced deformation under prolonged heat exposure.

Despite these advancements, significant challenges persist in thermal resistance optimization. For aramid fibers, oxidative degradation remains a critical limitation at elevated temperatures, particularly in oxygen-rich environments. This degradation manifests as chain scission and crosslinking, resulting in compromised mechanical properties. Additionally, moisture absorption at high temperatures accelerates hydrolytic degradation, further limiting aramid's performance in humid, high-temperature settings.

PTFE faces distinct challenges in thermal resistance applications. While exhibiting excellent chemical stability, PTFE undergoes dimensional changes and creep under load at elevated temperatures. The material's relatively high coefficient of thermal expansion creates design challenges for precision components operating across wide temperature ranges. Furthermore, PTFE experiences a phase transition at approximately 19°C, leading to volume changes that can affect dimensional stability in applications crossing this temperature threshold.

Manufacturing consistency represents another significant challenge for both materials. Production of aramid fibers with uniform heat resistance properties requires precise control of polymerization conditions and post-processing treatments. Similarly, PTFE processing demands careful management of sintering parameters to achieve optimal crystallinity and subsequent thermal performance.

The geographical distribution of thermal resistance technology development shows concentration in advanced manufacturing regions. Japan, the United States, and Germany lead in aramid fiber thermal resistance innovations, while PTFE thermal technology advancements are primarily centered in the United States, China, and Germany. This distribution reflects both historical expertise and current R&D investment patterns in high-performance materials.

Regulatory considerations further complicate the landscape, with increasingly stringent fire safety and emissions standards driving demand for improved thermal resistance while simultaneously restricting certain manufacturing processes and additives traditionally used to enhance temperature tolerance.

Recent technological developments have enhanced the thermal resistance properties of both materials. Advanced aramid fiber variants incorporating heat-stabilizing additives have shown improved performance in extreme temperature environments. Similarly, modified PTFE formulations with reinforcing fillers have demonstrated enhanced thermal stability and reduced deformation under prolonged heat exposure.

Despite these advancements, significant challenges persist in thermal resistance optimization. For aramid fibers, oxidative degradation remains a critical limitation at elevated temperatures, particularly in oxygen-rich environments. This degradation manifests as chain scission and crosslinking, resulting in compromised mechanical properties. Additionally, moisture absorption at high temperatures accelerates hydrolytic degradation, further limiting aramid's performance in humid, high-temperature settings.

PTFE faces distinct challenges in thermal resistance applications. While exhibiting excellent chemical stability, PTFE undergoes dimensional changes and creep under load at elevated temperatures. The material's relatively high coefficient of thermal expansion creates design challenges for precision components operating across wide temperature ranges. Furthermore, PTFE experiences a phase transition at approximately 19°C, leading to volume changes that can affect dimensional stability in applications crossing this temperature threshold.

Manufacturing consistency represents another significant challenge for both materials. Production of aramid fibers with uniform heat resistance properties requires precise control of polymerization conditions and post-processing treatments. Similarly, PTFE processing demands careful management of sintering parameters to achieve optimal crystallinity and subsequent thermal performance.

The geographical distribution of thermal resistance technology development shows concentration in advanced manufacturing regions. Japan, the United States, and Germany lead in aramid fiber thermal resistance innovations, while PTFE thermal technology advancements are primarily centered in the United States, China, and Germany. This distribution reflects both historical expertise and current R&D investment patterns in high-performance materials.

Regulatory considerations further complicate the landscape, with increasingly stringent fire safety and emissions standards driving demand for improved thermal resistance while simultaneously restricting certain manufacturing processes and additives traditionally used to enhance temperature tolerance.

Technical Comparison of Aramid and PTFE Solutions

01 Temperature tolerance characteristics of aramid fiber and PTFE

Aramid fibers and PTFE both exhibit exceptional temperature tolerance properties. Aramid fibers can typically withstand continuous operating temperatures of 200-250°C while maintaining their mechanical properties, with short-term exposure tolerance up to 400°C. PTFE has an even higher temperature resistance, functioning effectively from -200°C to 260°C continuously, with brief exposure capability up to 300°C. These materials retain their structural integrity and performance characteristics even under extreme temperature conditions, making them suitable for high-temperature applications.- Temperature tolerance characteristics of aramid fiber and PTFE composites: Aramid fiber and PTFE composites demonstrate exceptional temperature tolerance properties, with aramid fibers typically withstanding temperatures up to 500°C in short exposures while maintaining structural integrity. PTFE contributes excellent thermal stability up to 260°C continuous operation. When combined, these materials create composites that can function effectively in extreme temperature environments while preserving mechanical properties and chemical resistance, making them suitable for high-temperature industrial applications.

- High-temperature filtration applications using aramid fiber and PTFE membranes: Aramid fiber reinforced PTFE membranes are extensively used in high-temperature filtration systems. These composite materials can maintain filtration efficiency at elevated temperatures up to 280°C in continuous operation. The aramid fiber provides structural support while the PTFE membrane offers chemical resistance and non-stick properties. These filtration systems are particularly valuable in industrial processes involving hot gases, chemical processing, and power generation where both heat resistance and filtration performance are critical requirements.

- Thermal protective equipment incorporating aramid fiber and PTFE: Thermal protective equipment often incorporates aramid fiber and PTFE materials to provide heat resistance and safety in extreme environments. These materials are used in firefighting gear, industrial safety equipment, and heat shields where they can withstand temperatures exceeding 400°C for short periods. The aramid fiber provides strength and flame resistance while the PTFE layer adds thermal insulation and prevents moisture penetration. This combination offers optimal protection against heat, flames, and thermal radiation while maintaining flexibility and durability.

- Enhanced mechanical properties of aramid-PTFE composites at high temperatures: Aramid fiber reinforced PTFE composites maintain superior mechanical properties at elevated temperatures compared to conventional materials. These composites retain up to 70% of their room temperature strength at 200°C and demonstrate minimal creep under load at high temperatures. The aramid fibers provide tensile strength and dimensional stability while the PTFE matrix contributes low friction and chemical resistance. This combination results in components that can withstand mechanical stress under extreme thermal conditions, making them ideal for bearings, seals, and structural components in high-temperature environments.

- Manufacturing techniques for temperature-resistant aramid-PTFE materials: Specialized manufacturing techniques are employed to optimize the temperature tolerance of aramid-PTFE materials. These include sintering processes at controlled temperatures, compression molding under specific pressure conditions, and surface treatment methods to enhance fiber-matrix adhesion. Advanced techniques such as electron beam irradiation can improve the cross-linking of PTFE while maintaining the aramid fiber integrity. These manufacturing processes are critical for producing materials that can withstand temperature cycling, thermal shock, and prolonged exposure to extreme temperatures while maintaining their functional properties.

02 Composite materials combining aramid fiber and PTFE

Combining aramid fibers with PTFE creates composite materials with enhanced temperature tolerance and mechanical properties. These composites leverage the high tensile strength of aramid fibers and the excellent chemical resistance and low friction properties of PTFE. The resulting materials demonstrate improved heat resistance, dimensional stability, and durability under thermal cycling. Such composites are engineered to maintain their structural integrity and functional properties across a wider temperature range than either material alone.Expand Specific Solutions03 Applications in high-temperature environments

Aramid fiber and PTFE materials are extensively used in high-temperature industrial applications. These include thermal insulation systems, fire-resistant barriers, high-temperature filtration systems, and components for aerospace and automotive industries. The materials' ability to maintain structural integrity and performance at elevated temperatures makes them ideal for environments where conventional materials would degrade or fail. Their application extends to protective clothing, gaskets, seals, and other components exposed to extreme thermal conditions.Expand Specific Solutions04 Surface treatments and modifications for enhanced temperature performance

Various surface treatments and modifications can enhance the temperature tolerance of aramid fibers and PTFE. These include chemical treatments, plasma processing, and the application of specialized coatings. Such modifications can improve the materials' resistance to thermal degradation, enhance their mechanical properties at high temperatures, and extend their service life in extreme thermal environments. Modified aramid fibers and PTFE materials show improved interfacial adhesion in composites and better retention of properties during thermal cycling.Expand Specific Solutions05 Testing and performance evaluation methods

Specific testing methodologies are employed to evaluate the temperature tolerance of aramid fiber and PTFE materials. These include thermal gravimetric analysis, differential scanning calorimetry, heat deflection temperature testing, and accelerated aging tests under controlled temperature conditions. Performance evaluation also encompasses mechanical testing at various temperatures to assess strength retention, dimensional stability, and other critical properties. These standardized testing protocols help determine the materials' suitability for specific high-temperature applications and predict their long-term performance.Expand Specific Solutions

Key Manufacturers and Competitive Landscape

The aramid fiber and PTFE temperature tolerance market is in a mature growth phase, with an estimated global market size of $5-7 billion and steady annual growth of 4-6%. The competitive landscape features established industry leaders like DuPont de Nemours (Kevlar aramid fiber pioneer) and W.L. Gore & Associates (PTFE innovations), alongside emerging players such as Zhongfang New Material Co. and Tokai Senko KK. Technical maturity varies between the technologies - aramid fibers excel in high tensile strength at elevated temperatures (up to 500°C), while PTFE offers superior chemical resistance and maintains properties from -200°C to 260°C. Companies like Teijin, Kaneka, and Daikin are advancing hybrid solutions combining both materials' advantages, particularly targeting aerospace, automotive, and industrial applications requiring extreme temperature performance.

DuPont de Nemours, Inc.

Technical Solution: DuPont's approach to temperature tolerance comparison between Aramid Fiber (Kevlar/Nomex) and PTFE involves comprehensive material science research. Their Aramid fibers demonstrate exceptional thermal stability up to 370-425°C with minimal degradation, maintaining structural integrity through proprietary spinning techniques and molecular orientation processes. For PTFE (Teflon), DuPont has developed formulations with continuous service temperatures of -240°C to 260°C, with short-term exposure capability up to 300°C. Their research shows that while PTFE offers superior chemical resistance and lower friction coefficients across temperature ranges, Aramid fibers provide significantly better tensile strength retention at elevated temperatures. DuPont's differential scanning calorimetry testing reveals Aramid fibers maintain approximately 70% of room temperature strength at 250°C, whereas PTFE begins significant deformation above 260°C. Their proprietary cross-linking technology for Aramid fibers enhances temperature resistance through improved intermolecular bonding.

Strengths: DuPont possesses extensive historical expertise in both materials, allowing for highly optimized formulations. Their global manufacturing infrastructure enables consistent quality control across production facilities. Weaknesses: Their Aramid solutions typically command premium pricing compared to competitors, and their PTFE products show slightly lower maximum temperature tolerance than some specialized competitors' offerings.

W. L. Gore & Associates, Inc.

Technical Solution: Gore's temperature tolerance evaluation between Aramid fiber and PTFE centers on their proprietary expanded PTFE (ePTFE) technology. Their research demonstrates that standard PTFE maintains functional properties between -268°C to 260°C, with their enhanced ePTFE formulations pushing continuous operating temperatures to 315°C in certain applications. Gore's testing methodology includes thermal gravimetric analysis showing ePTFE retains 98% mass at 300°C for 1000 hours of continuous exposure. For comparative analysis, Gore evaluates aramid fibers (primarily meta-aramids) which demonstrate thermal decomposition beginning at approximately 370-400°C. Their research indicates aramid fibers maintain superior tensile strength at elevated temperatures (retaining approximately 60% strength at 300°C), while their ePTFE materials offer better chemical resistance across temperature ranges. Gore's proprietary lamination processes combine both materials in composite structures, leveraging aramid's mechanical strength with PTFE's chemical inertness for applications requiring both properties across wide temperature ranges.

Strengths: Gore's ePTFE technology offers unmatched microporous structure control, providing superior performance in filtration and membrane applications across temperature ranges. Their composite material expertise enables custom solutions combining both materials' advantages. Weaknesses: Their specialized manufacturing processes result in higher production costs compared to conventional PTFE products, and their aramid composite solutions have more limited chemical resistance in certain aggressive environments.

Critical Patents and Research in Heat-Resistant Materials

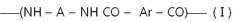

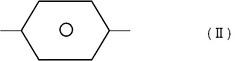

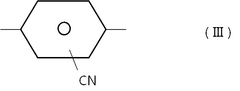

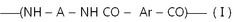

High-elongation copolymerized aramid fiber

PatentWO2017026748A1

Innovation

- Aramid copolymer fibers with an aromatic group substituted by a cyano group (-CN) are produced using a process that quickly extracts organic solvents during coagulation and washing, reducing crystallinity and crystal size, thereby loosening the fiber structure and enhancing elongation to 4.0-6.5%.

Environmental Impact and Sustainability Considerations

The environmental impact of materials selection has become increasingly critical in engineering decisions, particularly when comparing high-performance materials like aramid fibers and PTFE. When evaluating these materials specifically for temperature tolerance applications, their environmental footprints differ significantly throughout their lifecycles.

Aramid fiber production requires energy-intensive polymerization processes and involves chemicals such as para-phenylenediamine and terephthaloyl chloride. These manufacturing processes generate considerable greenhouse gas emissions and potentially hazardous waste streams. However, aramid fibers offer exceptional durability and longevity, which can offset initial environmental impacts through extended product lifecycles and reduced replacement frequency.

PTFE production, conversely, has historically involved perfluorooctanoic acid (PFOA), a persistent environmental contaminant. While many manufacturers have transitioned to PFOA-free production methods, PTFE's environmental persistence remains concerning. These fluoropolymers do not naturally degrade and can remain in ecosystems indefinitely. Nevertheless, PTFE's exceptional chemical resistance and temperature stability enable long service lives in extreme environments.

From a sustainability perspective, end-of-life considerations reveal further distinctions. Aramid fibers can be mechanically recycled through grinding processes for use as reinforcement materials in composites, though chemical recycling remains challenging. Some manufacturers have implemented take-back programs to facilitate closed-loop systems for aramid products.

PTFE recycling presents greater challenges due to its chemical stability. Current recycling methods primarily involve mechanical processing rather than chemical breakdown. The material's persistence creates significant disposal concerns, particularly when used in temperature-critical applications where material degradation may eventually occur.

Energy efficiency during service life represents another important sustainability factor. In high-temperature applications, the superior thermal stability of PTFE (functional up to 260°C) versus aramid fibers (typically limited to 200-250°C depending on specific formulation) may reduce energy requirements in certain systems by enabling more efficient thermal management.

Water consumption and toxicity profiles also differ between these materials. Aramid fiber production typically requires substantial water usage for processing and cooling, while PTFE manufacturing generally has lower direct water requirements but potentially higher toxicity concerns related to fluorochemical production.

As industries increasingly adopt lifecycle assessment methodologies, the environmental trade-offs between these materials' temperature tolerance capabilities must be balanced against their broader sustainability impacts, particularly as regulatory frameworks around persistent synthetic materials continue to evolve globally.

Aramid fiber production requires energy-intensive polymerization processes and involves chemicals such as para-phenylenediamine and terephthaloyl chloride. These manufacturing processes generate considerable greenhouse gas emissions and potentially hazardous waste streams. However, aramid fibers offer exceptional durability and longevity, which can offset initial environmental impacts through extended product lifecycles and reduced replacement frequency.

PTFE production, conversely, has historically involved perfluorooctanoic acid (PFOA), a persistent environmental contaminant. While many manufacturers have transitioned to PFOA-free production methods, PTFE's environmental persistence remains concerning. These fluoropolymers do not naturally degrade and can remain in ecosystems indefinitely. Nevertheless, PTFE's exceptional chemical resistance and temperature stability enable long service lives in extreme environments.

From a sustainability perspective, end-of-life considerations reveal further distinctions. Aramid fibers can be mechanically recycled through grinding processes for use as reinforcement materials in composites, though chemical recycling remains challenging. Some manufacturers have implemented take-back programs to facilitate closed-loop systems for aramid products.

PTFE recycling presents greater challenges due to its chemical stability. Current recycling methods primarily involve mechanical processing rather than chemical breakdown. The material's persistence creates significant disposal concerns, particularly when used in temperature-critical applications where material degradation may eventually occur.

Energy efficiency during service life represents another important sustainability factor. In high-temperature applications, the superior thermal stability of PTFE (functional up to 260°C) versus aramid fibers (typically limited to 200-250°C depending on specific formulation) may reduce energy requirements in certain systems by enabling more efficient thermal management.

Water consumption and toxicity profiles also differ between these materials. Aramid fiber production typically requires substantial water usage for processing and cooling, while PTFE manufacturing generally has lower direct water requirements but potentially higher toxicity concerns related to fluorochemical production.

As industries increasingly adopt lifecycle assessment methodologies, the environmental trade-offs between these materials' temperature tolerance capabilities must be balanced against their broader sustainability impacts, particularly as regulatory frameworks around persistent synthetic materials continue to evolve globally.

Application-Specific Performance Analysis

When evaluating aramid fiber and PTFE for temperature tolerance, their performance varies significantly across different application environments. In aerospace applications, aramid fibers maintain structural integrity at temperatures up to 370°C for short durations, while exhibiting minimal strength degradation at continuous operating temperatures of 200-250°C. This makes them particularly valuable for components exposed to jet engine exhaust or friction-generated heat. PTFE, meanwhile, demonstrates superior performance in cryogenic aerospace environments, maintaining flexibility and sealing properties at temperatures as low as -200°C.

In chemical processing industries, PTFE's exceptional chemical resistance combined with temperature stability up to 260°C makes it the preferred choice for gaskets, valve seats, and linings in reactors containing aggressive chemicals at elevated temperatures. Aramid fibers show limitations in these environments, particularly when exposed to strong acids which can degrade their mechanical properties even at moderate temperatures of 100-150°C.

For electrical insulation applications, both materials demonstrate distinctive advantages. Aramid paper and films retain dimensional stability and dielectric strength at temperatures up to 220°C in transformer and motor applications. PTFE, with its temperature range of -200°C to 260°C, provides superior performance in high-frequency electronic applications where low dielectric loss at elevated temperatures is critical.

Automotive applications reveal interesting performance differentials. Aramid fibers in friction materials maintain consistent coefficient of friction up to 350°C intermittent exposure, making them ideal for brake components. PTFE-based components in transmission systems and engine seals demonstrate excellent lubricity and chemical resistance across the automotive temperature spectrum (-40°C to 150°C), but require reinforcement to address creep issues at the upper temperature range.

In personal protective equipment, aramid fibers maintain protective capabilities in firefighting gear at flash exposures up to 700°C, though prolonged exposure above 400°C leads to carbonization. PTFE membranes in high-temperature filtration systems operate continuously at 260°C while maintaining porosity and chemical resistance, though they require structural support to prevent mechanical failure.

These application-specific analyses demonstrate that temperature tolerance cannot be evaluated in isolation but must consider exposure duration, chemical environment, mechanical stress, and specific performance requirements of the intended application.

In chemical processing industries, PTFE's exceptional chemical resistance combined with temperature stability up to 260°C makes it the preferred choice for gaskets, valve seats, and linings in reactors containing aggressive chemicals at elevated temperatures. Aramid fibers show limitations in these environments, particularly when exposed to strong acids which can degrade their mechanical properties even at moderate temperatures of 100-150°C.

For electrical insulation applications, both materials demonstrate distinctive advantages. Aramid paper and films retain dimensional stability and dielectric strength at temperatures up to 220°C in transformer and motor applications. PTFE, with its temperature range of -200°C to 260°C, provides superior performance in high-frequency electronic applications where low dielectric loss at elevated temperatures is critical.

Automotive applications reveal interesting performance differentials. Aramid fibers in friction materials maintain consistent coefficient of friction up to 350°C intermittent exposure, making them ideal for brake components. PTFE-based components in transmission systems and engine seals demonstrate excellent lubricity and chemical resistance across the automotive temperature spectrum (-40°C to 150°C), but require reinforcement to address creep issues at the upper temperature range.

In personal protective equipment, aramid fibers maintain protective capabilities in firefighting gear at flash exposures up to 700°C, though prolonged exposure above 400°C leads to carbonization. PTFE membranes in high-temperature filtration systems operate continuously at 260°C while maintaining porosity and chemical resistance, though they require structural support to prevent mechanical failure.

These application-specific analyses demonstrate that temperature tolerance cannot be evaluated in isolation but must consider exposure duration, chemical environment, mechanical stress, and specific performance requirements of the intended application.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!