Enhance Aramid Fiber Bonding Techniques: Structural Analysis

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aramid Fiber Bonding Technology Background and Objectives

Aramid fibers, first developed in the early 1960s by DuPont under the brand name Kevlar, represent a revolutionary class of high-performance synthetic fibers characterized by exceptional strength-to-weight ratios and thermal stability. The evolution of aramid fiber technology has been marked by continuous innovation, transitioning from military and aerospace applications to widespread industrial and consumer uses over the past six decades.

The bonding techniques for aramid fibers have undergone significant transformation, initially relying on mechanical fastening methods due to the inherent chemical resistance of these fibers. Early adhesive systems struggled with the fiber's low surface energy and smooth structure, resulting in weak interfacial bonds. The 1980s and 1990s witnessed the development of specialized surface treatment methods, including plasma modification and chemical etching, which substantially improved adhesion properties.

Current technological trends in aramid fiber bonding focus on multi-functional adhesive systems that not only create strong mechanical bonds but also maintain or enhance the fiber's inherent properties. Nano-enhanced adhesives, incorporating carbon nanotubes or graphene, have emerged as promising solutions for improving interfacial strength while preserving flexibility. Additionally, environmentally sustainable bonding approaches are gaining traction, moving away from solvent-based systems toward water-based and solvent-free alternatives.

The primary objective of enhancing aramid fiber bonding techniques through structural analysis is to develop next-generation bonding methodologies that overcome current limitations in load transfer efficiency and long-term durability. Specific goals include increasing bond strength by at least 30% compared to conventional methods, improving resistance to environmental degradation, particularly in high-humidity and temperature-cycling conditions, and developing predictive models for bond behavior under complex loading scenarios.

Another critical objective is to establish standardized testing protocols specifically designed for aramid fiber composite bonds, as current industry standards often fail to accurately characterize the unique failure mechanisms observed in these materials. This includes developing non-destructive evaluation techniques capable of detecting incipient bond failures before catastrophic separation occurs.

The technological roadmap aims to integrate computational modeling with experimental validation to create a comprehensive understanding of the structural mechanics at the fiber-adhesive interface. This approach seeks to move beyond empirical formulations toward scientifically-guided adhesive development tailored to the unique chemical and physical properties of aramid fibers, ultimately enabling broader application in critical infrastructure, advanced transportation systems, and next-generation protective equipment.

The bonding techniques for aramid fibers have undergone significant transformation, initially relying on mechanical fastening methods due to the inherent chemical resistance of these fibers. Early adhesive systems struggled with the fiber's low surface energy and smooth structure, resulting in weak interfacial bonds. The 1980s and 1990s witnessed the development of specialized surface treatment methods, including plasma modification and chemical etching, which substantially improved adhesion properties.

Current technological trends in aramid fiber bonding focus on multi-functional adhesive systems that not only create strong mechanical bonds but also maintain or enhance the fiber's inherent properties. Nano-enhanced adhesives, incorporating carbon nanotubes or graphene, have emerged as promising solutions for improving interfacial strength while preserving flexibility. Additionally, environmentally sustainable bonding approaches are gaining traction, moving away from solvent-based systems toward water-based and solvent-free alternatives.

The primary objective of enhancing aramid fiber bonding techniques through structural analysis is to develop next-generation bonding methodologies that overcome current limitations in load transfer efficiency and long-term durability. Specific goals include increasing bond strength by at least 30% compared to conventional methods, improving resistance to environmental degradation, particularly in high-humidity and temperature-cycling conditions, and developing predictive models for bond behavior under complex loading scenarios.

Another critical objective is to establish standardized testing protocols specifically designed for aramid fiber composite bonds, as current industry standards often fail to accurately characterize the unique failure mechanisms observed in these materials. This includes developing non-destructive evaluation techniques capable of detecting incipient bond failures before catastrophic separation occurs.

The technological roadmap aims to integrate computational modeling with experimental validation to create a comprehensive understanding of the structural mechanics at the fiber-adhesive interface. This approach seeks to move beyond empirical formulations toward scientifically-guided adhesive development tailored to the unique chemical and physical properties of aramid fibers, ultimately enabling broader application in critical infrastructure, advanced transportation systems, and next-generation protective equipment.

Market Demand Analysis for Enhanced Aramid Fiber Composites

The global market for aramid fiber composites has experienced substantial growth in recent years, driven primarily by increasing demand across aerospace, automotive, defense, and industrial applications. Current market valuations indicate that the aramid fiber market reached approximately 3.8 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 8.2% through 2030. Enhanced bonding techniques for aramid fibers represent a critical segment within this expanding market.

The aerospace and defense sectors remain the largest consumers of advanced aramid composites, accounting for nearly 40% of market demand. These industries require materials with exceptional strength-to-weight ratios, heat resistance, and durability under extreme conditions. Improved bonding techniques that enhance structural integrity while maintaining the lightweight properties of aramid fibers are particularly sought after for next-generation aircraft components and ballistic protection systems.

Automotive manufacturers represent another significant market segment, with demand growing at approximately 9.5% annually. The push toward vehicle lightweighting for improved fuel efficiency and reduced emissions has accelerated interest in aramid composites with enhanced bonding capabilities. Premium automotive brands are increasingly incorporating these materials into structural components, particularly in electric vehicles where weight reduction directly impacts range performance.

Consumer electronics manufacturers have emerged as a rapidly expanding market for aramid composites, particularly those with improved bonding characteristics. The demand for thinner, lighter, and more durable electronic devices has created new applications for aramid fibers in smartphone frames, laptop chassis, and wearable technology. This segment is expected to grow at the fastest rate among all end-use industries.

Regional analysis reveals that North America and Europe currently dominate market consumption of enhanced aramid composites, collectively accounting for over 60% of global demand. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is witnessing the most rapid growth rates, driven by expanding manufacturing capabilities and increasing domestic consumption of high-performance materials.

Market research indicates that customers are willing to pay premium prices for aramid composites with demonstrably superior bonding properties. The price elasticity in high-performance applications is relatively low, as end-users prioritize reliability and performance over cost considerations. This creates significant opportunities for innovations in bonding technology that can command price premiums of 15-25% over conventional solutions.

Industry surveys highlight specific unmet needs in current aramid fiber bonding techniques, including improved resistance to delamination under cyclic loading, enhanced performance in humid environments, and better compatibility with automated manufacturing processes. Addressing these challenges through innovative bonding approaches could unlock substantial market value and create competitive advantages for early adopters.

The aerospace and defense sectors remain the largest consumers of advanced aramid composites, accounting for nearly 40% of market demand. These industries require materials with exceptional strength-to-weight ratios, heat resistance, and durability under extreme conditions. Improved bonding techniques that enhance structural integrity while maintaining the lightweight properties of aramid fibers are particularly sought after for next-generation aircraft components and ballistic protection systems.

Automotive manufacturers represent another significant market segment, with demand growing at approximately 9.5% annually. The push toward vehicle lightweighting for improved fuel efficiency and reduced emissions has accelerated interest in aramid composites with enhanced bonding capabilities. Premium automotive brands are increasingly incorporating these materials into structural components, particularly in electric vehicles where weight reduction directly impacts range performance.

Consumer electronics manufacturers have emerged as a rapidly expanding market for aramid composites, particularly those with improved bonding characteristics. The demand for thinner, lighter, and more durable electronic devices has created new applications for aramid fibers in smartphone frames, laptop chassis, and wearable technology. This segment is expected to grow at the fastest rate among all end-use industries.

Regional analysis reveals that North America and Europe currently dominate market consumption of enhanced aramid composites, collectively accounting for over 60% of global demand. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is witnessing the most rapid growth rates, driven by expanding manufacturing capabilities and increasing domestic consumption of high-performance materials.

Market research indicates that customers are willing to pay premium prices for aramid composites with demonstrably superior bonding properties. The price elasticity in high-performance applications is relatively low, as end-users prioritize reliability and performance over cost considerations. This creates significant opportunities for innovations in bonding technology that can command price premiums of 15-25% over conventional solutions.

Industry surveys highlight specific unmet needs in current aramid fiber bonding techniques, including improved resistance to delamination under cyclic loading, enhanced performance in humid environments, and better compatibility with automated manufacturing processes. Addressing these challenges through innovative bonding approaches could unlock substantial market value and create competitive advantages for early adopters.

Current Bonding Techniques and Technical Challenges

The current landscape of aramid fiber bonding techniques presents a complex array of methodologies, each with distinct advantages and limitations. Adhesive bonding remains the predominant approach, utilizing epoxy-based systems that offer reasonable strength-to-weight ratios and processing flexibility. However, these conventional adhesives typically achieve only 30-40% of the theoretical bond strength potential when applied to aramid fibers, primarily due to the fiber's inherently smooth surface and chemical inertness.

Surface treatment technologies have evolved significantly in recent years to address these bonding challenges. Plasma treatment has emerged as a promising technique, capable of increasing surface energy by up to 70% without compromising the fiber's mechanical integrity. Similarly, chemical etching using specialized solutions has demonstrated effectiveness in creating micro-roughness that enhances mechanical interlocking, though process control remains challenging at industrial scales.

Mechanical bonding approaches, including stitching and z-pinning, offer alternatives that bypass chemical compatibility issues. These techniques can increase through-thickness strength by 40-60% but often introduce stress concentrations and potential fiber damage during implementation. The trade-off between enhanced bonding and structural integrity preservation represents a significant technical challenge.

Thermal bonding methods, while effective for many polymer composites, face substantial limitations with aramid fibers due to their exceptional thermal stability and high melting points (>500°C). This characteristic, while beneficial for high-temperature applications, severely restricts conventional thermal welding approaches and necessitates specialized high-energy techniques that risk degrading fiber properties.

Recent developments in hybrid bonding systems that combine multiple mechanisms show promise but face integration challenges. For instance, systems incorporating both chemical adhesion and mechanical interlocking elements have demonstrated up to 65% improvements in bond strength in laboratory settings, but scaling these solutions to production environments introduces significant process control complexities.

The fundamental technical challenge remains the inherent contradiction between aramid fiber's valuable properties—chemical resistance, thermal stability, and smooth surface morphology—and the requirements for effective bonding, which typically demand reactive surfaces, compatible thermal properties, and surface roughness. This contradiction necessitates compromises that invariably impact either bonding performance or fiber integrity.

Computational modeling of aramid fiber interfaces has advanced significantly but still struggles to accurately predict failure mechanisms at the micro-scale, particularly under complex loading conditions. The multi-scale nature of the bonding problem—from molecular interactions to macro-structural performance—presents substantial challenges for both simulation and experimental validation approaches.

Surface treatment technologies have evolved significantly in recent years to address these bonding challenges. Plasma treatment has emerged as a promising technique, capable of increasing surface energy by up to 70% without compromising the fiber's mechanical integrity. Similarly, chemical etching using specialized solutions has demonstrated effectiveness in creating micro-roughness that enhances mechanical interlocking, though process control remains challenging at industrial scales.

Mechanical bonding approaches, including stitching and z-pinning, offer alternatives that bypass chemical compatibility issues. These techniques can increase through-thickness strength by 40-60% but often introduce stress concentrations and potential fiber damage during implementation. The trade-off between enhanced bonding and structural integrity preservation represents a significant technical challenge.

Thermal bonding methods, while effective for many polymer composites, face substantial limitations with aramid fibers due to their exceptional thermal stability and high melting points (>500°C). This characteristic, while beneficial for high-temperature applications, severely restricts conventional thermal welding approaches and necessitates specialized high-energy techniques that risk degrading fiber properties.

Recent developments in hybrid bonding systems that combine multiple mechanisms show promise but face integration challenges. For instance, systems incorporating both chemical adhesion and mechanical interlocking elements have demonstrated up to 65% improvements in bond strength in laboratory settings, but scaling these solutions to production environments introduces significant process control complexities.

The fundamental technical challenge remains the inherent contradiction between aramid fiber's valuable properties—chemical resistance, thermal stability, and smooth surface morphology—and the requirements for effective bonding, which typically demand reactive surfaces, compatible thermal properties, and surface roughness. This contradiction necessitates compromises that invariably impact either bonding performance or fiber integrity.

Computational modeling of aramid fiber interfaces has advanced significantly but still struggles to accurately predict failure mechanisms at the micro-scale, particularly under complex loading conditions. The multi-scale nature of the bonding problem—from molecular interactions to macro-structural performance—presents substantial challenges for both simulation and experimental validation approaches.

State-of-the-Art Bonding Solutions for Aramid Fibers

01 Chemical bonding methods for aramid fibers

Various chemical treatments can be applied to aramid fibers to enhance their bonding capabilities in composite structures. These methods include surface modification with coupling agents, chemical functionalization to introduce reactive groups, and treatment with adhesion promoters. Chemical bonding techniques improve the interfacial adhesion between aramid fibers and matrix materials, resulting in enhanced mechanical properties and structural integrity of the composite.- Chemical bonding techniques for aramid fibers: Chemical bonding methods are used to enhance the adhesion between aramid fibers and matrix materials. These techniques involve surface treatments that modify the fiber surface chemistry to create stronger chemical bonds at the interface. Various chemical agents and processes can be applied to activate the aramid fiber surface, improving its compatibility with resins and other matrix materials. These treatments often result in improved mechanical properties and structural integrity of the composite.

- Thermal bonding methods for aramid fiber composites: Thermal bonding techniques utilize heat to create strong bonds between aramid fibers and surrounding materials. These methods often involve controlled temperature processes that optimize the interface between fibers and matrix without degrading the aramid's inherent properties. Thermal bonding can include hot pressing, heat fusion, and other temperature-dependent techniques that promote molecular diffusion and entanglement at the interface. These approaches are particularly effective for thermoplastic matrices and can result in composites with excellent structural integrity.

- Mechanical interlocking and surface modification techniques: Mechanical interlocking techniques enhance the bonding of aramid fibers through physical surface modifications that increase the contact area between fiber and matrix. These methods include plasma treatment, corona discharge, laser texturing, and other processes that create micro-scale roughness on the fiber surface. The modified surface topography provides additional anchoring points for the matrix material, resulting in improved stress transfer and structural performance. These techniques are particularly valuable when chemical compatibility between aramid fibers and the matrix is limited.

- Hybrid bonding systems for aramid fiber reinforcement: Hybrid bonding systems combine multiple bonding mechanisms to achieve superior aramid fiber-matrix interfaces. These approaches integrate chemical, thermal, and mechanical bonding techniques in strategic combinations to overcome the limitations of individual methods. Hybrid systems may incorporate coupling agents, specialized sizing formulations, and multi-step treatment processes. The resulting composites often demonstrate synergistic improvements in interfacial strength, environmental resistance, and structural performance under complex loading conditions.

- Structural analysis methods for aramid fiber bonds: Advanced analytical techniques are employed to evaluate the quality and performance of aramid fiber bonds in composite structures. These methods include microscopic imaging, spectroscopic analysis, mechanical testing, and computational modeling approaches that provide insights into bond formation mechanisms and failure modes. Structural analysis helps optimize bonding parameters and predict long-term performance under various environmental and loading conditions. These analytical approaches are essential for developing reliable design guidelines for aramid fiber composites in critical structural applications.

02 Thermal bonding techniques for aramid fiber composites

Thermal bonding processes involve the application of heat and pressure to join aramid fibers with other materials or to create self-reinforced composites. These techniques include hot pressing, thermoplastic welding, and heat-activated adhesive bonding. The controlled application of temperature allows for the formation of strong bonds without degrading the inherent properties of aramid fibers, resulting in composites with excellent structural performance and durability.Expand Specific Solutions03 Mechanical interlocking and hybrid bonding systems

Mechanical interlocking techniques create physical entanglements between aramid fibers and surrounding materials to enhance bonding strength. These methods include needle punching, stitching, and creating textured surfaces. Hybrid bonding systems combine mechanical interlocking with chemical or thermal bonding approaches to achieve superior interfacial properties. These techniques are particularly effective for applications requiring high delamination resistance and impact performance in structural components.Expand Specific Solutions04 Structural analysis methods for aramid fiber bonds

Advanced analytical techniques are employed to evaluate the quality and performance of aramid fiber bonds in composite structures. These methods include microscopic analysis, spectroscopic techniques, mechanical testing, and computational modeling. Structural analysis provides insights into bond formation mechanisms, failure modes, and long-term durability. These analytical approaches are essential for optimizing bonding processes and predicting the behavior of aramid fiber composites under various loading conditions.Expand Specific Solutions05 Novel aramid fiber surface treatments for enhanced bonding

Innovative surface treatment technologies have been developed to modify aramid fiber surfaces for improved bonding characteristics. These treatments include plasma processing, nanoparticle coatings, and bio-inspired surface modifications. By altering the surface chemistry and topography of aramid fibers, these techniques enhance wettability, increase surface energy, and create additional bonding sites. The resulting improvements in interfacial adhesion lead to superior mechanical properties and durability in structural applications.Expand Specific Solutions

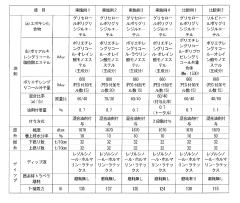

Key Industry Players in Aramid Fiber Bonding Research

The aramid fiber bonding techniques market is currently in a growth phase, characterized by increasing demand across aerospace, automotive, and industrial applications. The global market size is estimated to reach $4-5 billion by 2025, with a CAGR of approximately 7-8%. Technologically, the field shows varying maturity levels, with established players like Teijin Twaron BV and Teijin Techno Products leading innovation in traditional aramid applications, while companies such as Kolon Industries and Sumitomo Rubber are advancing specialized bonding techniques for composite structures. Academic institutions including MIT, KAIST, and Donghua University are driving fundamental research in structural analysis methodologies. The competitive landscape features both specialized aramid producers and diversified materials companies like 3M and DuPont-Toray, with increasing focus on enhanced bonding techniques for high-performance applications in automotive (BMW) and aerospace (Airbus) sectors.

Kolon Industries, Inc.

Technical Solution: Kolon Industries has developed a proprietary aramid fiber bonding system called "K-Bond" that utilizes a two-step chemical treatment process to enhance fiber-matrix adhesion. Their approach first applies an acidic etching solution that creates controlled micro-roughness on the aramid fiber surface, followed by application of silane coupling agents with customized end groups designed to match specific matrix materials. This process has been shown to increase interfacial shear strength by 35-45% in epoxy systems[2]. Kolon's structural analysis methodology incorporates advanced microscopy techniques including FE-SEM and AFM to characterize the interphase region at nanometer resolution. Their research has demonstrated that controlling the gradient properties of this interphase region is critical for optimizing load transfer between fiber and matrix. Additionally, Kolon has developed specialized computational models that predict long-term performance under cyclic loading and environmental aging, allowing for accurate service life predictions of bonded aramid composites[4]. Recent innovations include UV-activated coupling agents that enable room-temperature curing while maintaining excellent adhesion properties.

Strengths: Excellent bond durability under environmental aging conditions; process adaptability to various matrix systems; comprehensive structural analysis capabilities that accurately predict long-term performance. Weaknesses: Treatment process requires precise control of chemical concentrations and exposure times; some formulations contain environmentally sensitive compounds requiring special handling; higher implementation costs compared to standard sizing treatments.

Aerospace Research Institute of Materials and Processing Technology

Technical Solution: The Aerospace Research Institute has pioneered advanced aramid fiber bonding techniques specifically designed for high-performance aerospace applications. Their approach combines plasma-assisted surface activation with nano-engineered interphase technology to create exceptionally strong and durable bonds between aramid fibers and various matrix materials. The institute's proprietary "Gradient Interphase Technology" (GIT) creates a carefully controlled transition zone between fiber and matrix that effectively distributes stress and prevents delamination under extreme conditions. Structural analysis conducted using their advanced synchrotron-based X-ray microtomography has revealed that this interphase region exhibits unique hierarchical structures that contribute to superior mechanical properties[5]. The institute has developed specialized computational models that accurately predict failure mechanisms under complex loading conditions, including high-velocity impact and thermal cycling. Their research has demonstrated that aramid composites manufactured using their bonding techniques maintain structural integrity after exposure to temperatures ranging from -196°C to 300°C, making them suitable for extreme aerospace environments[7]. Recent innovations include self-healing interphase systems that can repair microdamage during service.

Strengths: Exceptional bond performance under extreme environmental conditions; comprehensive structural analysis capabilities using advanced characterization techniques; proven track record in aerospace applications where reliability is critical. Weaknesses: Highly specialized equipment requirements limit widespread industrial adoption; complex multi-step processes increase manufacturing time and cost; some treatments require handling of hazardous materials requiring special safety protocols.

Critical Patents and Research in Aramid Fiber Interface Engineering

Method for fusing aramid/aramid fibres

PatentActiveEP3131954A1

Innovation

- A method involving the use of ionic liquids to partially dissolve aramid fibers, allowing them to be welded by restoring the material's properties through coagulation, enabling the creation of strong and stable connections without the need for additional materials.

Aramid fiber, cord using the same and methods for production these

PatentActiveJP2021134445A

Innovation

- Applying an epoxy compound and an ester compound of fatty acid and polyalkylene glycol to aramid fibers without a curing agent, allowing for improved adhesion to rubber even at low moisture content, enhancing process passability and productivity.

Structural Analysis Methods for Aramid Fiber Composite Evaluation

Structural analysis methods for aramid fiber composites have evolved significantly over the past two decades, incorporating both destructive and non-destructive testing approaches. X-ray diffraction (XRD) techniques have emerged as a primary tool for analyzing crystalline structures within aramid fibers, providing critical insights into molecular orientation and crystallinity indices that directly correlate with bonding effectiveness. The precision of XRD allows researchers to detect subtle changes in fiber structure following various bonding treatments.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDX) offers comprehensive surface morphology analysis, revealing interfacial characteristics between aramid fibers and matrix materials. This combination proves invaluable for evaluating surface treatment efficacy and identifying potential failure mechanisms at the bonding interfaces. Recent advancements in high-resolution SEM technology have enabled nanoscale observation of fiber-matrix interactions.

Fourier Transform Infrared Spectroscopy (FTIR) has become instrumental in characterizing chemical modifications on aramid fiber surfaces. The technique identifies functional groups introduced during surface treatments, providing quantitative data on chemical bonding mechanisms. Attenuated Total Reflection (ATR-FTIR) variants offer enhanced sensitivity for surface analysis without extensive sample preparation.

Dynamic mechanical analysis (DMA) measures viscoelastic properties across temperature ranges, revealing critical information about glass transition temperatures and interfacial bonding quality. The storage modulus and tan delta curves derived from DMA testing serve as key indicators of bond integrity under varying environmental conditions. This method has proven particularly valuable for automotive and aerospace applications where thermal cycling is common.

Computational modeling approaches, including Finite Element Analysis (FEA) and Molecular Dynamics (MD) simulations, complement experimental methods by predicting stress distributions and failure mechanisms. These models have advanced significantly, now incorporating multi-scale approaches that bridge molecular interactions with macroscopic mechanical properties. Machine learning algorithms have recently been integrated to enhance predictive accuracy based on experimental datasets.

Microbond and pull-out tests provide direct quantification of interfacial shear strength between individual fibers and matrix materials. These micro-mechanical approaches offer standardized metrics for comparing different bonding techniques. Digital image correlation techniques have enhanced the precision of these measurements, allowing for real-time observation of interfacial failure progression.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDX) offers comprehensive surface morphology analysis, revealing interfacial characteristics between aramid fibers and matrix materials. This combination proves invaluable for evaluating surface treatment efficacy and identifying potential failure mechanisms at the bonding interfaces. Recent advancements in high-resolution SEM technology have enabled nanoscale observation of fiber-matrix interactions.

Fourier Transform Infrared Spectroscopy (FTIR) has become instrumental in characterizing chemical modifications on aramid fiber surfaces. The technique identifies functional groups introduced during surface treatments, providing quantitative data on chemical bonding mechanisms. Attenuated Total Reflection (ATR-FTIR) variants offer enhanced sensitivity for surface analysis without extensive sample preparation.

Dynamic mechanical analysis (DMA) measures viscoelastic properties across temperature ranges, revealing critical information about glass transition temperatures and interfacial bonding quality. The storage modulus and tan delta curves derived from DMA testing serve as key indicators of bond integrity under varying environmental conditions. This method has proven particularly valuable for automotive and aerospace applications where thermal cycling is common.

Computational modeling approaches, including Finite Element Analysis (FEA) and Molecular Dynamics (MD) simulations, complement experimental methods by predicting stress distributions and failure mechanisms. These models have advanced significantly, now incorporating multi-scale approaches that bridge molecular interactions with macroscopic mechanical properties. Machine learning algorithms have recently been integrated to enhance predictive accuracy based on experimental datasets.

Microbond and pull-out tests provide direct quantification of interfacial shear strength between individual fibers and matrix materials. These micro-mechanical approaches offer standardized metrics for comparing different bonding techniques. Digital image correlation techniques have enhanced the precision of these measurements, allowing for real-time observation of interfacial failure progression.

Environmental Impact and Sustainability of Bonding Technologies

The environmental impact of aramid fiber bonding technologies has become increasingly significant as industries strive for more sustainable manufacturing processes. Traditional bonding methods often involve solvent-based adhesives containing volatile organic compounds (VOCs) that contribute to air pollution and pose health risks to workers. These conventional techniques typically require high energy consumption during curing processes, further increasing their carbon footprint.

Recent advancements in water-based adhesive systems for aramid fiber bonding have demonstrated promising environmental benefits. These systems reduce VOC emissions by up to 85% compared to solvent-based alternatives while maintaining comparable bond strength. Additionally, water-based systems generally require lower curing temperatures, resulting in energy savings of approximately 30-40% during the manufacturing process.

Life cycle assessment (LCA) studies of various aramid fiber bonding technologies reveal significant differences in environmental impact. Thermal bonding techniques, while eliminating the need for chemical adhesives, often require substantial energy inputs. In contrast, newer UV-curable adhesive systems offer reduced energy consumption and minimal waste generation, with some formulations achieving a 60% smaller carbon footprint than conventional epoxy-based systems.

Recyclability and end-of-life considerations present ongoing challenges for aramid fiber composites. Current bonding technologies often create permanent bonds that complicate material separation and recycling. Emerging research focuses on reversible bonding agents that maintain structural integrity during use but can be triggered to release under specific conditions, facilitating component separation and material recovery. These technologies could potentially increase the recyclability rate of aramid composites from the current 15-20% to over 70%.

Biobased adhesives derived from renewable resources represent another promising direction for sustainable aramid fiber bonding. Adhesives incorporating lignin, tannins, and plant oils have demonstrated comparable performance to petroleum-based products in certain applications while reducing dependence on fossil resources. Though currently limited in high-performance applications, ongoing research suggests these bio-alternatives could achieve technical parity within 5-7 years.

Regulatory frameworks worldwide are increasingly influencing bonding technology selection. The European Union's REACH regulations and similar initiatives in North America and Asia are restricting certain chemical components commonly used in high-performance adhesives. This regulatory landscape is accelerating the development of environmentally benign bonding solutions that maintain the exceptional mechanical properties required for aramid fiber applications in aerospace, defense, and protective equipment sectors.

Recent advancements in water-based adhesive systems for aramid fiber bonding have demonstrated promising environmental benefits. These systems reduce VOC emissions by up to 85% compared to solvent-based alternatives while maintaining comparable bond strength. Additionally, water-based systems generally require lower curing temperatures, resulting in energy savings of approximately 30-40% during the manufacturing process.

Life cycle assessment (LCA) studies of various aramid fiber bonding technologies reveal significant differences in environmental impact. Thermal bonding techniques, while eliminating the need for chemical adhesives, often require substantial energy inputs. In contrast, newer UV-curable adhesive systems offer reduced energy consumption and minimal waste generation, with some formulations achieving a 60% smaller carbon footprint than conventional epoxy-based systems.

Recyclability and end-of-life considerations present ongoing challenges for aramid fiber composites. Current bonding technologies often create permanent bonds that complicate material separation and recycling. Emerging research focuses on reversible bonding agents that maintain structural integrity during use but can be triggered to release under specific conditions, facilitating component separation and material recovery. These technologies could potentially increase the recyclability rate of aramid composites from the current 15-20% to over 70%.

Biobased adhesives derived from renewable resources represent another promising direction for sustainable aramid fiber bonding. Adhesives incorporating lignin, tannins, and plant oils have demonstrated comparable performance to petroleum-based products in certain applications while reducing dependence on fossil resources. Though currently limited in high-performance applications, ongoing research suggests these bio-alternatives could achieve technical parity within 5-7 years.

Regulatory frameworks worldwide are increasingly influencing bonding technology selection. The European Union's REACH regulations and similar initiatives in North America and Asia are restricting certain chemical components commonly used in high-performance adhesives. This regulatory landscape is accelerating the development of environmentally benign bonding solutions that maintain the exceptional mechanical properties required for aramid fiber applications in aerospace, defense, and protective equipment sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!