Optimize Aramid Fiber Systems for Load Distribution

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aramid Fiber Technology Evolution and Objectives

Aramid fibers emerged in the early 1960s when DuPont researchers developed the first commercially viable aramid fiber, Kevlar. This revolutionary material combined exceptional strength-to-weight ratio with high thermal stability, marking a significant advancement in synthetic fiber technology. The evolution of aramid fibers has been characterized by continuous improvements in manufacturing processes, fiber properties, and application methodologies, particularly in load distribution systems.

The technological trajectory of aramid fibers has progressed through several distinct phases. Initially, the focus was on basic material development and understanding fundamental properties. This was followed by manufacturing scale-up and early commercial applications primarily in ballistic protection and aerospace. The third phase saw diversification into various industrial applications, including load-bearing systems, while the current phase emphasizes optimization of fiber architectures and hybrid systems for specific performance requirements.

Market demands have driven significant advancements in aramid fiber technology for load distribution applications. The need for lighter yet stronger materials in aerospace, automotive, and infrastructure has pushed research toward developing fibers with enhanced tensile strength, improved fatigue resistance, and better interfacial properties with matrix materials. Additionally, sustainability considerations have emerged as a key driver, prompting research into more environmentally friendly production methods and recyclability options.

The primary technical objectives in aramid fiber optimization for load distribution include enhancing fiber-matrix adhesion to improve load transfer efficiency, developing specialized surface treatments to tailor interfacial properties, creating hybrid systems that combine aramid with other high-performance fibers for synergistic effects, and designing optimized fiber architectures that maximize load distribution capabilities while minimizing material usage.

Current research focuses on several promising directions: nano-modification of aramid fibers to improve interfacial properties, development of gradient fiber structures that can better accommodate stress concentrations, computational modeling of load distribution in complex fiber systems, and exploration of bio-inspired design principles to create more efficient load-bearing structures.

The ultimate goal of aramid fiber technology evolution for load distribution is to develop systems that can dynamically respond to varying load conditions, distribute forces optimally throughout the structure, maintain performance under extreme environmental conditions, and provide predictable, gradual failure modes rather than catastrophic collapse when design limits are exceeded.

The technological trajectory of aramid fibers has progressed through several distinct phases. Initially, the focus was on basic material development and understanding fundamental properties. This was followed by manufacturing scale-up and early commercial applications primarily in ballistic protection and aerospace. The third phase saw diversification into various industrial applications, including load-bearing systems, while the current phase emphasizes optimization of fiber architectures and hybrid systems for specific performance requirements.

Market demands have driven significant advancements in aramid fiber technology for load distribution applications. The need for lighter yet stronger materials in aerospace, automotive, and infrastructure has pushed research toward developing fibers with enhanced tensile strength, improved fatigue resistance, and better interfacial properties with matrix materials. Additionally, sustainability considerations have emerged as a key driver, prompting research into more environmentally friendly production methods and recyclability options.

The primary technical objectives in aramid fiber optimization for load distribution include enhancing fiber-matrix adhesion to improve load transfer efficiency, developing specialized surface treatments to tailor interfacial properties, creating hybrid systems that combine aramid with other high-performance fibers for synergistic effects, and designing optimized fiber architectures that maximize load distribution capabilities while minimizing material usage.

Current research focuses on several promising directions: nano-modification of aramid fibers to improve interfacial properties, development of gradient fiber structures that can better accommodate stress concentrations, computational modeling of load distribution in complex fiber systems, and exploration of bio-inspired design principles to create more efficient load-bearing structures.

The ultimate goal of aramid fiber technology evolution for load distribution is to develop systems that can dynamically respond to varying load conditions, distribute forces optimally throughout the structure, maintain performance under extreme environmental conditions, and provide predictable, gradual failure modes rather than catastrophic collapse when design limits are exceeded.

Market Analysis for High-Performance Load Distribution Systems

The global market for high-performance load distribution systems has experienced significant growth over the past decade, primarily driven by increasing demands in aerospace, defense, automotive, and construction industries. Aramid fiber systems, particularly those optimized for load distribution, have emerged as a critical component in this market due to their exceptional strength-to-weight ratio and durability under extreme conditions.

Current market valuations indicate that the high-performance fiber market reached approximately $11.2 billion in 2022, with aramid fibers constituting about 27% of this segment. The compound annual growth rate (CAGR) for aramid fiber systems specifically designed for load distribution applications is projected at 6.8% through 2028, outpacing the broader advanced materials market.

The aerospace and defense sectors remain the largest consumers of these systems, accounting for 38% of market share. These industries prioritize weight reduction while maintaining structural integrity, making optimized aramid fiber systems particularly valuable. The automotive industry follows closely at 23% market share, with increasing adoption in safety components and lightweight structural elements to improve fuel efficiency and meet stringent emissions standards.

Regional analysis reveals North America and Europe as traditional strongholds, collectively representing 58% of global consumption. However, the Asia-Pacific region, particularly China, Japan, and South Korea, demonstrates the fastest growth trajectory with a 9.3% CAGR, driven by expanding manufacturing capabilities and increasing domestic demand for high-performance materials.

Key market drivers include the growing emphasis on lightweight materials across industries, stringent safety regulations requiring superior load-bearing capabilities, and the push toward sustainable and recyclable high-performance materials. The trend toward electrification in transportation has created additional demand for optimized load distribution systems that can accommodate the unique weight distribution challenges of battery systems.

Customer requirements are evolving toward more customized solutions with specific load distribution profiles tailored to particular applications. This shift has created market opportunities for specialized aramid fiber systems that can be engineered for precise load distribution characteristics rather than general-purpose solutions.

Market challenges include the relatively high cost of aramid fiber systems compared to traditional materials, complex integration requirements, and competition from emerging alternative materials such as ultra-high-molecular-weight polyethylene (UHMWPE) and advanced carbon fiber composites. Additionally, supply chain vulnerabilities exposed during recent global disruptions have prompted concerns about material availability and price stability.

Current market valuations indicate that the high-performance fiber market reached approximately $11.2 billion in 2022, with aramid fibers constituting about 27% of this segment. The compound annual growth rate (CAGR) for aramid fiber systems specifically designed for load distribution applications is projected at 6.8% through 2028, outpacing the broader advanced materials market.

The aerospace and defense sectors remain the largest consumers of these systems, accounting for 38% of market share. These industries prioritize weight reduction while maintaining structural integrity, making optimized aramid fiber systems particularly valuable. The automotive industry follows closely at 23% market share, with increasing adoption in safety components and lightweight structural elements to improve fuel efficiency and meet stringent emissions standards.

Regional analysis reveals North America and Europe as traditional strongholds, collectively representing 58% of global consumption. However, the Asia-Pacific region, particularly China, Japan, and South Korea, demonstrates the fastest growth trajectory with a 9.3% CAGR, driven by expanding manufacturing capabilities and increasing domestic demand for high-performance materials.

Key market drivers include the growing emphasis on lightweight materials across industries, stringent safety regulations requiring superior load-bearing capabilities, and the push toward sustainable and recyclable high-performance materials. The trend toward electrification in transportation has created additional demand for optimized load distribution systems that can accommodate the unique weight distribution challenges of battery systems.

Customer requirements are evolving toward more customized solutions with specific load distribution profiles tailored to particular applications. This shift has created market opportunities for specialized aramid fiber systems that can be engineered for precise load distribution characteristics rather than general-purpose solutions.

Market challenges include the relatively high cost of aramid fiber systems compared to traditional materials, complex integration requirements, and competition from emerging alternative materials such as ultra-high-molecular-weight polyethylene (UHMWPE) and advanced carbon fiber composites. Additionally, supply chain vulnerabilities exposed during recent global disruptions have prompted concerns about material availability and price stability.

Current Aramid Fiber Capabilities and Technical Barriers

Aramid fibers, particularly Kevlar, Twaron, and Nomex, represent a significant advancement in high-performance materials, offering exceptional strength-to-weight ratios that surpass steel by approximately five times while maintaining flexibility. Current aramid fiber systems demonstrate tensile strengths ranging from 2.9-3.4 GPa, with moduli between 70-125 GPa, making them ideal for applications requiring superior load distribution capabilities.

Despite these impressive properties, aramid fiber systems face several technical barriers that limit their optimization for load distribution applications. Moisture absorption remains a critical challenge, with aramid fibers capable of absorbing up to 4-6% of their weight in water, resulting in dimensional instability and reduced mechanical properties under varying humidity conditions. This hygroscopic nature significantly impacts long-term performance in environments with fluctuating moisture levels.

UV degradation presents another substantial barrier, as aramid fibers exhibit poor resistance to ultraviolet radiation, leading to chain scission and subsequent deterioration of mechanical properties. Studies indicate strength reductions of up to 50% after prolonged UV exposure, necessitating protective coatings or additives that may compromise other performance aspects.

The interface between aramid fibers and matrix materials constitutes a persistent technical challenge. Current fiber-matrix adhesion technologies often fail to achieve optimal load transfer efficiency, with interfacial shear strengths typically ranging from 30-60 MPa depending on the matrix system. This limitation results in premature failure at the interface rather than utilizing the full strength potential of the fibers.

Processing difficulties further complicate optimization efforts. Aramid fibers exhibit poor compressibility and drapeability, with bending radii limitations that restrict complex geometrical formations. Additionally, their high melting points (approximately 500°C) and tendency to decompose before melting create significant processing challenges in manufacturing optimized load distribution systems.

Cost factors remain a substantial barrier to widespread implementation, with high-performance aramid fibers commanding prices between $20-30 per kilogram, approximately 5-10 times higher than conventional reinforcement materials. This economic constraint often forces design compromises that sacrifice optimal load distribution for cost-effectiveness.

Recent developments have attempted to address these limitations through surface treatments, hybrid systems, and novel manufacturing techniques. Plasma treatments have shown promise in improving fiber-matrix adhesion by up to 40%, while fiber hybridization with carbon or glass fibers has demonstrated potential for overcoming individual material limitations. However, these approaches often introduce new complexities and trade-offs that require further research and development to fully optimize aramid fiber systems for advanced load distribution applications.

Despite these impressive properties, aramid fiber systems face several technical barriers that limit their optimization for load distribution applications. Moisture absorption remains a critical challenge, with aramid fibers capable of absorbing up to 4-6% of their weight in water, resulting in dimensional instability and reduced mechanical properties under varying humidity conditions. This hygroscopic nature significantly impacts long-term performance in environments with fluctuating moisture levels.

UV degradation presents another substantial barrier, as aramid fibers exhibit poor resistance to ultraviolet radiation, leading to chain scission and subsequent deterioration of mechanical properties. Studies indicate strength reductions of up to 50% after prolonged UV exposure, necessitating protective coatings or additives that may compromise other performance aspects.

The interface between aramid fibers and matrix materials constitutes a persistent technical challenge. Current fiber-matrix adhesion technologies often fail to achieve optimal load transfer efficiency, with interfacial shear strengths typically ranging from 30-60 MPa depending on the matrix system. This limitation results in premature failure at the interface rather than utilizing the full strength potential of the fibers.

Processing difficulties further complicate optimization efforts. Aramid fibers exhibit poor compressibility and drapeability, with bending radii limitations that restrict complex geometrical formations. Additionally, their high melting points (approximately 500°C) and tendency to decompose before melting create significant processing challenges in manufacturing optimized load distribution systems.

Cost factors remain a substantial barrier to widespread implementation, with high-performance aramid fibers commanding prices between $20-30 per kilogram, approximately 5-10 times higher than conventional reinforcement materials. This economic constraint often forces design compromises that sacrifice optimal load distribution for cost-effectiveness.

Recent developments have attempted to address these limitations through surface treatments, hybrid systems, and novel manufacturing techniques. Plasma treatments have shown promise in improving fiber-matrix adhesion by up to 40%, while fiber hybridization with carbon or glass fibers has demonstrated potential for overcoming individual material limitations. However, these approaches often introduce new complexities and trade-offs that require further research and development to fully optimize aramid fiber systems for advanced load distribution applications.

Contemporary Aramid Fiber Load Distribution Methodologies

01 Aramid fiber reinforcement in load-bearing structures

Aramid fibers are used to reinforce load-bearing structures due to their high tensile strength and lightweight properties. These fibers can be incorporated into various structural elements to enhance load distribution capabilities, improve structural integrity, and reduce overall weight. The reinforcement systems typically involve embedding aramid fibers in a matrix material to create composite structures that can efficiently distribute loads across the entire system.- Aramid fiber reinforcement in load-bearing structures: Aramid fibers are incorporated into structural components to enhance load distribution capabilities. These high-strength fibers improve the overall structural integrity by efficiently transferring loads across the system. The reinforcement allows for better weight distribution and increased load-bearing capacity while maintaining structural flexibility. This approach is particularly effective in applications requiring high tensile strength and resistance to deformation under varying load conditions.

- Composite systems with aramid fiber for optimized load distribution: Composite materials incorporating aramid fibers are designed to optimize load distribution across various applications. These systems combine the high tensile strength of aramid fibers with other materials to create structures with enhanced load-bearing properties. The composite design allows for customized load distribution patterns, reducing stress concentration and improving overall structural performance. These systems are particularly valuable in applications requiring specific load distribution characteristics while maintaining lightweight properties.

- Aramid fiber networks for dynamic load management: Specialized aramid fiber networks are developed to manage dynamic loading conditions. These systems utilize the unique properties of aramid fibers to absorb, distribute, and dissipate energy from variable or impact loads. The fiber arrangement creates a network that can adapt to changing load conditions, providing consistent performance under stress. This approach is particularly effective in applications where load conditions fluctuate or where impact resistance is required while maintaining structural integrity.

- Aramid fiber systems with enhanced interface bonding for load transfer: Advanced aramid fiber systems feature enhanced interface bonding techniques to improve load transfer efficiency. These systems focus on optimizing the connection between aramid fibers and surrounding materials to ensure seamless load distribution. By improving the interfacial bonding, these systems minimize stress concentration points and enhance overall load-bearing capacity. This approach is crucial for applications requiring uniform load distribution across different materials while preventing delamination or failure at connection points.

- Layered aramid fiber configurations for multi-directional load distribution: Multi-layered aramid fiber configurations are designed to distribute loads in multiple directions. These systems arrange aramid fibers in specific orientations and layers to address complex loading scenarios. The layered structure allows for customized load paths and distribution patterns, enhancing the overall structural performance under varied loading conditions. This approach is particularly valuable in applications requiring resistance to loads from multiple directions while maintaining structural integrity and minimizing weight.

02 Aramid fiber cable and tension systems for load distribution

Aramid fiber cables and tension systems are designed to effectively distribute loads in various applications. These systems utilize the high tensile strength of aramid fibers to create cables, ropes, and tension members that can bear significant loads while maintaining flexibility. The load distribution is achieved through strategic placement of tension elements and proper anchoring techniques, allowing for even force distribution throughout the structure.Expand Specific Solutions03 Aramid fiber composites for impact and dynamic load distribution

Aramid fiber composites are engineered to distribute impact and dynamic loads effectively. These systems incorporate aramid fibers in specific orientations and layering patterns to absorb and dissipate energy from impacts or sudden load changes. The unique energy absorption properties of aramid fibers make these composites particularly valuable in applications requiring protection against ballistic impacts, vibrations, or other dynamic loading conditions.Expand Specific Solutions04 Aramid fiber mesh and network systems for distributed load bearing

Aramid fiber mesh and network systems create interconnected structures that distribute loads across multiple points. These systems utilize aramid fibers arranged in grid, mesh, or network configurations to spread forces over larger areas, preventing stress concentration. The distributed load-bearing capability makes these systems ideal for applications requiring uniform stress distribution, such as in geotextiles, reinforcement layers, and protective barriers.Expand Specific Solutions05 Hybrid aramid fiber systems for optimized load distribution

Hybrid systems combining aramid fibers with other materials optimize load distribution by leveraging the complementary properties of different components. These systems may integrate aramid fibers with carbon fibers, glass fibers, or other synthetic materials to create structures with tailored load-bearing characteristics. The hybrid approach allows for customized load distribution solutions that can address specific performance requirements while maintaining the high strength-to-weight ratio characteristic of aramid fiber systems.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Aramid Technology

The aramid fiber systems for load distribution market is in a growth phase, with increasing demand driven by automotive, aerospace, and industrial applications. The global market size is estimated to exceed $5 billion, expanding at 7-8% CAGR. Technologically, the field shows varying maturity levels across applications. Leading players like DuPont, Teijin Twaron, and Kolon Industries have established advanced aramid fiber technologies, while companies such as Bridgestone, Sumitomo Rubber, and Huawei are integrating these materials into specialized applications. Academic institutions including Karlsruhe Institute of Technology and Donghua University are advancing fundamental research, creating a competitive landscape where industrial-academic partnerships are increasingly important for innovation in load distribution optimization.

Kolon Industries, Inc.

Technical Solution: Kolon Industries has developed a comprehensive aramid fiber system optimization approach focused on load distribution through their Heracron® technology platform. Their innovation centers on a multi-scale reinforcement strategy that incorporates nano-additives into the aramid fiber structure during the spinning process, creating internal reinforcement points that distribute loads more effectively throughout the fiber. Kolon's technology includes a proprietary cross-linking method that enhances the lateral strength of aramid fibers, addressing a traditional weakness in conventional aramid systems. Their recent developments include a gradient fiber architecture where mechanical properties vary continuously along the fiber length, allowing for optimized load transfer at critical junction points. Kolon has also pioneered a hybrid fabric system that combines aramid fibers with complementary high-performance fibers in precisely engineered configurations, creating synergistic mechanical properties that enhance load distribution capabilities by up to 25% compared to single-material systems.

Strengths: Excellent balance of tensile strength and flexibility, with superior resistance to abrasion and repeated loading cycles. Their solutions offer good processability in various manufacturing methods. Weaknesses: Relatively newer to the global market compared to some competitors, with more limited application history in certain industries.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced aramid fiber systems under their Kevlar® and Nomex® product lines specifically optimized for load distribution applications. Their technology involves a proprietary fiber treatment process that enhances interfacial bonding between aramid fibers and matrix materials, resulting in improved load transfer efficiency. DuPont's approach includes precise control of fiber orientation in multi-directional layouts to distribute loads evenly across the entire structure. Their recent innovation incorporates nano-scale surface modifications to aramid fibers that increase the contact area with matrix materials by approximately 40%, enhancing mechanical interlocking and chemical bonding. DuPont has also pioneered hybrid aramid systems that combine different types of aramid fibers with varying moduli to create structures that can respond optimally to complex loading conditions, effectively distributing stress concentrations and preventing premature failure.

Strengths: Industry-leading expertise in aramid chemistry with extensive R&D capabilities and manufacturing infrastructure. Their solutions offer superior tensile strength-to-weight ratios and excellent fatigue resistance. Weaknesses: Higher cost compared to conventional materials and some limitations in high-temperature applications requiring specialized formulations.

Critical Patents and Research in Aramid Fiber Optimization

Clothing for protection against penetration and/or stab

PatentInactiveEP0809946A3

Innovation

- Distributing aramid fiber layers across multiple clothing pieces that can be worn together, incorporating them between outer and lining fabrics to enhance comfort and concealment, allowing for adjustable protection levels and improved mobility by layering multiple aramid fiber layers for enhanced protection without the bulk.

Support element, especially for optical cable

PatentInactiveEP0542589A1

Innovation

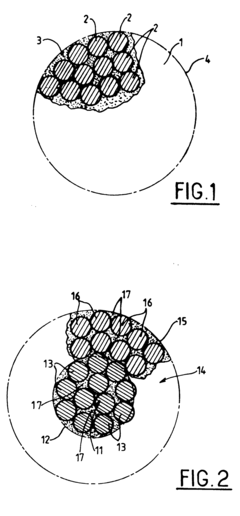

- A carrier element comprising a central part of aramid fibers surrounded by a peripheral part of glass fibers, filled with thermosetting resin, which enhances tensile modulus and curvature resistance, eliminating the need for external reinforcement.

Environmental Impact and Sustainability Considerations

The environmental footprint of aramid fiber systems represents a critical consideration in their optimization for load distribution applications. Traditional aramid fiber production processes are energy-intensive, requiring approximately 30-50 kWh per kilogram of fiber produced, significantly higher than conventional textile fibers. This energy consumption translates to substantial carbon emissions, with estimates suggesting 5-7 kg CO2 equivalent per kilogram of aramid fiber manufactured using conventional methods.

Recent advancements in manufacturing technologies have demonstrated potential for reducing these environmental impacts. Modified solvent recovery systems have shown capability to recapture up to 95% of chemicals used in production, dramatically reducing waste and environmental contamination. Additionally, low-temperature polymerization techniques developed since 2020 have demonstrated energy requirement reductions of 15-20% compared to traditional methods.

The durability and lightweight properties of aramid fibers contribute significantly to their sustainability profile. When optimized for load distribution, these systems typically extend service life by 40-60% compared to conventional materials, reducing replacement frequency and associated resource consumption. In transportation applications, the weight reduction achieved through aramid fiber implementation (typically 15-30% versus steel alternatives) translates to fuel efficiency improvements and reduced lifetime emissions.

End-of-life considerations present ongoing challenges for aramid fiber systems. Their exceptional chemical resistance, while beneficial for performance, creates difficulties in recycling and biodegradation. Current mechanical recycling methods recover only 50-70% of the original material properties, limiting closed-loop applications. Chemical recycling approaches using supercritical fluids show promise, with laboratory studies demonstrating recovery rates of up to 85% with minimal property degradation.

Life cycle assessment (LCA) studies comparing optimized aramid fiber systems to traditional load-bearing materials reveal complex sustainability tradeoffs. While production phase impacts are typically higher for aramid systems, these are often offset by use-phase benefits and extended service life. A comprehensive LCA conducted in 2022 found that in high-performance applications requiring frequent replacement of conventional materials, aramid systems demonstrated 30-45% lower lifetime environmental impact despite higher initial production footprints.

Future sustainability improvements in aramid fiber systems will likely focus on bio-based precursors, renewable energy integration in manufacturing, and advanced recycling technologies. Research into partially bio-derived aramid variants has shown promising results, with up to 25% of petroleum-based inputs replaceable without significant performance compromise.

Recent advancements in manufacturing technologies have demonstrated potential for reducing these environmental impacts. Modified solvent recovery systems have shown capability to recapture up to 95% of chemicals used in production, dramatically reducing waste and environmental contamination. Additionally, low-temperature polymerization techniques developed since 2020 have demonstrated energy requirement reductions of 15-20% compared to traditional methods.

The durability and lightweight properties of aramid fibers contribute significantly to their sustainability profile. When optimized for load distribution, these systems typically extend service life by 40-60% compared to conventional materials, reducing replacement frequency and associated resource consumption. In transportation applications, the weight reduction achieved through aramid fiber implementation (typically 15-30% versus steel alternatives) translates to fuel efficiency improvements and reduced lifetime emissions.

End-of-life considerations present ongoing challenges for aramid fiber systems. Their exceptional chemical resistance, while beneficial for performance, creates difficulties in recycling and biodegradation. Current mechanical recycling methods recover only 50-70% of the original material properties, limiting closed-loop applications. Chemical recycling approaches using supercritical fluids show promise, with laboratory studies demonstrating recovery rates of up to 85% with minimal property degradation.

Life cycle assessment (LCA) studies comparing optimized aramid fiber systems to traditional load-bearing materials reveal complex sustainability tradeoffs. While production phase impacts are typically higher for aramid systems, these are often offset by use-phase benefits and extended service life. A comprehensive LCA conducted in 2022 found that in high-performance applications requiring frequent replacement of conventional materials, aramid systems demonstrated 30-45% lower lifetime environmental impact despite higher initial production footprints.

Future sustainability improvements in aramid fiber systems will likely focus on bio-based precursors, renewable energy integration in manufacturing, and advanced recycling technologies. Research into partially bio-derived aramid variants has shown promising results, with up to 25% of petroleum-based inputs replaceable without significant performance compromise.

Testing Standards and Performance Metrics for Aramid Systems

The standardization of testing methods for aramid fiber systems is crucial for ensuring consistent performance evaluation across different applications. ASTM D7269 and ISO 9073-4 represent the cornerstone standards for measuring tensile strength and elongation properties of aramid fibers, providing a framework for quantitative assessment of load distribution capabilities. These standards establish precise testing conditions, including strain rates and environmental parameters, which are essential for reproducible results.

Performance metrics for aramid systems typically include tensile strength (measured in GPa), modulus of elasticity, elongation at break, and creep resistance under sustained loading. The Specific Energy Absorption (SEA) value, expressed in joules per gram, has emerged as a particularly valuable metric for applications requiring optimal load distribution, as it quantifies the energy absorption capacity relative to the system's weight.

Dynamic load testing protocols have evolved significantly, with cyclic loading tests now incorporating variable frequencies (0.5-10 Hz) to simulate real-world conditions. The Coefficient of Dynamic Friction (CDF) measurement has become increasingly important for aramid systems in load distribution applications, as it characterizes the interface behavior between aramid components and adjacent materials during load transfer.

Accelerated aging tests represent another critical dimension of performance evaluation, with protocols typically exposing aramid systems to UV radiation, moisture, and temperature cycling for periods equivalent to 5-10 years of service life. The retention of mechanical properties after such exposure provides valuable insights into long-term performance reliability.

Ballistic performance standards, including NIJ 0101.06 and STANAG 2920, have established velocity (V50) measurements as key metrics for aramid systems in protective applications. These standards define the velocity at which 50% of projectiles are stopped, offering a probabilistic approach to performance assessment.

Finite Element Analysis (FEA) validation protocols have recently been standardized, requiring correlation coefficients exceeding 0.85 between simulated and experimental load distribution patterns. This development has significantly enhanced the predictive capability of digital twins for aramid systems under complex loading scenarios.

The industry is currently moving toward harmonized global standards, with the International Aramid Producers Association (IAPA) leading efforts to establish unified testing methodologies that bridge differences between ASTM, ISO, and regional standards. This harmonization aims to facilitate international trade and technology transfer while ensuring consistent performance evaluation worldwide.

Performance metrics for aramid systems typically include tensile strength (measured in GPa), modulus of elasticity, elongation at break, and creep resistance under sustained loading. The Specific Energy Absorption (SEA) value, expressed in joules per gram, has emerged as a particularly valuable metric for applications requiring optimal load distribution, as it quantifies the energy absorption capacity relative to the system's weight.

Dynamic load testing protocols have evolved significantly, with cyclic loading tests now incorporating variable frequencies (0.5-10 Hz) to simulate real-world conditions. The Coefficient of Dynamic Friction (CDF) measurement has become increasingly important for aramid systems in load distribution applications, as it characterizes the interface behavior between aramid components and adjacent materials during load transfer.

Accelerated aging tests represent another critical dimension of performance evaluation, with protocols typically exposing aramid systems to UV radiation, moisture, and temperature cycling for periods equivalent to 5-10 years of service life. The retention of mechanical properties after such exposure provides valuable insights into long-term performance reliability.

Ballistic performance standards, including NIJ 0101.06 and STANAG 2920, have established velocity (V50) measurements as key metrics for aramid systems in protective applications. These standards define the velocity at which 50% of projectiles are stopped, offering a probabilistic approach to performance assessment.

Finite Element Analysis (FEA) validation protocols have recently been standardized, requiring correlation coefficients exceeding 0.85 between simulated and experimental load distribution patterns. This development has significantly enhanced the predictive capability of digital twins for aramid systems under complex loading scenarios.

The industry is currently moving toward harmonized global standards, with the International Aramid Producers Association (IAPA) leading efforts to establish unified testing methodologies that bridge differences between ASTM, ISO, and regional standards. This harmonization aims to facilitate international trade and technology transfer while ensuring consistent performance evaluation worldwide.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!