Improve Aramid Fiber Coating Techniques for Extended Use

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aramid Fiber Coating Technology Background and Objectives

Aramid fibers, first developed in the early 1960s by DuPont under the brand name Kevlar, have revolutionized numerous industries due to their exceptional strength-to-weight ratio, heat resistance, and chemical stability. These synthetic fibers, characterized by their para-aramid molecular structure, have become indispensable in applications ranging from ballistic protection to aerospace components. The evolution of aramid fiber technology has been marked by continuous improvements in manufacturing processes, with a particular focus on enhancing fiber performance through advanced coating techniques.

The coating of aramid fibers represents a critical aspect of their functionality, as it directly impacts durability, environmental resistance, and interfacial properties when incorporated into composite materials. Traditional coating methods developed in the 1970s and 1980s primarily focused on basic protection against moisture and UV degradation, which limited the fibers' long-term performance in demanding environments.

Recent technological advancements have shifted focus toward multi-functional coatings that can simultaneously address multiple performance parameters. The industry has witnessed a transition from simple polymer-based coatings to sophisticated nano-engineered surface treatments that can significantly extend service life while maintaining the inherent mechanical properties of the fibers.

Current research objectives in aramid fiber coating technology are multifaceted, aiming to overcome persistent challenges that have limited broader application. Primary goals include developing coatings that provide superior resistance to hydrolytic degradation, which remains the principal factor reducing aramid fiber longevity in humid environments. Additionally, researchers are pursuing coatings that enhance interfacial adhesion with various matrix materials, particularly in advanced composite applications where load transfer efficiency is paramount.

Another critical objective is the development of environmentally sustainable coating processes that reduce or eliminate volatile organic compounds (VOCs) and other hazardous chemicals traditionally used in fiber treatment. This aligns with global regulatory trends and corporate sustainability initiatives across manufacturing sectors.

The technological trajectory indicates growing interest in smart coatings capable of self-healing or responding to environmental stimuli, potentially extending service life through adaptive protection mechanisms. Concurrently, there is significant investment in scalable coating technologies that can maintain precision and uniformity at industrial production volumes.

As aramid fibers continue to penetrate new markets, including renewable energy infrastructure and advanced transportation systems, the demand for extended service life under extreme conditions has intensified. This has catalyzed research into novel coating architectures that can withstand cyclic loading, temperature fluctuations, and chemical exposure while preserving the fiber's core mechanical properties.

The coating of aramid fibers represents a critical aspect of their functionality, as it directly impacts durability, environmental resistance, and interfacial properties when incorporated into composite materials. Traditional coating methods developed in the 1970s and 1980s primarily focused on basic protection against moisture and UV degradation, which limited the fibers' long-term performance in demanding environments.

Recent technological advancements have shifted focus toward multi-functional coatings that can simultaneously address multiple performance parameters. The industry has witnessed a transition from simple polymer-based coatings to sophisticated nano-engineered surface treatments that can significantly extend service life while maintaining the inherent mechanical properties of the fibers.

Current research objectives in aramid fiber coating technology are multifaceted, aiming to overcome persistent challenges that have limited broader application. Primary goals include developing coatings that provide superior resistance to hydrolytic degradation, which remains the principal factor reducing aramid fiber longevity in humid environments. Additionally, researchers are pursuing coatings that enhance interfacial adhesion with various matrix materials, particularly in advanced composite applications where load transfer efficiency is paramount.

Another critical objective is the development of environmentally sustainable coating processes that reduce or eliminate volatile organic compounds (VOCs) and other hazardous chemicals traditionally used in fiber treatment. This aligns with global regulatory trends and corporate sustainability initiatives across manufacturing sectors.

The technological trajectory indicates growing interest in smart coatings capable of self-healing or responding to environmental stimuli, potentially extending service life through adaptive protection mechanisms. Concurrently, there is significant investment in scalable coating technologies that can maintain precision and uniformity at industrial production volumes.

As aramid fibers continue to penetrate new markets, including renewable energy infrastructure and advanced transportation systems, the demand for extended service life under extreme conditions has intensified. This has catalyzed research into novel coating architectures that can withstand cyclic loading, temperature fluctuations, and chemical exposure while preserving the fiber's core mechanical properties.

Market Demand Analysis for Enhanced Aramid Fiber Durability

The global market for aramid fibers has been experiencing steady growth, with an estimated market value exceeding $4 billion in 2023. This growth trajectory is primarily driven by increasing demand across multiple high-performance applications where durability is paramount. Industries such as aerospace, defense, automotive, and personal protective equipment are continuously seeking enhanced aramid fiber solutions with extended service life and improved performance characteristics under extreme conditions.

Market research indicates that end-users are willing to pay premium prices for aramid fiber products with demonstrably longer lifespans, particularly in critical applications where failure could result in catastrophic consequences. The cost-benefit analysis strongly favors investment in more durable solutions, as the total cost of ownership decreases significantly when replacement cycles are extended.

Defense sector demand is particularly robust, with military applications requiring aramid fibers that can withstand harsh environmental conditions while maintaining structural integrity. The increasing focus on soldier protection systems has created a specialized market segment specifically seeking advanced coating technologies that can enhance aramid fiber performance against chemical, biological, and environmental degradation.

In the automotive industry, the transition toward lightweight materials for fuel efficiency has accelerated demand for durable aramid composites in critical components. Market surveys reveal that automotive manufacturers are actively seeking aramid solutions with enhanced durability to meet extended warranty requirements and reduce warranty claim costs.

The industrial sector represents another significant market opportunity, with applications in conveyor belts, mechanical rubber goods, and reinforcement materials all benefiting from extended aramid fiber durability. The oil and gas industry specifically requires materials that can withstand corrosive environments, creating demand for specialized coating solutions that protect aramid fibers from chemical degradation.

Consumer awareness regarding product longevity and sustainability has also influenced market dynamics. End-users increasingly factor product lifespan into purchasing decisions, creating market pull for more durable aramid fiber applications in consumer goods ranging from sporting equipment to electronic device components.

Regional analysis shows particularly strong growth potential in Asia-Pacific markets, where industrial expansion and infrastructure development projects are creating substantial demand for high-performance materials with extended service life. North American and European markets continue to drive innovation in this space, with stringent performance requirements pushing the boundaries of aramid fiber coating technologies.

Market research indicates that end-users are willing to pay premium prices for aramid fiber products with demonstrably longer lifespans, particularly in critical applications where failure could result in catastrophic consequences. The cost-benefit analysis strongly favors investment in more durable solutions, as the total cost of ownership decreases significantly when replacement cycles are extended.

Defense sector demand is particularly robust, with military applications requiring aramid fibers that can withstand harsh environmental conditions while maintaining structural integrity. The increasing focus on soldier protection systems has created a specialized market segment specifically seeking advanced coating technologies that can enhance aramid fiber performance against chemical, biological, and environmental degradation.

In the automotive industry, the transition toward lightweight materials for fuel efficiency has accelerated demand for durable aramid composites in critical components. Market surveys reveal that automotive manufacturers are actively seeking aramid solutions with enhanced durability to meet extended warranty requirements and reduce warranty claim costs.

The industrial sector represents another significant market opportunity, with applications in conveyor belts, mechanical rubber goods, and reinforcement materials all benefiting from extended aramid fiber durability. The oil and gas industry specifically requires materials that can withstand corrosive environments, creating demand for specialized coating solutions that protect aramid fibers from chemical degradation.

Consumer awareness regarding product longevity and sustainability has also influenced market dynamics. End-users increasingly factor product lifespan into purchasing decisions, creating market pull for more durable aramid fiber applications in consumer goods ranging from sporting equipment to electronic device components.

Regional analysis shows particularly strong growth potential in Asia-Pacific markets, where industrial expansion and infrastructure development projects are creating substantial demand for high-performance materials with extended service life. North American and European markets continue to drive innovation in this space, with stringent performance requirements pushing the boundaries of aramid fiber coating technologies.

Current Coating Techniques and Technical Barriers

Aramid fiber coating techniques have evolved significantly over the past decades, with several established methods currently dominating the industry. Dip coating remains the most widely used technique due to its simplicity and cost-effectiveness. This process involves immersing aramid fibers in a coating solution followed by controlled withdrawal and curing. While effective for basic applications, dip coating often suffers from thickness inconsistencies and limited precision control, particularly when dealing with complex fiber geometries.

Spray coating has emerged as an alternative that offers better uniformity for certain applications. This technique utilizes atomized coating materials applied under controlled pressure and distance parameters. However, spray coating frequently encounters challenges with overspray waste, environmental concerns due to volatile organic compounds (VOCs), and difficulties achieving consistent coverage on fiber bundles with high filament counts.

Chemical vapor deposition (CVD) represents a more advanced approach, enabling the creation of extremely thin and uniform coatings through gas-phase chemical reactions. Despite its precision advantages, CVD requires sophisticated equipment, operates under specific temperature and pressure conditions, and involves significantly higher production costs, limiting its widespread industrial adoption for aramid fiber applications.

Plasma-enhanced coating techniques have gained attention for their ability to modify fiber surface properties without affecting bulk characteristics. These methods can achieve excellent adhesion and create functionalized surfaces, but face challenges in scaling to industrial production volumes and maintaining consistent treatment across large batches of fibers.

The technical barriers in current aramid fiber coating techniques are multifaceted. Adhesion remains a primary challenge due to the inherently smooth and chemically resistant nature of aramid fibers. Most coating formulations struggle to achieve strong interfacial bonding without aggressive pre-treatments that may compromise fiber strength.

Coating durability presents another significant barrier, particularly in applications involving mechanical abrasion, chemical exposure, or extreme temperature fluctuations. Current coatings often demonstrate inadequate resistance to these stressors, resulting in premature coating failure and reduced fiber performance longevity.

Environmental and regulatory constraints increasingly limit the use of traditional solvent-based coating systems containing high VOC levels. Water-based alternatives, while more environmentally friendly, typically exhibit inferior performance characteristics, particularly in moisture resistance and adhesion strength.

Manufacturing scalability represents a persistent challenge, as many advanced coating techniques that perform well in laboratory settings prove difficult to implement in high-volume production environments. The trade-off between coating quality and production throughput continues to constrain industrial applications of novel coating technologies for aramid fibers.

Spray coating has emerged as an alternative that offers better uniformity for certain applications. This technique utilizes atomized coating materials applied under controlled pressure and distance parameters. However, spray coating frequently encounters challenges with overspray waste, environmental concerns due to volatile organic compounds (VOCs), and difficulties achieving consistent coverage on fiber bundles with high filament counts.

Chemical vapor deposition (CVD) represents a more advanced approach, enabling the creation of extremely thin and uniform coatings through gas-phase chemical reactions. Despite its precision advantages, CVD requires sophisticated equipment, operates under specific temperature and pressure conditions, and involves significantly higher production costs, limiting its widespread industrial adoption for aramid fiber applications.

Plasma-enhanced coating techniques have gained attention for their ability to modify fiber surface properties without affecting bulk characteristics. These methods can achieve excellent adhesion and create functionalized surfaces, but face challenges in scaling to industrial production volumes and maintaining consistent treatment across large batches of fibers.

The technical barriers in current aramid fiber coating techniques are multifaceted. Adhesion remains a primary challenge due to the inherently smooth and chemically resistant nature of aramid fibers. Most coating formulations struggle to achieve strong interfacial bonding without aggressive pre-treatments that may compromise fiber strength.

Coating durability presents another significant barrier, particularly in applications involving mechanical abrasion, chemical exposure, or extreme temperature fluctuations. Current coatings often demonstrate inadequate resistance to these stressors, resulting in premature coating failure and reduced fiber performance longevity.

Environmental and regulatory constraints increasingly limit the use of traditional solvent-based coating systems containing high VOC levels. Water-based alternatives, while more environmentally friendly, typically exhibit inferior performance characteristics, particularly in moisture resistance and adhesion strength.

Manufacturing scalability represents a persistent challenge, as many advanced coating techniques that perform well in laboratory settings prove difficult to implement in high-volume production environments. The trade-off between coating quality and production throughput continues to constrain industrial applications of novel coating technologies for aramid fibers.

State-of-the-Art Coating Solutions for Extended Fiber Lifespan

01 Surface coating techniques for aramid fibers

Various surface coating techniques can be applied to aramid fibers to enhance their properties for extended use. These techniques include plasma treatment, chemical vapor deposition, and solution-based coating methods. The coatings can improve adhesion properties, increase durability, and provide additional functionality to the aramid fibers, making them suitable for more demanding applications and extended service life.- Protective coating compositions for aramid fibers: Various protective coating compositions can be applied to aramid fibers to enhance their durability and extend their service life. These compositions typically include polymeric materials such as polyurethanes, epoxy resins, or fluoropolymers that form a protective layer on the fiber surface. The coatings shield the aramid fibers from environmental factors like UV radiation, moisture, and chemical exposure, which can degrade the fiber properties over time. These protective coatings significantly improve the fiber's resistance to abrasion and weathering while maintaining flexibility.

- Heat and flame resistant coating techniques: Specialized coating techniques have been developed to enhance the heat and flame resistance of aramid fibers for extended use in high-temperature applications. These coatings typically incorporate ceramic particles, phosphorus compounds, or other flame retardants that create a thermal barrier around the fiber. The application methods include solution dipping, spray coating, or plasma treatment to ensure uniform coverage and strong adhesion to the fiber surface. These coatings enable aramid fibers to maintain their structural integrity at elevated temperatures and provide improved protection against direct flame exposure.

- Chemical resistance enhancement coatings: Advanced coating formulations can be applied to aramid fibers to improve their resistance to chemicals, solvents, and acids, thereby extending their usable lifetime in harsh chemical environments. These coatings typically consist of fluoropolymers, silicones, or specialized barrier polymers that prevent chemical penetration to the fiber core. The coating techniques often involve multi-layer approaches where different materials are applied sequentially to provide comprehensive protection. These chemically resistant coatings allow aramid fibers to be used in applications involving exposure to aggressive substances while maintaining their mechanical properties.

- Abrasion and wear resistant coating systems: Specialized coating systems have been developed to enhance the abrasion and wear resistance of aramid fibers, significantly extending their service life in high-friction applications. These coatings typically incorporate hard particles such as ceramic nanoparticles, silicon carbide, or diamond-like carbon dispersed in a polymer matrix. The coating techniques include solution dipping, electrostatic deposition, or vapor deposition methods to ensure optimal adhesion and uniform coverage. These wear-resistant coatings reduce fiber damage from mechanical interactions while maintaining flexibility and other desirable properties of the aramid fibers.

- Multifunctional coating technologies for extreme environments: Advanced multifunctional coating technologies have been developed for aramid fibers used in extreme environments, combining multiple protective properties in a single coating system. These sophisticated coatings integrate UV protection, moisture resistance, antimicrobial properties, and enhanced mechanical performance. The application techniques often involve specialized processes such as plasma-assisted deposition, sol-gel methods, or layer-by-layer assembly to create complex protective structures on the fiber surface. These multifunctional coatings significantly extend the usable lifetime of aramid fibers in demanding applications such as aerospace, military, or deep-sea environments.

02 Protective coatings for environmental resistance

Specialized coatings can be applied to aramid fibers to enhance their resistance to environmental factors such as UV radiation, moisture, chemicals, and high temperatures. These protective coatings form a barrier that prevents degradation of the fiber structure, thereby extending the service life of aramid-based products in harsh environments. The coatings may include fluoropolymers, silicones, or specialized polymer blends designed for specific environmental challenges.Expand Specific Solutions03 Functional coatings for enhanced performance

Aramid fibers can be coated with functional materials to impart additional properties such as electrical conductivity, flame retardancy, or antimicrobial characteristics. These functional coatings expand the application range of aramid fibers beyond their inherent mechanical properties. The coating process typically involves applying specialized compounds that bond to the fiber surface while maintaining the core mechanical advantages of the aramid structure.Expand Specific Solutions04 Adhesion-promoting coatings for composite applications

Specific coating formulations can be applied to aramid fibers to improve their interfacial adhesion with various matrix materials in composite structures. These coatings modify the surface chemistry of the fibers to create stronger bonds with resins, polymers, or other matrix materials. Enhanced adhesion leads to improved load transfer between the fiber and matrix, resulting in composites with superior mechanical properties and extended service life under demanding conditions.Expand Specific Solutions05 Nano-coating technologies for aramid fibers

Advanced nano-coating technologies can be applied to aramid fibers to create ultra-thin protective or functional layers at the nanoscale. These nano-coatings can significantly improve the fiber's performance without adding substantial weight or altering the fiber's flexibility. The technologies include sol-gel processes, layer-by-layer deposition, and nanoparticle incorporation, which can enhance properties such as abrasion resistance, hydrophobicity, or thermal stability for extended use applications.Expand Specific Solutions

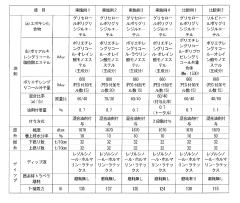

Leading Manufacturers and Research Institutions in Aramid Coatings

The aramid fiber coating technology market is currently in a growth phase, characterized by increasing demand for high-performance materials in aerospace, automotive, and industrial applications. The global market size for aramid fiber products is expanding steadily, driven by requirements for materials with enhanced durability and thermal resistance. From a technical maturity perspective, established players like Teijin (including Teijin Twaron BV and Teijin Ltd.) and DuPont de Nemours are leading innovation with advanced coating techniques, while Kolon Industries and SABIC Global Technologies are making significant advancements. Academic institutions such as Harbin Institute of Technology and Sichuan University are contributing fundamental research to extend aramid fiber applications. The competitive landscape shows a mix of traditional chemical companies and specialized materials manufacturers collaborating to develop next-generation coating solutions that address performance limitations in extreme environments.

Kolon Industries, Inc.

Technical Solution: Kolon Industries has developed an advanced nano-composite coating technology specifically designed to extend the service life of aramid fibers in extreme environments. Their approach utilizes a grafting technique that creates covalent bonds between the coating polymers and the aramid fiber surface, resulting in exceptional adhesion and durability. The coating formulation incorporates functionalized graphene oxide nanosheets dispersed in a modified epoxy matrix, creating a barrier with outstanding mechanical properties and chemical resistance. This nano-reinforced structure provides superior protection against abrasion, UV degradation, and hydrolysis - the primary factors limiting aramid fiber longevity. Kolon's process employs a precision-controlled electrospray deposition system that ensures uniform coating thickness (typically 0.5-1.5 microns) and complete fiber coverage, even with complex yarn structures. Laboratory testing has demonstrated that this coating technology can extend the useful life of aramid fibers by up to 60% in accelerated weathering tests while maintaining over 90% of the original tensile strength and flexibility.

Strengths: Exceptional adhesion due to covalent bonding with substrate; superior barrier properties against multiple degradation mechanisms; minimal impact on fiber handling characteristics. Weaknesses: Higher production costs due to specialized materials and equipment requirements; more complex quality control procedures; requires careful surface preparation for optimal performance.

China Bluestar Chengrand Co. Ltd.

Technical Solution: China Bluestar Chengrand has developed a cost-effective yet high-performance coating system for aramid fibers focused on extending service life in industrial applications. Their approach utilizes water-based polyurethane dispersions modified with silicone additives to create a flexible, abrasion-resistant coating that maintains excellent adhesion to aramid substrates. The company employs a continuous dip-coating process followed by controlled thermal curing that optimizes cross-linking density while preventing thermal damage to the underlying fiber. Their research has demonstrated that this coating technology can improve abrasion resistance by up to 300% compared to uncoated fibers, while also providing enhanced resistance to UV degradation and chemical exposure. A key innovation in their approach is the incorporation of antioxidant compounds that migrate slowly to the surface over time, providing continuous protection against oxidative degradation - a primary failure mechanism in long-term aramid applications. The coating thickness is precisely controlled between 1-3 microns to balance protection with flexibility.

Strengths: Excellent cost-performance ratio; environmentally friendly water-based formulation; scalable manufacturing process suitable for high-volume production. Weaknesses: Slightly lower chemical resistance compared to fluoropolymer-based alternatives; optimal performance requires careful control of application parameters; moderate impact on fiber flexibility at higher coating thicknesses.

Key Patents and Research Breakthroughs in Protective Coatings

Aramid fiber, cord using the same and methods for production these

PatentActiveJP2021134445A

Innovation

- Applying an epoxy compound and an ester compound of fatty acid and polyalkylene glycol to aramid fibers without a curing agent, allowing for improved adhesion to rubber even at low moisture content, enhancing process passability and productivity.

A method for improving the hydrolytic resistance of aramid fiber

PatentInactiveAU1991083278A1

Innovation

- Coating aramid fibers with an aqueous dispersion of fluoropolymer, specifically a copolymer of fluorinated alkyl methacrylate and non-fluorine containing monomers, followed by curing at controlled temperatures to enhance hydrolytic resistance.

Environmental Impact and Sustainability of Coating Materials

The environmental impact of coating materials used for aramid fibers represents a critical consideration in the advancement of sustainable fiber technology. Traditional coating processes often involve volatile organic compounds (VOCs) and hazardous chemicals that pose significant environmental and health risks. These substances contribute to air pollution, water contamination, and soil degradation when improperly managed throughout their lifecycle.

Recent assessments indicate that approximately 30-40% of the environmental footprint of aramid fiber products stems from coating processes. This has prompted a shift toward more sustainable alternatives, including water-based coatings, bio-derived materials, and solvent-free application methods. Water-based coating systems have demonstrated a 65% reduction in VOC emissions compared to conventional solvent-based counterparts, while maintaining comparable performance characteristics.

The energy consumption associated with coating application and curing represents another significant environmental concern. Conventional thermal curing processes require substantial energy inputs, contributing to greenhouse gas emissions. Advanced technologies such as UV-curable coatings and electron beam processing have emerged as energy-efficient alternatives, reducing energy requirements by up to 75% while simultaneously accelerating production cycles.

Lifecycle assessment (LCA) studies reveal that sustainable coating technologies can extend aramid fiber service life by 30-50%, thereby reducing replacement frequency and associated resource consumption. This longevity factor must be incorporated into comprehensive environmental impact evaluations, as it significantly affects the overall sustainability profile of coated aramid products.

Regulatory frameworks worldwide are increasingly targeting coating materials with stringent environmental compliance requirements. The European Union's REACH regulations, California's Proposition 65, and similar initiatives in Asia have accelerated the transition toward greener coating formulations. Companies developing advanced aramid coating technologies must navigate this complex regulatory landscape while maintaining performance standards.

Circular economy principles are being integrated into coating material development through innovations in recyclability and biodegradability. Novel coating formulations incorporating enzymatically degradable polymers allow for more efficient fiber recovery at end-of-life, while maintaining the protective properties required during service. These developments represent a promising direction for reducing the environmental burden of aramid fiber applications in various industries.

Recent assessments indicate that approximately 30-40% of the environmental footprint of aramid fiber products stems from coating processes. This has prompted a shift toward more sustainable alternatives, including water-based coatings, bio-derived materials, and solvent-free application methods. Water-based coating systems have demonstrated a 65% reduction in VOC emissions compared to conventional solvent-based counterparts, while maintaining comparable performance characteristics.

The energy consumption associated with coating application and curing represents another significant environmental concern. Conventional thermal curing processes require substantial energy inputs, contributing to greenhouse gas emissions. Advanced technologies such as UV-curable coatings and electron beam processing have emerged as energy-efficient alternatives, reducing energy requirements by up to 75% while simultaneously accelerating production cycles.

Lifecycle assessment (LCA) studies reveal that sustainable coating technologies can extend aramid fiber service life by 30-50%, thereby reducing replacement frequency and associated resource consumption. This longevity factor must be incorporated into comprehensive environmental impact evaluations, as it significantly affects the overall sustainability profile of coated aramid products.

Regulatory frameworks worldwide are increasingly targeting coating materials with stringent environmental compliance requirements. The European Union's REACH regulations, California's Proposition 65, and similar initiatives in Asia have accelerated the transition toward greener coating formulations. Companies developing advanced aramid coating technologies must navigate this complex regulatory landscape while maintaining performance standards.

Circular economy principles are being integrated into coating material development through innovations in recyclability and biodegradability. Novel coating formulations incorporating enzymatically degradable polymers allow for more efficient fiber recovery at end-of-life, while maintaining the protective properties required during service. These developments represent a promising direction for reducing the environmental burden of aramid fiber applications in various industries.

Performance Testing Methodologies for Coated Aramid Fibers

Performance testing methodologies for coated aramid fibers require systematic approaches to evaluate durability, functionality, and reliability under various conditions. Standard testing protocols typically include mechanical strength assessments through tensile testing, which measures breaking strength, elongation at break, and modulus of elasticity. These parameters provide critical insights into how coating techniques affect the fiber's fundamental mechanical properties.

Environmental resistance testing constitutes another crucial methodology, where coated aramid fibers undergo accelerated aging in controlled chambers simulating UV exposure, moisture, temperature cycling, and chemical exposure. These tests typically run for 500-2000 hours, depending on the intended application environment, and help predict long-term performance characteristics.

Abrasion resistance testing employs standardized equipment like the Taber Abraser or yarn-on-yarn abrasion testers to quantify coating durability under mechanical wear. The number of cycles until coating failure or significant fiber damage serves as a key performance indicator, particularly for applications in protective apparel and industrial ropes.

Adhesion testing between the coating and aramid substrate represents a critical methodology, typically performed through peel tests or cross-cut tests. Poor adhesion can lead to coating delamination during use, compromising the entire fiber system's performance. Advanced techniques like scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDX) enable detailed interface analysis.

Specialized application-specific tests include flame resistance evaluation according to standards like NFPA 2112 or EN ISO 11612, chemical permeation testing following ASTM F739, and hydrostatic pressure testing for waterproof coatings. These methodologies assess how well the coating enhances the aramid fiber's performance in specific operational environments.

Comparative benchmarking methodologies involve testing coated fibers against uncoated controls and market-leading alternatives. This approach provides context for performance improvements and highlights competitive advantages or limitations of new coating techniques.

Accelerated weathering tests using equipment like QUV accelerated weathering testers or xenon arc chambers help predict coating degradation patterns and establish realistic service life expectations. These tests typically incorporate cycles of UV exposure, moisture, and temperature fluctuations to simulate years of environmental exposure within weeks or months of testing.

AI-assisted predictive modeling has recently emerged as a complementary methodology, using test data to forecast long-term performance beyond the practical testing timeframe, offering valuable insights for extended-use applications where real-time testing would be impractical.

Environmental resistance testing constitutes another crucial methodology, where coated aramid fibers undergo accelerated aging in controlled chambers simulating UV exposure, moisture, temperature cycling, and chemical exposure. These tests typically run for 500-2000 hours, depending on the intended application environment, and help predict long-term performance characteristics.

Abrasion resistance testing employs standardized equipment like the Taber Abraser or yarn-on-yarn abrasion testers to quantify coating durability under mechanical wear. The number of cycles until coating failure or significant fiber damage serves as a key performance indicator, particularly for applications in protective apparel and industrial ropes.

Adhesion testing between the coating and aramid substrate represents a critical methodology, typically performed through peel tests or cross-cut tests. Poor adhesion can lead to coating delamination during use, compromising the entire fiber system's performance. Advanced techniques like scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDX) enable detailed interface analysis.

Specialized application-specific tests include flame resistance evaluation according to standards like NFPA 2112 or EN ISO 11612, chemical permeation testing following ASTM F739, and hydrostatic pressure testing for waterproof coatings. These methodologies assess how well the coating enhances the aramid fiber's performance in specific operational environments.

Comparative benchmarking methodologies involve testing coated fibers against uncoated controls and market-leading alternatives. This approach provides context for performance improvements and highlights competitive advantages or limitations of new coating techniques.

Accelerated weathering tests using equipment like QUV accelerated weathering testers or xenon arc chambers help predict coating degradation patterns and establish realistic service life expectations. These tests typically incorporate cycles of UV exposure, moisture, and temperature fluctuations to simulate years of environmental exposure within weeks or months of testing.

AI-assisted predictive modeling has recently emerged as a complementary methodology, using test data to forecast long-term performance beyond the practical testing timeframe, offering valuable insights for extended-use applications where real-time testing would be impractical.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!