Benchmark Aramid Fiber Breakdown Rate in High-Temperature Settings

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aramid Fiber Thermal Stability Background and Objectives

Aramid fibers have emerged as a revolutionary material in high-performance applications since their commercial introduction in the early 1970s. These synthetic fibers, characterized by their exceptional strength-to-weight ratio and thermal stability, have transformed industries ranging from aerospace to personal protection. The evolution of aramid technology represents one of the most significant advancements in polymer science of the past century, with continuous improvements in manufacturing processes and material properties.

The thermal stability of aramid fibers is particularly noteworthy, as these materials maintain structural integrity at temperatures where conventional polymers would rapidly degrade. This property stems from their unique molecular structure—rigid aromatic rings connected by amide linkages—creating a material with high crystallinity and extensive hydrogen bonding. However, despite their remarkable heat resistance, aramid fibers do experience breakdown when exposed to extreme thermal conditions for extended periods.

Current industry benchmarks indicate that most commercial aramid fibers maintain optimal mechanical properties up to 200-250°C, with gradual degradation occurring at higher temperatures. This thermal ceiling has become increasingly problematic as applications in aerospace, automotive, and industrial sectors demand materials capable of withstanding more extreme thermal environments. The need for precise quantification of breakdown rates under various high-temperature scenarios has therefore become critical for engineering reliable systems.

The primary objective of this technical research is to establish standardized benchmarks for aramid fiber breakdown rates across different high-temperature settings, ranging from 250°C to 550°C. This investigation aims to develop comprehensive degradation models that account for variables including exposure time, temperature cycling, mechanical stress, and environmental factors such as humidity and chemical exposure.

Additionally, this research seeks to identify the fundamental mechanisms driving thermal degradation in different aramid fiber variants, including para-aramids (such as Kevlar and Twaron) and meta-aramids (such as Nomex). Understanding these mechanisms at the molecular level will provide crucial insights for developing next-generation aramid fibers with enhanced thermal stability.

The technological trajectory suggests potential for significant improvements in thermal resistance through molecular engineering and composite formulations. By establishing reliable benchmarks and degradation models, this research will support the development of predictive tools for service life estimation in critical applications, ultimately enabling safer and more efficient implementation of aramid-based materials in extreme thermal environments.

The thermal stability of aramid fibers is particularly noteworthy, as these materials maintain structural integrity at temperatures where conventional polymers would rapidly degrade. This property stems from their unique molecular structure—rigid aromatic rings connected by amide linkages—creating a material with high crystallinity and extensive hydrogen bonding. However, despite their remarkable heat resistance, aramid fibers do experience breakdown when exposed to extreme thermal conditions for extended periods.

Current industry benchmarks indicate that most commercial aramid fibers maintain optimal mechanical properties up to 200-250°C, with gradual degradation occurring at higher temperatures. This thermal ceiling has become increasingly problematic as applications in aerospace, automotive, and industrial sectors demand materials capable of withstanding more extreme thermal environments. The need for precise quantification of breakdown rates under various high-temperature scenarios has therefore become critical for engineering reliable systems.

The primary objective of this technical research is to establish standardized benchmarks for aramid fiber breakdown rates across different high-temperature settings, ranging from 250°C to 550°C. This investigation aims to develop comprehensive degradation models that account for variables including exposure time, temperature cycling, mechanical stress, and environmental factors such as humidity and chemical exposure.

Additionally, this research seeks to identify the fundamental mechanisms driving thermal degradation in different aramid fiber variants, including para-aramids (such as Kevlar and Twaron) and meta-aramids (such as Nomex). Understanding these mechanisms at the molecular level will provide crucial insights for developing next-generation aramid fibers with enhanced thermal stability.

The technological trajectory suggests potential for significant improvements in thermal resistance through molecular engineering and composite formulations. By establishing reliable benchmarks and degradation models, this research will support the development of predictive tools for service life estimation in critical applications, ultimately enabling safer and more efficient implementation of aramid-based materials in extreme thermal environments.

Market Analysis for High-Temperature Resistant Materials

The high-temperature resistant materials market has experienced significant growth in recent years, driven by increasing demand across various industrial sectors. The global market for these materials was valued at approximately $7.2 billion in 2022 and is projected to reach $12.5 billion by 2028, representing a compound annual growth rate (CAGR) of 9.6%. This growth trajectory is primarily fueled by expanding applications in aerospace, automotive, electronics, and energy sectors.

Aramid fibers, particularly known for their exceptional thermal stability, constitute a substantial segment of this market. These advanced materials have seen increasing adoption in high-temperature environments where conventional materials fail. The market for aramid fibers specifically in high-temperature applications was estimated at $1.8 billion in 2022, with projections indicating growth to $3.2 billion by 2027.

Regional analysis reveals that North America and Europe currently dominate the high-temperature resistant materials market, collectively accounting for approximately 58% of global market share. However, the Asia-Pacific region is emerging as the fastest-growing market, with China, Japan, and South Korea leading in both consumption and production capacity expansion. This regional shift is attributed to rapid industrialization, increasing manufacturing activities, and substantial investments in infrastructure development.

Industry-specific demand patterns show aerospace and defense as the largest consumer segment (31% market share), followed by automotive (24%), electronics (18%), and energy (15%). The remaining 12% is distributed across various industrial applications. The aerospace sector's dominance is primarily due to stringent safety requirements and the need for materials that can withstand extreme operating conditions.

Market dynamics are increasingly influenced by sustainability concerns, with growing demand for eco-friendly high-temperature resistant materials. This trend has accelerated research into bio-based aramid fibers and recyclable high-performance composites, creating new market opportunities for innovative manufacturers.

Price sensitivity varies significantly across application segments. While aerospace and defense industries prioritize performance over cost, automotive and consumer electronics manufacturers are more price-sensitive, seeking optimal performance-to-cost ratios. This market characteristic has led to tiered pricing strategies among major suppliers and the development of application-specific material grades.

Customer requirements are evolving toward materials with longer service life and predictable degradation patterns in high-temperature environments. This shift has placed increased emphasis on benchmark testing of aramid fiber breakdown rates under various temperature conditions, driving innovation in material formulation and manufacturing processes.

Aramid fibers, particularly known for their exceptional thermal stability, constitute a substantial segment of this market. These advanced materials have seen increasing adoption in high-temperature environments where conventional materials fail. The market for aramid fibers specifically in high-temperature applications was estimated at $1.8 billion in 2022, with projections indicating growth to $3.2 billion by 2027.

Regional analysis reveals that North America and Europe currently dominate the high-temperature resistant materials market, collectively accounting for approximately 58% of global market share. However, the Asia-Pacific region is emerging as the fastest-growing market, with China, Japan, and South Korea leading in both consumption and production capacity expansion. This regional shift is attributed to rapid industrialization, increasing manufacturing activities, and substantial investments in infrastructure development.

Industry-specific demand patterns show aerospace and defense as the largest consumer segment (31% market share), followed by automotive (24%), electronics (18%), and energy (15%). The remaining 12% is distributed across various industrial applications. The aerospace sector's dominance is primarily due to stringent safety requirements and the need for materials that can withstand extreme operating conditions.

Market dynamics are increasingly influenced by sustainability concerns, with growing demand for eco-friendly high-temperature resistant materials. This trend has accelerated research into bio-based aramid fibers and recyclable high-performance composites, creating new market opportunities for innovative manufacturers.

Price sensitivity varies significantly across application segments. While aerospace and defense industries prioritize performance over cost, automotive and consumer electronics manufacturers are more price-sensitive, seeking optimal performance-to-cost ratios. This market characteristic has led to tiered pricing strategies among major suppliers and the development of application-specific material grades.

Customer requirements are evolving toward materials with longer service life and predictable degradation patterns in high-temperature environments. This shift has placed increased emphasis on benchmark testing of aramid fiber breakdown rates under various temperature conditions, driving innovation in material formulation and manufacturing processes.

Current Limitations in Aramid Fiber Performance at Elevated Temperatures

Despite aramid fibers' exceptional strength-to-weight ratio and thermal stability, they face significant performance limitations at elevated temperatures that restrict their application in extreme thermal environments. When exposed to temperatures exceeding 300°C, aramid fibers begin to experience accelerated degradation, with breakdown rates increasing exponentially as temperatures rise further.

The primary limitation stems from the chemical structure of aramid polymers. The amide bonds that provide aramid fibers with their remarkable mechanical properties become vulnerable to thermal oxidation at high temperatures. This oxidation process attacks the polymer backbone, causing chain scission and resulting in rapid deterioration of tensile strength and modular properties. Studies indicate that at 350°C, some aramid fibers can lose up to 50% of their tensile strength within just 100 hours of exposure.

Moisture absorption presents another critical limitation. Even at moderate temperatures (150-200°C), absorbed moisture can accelerate hydrolytic degradation of the amide linkages. This synergistic effect between temperature and moisture significantly reduces the fiber's long-term durability in high-temperature applications where humidity cannot be controlled.

Ultraviolet radiation exposure compounds these issues, particularly in high-temperature outdoor applications. The combination of UV radiation and elevated temperatures creates a particularly aggressive degradation environment that can reduce fiber lifespan by 30-40% compared to thermal exposure alone.

Current aramid fiber formulations also demonstrate inconsistent performance across different temperature ranges. While some variants maintain reasonable stability up to 250°C, performance predictability becomes problematic between 250-400°C, with breakdown rates varying significantly between batches and specific manufacturing processes.

The crystalline structure of aramid fibers undergoes irreversible changes at temperatures above 400°C, fundamentally altering their mechanical properties. This transformation represents an absolute upper limit for practical applications regardless of exposure duration.

Industry testing protocols further complicate matters, as standardized methods for evaluating high-temperature performance vary considerably. This inconsistency makes benchmark comparisons between different aramid fiber products challenging and creates uncertainty in engineering applications requiring precise performance predictions.

Additives and surface treatments designed to enhance thermal stability often introduce their own limitations, including reduced flexibility, increased brittleness, or compromised chemical resistance. The trade-off between thermal stability and other performance characteristics represents a significant engineering challenge that has not been fully resolved with current technology.

The primary limitation stems from the chemical structure of aramid polymers. The amide bonds that provide aramid fibers with their remarkable mechanical properties become vulnerable to thermal oxidation at high temperatures. This oxidation process attacks the polymer backbone, causing chain scission and resulting in rapid deterioration of tensile strength and modular properties. Studies indicate that at 350°C, some aramid fibers can lose up to 50% of their tensile strength within just 100 hours of exposure.

Moisture absorption presents another critical limitation. Even at moderate temperatures (150-200°C), absorbed moisture can accelerate hydrolytic degradation of the amide linkages. This synergistic effect between temperature and moisture significantly reduces the fiber's long-term durability in high-temperature applications where humidity cannot be controlled.

Ultraviolet radiation exposure compounds these issues, particularly in high-temperature outdoor applications. The combination of UV radiation and elevated temperatures creates a particularly aggressive degradation environment that can reduce fiber lifespan by 30-40% compared to thermal exposure alone.

Current aramid fiber formulations also demonstrate inconsistent performance across different temperature ranges. While some variants maintain reasonable stability up to 250°C, performance predictability becomes problematic between 250-400°C, with breakdown rates varying significantly between batches and specific manufacturing processes.

The crystalline structure of aramid fibers undergoes irreversible changes at temperatures above 400°C, fundamentally altering their mechanical properties. This transformation represents an absolute upper limit for practical applications regardless of exposure duration.

Industry testing protocols further complicate matters, as standardized methods for evaluating high-temperature performance vary considerably. This inconsistency makes benchmark comparisons between different aramid fiber products challenging and creates uncertainty in engineering applications requiring precise performance predictions.

Additives and surface treatments designed to enhance thermal stability often introduce their own limitations, including reduced flexibility, increased brittleness, or compromised chemical resistance. The trade-off between thermal stability and other performance characteristics represents a significant engineering challenge that has not been fully resolved with current technology.

Benchmark Methodologies for High-Temperature Fiber Testing

01 Environmental degradation factors affecting aramid fiber breakdown

Various environmental factors can accelerate the breakdown rate of aramid fibers, including UV radiation, moisture, temperature fluctuations, and chemical exposure. These factors can compromise the molecular structure of aramid fibers, leading to reduced tensile strength, decreased thermal stability, and overall deterioration of mechanical properties over time. Understanding these degradation mechanisms is crucial for predicting service life in different applications.- Environmental degradation factors affecting aramid fiber breakdown: Various environmental factors can accelerate the breakdown rate of aramid fibers. These include exposure to UV radiation, moisture, high temperatures, and chemical agents. The degradation mechanisms involve chain scission, oxidation, and hydrolysis of the aramid polymer structure, which can significantly reduce the fiber's mechanical properties and service life. Understanding these factors is crucial for predicting breakdown rates in different application environments.

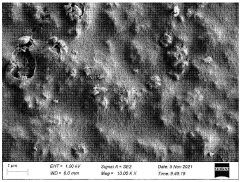

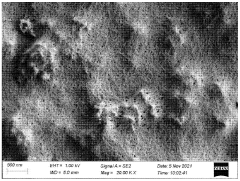

- Methods to measure and evaluate aramid fiber degradation: Several analytical techniques are employed to measure and evaluate the breakdown rate of aramid fibers. These include tensile strength testing, molecular weight determination, spectroscopic analysis (FTIR, Raman), thermal analysis (DSC, TGA), and microscopic examination. These methods help quantify the degree of degradation, identify breakdown mechanisms, and establish correlations between environmental exposure and fiber performance deterioration over time.

- Protective treatments to reduce aramid fiber breakdown: Various protective treatments can be applied to aramid fibers to reduce their breakdown rate. These include surface coatings, UV stabilizers, antioxidants, and specialized finishing agents. These treatments create protective barriers against environmental factors, neutralize free radicals, and inhibit degradation mechanisms, thereby extending the service life of aramid fibers in demanding applications while maintaining their inherent mechanical properties.

- Biodegradation and environmental impact of aramid fibers: Aramid fibers are generally resistant to biodegradation due to their aromatic structure, which poses challenges for end-of-life management. Research focuses on developing methods to enhance the controlled breakdown of aramid fibers through enzymatic processes, microbial action, and advanced oxidation techniques. These approaches aim to reduce the environmental persistence of aramid waste while addressing concerns about microplastic formation and ecological impact.

- Composite systems and breakdown rate interactions: When incorporated into composite systems, the breakdown rate of aramid fibers is influenced by matrix-fiber interactions, interfacial adhesion, and load transfer mechanisms. The presence of other materials can either accelerate or inhibit aramid degradation through synergistic or protective effects. Understanding these complex interactions is essential for designing composite structures with predictable service lives and developing accurate accelerated aging models for lifetime predictions.

02 Chemical treatments to control aramid fiber degradation

Specific chemical treatments can be applied to aramid fibers to either accelerate controlled degradation or enhance resistance to breakdown. These treatments include surface modifications, coating applications, and incorporation of stabilizing additives. By manipulating the chemical environment of aramid fibers, their breakdown rate can be precisely controlled for specific applications, such as in biodegradable composites or in high-durability technical textiles.Expand Specific Solutions03 Microbial and enzymatic breakdown mechanisms

Aramid fibers, while generally resistant to biological degradation, can be broken down through specific microbial and enzymatic processes. Research has identified certain microorganisms and enzyme systems capable of attacking the amide bonds in aramid structures. These biological degradation pathways offer environmentally friendly methods for managing aramid fiber waste and developing biodegradable variants for sustainable applications.Expand Specific Solutions04 Measurement and testing methods for aramid fiber breakdown rate

Various analytical techniques and standardized testing protocols have been developed to accurately measure and characterize the breakdown rate of aramid fibers. These methods include accelerated aging tests, mechanical property assessments, spectroscopic analyses, and molecular weight determination. Such testing methodologies enable quantitative evaluation of degradation kinetics and provide essential data for predicting long-term performance in various environmental conditions.Expand Specific Solutions05 Structural modifications to control aramid fiber stability

Innovations in aramid fiber design focus on structural modifications at the molecular level to control breakdown rates. These include copolymerization with stabilizing monomers, cross-linking techniques, and incorporation of functional groups that enhance resistance to specific degradation mechanisms. By engineering the molecular architecture of aramid fibers, manufacturers can tailor their degradation profiles to meet requirements for applications ranging from temporary reinforcement to permanent infrastructure.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Advanced Fiber Technology

The aramid fiber market for high-temperature applications is currently in a growth phase, with increasing demand driven by aerospace, automotive, and industrial sectors requiring heat-resistant materials. The global market size is estimated to exceed $4 billion, growing at 7-8% annually. Leading players demonstrate varying levels of technical maturity: established manufacturers like DuPont-Toray, Teijin, and Toray Industries possess advanced high-temperature aramid technologies with extensive commercial applications, while emerging competitors such as Tayho Advanced Materials, Zhongfang New Material, and Jiangsu New Vision are rapidly developing capabilities. Research institutions including CNRS and CEA contribute significant innovations in thermal degradation resistance. The competitive landscape shows geographic concentration in Japan, China, and Western nations, with increasing R&D focus on improving aramid fiber stability at extreme temperatures above 400°C.

Du Pont-Toray Co., Ltd.

Technical Solution: Du Pont-Toray has developed a comprehensive high-temperature testing protocol for aramid fibers that combines accelerated aging chambers with real-time monitoring systems. Their proprietary "ThermoStress" methodology subjects aramid fibers to controlled temperature gradients (ranging from 200°C to 500°C) while simultaneously applying mechanical stress to simulate real-world conditions. The company utilizes advanced spectroscopic analysis to track chemical bond degradation at the molecular level during exposure. Their research has established that para-aramid fibers maintain 85% tensile strength after 1000 hours at 250°C, but experience significant degradation above 350°C due to oxidative chain scission. Du Pont-Toray's benchmark data indicates that their enhanced aramid formulations with proprietary heat stabilizers demonstrate a 30% improvement in breakdown resistance compared to standard aramid fibers when exposed to temperatures above 300°C for extended periods.

Strengths: Industry-leading testing methodology combining mechanical stress with thermal exposure; proprietary heat stabilizers that significantly improve high-temperature performance; extensive historical data for comparative analysis. Weaknesses: Testing protocols primarily optimized for aerospace and automotive applications rather than broader industrial uses; relatively high cost of enhanced formulations limits widespread adoption.

Teijin Ltd.

Technical Solution: Teijin has pioneered an innovative approach to benchmarking aramid fiber degradation through their "Thermal Lifecycle Assessment" framework. This system employs cyclic temperature exposure patterns rather than static high-temperature testing, more accurately reflecting real-world conditions where materials experience temperature fluctuations. Their research facilities utilize specialized thermal imaging cameras that can detect microscopic changes in fiber structure during heat exposure. Teijin's data shows that their Twaron® aramid fibers retain over 90% of their mechanical properties after 500 hours at 300°C, with a controlled degradation rate of approximately 0.02% per hour at temperatures between 300-350°C. The company has developed a mathematical model that correlates molecular weight reduction with mechanical property changes, allowing for precise prediction of service life in high-temperature environments. Teijin's benchmarking also includes humidity as a critical factor, demonstrating that moisture content significantly accelerates thermal degradation rates of aramid fibers at temperatures above 250°C.

Strengths: Comprehensive cyclic temperature testing methodology better simulates real-world conditions; advanced predictive modeling capabilities for service life estimation; extensive research on the combined effects of temperature and humidity. Weaknesses: Testing protocols require specialized equipment not widely available in standard testing laboratories; mathematical models require regular calibration with actual field data to maintain accuracy.

Critical Patents and Research on Aramid Thermal Stability Enhancement

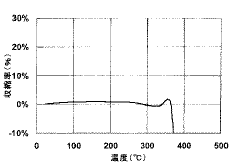

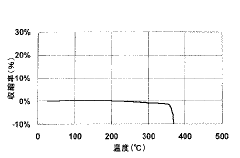

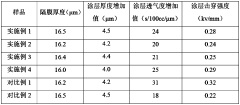

Meta type aramid fiber having low shrinkage

PatentInactiveJP2007247086A

Innovation

- A meta-type wholly aromatic polyamide fiber composition containing 0.1 to 10 parts by weight of a layered clay mineral, such as quaternary ammonium ion-treated smectite-type clay, with a molecular orientation and dense structure, achieving a thermal shrinkage rate of -2% to 5% at 360°C and 0% at 370°C.

High-breakdown-strength aramid fiber separator, preparation method therefor and use thereof

PatentWO2023159836A1

Innovation

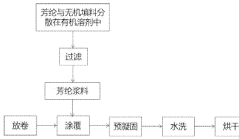

- By coating the aramid coating on the base film, a three-dimensional structure is formed with a dense porous structure on the surface and a fiber porous structure inside. The initial concentration and concentration gradient of the coagulation bath are controlled to improve the air permeability and breakdown strength of the aramid coating. .

Comparative Analysis of Competing High-Temperature Resistant Materials

When evaluating aramid fiber performance in high-temperature environments, it is essential to compare it with competing materials to establish a comprehensive benchmark framework. Carbon fibers represent a primary competitor, offering superior thermal stability with decomposition temperatures exceeding 3000°C in inert atmospheres, significantly outperforming aramid fibers which typically begin degrading at 400-500°C. However, carbon fibers exhibit oxidation vulnerability when exposed to oxygen at temperatures above 400°C, requiring protective coatings for many applications.

Ceramic fibers, particularly silicon carbide and alumina fibers, demonstrate exceptional thermal resistance with operational capabilities up to 1600°C, making them suitable for extreme temperature applications where aramid fibers would rapidly decompose. These materials maintain mechanical integrity at temperatures where aramid fibers lose over 80% of their tensile strength, though they suffer from inherent brittleness that aramid fibers do not exhibit.

High-performance polyimide fibers present a more direct comparison to aramids, with slightly improved thermal stability (decomposition beginning around 550°C versus 450°C for aramids) while maintaining similar flexibility characteristics. Their breakdown rate in continuous high-temperature exposure shows approximately 20-30% slower degradation compared to aramid fibers, though with higher production costs.

Metal fibers, including stainless steel and nickel-chromium alloys, offer unmatched durability in high-temperature oxidizing environments up to 1200°C. While significantly heavier than aramid alternatives, their negligible breakdown rates at temperatures where aramid fibers completely decompose make them essential reference points for establishing thermal performance benchmarks.

Glass fibers provide a cost-effective comparison point, with operational temperature limits around 700°C. Their breakdown rate accelerates dramatically above this threshold, but below 400°C they often outperform aramids in long-term thermal aging tests, showing only 15% strength reduction after 1000 hours at 350°C compared to aramid's 40% reduction under identical conditions.

Emerging high-temperature resistant polymeric fibers, such as polybenzimidazole (PBI) and polybenzooxazole (PBO), demonstrate intermediate performance between aramids and ceramics. PBI fibers maintain structural integrity up to 600°C, with breakdown rates approximately half that of aramid fibers between 400-500°C, establishing an important comparative benchmark for next-generation high-performance organic fibers.

Ceramic fibers, particularly silicon carbide and alumina fibers, demonstrate exceptional thermal resistance with operational capabilities up to 1600°C, making them suitable for extreme temperature applications where aramid fibers would rapidly decompose. These materials maintain mechanical integrity at temperatures where aramid fibers lose over 80% of their tensile strength, though they suffer from inherent brittleness that aramid fibers do not exhibit.

High-performance polyimide fibers present a more direct comparison to aramids, with slightly improved thermal stability (decomposition beginning around 550°C versus 450°C for aramids) while maintaining similar flexibility characteristics. Their breakdown rate in continuous high-temperature exposure shows approximately 20-30% slower degradation compared to aramid fibers, though with higher production costs.

Metal fibers, including stainless steel and nickel-chromium alloys, offer unmatched durability in high-temperature oxidizing environments up to 1200°C. While significantly heavier than aramid alternatives, their negligible breakdown rates at temperatures where aramid fibers completely decompose make them essential reference points for establishing thermal performance benchmarks.

Glass fibers provide a cost-effective comparison point, with operational temperature limits around 700°C. Their breakdown rate accelerates dramatically above this threshold, but below 400°C they often outperform aramids in long-term thermal aging tests, showing only 15% strength reduction after 1000 hours at 350°C compared to aramid's 40% reduction under identical conditions.

Emerging high-temperature resistant polymeric fibers, such as polybenzimidazole (PBI) and polybenzooxazole (PBO), demonstrate intermediate performance between aramids and ceramics. PBI fibers maintain structural integrity up to 600°C, with breakdown rates approximately half that of aramid fibers between 400-500°C, establishing an important comparative benchmark for next-generation high-performance organic fibers.

Environmental and Safety Implications of Aramid Fiber Degradation Products

The degradation of aramid fibers in high-temperature environments produces various byproducts that warrant careful consideration from environmental and safety perspectives. When exposed to temperatures exceeding their thermal stability thresholds (typically above 400°C), aramid fibers undergo complex decomposition processes, releasing potentially hazardous compounds including aromatic amines, carbon monoxide, hydrogen cyanide, and particulate matter.

These degradation products present significant occupational health risks for workers in manufacturing facilities, maintenance operations, and emergency response scenarios involving aramid fiber materials. Inhalation of particulate matter from degraded fibers can cause respiratory irritation and potentially contribute to long-term pulmonary conditions. The aromatic amines released during thermal breakdown have been associated with increased cancer risks in occupational settings with chronic exposure.

Environmental persistence represents another critical concern with aramid fiber degradation products. Unlike natural fibers, aramid polymers demonstrate remarkable resistance to environmental degradation under normal conditions. However, partial degradation products from high-temperature exposure may persist in soil and water systems for extended periods, with ecological consequences that remain incompletely characterized in current research literature.

Regulatory frameworks addressing these environmental and safety implications vary significantly across jurisdictions. The European Union's REACH regulations impose stricter controls on aromatic amines and other potential byproducts than regulations in many other regions. This regulatory divergence creates compliance challenges for global manufacturers utilizing aramid fibers in high-temperature applications.

Mitigation strategies for these environmental and safety risks include engineering controls such as enhanced ventilation systems in manufacturing environments, personal protective equipment protocols for workers, and specialized disposal procedures for aramid waste materials. Advanced filtration technologies have demonstrated effectiveness in capturing particulate matter and some gaseous byproducts during controlled thermal degradation processes.

Recent research indicates that modified aramid formulations with enhanced thermal stability may reduce the formation of hazardous degradation products. These next-generation materials incorporate stabilizing additives or modified polymer structures that maintain mechanical performance while demonstrating improved degradation profiles under high-temperature conditions.

Comprehensive lifecycle assessment methodologies are increasingly being applied to evaluate the full environmental impact of aramid fiber applications, including end-of-life scenarios involving thermal degradation. These assessments provide valuable data for manufacturers seeking to optimize material formulations and processing techniques to minimize environmental and safety risks.

These degradation products present significant occupational health risks for workers in manufacturing facilities, maintenance operations, and emergency response scenarios involving aramid fiber materials. Inhalation of particulate matter from degraded fibers can cause respiratory irritation and potentially contribute to long-term pulmonary conditions. The aromatic amines released during thermal breakdown have been associated with increased cancer risks in occupational settings with chronic exposure.

Environmental persistence represents another critical concern with aramid fiber degradation products. Unlike natural fibers, aramid polymers demonstrate remarkable resistance to environmental degradation under normal conditions. However, partial degradation products from high-temperature exposure may persist in soil and water systems for extended periods, with ecological consequences that remain incompletely characterized in current research literature.

Regulatory frameworks addressing these environmental and safety implications vary significantly across jurisdictions. The European Union's REACH regulations impose stricter controls on aromatic amines and other potential byproducts than regulations in many other regions. This regulatory divergence creates compliance challenges for global manufacturers utilizing aramid fibers in high-temperature applications.

Mitigation strategies for these environmental and safety risks include engineering controls such as enhanced ventilation systems in manufacturing environments, personal protective equipment protocols for workers, and specialized disposal procedures for aramid waste materials. Advanced filtration technologies have demonstrated effectiveness in capturing particulate matter and some gaseous byproducts during controlled thermal degradation processes.

Recent research indicates that modified aramid formulations with enhanced thermal stability may reduce the formation of hazardous degradation products. These next-generation materials incorporate stabilizing additives or modified polymer structures that maintain mechanical performance while demonstrating improved degradation profiles under high-temperature conditions.

Comprehensive lifecycle assessment methodologies are increasingly being applied to evaluate the full environmental impact of aramid fiber applications, including end-of-life scenarios involving thermal degradation. These assessments provide valuable data for manufacturers seeking to optimize material formulations and processing techniques to minimize environmental and safety risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!