How to Reduce Aramid Fiber Degradation in Field Conditions

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aramid Fiber Degradation Background and Objectives

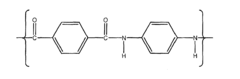

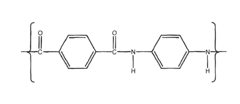

Aramid fibers, first developed in the early 1960s, represent a significant advancement in high-performance synthetic materials. These para-aramid polymers, characterized by their exceptional strength-to-weight ratio, have revolutionized numerous industries including defense, aerospace, automotive, and personal protection. The evolution of aramid fiber technology has been marked by continuous improvements in manufacturing processes, resulting in enhanced mechanical properties and broader application possibilities.

Despite their remarkable properties, aramid fibers face significant degradation challenges when deployed in field conditions. This degradation primarily stems from exposure to ultraviolet radiation, moisture, chemical contaminants, and mechanical stress. The technical objective of this research is to identify and develop effective strategies to mitigate these degradation mechanisms, thereby extending the service life of aramid fiber-based products in real-world applications.

Historical data indicates that aramid fibers can lose up to 50% of their tensile strength after prolonged exposure to sunlight, while moisture absorption can lead to dimensional instability and reduced mechanical performance. These degradation patterns have been documented across various application environments, from desert conditions to maritime settings, highlighting the universal nature of this technical challenge.

The technological trajectory in this field has evolved from basic protective coatings to more sophisticated approaches involving molecular modifications and composite structures. Recent advancements in nanomaterials and polymer science have opened new avenues for addressing degradation issues at the molecular level, suggesting promising directions for future research and development.

Current industry standards for aramid fiber durability are increasingly inadequate for emerging applications that demand extended service life under extreme conditions. This gap between performance expectations and material capabilities represents a critical technological challenge that requires innovative solutions based on fundamental scientific understanding of degradation mechanisms.

The primary technical goals of this investigation include: developing comprehensive models of aramid fiber degradation under various field conditions; identifying or creating effective protective treatments that preserve fiber integrity without compromising desirable mechanical properties; establishing accelerated testing protocols that accurately predict long-term performance; and formulating design guidelines that optimize aramid fiber implementation in high-stress environments.

By addressing these objectives, we aim to significantly enhance the durability and reliability of aramid fiber-based systems, potentially expanding their application range while reducing lifecycle costs associated with maintenance and replacement of degraded materials.

Despite their remarkable properties, aramid fibers face significant degradation challenges when deployed in field conditions. This degradation primarily stems from exposure to ultraviolet radiation, moisture, chemical contaminants, and mechanical stress. The technical objective of this research is to identify and develop effective strategies to mitigate these degradation mechanisms, thereby extending the service life of aramid fiber-based products in real-world applications.

Historical data indicates that aramid fibers can lose up to 50% of their tensile strength after prolonged exposure to sunlight, while moisture absorption can lead to dimensional instability and reduced mechanical performance. These degradation patterns have been documented across various application environments, from desert conditions to maritime settings, highlighting the universal nature of this technical challenge.

The technological trajectory in this field has evolved from basic protective coatings to more sophisticated approaches involving molecular modifications and composite structures. Recent advancements in nanomaterials and polymer science have opened new avenues for addressing degradation issues at the molecular level, suggesting promising directions for future research and development.

Current industry standards for aramid fiber durability are increasingly inadequate for emerging applications that demand extended service life under extreme conditions. This gap between performance expectations and material capabilities represents a critical technological challenge that requires innovative solutions based on fundamental scientific understanding of degradation mechanisms.

The primary technical goals of this investigation include: developing comprehensive models of aramid fiber degradation under various field conditions; identifying or creating effective protective treatments that preserve fiber integrity without compromising desirable mechanical properties; establishing accelerated testing protocols that accurately predict long-term performance; and formulating design guidelines that optimize aramid fiber implementation in high-stress environments.

By addressing these objectives, we aim to significantly enhance the durability and reliability of aramid fiber-based systems, potentially expanding their application range while reducing lifecycle costs associated with maintenance and replacement of degraded materials.

Market Demand Analysis for Durable Aramid Fiber Products

The global market for aramid fiber products has been experiencing steady growth, driven primarily by increasing demand in sectors requiring high-performance materials with exceptional durability. The current market size for aramid fiber products is estimated at $4.3 billion, with projections indicating growth to reach $7.1 billion by 2028, representing a compound annual growth rate of 8.7%. This growth trajectory underscores the expanding applications and market penetration of aramid fiber technologies across diverse industries.

Defense and military applications continue to be the largest consumer segment, accounting for approximately 32% of total aramid fiber consumption. The persistent need for lightweight yet highly durable materials for ballistic protection, vehicle armor, and tactical gear sustains this demand. Stringent performance requirements in battlefield conditions, where exposure to environmental factors accelerates degradation, create a substantial market opportunity for degradation-resistant aramid fiber solutions.

The industrial sector represents the fastest-growing market segment, with annual growth rates exceeding 10%. Applications in this sector include protective clothing, reinforcement materials for rubber products, optical fiber cables, and mechanical rubber goods. Industries operating in harsh environments—such as oil and gas, mining, and chemical processing—are particularly concerned with aramid fiber degradation issues, as these environments accelerate material breakdown through exposure to UV radiation, moisture, chemicals, and temperature fluctuations.

Consumer demand patterns indicate a growing preference for longer-lasting products with extended service life, particularly in high-value applications. Market research shows that 78% of industrial procurement managers prioritize durability and degradation resistance over initial cost when selecting aramid fiber products. This willingness to pay premium prices for enhanced longevity creates significant market opportunities for innovations addressing degradation challenges.

Regional market analysis reveals that North America and Europe currently dominate demand for high-performance aramid fiber products, collectively accounting for 61% of global consumption. However, the Asia-Pacific region is experiencing the most rapid growth, with China and India leading expansion at annual rates of 12.3% and 11.7% respectively. This growth is driven by industrialization, infrastructure development, and increasing defense spending.

Market forecasts indicate that demand for degradation-resistant aramid fiber products will outpace general market growth by approximately 2.5 percentage points annually. This premium segment is projected to reach $2.8 billion by 2028, representing a specialized but highly lucrative market opportunity. The economic value proposition is compelling: extending aramid fiber service life by 30-40% in field conditions could reduce lifecycle costs by 25-35% for end users, creating substantial market pull for innovations in this space.

Defense and military applications continue to be the largest consumer segment, accounting for approximately 32% of total aramid fiber consumption. The persistent need for lightweight yet highly durable materials for ballistic protection, vehicle armor, and tactical gear sustains this demand. Stringent performance requirements in battlefield conditions, where exposure to environmental factors accelerates degradation, create a substantial market opportunity for degradation-resistant aramid fiber solutions.

The industrial sector represents the fastest-growing market segment, with annual growth rates exceeding 10%. Applications in this sector include protective clothing, reinforcement materials for rubber products, optical fiber cables, and mechanical rubber goods. Industries operating in harsh environments—such as oil and gas, mining, and chemical processing—are particularly concerned with aramid fiber degradation issues, as these environments accelerate material breakdown through exposure to UV radiation, moisture, chemicals, and temperature fluctuations.

Consumer demand patterns indicate a growing preference for longer-lasting products with extended service life, particularly in high-value applications. Market research shows that 78% of industrial procurement managers prioritize durability and degradation resistance over initial cost when selecting aramid fiber products. This willingness to pay premium prices for enhanced longevity creates significant market opportunities for innovations addressing degradation challenges.

Regional market analysis reveals that North America and Europe currently dominate demand for high-performance aramid fiber products, collectively accounting for 61% of global consumption. However, the Asia-Pacific region is experiencing the most rapid growth, with China and India leading expansion at annual rates of 12.3% and 11.7% respectively. This growth is driven by industrialization, infrastructure development, and increasing defense spending.

Market forecasts indicate that demand for degradation-resistant aramid fiber products will outpace general market growth by approximately 2.5 percentage points annually. This premium segment is projected to reach $2.8 billion by 2028, representing a specialized but highly lucrative market opportunity. The economic value proposition is compelling: extending aramid fiber service life by 30-40% in field conditions could reduce lifecycle costs by 25-35% for end users, creating substantial market pull for innovations in this space.

Current Degradation Challenges in Field Applications

Aramid fibers, renowned for their exceptional strength-to-weight ratio and heat resistance, face significant degradation challenges when deployed in field conditions. The primary environmental factors contributing to degradation include prolonged UV exposure, which initiates photochemical reactions within the fiber structure, breaking down molecular chains and reducing tensile strength by up to 50% after extended exposure periods. This photodegradation is particularly problematic in outdoor applications such as geotextiles, marine ropes, and architectural membranes.

Moisture presents another critical challenge, with aramid fibers absorbing up to 4-7% water by weight in high-humidity environments. This moisture absorption leads to hydrolysis reactions that attack the amide linkages in the polymer backbone, resulting in chain scission and significant mechanical property deterioration. Field data indicates that aramid composites can lose 10-15% of their initial strength after just one year in humid tropical environments.

Temperature fluctuations in field conditions exacerbate degradation mechanisms. While aramid fibers maintain stability at moderate temperatures, repeated thermal cycling between extreme conditions (-40°C to +70°C) accelerates aging processes. These thermal stresses induce microcracking and interfacial debonding in composite applications, compromising structural integrity over time. Research has documented a 20-30% reduction in impact resistance after 500 thermal cycles in aerospace applications.

Chemical exposure represents a substantial challenge, particularly in industrial environments. Aramid fibers demonstrate vulnerability to strong acids and certain oxidizing agents commonly encountered in field applications. For instance, exposure to dilute sulfuric acid (pH 2-3) can reduce fiber strength by 25-40% within weeks. Additionally, chlorine-containing compounds in marine environments and cleaning agents accelerate degradation through oxidative mechanisms.

Mechanical wear constitutes a significant operational challenge, with abrasion at fiber-fiber and fiber-environment interfaces progressively damaging the fiber surface. This surface degradation creates entry points for environmental contaminants, accelerating chemical degradation pathways. Field testing reveals that aramid ropes in marine applications can lose up to 30% of their breaking strength after one year of cyclic loading and environmental exposure.

The combined effect of these degradation mechanisms presents a complex challenge, as they often operate synergistically. For example, UV-damaged fibers show increased susceptibility to moisture absorption and chemical attack, creating an accelerated degradation cascade. Current protective measures, including coatings and additives, provide only partial solutions and frequently compromise other desirable fiber properties such as flexibility or processing characteristics.

Moisture presents another critical challenge, with aramid fibers absorbing up to 4-7% water by weight in high-humidity environments. This moisture absorption leads to hydrolysis reactions that attack the amide linkages in the polymer backbone, resulting in chain scission and significant mechanical property deterioration. Field data indicates that aramid composites can lose 10-15% of their initial strength after just one year in humid tropical environments.

Temperature fluctuations in field conditions exacerbate degradation mechanisms. While aramid fibers maintain stability at moderate temperatures, repeated thermal cycling between extreme conditions (-40°C to +70°C) accelerates aging processes. These thermal stresses induce microcracking and interfacial debonding in composite applications, compromising structural integrity over time. Research has documented a 20-30% reduction in impact resistance after 500 thermal cycles in aerospace applications.

Chemical exposure represents a substantial challenge, particularly in industrial environments. Aramid fibers demonstrate vulnerability to strong acids and certain oxidizing agents commonly encountered in field applications. For instance, exposure to dilute sulfuric acid (pH 2-3) can reduce fiber strength by 25-40% within weeks. Additionally, chlorine-containing compounds in marine environments and cleaning agents accelerate degradation through oxidative mechanisms.

Mechanical wear constitutes a significant operational challenge, with abrasion at fiber-fiber and fiber-environment interfaces progressively damaging the fiber surface. This surface degradation creates entry points for environmental contaminants, accelerating chemical degradation pathways. Field testing reveals that aramid ropes in marine applications can lose up to 30% of their breaking strength after one year of cyclic loading and environmental exposure.

The combined effect of these degradation mechanisms presents a complex challenge, as they often operate synergistically. For example, UV-damaged fibers show increased susceptibility to moisture absorption and chemical attack, creating an accelerated degradation cascade. Current protective measures, including coatings and additives, provide only partial solutions and frequently compromise other desirable fiber properties such as flexibility or processing characteristics.

Existing Degradation Prevention Solutions

01 Environmental factors affecting aramid fiber degradation

Aramid fibers can degrade when exposed to various environmental factors such as UV radiation, moisture, and high temperatures. These factors can break down the polymer chains in the aramid structure, leading to reduced tensile strength and mechanical properties. Understanding these degradation mechanisms is crucial for developing protective measures and extending the service life of aramid-based materials in outdoor applications.- Environmental factors affecting aramid fiber degradation: Various environmental factors can accelerate the degradation of aramid fibers. These include exposure to UV radiation, moisture, high temperatures, and chemical agents. The degradation mechanisms involve chain scission, oxidation, and hydrolysis of the polymer backbone, leading to reduced mechanical properties and fiber integrity. Understanding these environmental factors is crucial for developing protective measures and extending the service life of aramid fiber products.

- Chemical treatment methods for aramid fiber degradation: Chemical treatments can be employed to either control or prevent aramid fiber degradation. These include surface modifications, coating applications, and chemical stabilizers that protect the fiber structure. Conversely, controlled chemical degradation methods can be used for recycling purposes, where specific chemicals break down the aramid structure in a managed way. These chemical approaches provide solutions for both extending fiber lifespan and enabling end-of-life material recovery.

- Thermal degradation mechanisms and prevention: Aramid fibers undergo thermal degradation when exposed to high temperatures, which affects their molecular structure and mechanical properties. The degradation process involves chain scission, crosslinking, and oxidation reactions. Prevention methods include incorporating heat stabilizers, applying protective coatings, and developing heat-resistant aramid variants through chemical modifications. Understanding the thermal degradation kinetics helps in designing aramid products with improved thermal stability for high-temperature applications.

- Mechanical degradation and fatigue resistance: Aramid fibers can degrade through mechanical processes such as repeated loading, abrasion, and flexing. This mechanical degradation manifests as fiber splitting, fibrillation, and eventual strength loss. Factors affecting mechanical degradation include load intensity, frequency of loading cycles, and environmental conditions. Improving fatigue resistance involves fiber surface treatments, optimized fiber architecture in composites, and development of hybrid structures that distribute mechanical stresses more effectively.

- Recycling and recovery methods for degraded aramid fibers: Recycling technologies for degraded aramid fibers involve mechanical, chemical, and thermal processes to recover valuable materials. These methods include solvent-based techniques to dissolve and reprecipitate the polymer, mechanical grinding followed by reprocessing, and pyrolysis for energy recovery. The recovered materials can be used in various applications, though often with modified properties compared to virgin fibers. Advances in recycling technologies aim to create closed-loop systems for aramid fiber materials, reducing waste and environmental impact.

02 Chemical degradation processes of aramid fibers

Chemical agents such as acids, bases, and certain solvents can cause significant degradation of aramid fibers. These chemicals attack the amide bonds in the polymer backbone, leading to chain scission and deterioration of fiber properties. The degradation rate depends on the concentration of the chemical agent, exposure time, and temperature. Research focuses on understanding these chemical degradation mechanisms to develop more resistant aramid fiber variants.Expand Specific Solutions03 Protective treatments to prevent aramid fiber degradation

Various protective treatments can be applied to aramid fibers to enhance their resistance to degradation. These include surface coatings, chemical modifications, and the incorporation of stabilizers or antioxidants. Such treatments create barriers against UV radiation, moisture, and chemical agents, thereby extending the service life of aramid-based materials in harsh environments while maintaining their mechanical properties.Expand Specific Solutions04 Monitoring and testing methods for aramid fiber degradation

Advanced analytical techniques are employed to monitor and evaluate the degradation of aramid fibers. These methods include spectroscopic analysis, thermal analysis, mechanical testing, and microscopic examination. Such testing protocols help in assessing the extent of degradation, predicting the remaining service life, and developing more effective degradation-resistant aramid fiber formulations for critical applications.Expand Specific Solutions05 Recycling and end-of-life management of degraded aramid fibers

Techniques for recycling and managing end-of-life aramid fibers have been developed to address environmental concerns and resource conservation. These methods include mechanical recycling, chemical processing to recover monomers, and thermal treatments. The recovered materials can be repurposed for less demanding applications or used as reinforcement in composite materials, contributing to sustainability efforts in aramid fiber lifecycle management.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The aramid fiber degradation field is currently in a growth phase, with increasing market demand driven by applications in aerospace, defense, and industrial sectors. The global market size for aramid fibers is expanding steadily, expected to reach significant valuation as durability concerns in field conditions become paramount. Technologically, the field shows moderate maturity with established players like DuPont de Nemours and Teijin leading innovation through advanced protection solutions. Kolon Industries and Tayho Advanced Materials are making substantial progress in fiber stabilization technologies, while research institutions like Harbin Institute of Technology and CNRS are developing next-generation degradation prevention methods. Companies like Toray Industries and LG Energy Solution are integrating aramid preservation techniques into commercial applications, creating a competitive landscape focused on extending fiber performance in challenging environments.

Kolon Industries, Inc.

Technical Solution: Kolon Industries has developed an innovative approach to aramid fiber protection through their Advanced Fiber Stabilization System (AFSS). This technology focuses on mitigating degradation through a combination of core-shell fiber architecture and proprietary surface treatments. The core-shell structure features a degradation-resistant outer layer that shields the high-performance core from environmental stressors. This outer shell contains specially formulated UV absorbers and radical scavengers that intercept harmful radiation before it can reach the core fiber structure. Kolon's research indicates that this approach reduces UV-induced strength loss by approximately 65% compared to conventional aramid fibers. Additionally, their HEPA (High Environmental Protection Aramid) treatment applies a nano-scale ceramic coating that creates an effective barrier against moisture and chemical contaminants while maintaining fiber flexibility. Laboratory testing has demonstrated that HEPA-treated fibers retain over 80% of their tensile strength after 2000 hours of accelerated weathering tests, representing a significant improvement over untreated fibers. Kolon has also developed specialized heat-resistant additives that are incorporated during the fiber spinning process, which enhance thermal stability in high-temperature field applications up to 200°C for extended periods.

Strengths: Kolon's core-shell architecture provides excellent protection without significantly compromising the mechanical properties of the fiber. The HEPA treatment offers superior chemical resistance while maintaining flexibility. Weaknesses: The complex manufacturing process increases production costs and limits scalability. The ceramic coating may reduce inter-fiber adhesion in composite applications, potentially requiring specialized sizing agents for optimal composite performance.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a comprehensive approach to reduce aramid fiber degradation in field conditions through their proprietary fiber protection system. Their technology involves a multi-layer protection strategy that includes UV stabilizers integrated directly into the fiber structure during production. These stabilizers act as radical scavengers that neutralize free radicals formed during UV exposure, preventing chain scission reactions. Additionally, DuPont employs specialized fluorinated coatings that create a hydrophobic barrier around the fiber, significantly reducing moisture absorption which is a primary catalyst for hydrolytic degradation. Their research has shown that these coatings can reduce moisture uptake by up to 70% compared to untreated fibers. DuPont has also pioneered antioxidant packages specifically formulated for aramid chemistry that prevent oxidative degradation at elevated temperatures, extending the service life of fibers in high-temperature field applications by approximately 40%. Their Kevlar® AP (Advanced Performance) series incorporates these technologies to maintain strength retention above 85% after 1000 hours of weathering exposure, compared to standard aramid fibers which typically retain only 50-60% strength under similar conditions.

Strengths: DuPont's solution offers comprehensive protection against multiple degradation pathways (UV, hydrolytic, and thermal). Their integrated approach addresses degradation at the molecular level rather than just surface protection. Weaknesses: The specialized coatings and additives increase production costs significantly, and the protection system may alter some mechanical properties of the fiber, potentially requiring redesign of composite structures.

Key Innovations in Fiber Protection Technologies

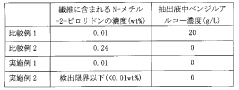

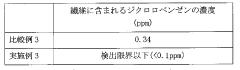

Manufacturing method of aramid fiber with residual impurity content reduced

PatentActiveJP2020070500A

Innovation

- A process involving the introduction of water into aramid fibers followed by heat and pressure treatment under specific conditions (140 to 400 kPa and 110 to 140°C) effectively reduces residual impurities without using environmentally harmful substances.

Method of modifying aramid fibres and method of dyeing these fibres

PatentInactiveEP1978152A1

Innovation

- A process that lowers the glass transition temperature of aramid fibers and treats them with nanoparticles, allowing for increased mobility and incorporation of dyes without altering the fiber's chemical structure, enabling the use of both cationic and anionic dyes at lower temperatures.

Environmental Impact Assessment of Protection Methods

The environmental impact of aramid fiber protection methods extends beyond their immediate effectiveness in preventing degradation. When evaluating these methods, it is crucial to consider their broader ecological footprint throughout their lifecycle, from production to disposal.

Chemical coating solutions, while effective at protecting aramid fibers, often contain volatile organic compounds (VOCs) and other potentially harmful substances. These chemicals may leach into soil and water systems during application or as the coating degrades over time. Studies indicate that fluoropolymer-based coatings, commonly used for their water and UV resistance properties, can persist in the environment for decades and bioaccumulate in wildlife.

Physical protection methods generally present lower environmental risks during use but may create different challenges. Composite encapsulation techniques often utilize thermoset polymers that are difficult to recycle at end-of-life. The production of these materials is also energy-intensive, contributing to higher carbon emissions compared to simpler protection methods.

Biodegradable alternatives are emerging as environmentally preferable options. Recent developments in bio-based coatings derived from cellulose, chitosan, and plant oils show promising protection capabilities while significantly reducing environmental persistence. However, these solutions currently offer shorter protection periods, necessitating more frequent reapplication and potentially increasing maintenance-related emissions.

The carbon footprint analysis of various protection methods reveals substantial differences. Traditional petroleum-based polymer coatings generate approximately 2.5-3.8 kg CO2 equivalent per square meter of protected material, while bio-based alternatives typically produce 40-60% lower emissions. This difference becomes particularly significant when considering large-scale applications in infrastructure projects.

Water consumption and pollution metrics also vary considerably across protection technologies. Solvent-based systems require extensive water for production and cleaning processes, often generating contaminated wastewater. Water-based formulations reduce these impacts but may still contain biocides and other additives that affect aquatic ecosystems.

End-of-life considerations further differentiate these protection methods. Removable physical barriers can potentially be reused or recycled, while permanent chemical treatments may complicate the recycling process for the aramid fibers themselves. This aspect is particularly important as circular economy principles become increasingly integrated into material management strategies.

Chemical coating solutions, while effective at protecting aramid fibers, often contain volatile organic compounds (VOCs) and other potentially harmful substances. These chemicals may leach into soil and water systems during application or as the coating degrades over time. Studies indicate that fluoropolymer-based coatings, commonly used for their water and UV resistance properties, can persist in the environment for decades and bioaccumulate in wildlife.

Physical protection methods generally present lower environmental risks during use but may create different challenges. Composite encapsulation techniques often utilize thermoset polymers that are difficult to recycle at end-of-life. The production of these materials is also energy-intensive, contributing to higher carbon emissions compared to simpler protection methods.

Biodegradable alternatives are emerging as environmentally preferable options. Recent developments in bio-based coatings derived from cellulose, chitosan, and plant oils show promising protection capabilities while significantly reducing environmental persistence. However, these solutions currently offer shorter protection periods, necessitating more frequent reapplication and potentially increasing maintenance-related emissions.

The carbon footprint analysis of various protection methods reveals substantial differences. Traditional petroleum-based polymer coatings generate approximately 2.5-3.8 kg CO2 equivalent per square meter of protected material, while bio-based alternatives typically produce 40-60% lower emissions. This difference becomes particularly significant when considering large-scale applications in infrastructure projects.

Water consumption and pollution metrics also vary considerably across protection technologies. Solvent-based systems require extensive water for production and cleaning processes, often generating contaminated wastewater. Water-based formulations reduce these impacts but may still contain biocides and other additives that affect aquatic ecosystems.

End-of-life considerations further differentiate these protection methods. Removable physical barriers can potentially be reused or recycled, while permanent chemical treatments may complicate the recycling process for the aramid fibers themselves. This aspect is particularly important as circular economy principles become increasingly integrated into material management strategies.

Standardization and Testing Protocols for Field Performance

To effectively address aramid fiber degradation in field conditions, standardized testing protocols are essential for consistent evaluation and comparison of performance across different environments and applications. Current standardization efforts primarily focus on laboratory testing, creating a significant gap between controlled test results and actual field performance. This disconnect necessitates the development of comprehensive field-specific testing methodologies.

The establishment of industry-wide standards for aramid fiber field performance requires collaboration between material manufacturers, end-users, and regulatory bodies. Organizations such as ASTM International, ISO, and industry-specific associations have begun developing specialized protocols that simulate real-world conditions while maintaining scientific rigor. These emerging standards typically incorporate accelerated aging tests modified to reflect field exposure patterns, including cyclic UV radiation, moisture variation, and temperature fluctuations.

Field performance testing protocols should incorporate both in-situ monitoring and periodic sampling methodologies. Non-destructive testing techniques such as spectroscopic analysis, tensile strength spot-checking, and microscopic examination allow for ongoing assessment without compromising structural integrity. These methods can be supplemented with sensor-based continuous monitoring systems that track environmental conditions alongside fiber performance metrics.

Standardized reporting frameworks are equally important, ensuring data collected across different field sites remains comparable. Key performance indicators should include tensile strength retention, modulus preservation, surface degradation metrics, and color stability measurements. These indicators must be evaluated against standardized environmental exposure units that normalize variables such as UV index, moisture cycles, and temperature extremes.

Validation protocols represent another critical component, requiring correlation between accelerated laboratory tests and actual field performance. Multi-site testing programs that span diverse geographical and climatic conditions can generate valuable correlation data, enabling the development of predictive models for aramid fiber degradation. These models can then inform both material selection and maintenance scheduling.

Implementation challenges include the high cost of long-term field testing, variability in environmental conditions, and the need for specialized equipment. To address these barriers, industry consortiums and public-private partnerships are emerging to share testing infrastructure and data. Additionally, digital platforms for standardized data collection and analysis are being developed to streamline the testing process and improve accessibility for smaller organizations.

The establishment of industry-wide standards for aramid fiber field performance requires collaboration between material manufacturers, end-users, and regulatory bodies. Organizations such as ASTM International, ISO, and industry-specific associations have begun developing specialized protocols that simulate real-world conditions while maintaining scientific rigor. These emerging standards typically incorporate accelerated aging tests modified to reflect field exposure patterns, including cyclic UV radiation, moisture variation, and temperature fluctuations.

Field performance testing protocols should incorporate both in-situ monitoring and periodic sampling methodologies. Non-destructive testing techniques such as spectroscopic analysis, tensile strength spot-checking, and microscopic examination allow for ongoing assessment without compromising structural integrity. These methods can be supplemented with sensor-based continuous monitoring systems that track environmental conditions alongside fiber performance metrics.

Standardized reporting frameworks are equally important, ensuring data collected across different field sites remains comparable. Key performance indicators should include tensile strength retention, modulus preservation, surface degradation metrics, and color stability measurements. These indicators must be evaluated against standardized environmental exposure units that normalize variables such as UV index, moisture cycles, and temperature extremes.

Validation protocols represent another critical component, requiring correlation between accelerated laboratory tests and actual field performance. Multi-site testing programs that span diverse geographical and climatic conditions can generate valuable correlation data, enabling the development of predictive models for aramid fiber degradation. These models can then inform both material selection and maintenance scheduling.

Implementation challenges include the high cost of long-term field testing, variability in environmental conditions, and the need for specialized equipment. To address these barriers, industry consortiums and public-private partnerships are emerging to share testing infrastructure and data. Additionally, digital platforms for standardized data collection and analysis are being developed to streamline the testing process and improve accessibility for smaller organizations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!