Benefits of V12 Engines in Extreme Climates

AUG 5, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Evolution

The V12 engine has undergone significant evolution since its inception in the early 20th century. Initially developed for luxury automobiles and aircraft, V12 engines have consistently pushed the boundaries of power, smoothness, and prestige. The timeline of V12 engine development showcases key milestones that have shaped its performance in extreme climates.

In the 1910s and 1920s, V12 engines emerged as a symbol of automotive excellence, with manufacturers like Packard and Daimler leading the way. These early V12s laid the foundation for future advancements, particularly in terms of power output and refinement. The 1930s saw further improvements, with companies like Cadillac and Lincoln introducing V12 engines that offered unprecedented levels of smoothness and torque.

The post-World War II era marked a significant shift in V12 engine development. Ferrari, in particular, became synonymous with V12 excellence, introducing a series of high-performance engines that excelled in both road cars and racing applications. This period also saw advancements in materials and manufacturing techniques, allowing for increased reliability and performance in varying climatic conditions.

The 1960s and 1970s brought about a focus on efficiency and emissions control, challenging V12 manufacturers to maintain performance while meeting new regulatory standards. This era saw the introduction of fuel injection systems and more sophisticated engine management, which proved crucial for optimizing V12 performance in extreme temperatures.

The 1980s and 1990s witnessed a renaissance in V12 engine technology, with brands like BMW and Mercedes-Benz introducing advanced V12 powerplants that combined high output with improved fuel efficiency. These engines incorporated cutting-edge technologies such as variable valve timing and multi-point fuel injection, enhancing their adaptability to diverse climatic conditions.

The turn of the millennium ushered in a new era of V12 engine development, characterized by the integration of advanced electronics and materials. Manufacturers like Aston Martin and Lamborghini pushed the boundaries of V12 performance, developing engines capable of producing over 700 horsepower while maintaining reliability in extreme environments.

Recent years have seen a focus on hybridization and electrification, even in the realm of V12 engines. This trend has led to the development of hybrid V12 powertrains that offer improved efficiency and performance across a wide range of operating conditions, including extreme climates. These advancements have allowed V12 engines to remain relevant in an increasingly environmentally conscious automotive landscape.

Throughout its evolution, the V12 engine has consistently demonstrated its ability to deliver exceptional performance, smoothness, and prestige. Its development trajectory has been marked by continuous improvements in power output, efficiency, and adaptability to various environmental conditions, making it a preferred choice for high-performance vehicles operating in extreme climates.

In the 1910s and 1920s, V12 engines emerged as a symbol of automotive excellence, with manufacturers like Packard and Daimler leading the way. These early V12s laid the foundation for future advancements, particularly in terms of power output and refinement. The 1930s saw further improvements, with companies like Cadillac and Lincoln introducing V12 engines that offered unprecedented levels of smoothness and torque.

The post-World War II era marked a significant shift in V12 engine development. Ferrari, in particular, became synonymous with V12 excellence, introducing a series of high-performance engines that excelled in both road cars and racing applications. This period also saw advancements in materials and manufacturing techniques, allowing for increased reliability and performance in varying climatic conditions.

The 1960s and 1970s brought about a focus on efficiency and emissions control, challenging V12 manufacturers to maintain performance while meeting new regulatory standards. This era saw the introduction of fuel injection systems and more sophisticated engine management, which proved crucial for optimizing V12 performance in extreme temperatures.

The 1980s and 1990s witnessed a renaissance in V12 engine technology, with brands like BMW and Mercedes-Benz introducing advanced V12 powerplants that combined high output with improved fuel efficiency. These engines incorporated cutting-edge technologies such as variable valve timing and multi-point fuel injection, enhancing their adaptability to diverse climatic conditions.

The turn of the millennium ushered in a new era of V12 engine development, characterized by the integration of advanced electronics and materials. Manufacturers like Aston Martin and Lamborghini pushed the boundaries of V12 performance, developing engines capable of producing over 700 horsepower while maintaining reliability in extreme environments.

Recent years have seen a focus on hybridization and electrification, even in the realm of V12 engines. This trend has led to the development of hybrid V12 powertrains that offer improved efficiency and performance across a wide range of operating conditions, including extreme climates. These advancements have allowed V12 engines to remain relevant in an increasingly environmentally conscious automotive landscape.

Throughout its evolution, the V12 engine has consistently demonstrated its ability to deliver exceptional performance, smoothness, and prestige. Its development trajectory has been marked by continuous improvements in power output, efficiency, and adaptability to various environmental conditions, making it a preferred choice for high-performance vehicles operating in extreme climates.

Extreme Climate Demand

The demand for V12 engines in extreme climates stems from their unique performance characteristics and reliability under challenging environmental conditions. In regions experiencing extreme cold or heat, vehicle engines face significant stress and operational challenges. V12 engines, with their larger displacement and increased number of cylinders, offer several advantages that make them particularly suitable for these harsh environments.

In extremely cold climates, such as those found in Arctic or Antarctic regions, V12 engines provide superior cold-start capabilities. The increased number of cylinders allows for more consistent combustion, even when temperatures drop well below freezing. This results in improved reliability and reduced wear on engine components during startup, a critical factor in areas where vehicles may be subjected to prolonged periods of inactivity in sub-zero temperatures.

Furthermore, the additional power output of V12 engines is beneficial in cold climates where vehicles often need to navigate through snow and ice. The increased torque available at lower RPMs allows for better traction and control in slippery conditions, enhancing overall vehicle safety and performance.

In extremely hot climates, such as desert environments, V12 engines demonstrate excellent heat dissipation properties. The larger engine block and increased surface area allow for more efficient cooling, reducing the risk of overheating in high-temperature conditions. This is particularly important for vehicles operating in remote areas where breakdowns due to overheating can be dangerous and costly.

The demand for V12 engines in extreme climates also extends to specialized industries operating in these environments. Mining operations in remote, harsh locations often rely on heavy-duty vehicles equipped with V12 engines for their durability and power output. Similarly, military applications in extreme climates benefit from the reliability and performance of V12 engines in mission-critical situations.

Luxury and high-performance vehicle markets in regions with extreme climates also contribute to the demand for V12 engines. These engines offer smooth operation and impressive power delivery, which are highly valued in premium vehicles designed to operate across a wide range of environmental conditions.

While the overall market for V12 engines is relatively niche, their specific advantages in extreme climates ensure a consistent demand from specialized sectors and discerning consumers who prioritize performance and reliability in challenging environments.

In extremely cold climates, such as those found in Arctic or Antarctic regions, V12 engines provide superior cold-start capabilities. The increased number of cylinders allows for more consistent combustion, even when temperatures drop well below freezing. This results in improved reliability and reduced wear on engine components during startup, a critical factor in areas where vehicles may be subjected to prolonged periods of inactivity in sub-zero temperatures.

Furthermore, the additional power output of V12 engines is beneficial in cold climates where vehicles often need to navigate through snow and ice. The increased torque available at lower RPMs allows for better traction and control in slippery conditions, enhancing overall vehicle safety and performance.

In extremely hot climates, such as desert environments, V12 engines demonstrate excellent heat dissipation properties. The larger engine block and increased surface area allow for more efficient cooling, reducing the risk of overheating in high-temperature conditions. This is particularly important for vehicles operating in remote areas where breakdowns due to overheating can be dangerous and costly.

The demand for V12 engines in extreme climates also extends to specialized industries operating in these environments. Mining operations in remote, harsh locations often rely on heavy-duty vehicles equipped with V12 engines for their durability and power output. Similarly, military applications in extreme climates benefit from the reliability and performance of V12 engines in mission-critical situations.

Luxury and high-performance vehicle markets in regions with extreme climates also contribute to the demand for V12 engines. These engines offer smooth operation and impressive power delivery, which are highly valued in premium vehicles designed to operate across a wide range of environmental conditions.

While the overall market for V12 engines is relatively niche, their specific advantages in extreme climates ensure a consistent demand from specialized sectors and discerning consumers who prioritize performance and reliability in challenging environments.

V12 Performance Limits

V12 engines, renowned for their power and smoothness, face unique challenges and opportunities in extreme climates. These environments, characterized by extreme temperatures, altitudes, and weather conditions, push the performance limits of V12 engines to their boundaries.

In cold climates, V12 engines demonstrate superior cold-start capabilities compared to smaller engines. The increased cylinder count allows for more even distribution of heat during startup, reducing wear on individual components. However, extreme cold can lead to increased oil viscosity, potentially causing lubrication issues in the complex V12 configuration.

At high altitudes, V12 engines maintain better performance due to their larger displacement and higher cylinder count. This allows them to compensate for the reduced air density more effectively than smaller engines. Nevertheless, the increased complexity of V12 engines may require more sophisticated altitude compensation systems to maintain optimal fuel-air mixtures.

In hot climates, V12 engines face challenges related to heat dissipation. The increased number of cylinders generates more heat, requiring advanced cooling systems to maintain optimal operating temperatures. However, the larger engine bay typically associated with V12 engines can accommodate more extensive cooling solutions, potentially mitigating this issue.

Extreme weather conditions, such as heavy rain or sandstorms, can test the sealing and filtration systems of V12 engines. The increased number of moving parts and larger intake systems may require more robust protection against environmental contaminants.

The performance limits of V12 engines in extreme climates are also influenced by fuel quality and availability. In remote or harsh environments, the ability to operate on lower-grade fuels without sacrificing performance becomes crucial. V12 engines, with their more complex fuel delivery systems, may require additional engineering to maintain flexibility in fuel requirements.

Durability and reliability in extreme conditions are critical factors. The increased number of components in V12 engines may lead to higher maintenance requirements and potential failure points. However, the robust construction typically associated with V12 engines can contribute to overall longevity when properly maintained.

In conclusion, while V12 engines offer significant advantages in extreme climates, particularly in terms of power delivery and cold-weather performance, they also face unique challenges. The key to maximizing their potential lies in specialized engineering solutions that address the specific demands of extreme environments while leveraging the inherent strengths of the V12 configuration.

In cold climates, V12 engines demonstrate superior cold-start capabilities compared to smaller engines. The increased cylinder count allows for more even distribution of heat during startup, reducing wear on individual components. However, extreme cold can lead to increased oil viscosity, potentially causing lubrication issues in the complex V12 configuration.

At high altitudes, V12 engines maintain better performance due to their larger displacement and higher cylinder count. This allows them to compensate for the reduced air density more effectively than smaller engines. Nevertheless, the increased complexity of V12 engines may require more sophisticated altitude compensation systems to maintain optimal fuel-air mixtures.

In hot climates, V12 engines face challenges related to heat dissipation. The increased number of cylinders generates more heat, requiring advanced cooling systems to maintain optimal operating temperatures. However, the larger engine bay typically associated with V12 engines can accommodate more extensive cooling solutions, potentially mitigating this issue.

Extreme weather conditions, such as heavy rain or sandstorms, can test the sealing and filtration systems of V12 engines. The increased number of moving parts and larger intake systems may require more robust protection against environmental contaminants.

The performance limits of V12 engines in extreme climates are also influenced by fuel quality and availability. In remote or harsh environments, the ability to operate on lower-grade fuels without sacrificing performance becomes crucial. V12 engines, with their more complex fuel delivery systems, may require additional engineering to maintain flexibility in fuel requirements.

Durability and reliability in extreme conditions are critical factors. The increased number of components in V12 engines may lead to higher maintenance requirements and potential failure points. However, the robust construction typically associated with V12 engines can contribute to overall longevity when properly maintained.

In conclusion, while V12 engines offer significant advantages in extreme climates, particularly in terms of power delivery and cold-weather performance, they also face unique challenges. The key to maximizing their potential lies in specialized engineering solutions that address the specific demands of extreme environments while leveraging the inherent strengths of the V12 configuration.

Climate Adaptation Tech

01 V12 Engine Design and Configuration

V12 engines are characterized by their unique configuration of twelve cylinders arranged in two banks of six, forming a V shape. This design offers a balance of power, smoothness, and compact packaging. The V12 layout allows for high power output while maintaining relatively compact dimensions, making it suitable for high-performance and luxury vehicles.- V12 Engine Design and Configuration: V12 engines are characterized by their unique configuration of twelve cylinders arranged in two banks of six, forming a V shape. This design offers a balance of power, smoothness, and compact packaging. The V12 layout allows for high power output while maintaining relatively compact dimensions, making it suitable for high-performance and luxury vehicles.

- Performance Optimization in V12 Engines: Various techniques are employed to optimize the performance of V12 engines. These may include advanced fuel injection systems, variable valve timing, turbocharging or supercharging, and precision engine management systems. Such optimizations aim to enhance power output, improve fuel efficiency, and reduce emissions while maintaining the characteristic smoothness of V12 engines.

- Control Systems for V12 Engines: Modern V12 engines incorporate sophisticated control systems to manage various aspects of engine operation. These systems may include electronic control units (ECUs) for engine management, advanced diagnostics, and integration with vehicle systems. Such control systems optimize performance, fuel efficiency, and emissions across different operating conditions.

- Manufacturing and Assembly Processes for V12 Engines: The production of V12 engines involves specialized manufacturing and assembly processes. These may include precision machining of engine components, advanced casting techniques for engine blocks, and sophisticated assembly lines. Quality control measures are crucial to ensure the reliability and performance of these complex engines.

- Historical Development of V12 Engines: The V12 engine configuration has a rich history in automotive and aviation applications. Early designs date back to the early 20th century, with significant developments occurring through World War II and into the modern era. The evolution of V12 engines reflects advancements in materials, manufacturing techniques, and engineering principles over time.

02 Engine Management Systems for V12 Engines

Advanced engine management systems are crucial for optimizing the performance and efficiency of V12 engines. These systems control various aspects such as fuel injection, ignition timing, and valve timing to ensure optimal power output, fuel economy, and emissions control. Modern V12 engines often incorporate sophisticated electronic control units to manage these complex systems.Expand Specific Solutions03 Fuel Efficiency Improvements in V12 Engines

Despite their high power output, modern V12 engines incorporate various technologies to improve fuel efficiency. These may include direct fuel injection, variable valve timing, cylinder deactivation, and advanced materials to reduce weight. Such innovations help to balance the power demands of V12 engines with increasing environmental and efficiency standards.Expand Specific Solutions04 Historical Development of V12 Engines

The development of V12 engines has a rich history dating back to the early 20th century. Early designs were often used in luxury automobiles and aircraft. Over time, V12 engines have evolved significantly, incorporating technological advancements in materials, manufacturing processes, and engine management systems to improve performance, reliability, and efficiency.Expand Specific Solutions05 Applications of V12 Engines

V12 engines find applications in various high-performance and luxury vehicles, including sports cars, luxury sedans, and some racing cars. They are prized for their smooth power delivery and prestigious status. In addition to automotive use, V12 engines have been employed in marine applications and certain types of stationary power generation systems where high power output and smooth operation are required.Expand Specific Solutions

Key V12 Manufacturers

The competition landscape for V12 engines in extreme climates is characterized by a mature market with established players. Major automotive manufacturers like GM, Honda, Audi, and Ford are at the forefront, leveraging their extensive R&D capabilities to enhance V12 performance in challenging environments. The market size is relatively niche, catering to high-end vehicles and specialized applications. Technologically, V12 engines for extreme climates are highly advanced, with companies like BorgWarner and Caterpillar contributing innovative solutions in thermal management and durability. The focus is on optimizing power output, fuel efficiency, and reliability under extreme temperature conditions, driving continuous improvement in this specialized sector.

GM Global Technology Operations LLC

Technical Solution: GM's V12 engine technology for extreme climates focuses on adaptive engine management and innovative materials. They employ a dynamic fuel injection system that adjusts fuel mixture based on ambient temperature and air density[5]. GM's V12 engines use advanced ceramic coatings on critical components to improve heat resistance and reduce thermal expansion in extreme temperatures. The engine block is designed with variable coolant flow paths that can be adjusted based on climate conditions. Additionally, GM has developed a smart alternator system that optimizes charging based on temperature and electrical load, improving overall efficiency in extreme climates[6].

Strengths: Adaptive engine management, improved efficiency in varying climates. Weaknesses: Higher initial cost, potential reliability issues with complex systems.

Honda Motor Co., Ltd.

Technical Solution: Honda's approach to V12 engines in extreme climates emphasizes reliability and efficiency. Their V12 design incorporates a variable displacement system that can deactivate cylinders in less demanding conditions, improving fuel efficiency while maintaining power when needed[7]. Honda uses advanced thermal barrier coatings on pistons and cylinder walls to reduce heat transfer and improve combustion efficiency across all temperature ranges. They have also developed a climate-adaptive lubrication system that adjusts oil viscosity based on temperature and engine load. In cold climates, Honda's V12 engines feature an innovative exhaust heat recovery system to quickly warm up the engine and improve overall efficiency[8].

Strengths: Excellent fuel efficiency, reliable performance in various climates. Weaknesses: Less focus on high-performance applications, potentially lower maximum power output compared to some competitors.

V12 Thermal Management

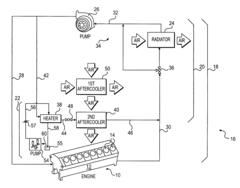

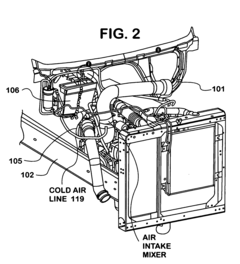

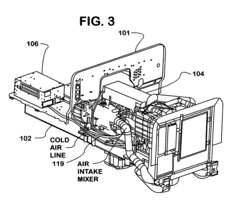

Engine system having dedicated thermal management system

PatentInactiveUS7886705B2

Innovation

- A thermal management system with two hydraulic circuits, one for cooling and another for heating, using engine-driven pumps and heat exchangers to regulate engine temperatures, allowing for both cooling and heating of intake air, thereby optimizing engine performance across varying conditions without relying on external power.

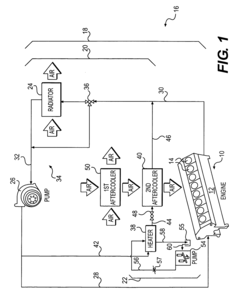

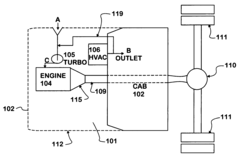

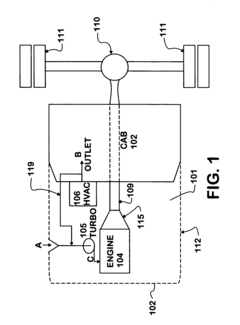

Vehicle intercool system

PatentInactiveUS7017531B2

Innovation

- A diversion line from the HVAC system is connected to the turbocharger inlet, allowing cooled air to be introduced in hot weather and warmed air in cold weather, thereby controlling engine intake air temperature and improving turbocharger efficiency.

Environmental Impact

The environmental impact of V12 engines in extreme climates is a complex issue that requires careful consideration. These powerful engines, while offering significant benefits in harsh conditions, also pose challenges to environmental sustainability. In extreme cold climates, V12 engines demonstrate superior performance due to their ability to maintain optimal operating temperatures more efficiently than smaller engines. This results in reduced warm-up times and lower fuel consumption during the initial stages of operation, potentially reducing overall emissions in these conditions.

However, the increased displacement and fuel consumption of V12 engines generally lead to higher carbon dioxide emissions compared to smaller engine configurations. This is particularly significant in urban environments within extreme climate regions, where frequent short trips and idling can exacerbate emission levels. The production of V12 engines also requires more raw materials and energy, contributing to a larger carbon footprint in the manufacturing process.

In extreme hot climates, V12 engines face different environmental challenges. Their larger size and higher heat output necessitate more robust cooling systems, which can lead to increased use of coolants and potential environmental risks associated with coolant disposal. Additionally, the higher fuel consumption in hot conditions can result in increased emissions of pollutants such as nitrogen oxides and particulate matter.

On the other hand, the durability and longevity of V12 engines in extreme climates can have positive environmental implications. Their robust design often results in longer service life, reducing the frequency of engine replacements and the associated environmental costs of manufacturing and disposal. Furthermore, the advanced engineering in modern V12 engines has led to improvements in fuel efficiency and emissions control technologies, mitigating some of their environmental impact.

The environmental impact of V12 engines in extreme climates also extends to noise pollution. While their smooth operation can reduce vibration-related noise, the sheer power output can contribute to higher noise levels, particularly in quiet arctic or desert environments. This can have detrimental effects on local wildlife and ecosystem balance.

In conclusion, while V12 engines offer significant performance benefits in extreme climates, their environmental impact is multifaceted. Balancing these powerful engines' advantages against their environmental footprint requires ongoing technological innovation and careful consideration of their application in specific extreme climate scenarios.

However, the increased displacement and fuel consumption of V12 engines generally lead to higher carbon dioxide emissions compared to smaller engine configurations. This is particularly significant in urban environments within extreme climate regions, where frequent short trips and idling can exacerbate emission levels. The production of V12 engines also requires more raw materials and energy, contributing to a larger carbon footprint in the manufacturing process.

In extreme hot climates, V12 engines face different environmental challenges. Their larger size and higher heat output necessitate more robust cooling systems, which can lead to increased use of coolants and potential environmental risks associated with coolant disposal. Additionally, the higher fuel consumption in hot conditions can result in increased emissions of pollutants such as nitrogen oxides and particulate matter.

On the other hand, the durability and longevity of V12 engines in extreme climates can have positive environmental implications. Their robust design often results in longer service life, reducing the frequency of engine replacements and the associated environmental costs of manufacturing and disposal. Furthermore, the advanced engineering in modern V12 engines has led to improvements in fuel efficiency and emissions control technologies, mitigating some of their environmental impact.

The environmental impact of V12 engines in extreme climates also extends to noise pollution. While their smooth operation can reduce vibration-related noise, the sheer power output can contribute to higher noise levels, particularly in quiet arctic or desert environments. This can have detrimental effects on local wildlife and ecosystem balance.

In conclusion, while V12 engines offer significant performance benefits in extreme climates, their environmental impact is multifaceted. Balancing these powerful engines' advantages against their environmental footprint requires ongoing technological innovation and careful consideration of their application in specific extreme climate scenarios.

Regulatory Challenges

The regulatory landscape surrounding V12 engines in extreme climates presents a complex set of challenges for manufacturers and operators. Environmental regulations, particularly those focused on emissions reduction, pose significant hurdles for V12 engines known for their high fuel consumption and carbon output. In regions with extreme climates, these regulations may be even more stringent due to the increased environmental sensitivity of these areas.

Noise pollution regulations also play a crucial role in the deployment of V12 engines. The powerful nature of these engines often results in higher noise levels, which can be problematic in both urban and remote environments. Extreme climates may exacerbate this issue, as sound can travel differently in very cold or hot conditions, potentially leading to stricter noise control measures.

Safety regulations present another layer of complexity. V12 engines operating in extreme climates must meet rigorous safety standards to ensure reliable performance under harsh conditions. This includes regulations related to cold-starting capabilities, heat management, and overall durability in the face of temperature extremes.

Fuel quality regulations can also impact the use of V12 engines in extreme climates. Different regions may have varying fuel standards, and engines must be adaptable to these differences while maintaining performance and compliance with emissions regulations. This challenge is particularly acute in remote areas where fuel quality may be inconsistent.

Import and export regulations can affect the global distribution of V12 engines designed for extreme climates. Tariffs, trade agreements, and local content requirements may influence the manufacturing and deployment strategies for these specialized engines.

Lastly, end-of-life and recycling regulations are becoming increasingly important. As environmental concerns grow, manufacturers must consider the entire lifecycle of their engines, including disposal and recycling processes. This is particularly challenging for engines designed to withstand extreme conditions, as they may contain specialized materials or components that require specific handling.

Navigating these regulatory challenges requires a comprehensive approach that balances performance requirements with compliance across various jurisdictions. Manufacturers must invest in research and development to create innovative solutions that meet both the demands of extreme climates and the evolving regulatory landscape.

Noise pollution regulations also play a crucial role in the deployment of V12 engines. The powerful nature of these engines often results in higher noise levels, which can be problematic in both urban and remote environments. Extreme climates may exacerbate this issue, as sound can travel differently in very cold or hot conditions, potentially leading to stricter noise control measures.

Safety regulations present another layer of complexity. V12 engines operating in extreme climates must meet rigorous safety standards to ensure reliable performance under harsh conditions. This includes regulations related to cold-starting capabilities, heat management, and overall durability in the face of temperature extremes.

Fuel quality regulations can also impact the use of V12 engines in extreme climates. Different regions may have varying fuel standards, and engines must be adaptable to these differences while maintaining performance and compliance with emissions regulations. This challenge is particularly acute in remote areas where fuel quality may be inconsistent.

Import and export regulations can affect the global distribution of V12 engines designed for extreme climates. Tariffs, trade agreements, and local content requirements may influence the manufacturing and deployment strategies for these specialized engines.

Lastly, end-of-life and recycling regulations are becoming increasingly important. As environmental concerns grow, manufacturers must consider the entire lifecycle of their engines, including disposal and recycling processes. This is particularly challenging for engines designed to withstand extreme conditions, as they may contain specialized materials or components that require specific handling.

Navigating these regulatory challenges requires a comprehensive approach that balances performance requirements with compliance across various jurisdictions. Manufacturers must invest in research and development to create innovative solutions that meet both the demands of extreme climates and the evolving regulatory landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!