Bioconversion Techniques for Producing Dimethyl Ether

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Bioconversion Background and Objectives

Dimethyl ether (DME) has emerged as a promising alternative fuel due to its clean-burning properties and potential to reduce greenhouse gas emissions. The bioconversion of DME represents a significant advancement in sustainable energy production, aligning with global efforts to transition towards renewable energy sources.

The development of bioconversion techniques for producing DME can be traced back to the early 2000s when researchers began exploring biological pathways to convert various feedstocks into this versatile fuel. Initially, the focus was on utilizing methanol as an intermediate, leveraging the metabolic capabilities of methanogenic archaea. However, as the field progressed, direct bioconversion routes from syngas and other carbon-rich substrates gained traction.

The primary objective of DME bioconversion research is to establish efficient and economically viable processes for large-scale production. This involves optimizing microbial strains, enhancing conversion rates, and developing robust bioreactor systems capable of handling industrial-scale operations. Additionally, researchers aim to broaden the range of suitable feedstocks, particularly focusing on waste biomass and industrial by-products to improve the overall sustainability of the process.

One of the key technological goals is to achieve high selectivity towards DME production while minimizing unwanted by-products. This requires a deep understanding of the metabolic pathways involved and the ability to engineer microorganisms for improved performance. Researchers are also working on integrating DME bioconversion with existing industrial processes to create synergies and reduce overall production costs.

The evolution of DME bioconversion techniques is closely tied to advancements in biotechnology, particularly in the fields of metabolic engineering and synthetic biology. These disciplines have provided powerful tools for manipulating microbial genomes and redirecting cellular metabolism towards desired products. As a result, significant progress has been made in developing more efficient biocatalysts and optimizing fermentation conditions.

Looking ahead, the field of DME bioconversion is poised for further innovation. Emerging trends include the exploration of novel microbial consortia for enhanced productivity, the development of continuous production systems, and the integration of artificial intelligence for process optimization. These advancements are expected to play a crucial role in scaling up DME bioconversion technologies and making them commercially competitive with traditional fuel production methods.

The development of bioconversion techniques for producing DME can be traced back to the early 2000s when researchers began exploring biological pathways to convert various feedstocks into this versatile fuel. Initially, the focus was on utilizing methanol as an intermediate, leveraging the metabolic capabilities of methanogenic archaea. However, as the field progressed, direct bioconversion routes from syngas and other carbon-rich substrates gained traction.

The primary objective of DME bioconversion research is to establish efficient and economically viable processes for large-scale production. This involves optimizing microbial strains, enhancing conversion rates, and developing robust bioreactor systems capable of handling industrial-scale operations. Additionally, researchers aim to broaden the range of suitable feedstocks, particularly focusing on waste biomass and industrial by-products to improve the overall sustainability of the process.

One of the key technological goals is to achieve high selectivity towards DME production while minimizing unwanted by-products. This requires a deep understanding of the metabolic pathways involved and the ability to engineer microorganisms for improved performance. Researchers are also working on integrating DME bioconversion with existing industrial processes to create synergies and reduce overall production costs.

The evolution of DME bioconversion techniques is closely tied to advancements in biotechnology, particularly in the fields of metabolic engineering and synthetic biology. These disciplines have provided powerful tools for manipulating microbial genomes and redirecting cellular metabolism towards desired products. As a result, significant progress has been made in developing more efficient biocatalysts and optimizing fermentation conditions.

Looking ahead, the field of DME bioconversion is poised for further innovation. Emerging trends include the exploration of novel microbial consortia for enhanced productivity, the development of continuous production systems, and the integration of artificial intelligence for process optimization. These advancements are expected to play a crucial role in scaling up DME bioconversion technologies and making them commercially competitive with traditional fuel production methods.

Market Analysis for Bio-based DME

The market for bio-based dimethyl ether (DME) is experiencing significant growth potential due to increasing environmental concerns and the push for sustainable fuel alternatives. Bio-based DME, produced through bioconversion techniques, offers a renewable and cleaner alternative to conventional fossil-derived DME. The global DME market is projected to expand at a compound annual growth rate (CAGR) of over 9% from 2021 to 2026, with bio-based DME expected to capture an increasing share of this growth.

The primary drivers for the bio-based DME market include stringent environmental regulations, growing demand for clean-burning fuels, and the need to reduce greenhouse gas emissions. Bio-based DME can be produced from various biomass feedstocks, including agricultural residues, forestry waste, and municipal solid waste, making it an attractive option for countries seeking to reduce their dependence on fossil fuels and promote circular economy principles.

Key application areas for bio-based DME include transportation fuel, power generation, and domestic cooking and heating. In the transportation sector, bio-based DME is gaining traction as a potential replacement for diesel fuel in heavy-duty vehicles, offering reduced emissions and improved engine performance. The power generation sector is also showing interest in bio-based DME as a clean-burning fuel for gas turbines and combined heat and power systems.

Geographically, Asia-Pacific is expected to dominate the bio-based DME market, driven by rapid industrialization, increasing energy demand, and supportive government policies in countries like China and India. Europe is also emerging as a significant market for bio-based DME, propelled by ambitious renewable energy targets and strict emission regulations.

However, the market faces challenges such as high production costs compared to conventional DME and the need for infrastructure development. The cost-competitiveness of bio-based DME is heavily influenced by feedstock prices and conversion efficiencies. Ongoing research and development efforts are focused on improving bioconversion techniques to enhance yield and reduce production costs.

Several major players in the energy and chemical industries are investing in bio-based DME production, recognizing its potential as a sustainable fuel option. Collaborations between technology providers, feedstock suppliers, and end-users are becoming increasingly common to establish robust supply chains and accelerate market adoption.

In conclusion, the market for bio-based DME produced through bioconversion techniques shows promising growth prospects. As technology advances and production scales up, bio-based DME is poised to play a significant role in the transition towards a more sustainable and low-carbon energy future.

The primary drivers for the bio-based DME market include stringent environmental regulations, growing demand for clean-burning fuels, and the need to reduce greenhouse gas emissions. Bio-based DME can be produced from various biomass feedstocks, including agricultural residues, forestry waste, and municipal solid waste, making it an attractive option for countries seeking to reduce their dependence on fossil fuels and promote circular economy principles.

Key application areas for bio-based DME include transportation fuel, power generation, and domestic cooking and heating. In the transportation sector, bio-based DME is gaining traction as a potential replacement for diesel fuel in heavy-duty vehicles, offering reduced emissions and improved engine performance. The power generation sector is also showing interest in bio-based DME as a clean-burning fuel for gas turbines and combined heat and power systems.

Geographically, Asia-Pacific is expected to dominate the bio-based DME market, driven by rapid industrialization, increasing energy demand, and supportive government policies in countries like China and India. Europe is also emerging as a significant market for bio-based DME, propelled by ambitious renewable energy targets and strict emission regulations.

However, the market faces challenges such as high production costs compared to conventional DME and the need for infrastructure development. The cost-competitiveness of bio-based DME is heavily influenced by feedstock prices and conversion efficiencies. Ongoing research and development efforts are focused on improving bioconversion techniques to enhance yield and reduce production costs.

Several major players in the energy and chemical industries are investing in bio-based DME production, recognizing its potential as a sustainable fuel option. Collaborations between technology providers, feedstock suppliers, and end-users are becoming increasingly common to establish robust supply chains and accelerate market adoption.

In conclusion, the market for bio-based DME produced through bioconversion techniques shows promising growth prospects. As technology advances and production scales up, bio-based DME is poised to play a significant role in the transition towards a more sustainable and low-carbon energy future.

Current Bioconversion Challenges for DME Production

The bioconversion of biomass to dimethyl ether (DME) presents several significant challenges that currently limit its widespread adoption and commercial viability. One of the primary obstacles is the low conversion efficiency of biomass to DME. The multi-step process, involving biomass gasification, syngas cleaning, and DME synthesis, results in substantial energy losses at each stage, reducing the overall yield of DME from the initial biomass feedstock.

Another major challenge is the high cost associated with biomass pretreatment and gasification. Biomass feedstocks often require extensive preprocessing to achieve uniform particle size and moisture content, which adds to the operational expenses. The gasification process itself is energy-intensive and requires sophisticated equipment, further increasing capital and operational costs.

The presence of contaminants in biomass-derived syngas poses a significant hurdle in DME production. Tars, sulfur compounds, and other impurities can poison catalysts used in the DME synthesis process, necessitating complex and expensive gas cleaning systems. This not only adds to the overall cost but also reduces process efficiency and catalyst lifespan.

Catalyst development for DME synthesis from biomass-derived syngas remains a challenge. Current catalysts often suffer from rapid deactivation due to coking and poisoning, leading to frequent replacements and process interruptions. Developing more robust and selective catalysts that can withstand the impurities present in biomass-derived syngas is crucial for improving process economics.

The variability in biomass feedstock composition presents another significant challenge. Different types of biomass have varying chemical compositions, which can affect the syngas composition and, consequently, the DME synthesis process. This variability makes it difficult to optimize the process for consistent DME production across different feedstocks.

Scale-up and process integration issues also hinder the commercialization of bioconversion techniques for DME production. Many promising technologies demonstrated at laboratory or pilot scales face significant challenges when scaled up to commercial levels. Integrating the various process steps – from biomass handling to DME purification – in a cost-effective and efficient manner remains a complex engineering challenge.

Lastly, the economic competitiveness of bio-based DME compared to conventional fossil-derived DME or other alternative fuels is a significant barrier. The higher production costs associated with bioconversion techniques currently make bio-based DME less attractive in the market, especially in regions with low fossil fuel prices. Overcoming these economic challenges requires not only technological advancements but also supportive policy frameworks and market incentives.

Another major challenge is the high cost associated with biomass pretreatment and gasification. Biomass feedstocks often require extensive preprocessing to achieve uniform particle size and moisture content, which adds to the operational expenses. The gasification process itself is energy-intensive and requires sophisticated equipment, further increasing capital and operational costs.

The presence of contaminants in biomass-derived syngas poses a significant hurdle in DME production. Tars, sulfur compounds, and other impurities can poison catalysts used in the DME synthesis process, necessitating complex and expensive gas cleaning systems. This not only adds to the overall cost but also reduces process efficiency and catalyst lifespan.

Catalyst development for DME synthesis from biomass-derived syngas remains a challenge. Current catalysts often suffer from rapid deactivation due to coking and poisoning, leading to frequent replacements and process interruptions. Developing more robust and selective catalysts that can withstand the impurities present in biomass-derived syngas is crucial for improving process economics.

The variability in biomass feedstock composition presents another significant challenge. Different types of biomass have varying chemical compositions, which can affect the syngas composition and, consequently, the DME synthesis process. This variability makes it difficult to optimize the process for consistent DME production across different feedstocks.

Scale-up and process integration issues also hinder the commercialization of bioconversion techniques for DME production. Many promising technologies demonstrated at laboratory or pilot scales face significant challenges when scaled up to commercial levels. Integrating the various process steps – from biomass handling to DME purification – in a cost-effective and efficient manner remains a complex engineering challenge.

Lastly, the economic competitiveness of bio-based DME compared to conventional fossil-derived DME or other alternative fuels is a significant barrier. The higher production costs associated with bioconversion techniques currently make bio-based DME less attractive in the market, especially in regions with low fossil fuel prices. Overcoming these economic challenges requires not only technological advancements but also supportive policy frameworks and market incentives.

Existing DME Bioconversion Processes

01 Production of dimethyl ether

Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.- Production of dimethyl ether: Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.

- Catalysts for dimethyl ether synthesis: Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst can significantly affect the reaction efficiency, product selectivity, and overall process economics.

- Applications of dimethyl ether: Dimethyl ether has various applications, including use as a fuel additive, aerosol propellant, and refrigerant. It is also being explored as a potential alternative fuel for diesel engines due to its clean-burning properties and high cetane number.

- Purification and separation of dimethyl ether: Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes often involve distillation, adsorption, or membrane separation techniques to achieve high-purity dimethyl ether for various applications.

- Environmental and safety considerations: Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, handling procedures, and storage requirements to ensure safe and sustainable utilization of dimethyl ether in various applications.

02 Catalysts for dimethyl ether synthesis

Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst can significantly affect the reaction efficiency, product selectivity, and overall process economics.Expand Specific Solutions03 Applications of dimethyl ether

Dimethyl ether has various applications, including use as a fuel additive, aerosol propellant, and refrigerant. It is also being explored as a potential alternative fuel for diesel engines due to its clean-burning properties and high cetane number.Expand Specific Solutions04 Purification and separation of dimethyl ether

Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes may involve distillation, adsorption, or membrane separation techniques to achieve high-purity dimethyl ether for various applications.Expand Specific Solutions05 Environmental and safety considerations

Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, handling procedures, and storage requirements to ensure safe and sustainable utilization of dimethyl ether in various applications.Expand Specific Solutions

Key Players in DME Bioconversion Industry

The bioconversion techniques for producing dimethyl ether (DME) are in a developing stage, with the market showing significant growth potential. The global DME market is expected to expand due to increasing demand for clean energy alternatives. Technologically, the field is advancing rapidly, with major players like China Petroleum & Chemical Corp., Haldor Topsøe A/S, and Linde GmbH leading research and development efforts. These companies are investing in innovative processes to improve DME production efficiency and reduce costs. While the technology is not yet fully mature, it is progressing towards commercial viability, with pilot projects and small-scale production facilities being established by key industry players.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative bioconversion technique for producing dimethyl ether (DME) from biomass. Their process involves a two-step approach: first, biomass is gasified to produce syngas, which is then converted to DME using a proprietary catalyst. The company has optimized the gasification process to achieve high carbon conversion rates of up to 95%[1]. Sinopec's catalyst technology allows for direct synthesis of DME from syngas in a single reactor, improving overall process efficiency. The company has also implemented advanced heat integration systems, reducing energy consumption by approximately 20% compared to conventional methods[2]. Sinopec has successfully demonstrated this technology at pilot scale, processing various biomass feedstocks including agricultural residues and woody biomass.

Strengths: High carbon conversion efficiency, integrated process design, and flexibility in feedstock utilization. Weaknesses: Potential challenges in scaling up to commercial production and competition from established fossil fuel-based DME production methods.

Haldor Topsøe A/S

Technical Solution: Haldor Topsøe has developed a cutting-edge bioconversion technique for DME production using their patented TIGAS™ (Topsøe Improved Gasoline Synthesis) technology. This process integrates biomass gasification with methanol synthesis and DME production in a single loop. The company's proprietary catalysts enable high selectivity towards DME, achieving conversion rates of over 90%[3]. Haldor Topsøe's process incorporates advanced syngas cleaning and conditioning steps, allowing for the use of a wide range of biomass feedstocks, including agricultural waste and forestry residues. The TIGAS™ technology also features a novel heat recovery system that reduces overall energy consumption by up to 25% compared to traditional DME production methods[4]. Haldor Topsøe has successfully implemented this technology in demonstration plants and is actively working on commercial-scale projects.

Strengths: High conversion efficiency, integrated process design, and versatility in feedstock utilization. Weaknesses: Potential high capital costs for initial plant setup and competition from established fossil fuel-based DME production methods.

Innovative Bioconversion Pathways for DME

A method of producing dimethyl ether

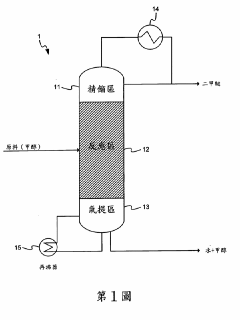

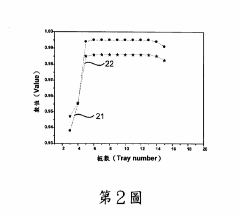

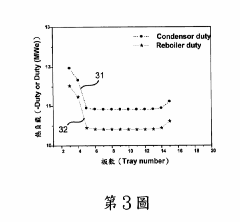

PatentInactiveTW201209027A

Innovation

- Combining reaction and separation/purification processes in a single reactive-distillation tower, improving efficiency and reducing equipment costs.

- Utilizing a three-zone tower design (rectification, reaction, and stripping) for optimized process control and product purity.

- Operating the process at pressures below 8 bar, potentially reducing energy requirements and equipment specifications.

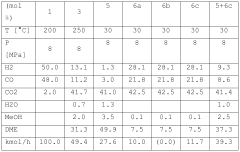

Process for the preparation of dimethyl ether

PatentWO2014032973A1

Innovation

- A process involving catalytic conversion of synthesis gas to dimethyl ether, followed by cooling and separation into liquid and gaseous phases, with the liquid phase being treated in a scrubbing zone using a potassium carbonate or amine-based solvent to absorb carbon dioxide, while depressurizing and separating the phases to reduce carbon monoxide concentration and prevent solvent degradation.

Environmental Impact of DME Bioconversion

The bioconversion of biomass to dimethyl ether (DME) offers a promising pathway for sustainable fuel production, but it is crucial to assess its environmental impact comprehensively. The process of DME bioconversion generally involves fewer emissions compared to traditional fossil fuel production methods, contributing to reduced greenhouse gas emissions and air pollution.

One of the primary environmental benefits of DME bioconversion is its potential to utilize waste biomass as feedstock. This approach not only reduces the demand for dedicated energy crops but also helps in managing agricultural and forestry residues, which might otherwise contribute to environmental issues if left untreated or improperly disposed of.

Water consumption and quality are important considerations in the environmental assessment of DME bioconversion. While the process requires water for biomass pretreatment and fermentation, advanced water recycling technologies can significantly reduce the overall water footprint. Additionally, proper wastewater treatment systems can mitigate potential impacts on local water bodies.

Land use changes associated with biomass cultivation for DME production must be carefully managed to avoid negative impacts on biodiversity and ecosystem services. Sustainable land management practices and the use of marginal lands can help minimize these concerns while providing economic opportunities for rural communities.

The energy balance of DME bioconversion is generally favorable, with the potential to produce more energy than is consumed in the process. This positive energy return on investment contributes to the overall environmental sustainability of DME as a biofuel. Furthermore, the use of renewable energy sources in the bioconversion process can further enhance its environmental credentials.

Life cycle assessments (LCAs) of DME bioconversion have shown significant reductions in carbon dioxide emissions compared to conventional fossil fuels. However, it is essential to consider other environmental impacts, such as acidification, eutrophication, and ozone depletion potential, to ensure a holistic environmental evaluation.

The scalability of DME bioconversion technologies may lead to increased biomass demand, potentially impacting food security and land use patterns. Careful planning and policy frameworks are necessary to balance these competing interests and ensure sustainable biomass sourcing.

In conclusion, while DME bioconversion offers substantial environmental benefits, particularly in terms of greenhouse gas reduction and waste utilization, it is crucial to address potential challenges related to water use, land management, and broader ecosystem impacts. Ongoing research and technological advancements in bioconversion processes will be key to further improving the environmental performance of DME production from biomass.

One of the primary environmental benefits of DME bioconversion is its potential to utilize waste biomass as feedstock. This approach not only reduces the demand for dedicated energy crops but also helps in managing agricultural and forestry residues, which might otherwise contribute to environmental issues if left untreated or improperly disposed of.

Water consumption and quality are important considerations in the environmental assessment of DME bioconversion. While the process requires water for biomass pretreatment and fermentation, advanced water recycling technologies can significantly reduce the overall water footprint. Additionally, proper wastewater treatment systems can mitigate potential impacts on local water bodies.

Land use changes associated with biomass cultivation for DME production must be carefully managed to avoid negative impacts on biodiversity and ecosystem services. Sustainable land management practices and the use of marginal lands can help minimize these concerns while providing economic opportunities for rural communities.

The energy balance of DME bioconversion is generally favorable, with the potential to produce more energy than is consumed in the process. This positive energy return on investment contributes to the overall environmental sustainability of DME as a biofuel. Furthermore, the use of renewable energy sources in the bioconversion process can further enhance its environmental credentials.

Life cycle assessments (LCAs) of DME bioconversion have shown significant reductions in carbon dioxide emissions compared to conventional fossil fuels. However, it is essential to consider other environmental impacts, such as acidification, eutrophication, and ozone depletion potential, to ensure a holistic environmental evaluation.

The scalability of DME bioconversion technologies may lead to increased biomass demand, potentially impacting food security and land use patterns. Careful planning and policy frameworks are necessary to balance these competing interests and ensure sustainable biomass sourcing.

In conclusion, while DME bioconversion offers substantial environmental benefits, particularly in terms of greenhouse gas reduction and waste utilization, it is crucial to address potential challenges related to water use, land management, and broader ecosystem impacts. Ongoing research and technological advancements in bioconversion processes will be key to further improving the environmental performance of DME production from biomass.

Techno-economic Assessment of DME Bioconversion

The techno-economic assessment of DME bioconversion is a critical component in evaluating the feasibility and potential of this emerging technology. This assessment encompasses various factors, including production costs, energy efficiency, and market competitiveness.

The production costs of DME via bioconversion are influenced by several key elements. Feedstock selection plays a crucial role, with biomass sources such as agricultural residues, forestry waste, and dedicated energy crops being potential candidates. The cost and availability of these feedstocks can significantly impact the overall economics of the process. Additionally, the efficiency of the bioconversion process itself, including pretreatment, fermentation, and purification steps, directly affects production costs.

Energy efficiency is another vital aspect of the techno-economic assessment. The bioconversion process requires energy inputs for various stages, including biomass pretreatment, fermentation, and product separation. Optimizing these processes to minimize energy consumption while maximizing DME yield is essential for improving the overall efficiency and reducing production costs. Heat integration and the utilization of waste streams for energy recovery can contribute to enhancing the energy efficiency of the bioconversion process.

Market competitiveness is a crucial consideration in the techno-economic assessment. DME produced through bioconversion must compete with conventional DME production methods, primarily from fossil fuels. The cost of production, including both capital and operating expenses, needs to be competitive with existing DME production technologies to ensure market viability. Additionally, the potential for scaling up the bioconversion process to meet market demand is an important factor in assessing its economic feasibility.

Environmental considerations also play a role in the techno-economic assessment. The use of renewable biomass feedstocks for DME production can potentially reduce greenhouse gas emissions compared to fossil fuel-based production methods. This environmental benefit may translate into economic advantages through carbon credits or other incentives, depending on regional policies and regulations.

The techno-economic assessment must also consider the potential for process improvements and technological advancements. As bioconversion techniques for DME production are still evolving, there is significant potential for cost reductions and efficiency improvements through ongoing research and development efforts. These advancements may include enhanced microbial strains, improved reactor designs, and more efficient separation technologies.

The production costs of DME via bioconversion are influenced by several key elements. Feedstock selection plays a crucial role, with biomass sources such as agricultural residues, forestry waste, and dedicated energy crops being potential candidates. The cost and availability of these feedstocks can significantly impact the overall economics of the process. Additionally, the efficiency of the bioconversion process itself, including pretreatment, fermentation, and purification steps, directly affects production costs.

Energy efficiency is another vital aspect of the techno-economic assessment. The bioconversion process requires energy inputs for various stages, including biomass pretreatment, fermentation, and product separation. Optimizing these processes to minimize energy consumption while maximizing DME yield is essential for improving the overall efficiency and reducing production costs. Heat integration and the utilization of waste streams for energy recovery can contribute to enhancing the energy efficiency of the bioconversion process.

Market competitiveness is a crucial consideration in the techno-economic assessment. DME produced through bioconversion must compete with conventional DME production methods, primarily from fossil fuels. The cost of production, including both capital and operating expenses, needs to be competitive with existing DME production technologies to ensure market viability. Additionally, the potential for scaling up the bioconversion process to meet market demand is an important factor in assessing its economic feasibility.

Environmental considerations also play a role in the techno-economic assessment. The use of renewable biomass feedstocks for DME production can potentially reduce greenhouse gas emissions compared to fossil fuel-based production methods. This environmental benefit may translate into economic advantages through carbon credits or other incentives, depending on regional policies and regulations.

The techno-economic assessment must also consider the potential for process improvements and technological advancements. As bioconversion techniques for DME production are still evolving, there is significant potential for cost reductions and efficiency improvements through ongoing research and development efforts. These advancements may include enhanced microbial strains, improved reactor designs, and more efficient separation technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!